Professional Documents

Culture Documents

Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burns

Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burns

Uploaded by

abbas ahmedCopyright:

Available Formats

You might also like

- Man NR20Document68 pagesMan NR20DP75% (8)

- An Analysis of Indicators Disclosed in Corporate Sustainability Reports PDFDocument16 pagesAn Analysis of Indicators Disclosed in Corporate Sustainability Reports PDFRahul PramaniNo ratings yet

- Annulus Vent Monitoring System For Flexible RisersDocument4 pagesAnnulus Vent Monitoring System For Flexible RisersConnor Sailor100% (1)

- Bryan Burgess For Oberlin City CouncilDocument2 pagesBryan Burgess For Oberlin City CouncilThe Morning JournalNo ratings yet

- (UL ANSI: FR-4.0) Conventional FR-4: Features ApplicationsDocument2 pages(UL ANSI: FR-4.0) Conventional FR-4: Features ApplicationsNOUREDDINE ELHAMRINo ratings yet

- A18 A19 CylinderDocument4 pagesA18 A19 CylinderBiswanath LenkaNo ratings yet

- A16 A17 CylinderDocument7 pagesA16 A17 Cylinderjaneesh RNo ratings yet

- A18 A19 CylinderDocument4 pagesA18 A19 CylinderkarthikNo ratings yet

- SBPT Catalogue DC CouplingDocument11 pagesSBPT Catalogue DC CouplingEserNo ratings yet

- Stackup - CN TDS 1911 03 S1000H S1000HBDocument2 pagesStackup - CN TDS 1911 03 S1000H S1000HBMuhamad Sayid Akil MhsAkilNo ratings yet

- Datasheet-Sandvik-12r11-En-V2020-08-27 14 - 00 Version 1Document5 pagesDatasheet-Sandvik-12r11-En-V2020-08-27 14 - 00 Version 1Kashish0% (1)

- Transmotec Datasheet SDS80120ADocument1 pageTransmotec Datasheet SDS80120Asaxadi4814No ratings yet

- Air Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesDocument4 pagesAir Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesBiswanath LenkaNo ratings yet

- Pile Design For AXIAL Forces Final CheckDocument4 pagesPile Design For AXIAL Forces Final CheckramesNo ratings yet

- MTO MuruganDocument2 pagesMTO MuruganBala SubramaniNo ratings yet

- Elmwood Temperatursicherung Eng TdsDocument6 pagesElmwood Temperatursicherung Eng TdsSebastianSimonNo ratings yet

- (Carbon Steel Air Plasma / Air Shield Cutting) Lead 15.3mDocument2 pages(Carbon Steel Air Plasma / Air Shield Cutting) Lead 15.3mNaser SulimanNo ratings yet

- Ancon EdjPro EPHIMini Edge Lifting SystemDocument2 pagesAncon EdjPro EPHIMini Edge Lifting SystemsashilaNo ratings yet

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- Using The Cut Charts: Torch SetupDocument30 pagesUsing The Cut Charts: Torch Setupjuan esteban RestrepoNo ratings yet

- PressedDocument46 pagesPressedsameh aboulsoudNo ratings yet

- Quotation: Machine FeaturesDocument5 pagesQuotation: Machine FeaturesZakhamaNo ratings yet

- Crosby 198Document1 pageCrosby 198oscar_jfrNo ratings yet

- Am 45HP SeriesDocument1 pageAm 45HP Serieskardelen aygunNo ratings yet

- Toptherm Roof-Mounted Fans: Air Throughput 400 - 800 M /HDocument1 pageToptherm Roof-Mounted Fans: Air Throughput 400 - 800 M /HMahasweta MitraNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- TornilleriaDocument26 pagesTornilleriacorpSIG corpSIGNo ratings yet

- 3 Slickline CapabilitiesDocument14 pages3 Slickline CapabilitiesHedi ChhidiNo ratings yet

- Data Sheet: P6Smb SeriesDocument4 pagesData Sheet: P6Smb SeriesZiritt Duran DavidNo ratings yet

- Shoulder Plugs GasketsDocument1 pageShoulder Plugs GasketssergioteroNo ratings yet

- Spit Epomax: Zinc Coated Steel (Standard Anchorage)Document12 pagesSpit Epomax: Zinc Coated Steel (Standard Anchorage)Sudhakar KrishnamurthyNo ratings yet

- Entech TPE Resin Datasheet 1Document4 pagesEntech TPE Resin Datasheet 1Ermin CisicNo ratings yet

- Achteck CatalogueDocument8 pagesAchteck CatalogueManas D SinghNo ratings yet

- Lit Circpac HP DataDocument2 pagesLit Circpac HP Databillel limaneNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- Info EN755 9Document19 pagesInfo EN755 9Don JonesNo ratings yet

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 pageRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNo ratings yet

- Key Features: Internal Mount Flange Facing Machine 12 - 60" (305 - 1525mm)Document3 pagesKey Features: Internal Mount Flange Facing Machine 12 - 60" (305 - 1525mm)DI DINo ratings yet

- Specification: EN9 - 070M55: Hollowbar - Co.zaDocument3 pagesSpecification: EN9 - 070M55: Hollowbar - Co.zaAnantha RamanNo ratings yet

- Brosure Kabel NA2XSYDocument5 pagesBrosure Kabel NA2XSYcandra handarsenNo ratings yet

- TAC-F - v1.1-OmegaAir - EngDocument12 pagesTAC-F - v1.1-OmegaAir - EngMột Lằn QuangNo ratings yet

- A25 A26 CylinderDocument5 pagesA25 A26 CylinderBiswanath LenkaNo ratings yet

- 18 EN 14509:2013 AVCP3: Declared Performance For Trapezoidal - KS1000/2000 RW 0818Document1 page18 EN 14509:2013 AVCP3: Declared Performance For Trapezoidal - KS1000/2000 RW 0818Far AwayNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- A16 A17 CylinderDocument7 pagesA16 A17 CylinderkarthikNo ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- 1PH8133-3AF02-2AA1-Z U60+X01 Datasheet enDocument1 page1PH8133-3AF02-2AA1-Z U60+X01 Datasheet enMohamad RagabNo ratings yet

- HPR XD Cut ChartsDocument46 pagesHPR XD Cut ChartsMunavir Ibnu KhaderNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- THHN TCDocument5 pagesTHHN TCjuan pablo castro gallegoNo ratings yet

- Blince OMR Hydraulic MotorDocument10 pagesBlince OMR Hydraulic MotorJoaquin CarvajalNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- LMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceDocument2 pagesLMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceTrong Hung NguyenNo ratings yet

- Actuators Complet RDocument44 pagesActuators Complet RAhmed ElkashifNo ratings yet

- ZF25ADocument4 pagesZF25A1380485No ratings yet

- Datasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1Document5 pagesDatasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1aceinsteinNo ratings yet

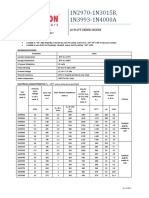

- 1N2970-1N3015B, 1N3993-1N4000A: 10 Watt Zener DiodesDocument5 pages1N2970-1N3015B, 1N3993-1N4000A: 10 Watt Zener DiodesAndres GalvezNo ratings yet

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNo ratings yet

- Flowserve Mark100 PesoDocument8 pagesFlowserve Mark100 PesoAnderson SiqueiraNo ratings yet

- X-Enp (Metal Deck Nail)Document10 pagesX-Enp (Metal Deck Nail)jojo_323No ratings yet

- Unitherm Cat 2210 Pre Insulated TubingDocument2 pagesUnitherm Cat 2210 Pre Insulated TubingSebas FaustoNo ratings yet

- HT Cable Sizing Calculation - Annexure - 1 - EtapDocument1 pageHT Cable Sizing Calculation - Annexure - 1 - Etapvenkatesh.gandhi91No ratings yet

- 2 PDFDocument1 page2 PDFabbas ahmedNo ratings yet

- A Pic Real Time Clock Ic RTC Using The ds1307 - Compress PDFDocument6 pagesA Pic Real Time Clock Ic RTC Using The ds1307 - Compress PDFabbas ahmedNo ratings yet

- Designing Smart Multipurpose Digital Clock Using RDocument5 pagesDesigning Smart Multipurpose Digital Clock Using Rabbas ahmedNo ratings yet

- Terms of Use - PlayrixDocument5 pagesTerms of Use - Playrixabbas ahmedNo ratings yet

- Universal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - UsDocument1 pageUniversal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - Usabbas ahmedNo ratings yet

- Universal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - UsDocument1 pageUniversal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - Usabbas ahmedNo ratings yet

- CD4060BMS: Pinout FeaturesDocument9 pagesCD4060BMS: Pinout Featuresabbas ahmedNo ratings yet

- LM 3914Document8 pagesLM 3914abbas ahmedNo ratings yet

- Content Handbook of Energy and Economic Statistics of Indonesia 2020Document111 pagesContent Handbook of Energy and Economic Statistics of Indonesia 2020Fabiola Marella PardedeNo ratings yet

- Chinese Standrad Pipe FittingsDocument79 pagesChinese Standrad Pipe FittingsDinh Nguyen DaoNo ratings yet

- Quality You Expect: Advantages at A GlanceDocument2 pagesQuality You Expect: Advantages at A GlanceNooruddin DeroNo ratings yet

- Ni-CD Battery Charger SpecificationDocument18 pagesNi-CD Battery Charger SpecificationAdrianne DouglasNo ratings yet

- Indian Standards ListDocument1 pageIndian Standards ListRaju ShresthaNo ratings yet

- Technical Note: I - Subject: Analysis, Measurement and Checking of BatteriesDocument7 pagesTechnical Note: I - Subject: Analysis, Measurement and Checking of Batteriesmebarki aberraoufNo ratings yet

- 6PH04 June 2011Document24 pages6PH04 June 2011areyouthere92No ratings yet

- Dynamics Chapter 7Document118 pagesDynamics Chapter 7Hisyammudin RoslanNo ratings yet

- Q.no 1. For Thermal Analysis, The Field Variable IsDocument128 pagesQ.no 1. For Thermal Analysis, The Field Variable IsAMOL JAGTAPNo ratings yet

- BD418 External - Annunciator - BTTY ANN 003 FiplexDocument1 pageBD418 External - Annunciator - BTTY ANN 003 Fiplexculeros1No ratings yet

- Electron Affinity: Atom MoleculeDocument3 pagesElectron Affinity: Atom MoleculeMj Sebastian GuadalupeNo ratings yet

- Product - Services CatalogDocument72 pagesProduct - Services CatalogFonc KitaNo ratings yet

- CombinedSci Chem Bio 5078 Y23 SyDocument56 pagesCombinedSci Chem Bio 5078 Y23 SykaboomzxcNo ratings yet

- Longitudinal Butt Joint Circumferential Lap Joint For Boiler ShellDocument3 pagesLongitudinal Butt Joint Circumferential Lap Joint For Boiler ShellAlvin Tung Kwong ChoongNo ratings yet

- Emergency LightDocument46 pagesEmergency Lightfunkisanju1No ratings yet

- Plates PDFDocument57 pagesPlates PDFÁlvaro Serrano100% (1)

- Geophysics and Medical PhysicsDocument5 pagesGeophysics and Medical PhysicsjanetpriscillaNo ratings yet

- PDS Lubrizol-6950pDocument4 pagesPDS Lubrizol-6950pBurcu Taşçı100% (1)

- CV Kadji Wolieu OMDocument2 pagesCV Kadji Wolieu OMkadjididieNo ratings yet

- Methods For The Reduction of Line LossesDocument5 pagesMethods For The Reduction of Line Lossesapi-232121477No ratings yet

- Product Identification Number - IngersollrandDocument6 pagesProduct Identification Number - Ingersollrandandy habibiNo ratings yet

- Cold Water SystemsDocument31 pagesCold Water Systemsjools100No ratings yet

- NEMA Contactors & StartersDocument148 pagesNEMA Contactors & Startersingreyes7No ratings yet

- M12 Plunger Pump Data: Forged ISO Drawing SpecificationsDocument4 pagesM12 Plunger Pump Data: Forged ISO Drawing SpecificationsAlfonso Alberto ArguelloNo ratings yet

- Hydrogen For TransportationDocument5 pagesHydrogen For Transportationrussell_hodgesNo ratings yet

- Control Panel PDFDocument18 pagesControl Panel PDFhector100% (1)

Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burns

Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burns

Uploaded by

abbas ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burns

Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burns

Uploaded by

abbas ahmedCopyright:

Available Formats

TORCH SETUP

Choose the consumables (cut charts)

WARNING

INSTANT-ON TORCHES

PLASMA ARC CAN CAUSE INJURY AND BURNS

I The plasma arc comes on immediately when the torch trigger is activated. Make

sure the power is OFF before changing consumables.

O

A complete set of shielded consumables is shipped with the T45m machine torch. In addition, an ohmic sensing

retaining cap is available for use with the T45m shielded consumables. Unshielded consumables and the T30v

(Powermax30) 30 A consumables are also available for use with the T45m.

Using the cut charts

The following sections provide illustrations of the consumable sets and cut charts for each set. Maximum cut speeds are

the fastest speeds possible to cut material without regard to cut quality. Recommended cut speeds are a good starting

point for finding the best quality cut (best angle, least dross, and best cut surface finish). You will need to adjust the

speeds for your application and your table to obtain the desired cut quality.

When cutting thin metal (3 mm/10 Ga or thinner), you may achieve a higher cut quality by using the T30v (Powermax30)

30 A consumables and cut charts.

T45m shielded consumables

220673 220713 220671 220670 220669

Shield Retaining cap Nozzle Swirl ring Electrode

or

220719

Ohmic sensing retaining cap

The cut charts for these consumables are shown on the following pages.

3-8 powermax45 Service Manual

TORCH SETUP

T45m shielded consumables Air flowrate (lpm)

Mild steel Hot 151

Metric Cold 165.2

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 9150 117 10160* 118

0.8 0.0 8650 116 10160* 117

30 1.5 3.8 mm 250%

0.9 8100 115 10160* 117

1.5 0.2 5650 111 7100 115

0.9 9652 115 10160* 112

0.0

1.5 8890 116 10160* 115

1.9 0.1 7100 117 9144 115

2.7 0.3 4800 117 6096 115

3.8 mm 250%

3.4 0.4 3550 117 4445 115

4.8 0.5 2150 118 2794 115

45 1.5

6.4 0.6 1500 120 1905 116

9.5 0.9 510 122 1016 116

12.7 510 132 635 125

15.9 280 138 356 127

Edge start recommended

19.1 200 140 254 131

25.4 100 146 127 142

* Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-9

TORCH SETUP

T45m shielded consumables Air flowrate (scfh)

Mild steel Hot 320

English Cold 360

Recommended Maximum

Torch-

Arc Pierce time

Material to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current delay

thickness distance height (ipm) (V) (ipm) (V)

(amps) (sec)

(in)

0.018 in

360 117 400* 118

(26 Ga)

0.030 in

0.0 340 116 400* 117

(22 Ga)

30 0.06 0.15 in 250%

0.036 in

320 115 400* 117

(20 Ga)

0.060 in

0.2 225 111 280 115

(16 Ga)

0.036 in

380 115 400* 112

(20 Ga)

0.0

0.060 in

350 116 400* 115

(16 Ga)

0.075 in

0.1 280 117 360 115

(14 Ga)

0.105 in

0.3 190 117 240 115

(12 Ga)

0.15 in 250%

0.135 in

0.4 140 117 175 115

(10 Ga)

0.188 in

0.5 85 118 110 115

(3/16 in)

45 0.06

0.250 in

0.6 60 120 75 116

(1/4 in)

0.375 in

0.9 32 122 40 116

(3/8 in)

0.500 in

20 132 25 125

(1/2 in)

0.625 in

11 138 14 127

(5/8 in)

Edge start recommended

0.750 in

8 140 10 131

(3/4 in)

1.000 in

4 146 5 142

(1 in)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

3-10 powermax45 Service Manual

TORCH SETUP

T45m shielded consumables

Air flowrate (lpm)

Stainless steel Hot 151

Metric

Cold 165.2

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 9150 119 10160* 123

0.8 0.0 8650 117 10160* 121

30 1.5 3.8 mm 250%

0.9 8100 115 10160* 119

1.5 0.2 3750 113 4700 118

0.9 7600 112 10160* 109

0.0

1.5 8100 112 10160* 125

1.9 0.1 7100 118 9144 115

2.7 0.3 4050 118 5080 116

3.8 mm 250%

3.4 0.4 3050 121 3810 118

45 1.5

4.8 0.5 1780 122 2159 118

6.4 0.6 1100 124 1397 120

9.5 0.8 760 126 813 121

12.7 350 132 457 128

Edge start recommended

19.1 175 136 229 131

* Maximum cut speed is limited by the test able’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-11

TORCH SETUP

T45m shielded consumables

Air flowrate (scfh)

Stainless steel Hot 320

English

Cold 360

Recommended Maximum

Torch-

Arc Pierce time Cut Cut

Material to-work Initial pierce Voltage Voltage

current delay Speed Speed

thickness distance height (V) (V)

(amps) (sec) (ipm) (ipm)

(in)

0.018 in

360 117 400* 123

(26 Ga)

0.030 in

0.0 340 116 400* 121

(22 Ga)

30 0.06 0.15 in 250%

0.036 in

320 115 400* 119

(20 Ga)

0.060 in

0.2 145 111 185 118

(16 Ga)

0.036 in

300 115 400* 109

(20 Ga)

0.0

0.060 in

320 116 400* 125

(16 Ga)

0.075 in

0.1 280 117 360 115

(14 Ga)

0.105 in

0.3 160 117 200 116

(12 Ga)

0.15 in 250%

0.135 in

0.4 120 117 150 118

(10 Ga)

45 0.06

0.188 in

0.5 70 118 85 118

(3/16 in)

0.250 in

0.6 44 120 55 120

(1/4 in)

0.375 in

0.8 30 122 32 121

(3/8 in)

0.500 in

14 132 18 128

(1/2 in)

Edge start recommended

0.750 in

7 140 9 131

(3/4 in)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

3-12 powermax45 Service Manual

TORCH SETUP

T45m shielded consumables

Air flowrate (lpm)

Aluminum Hot 151

Metric

Cold 165.2

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

1.2 0.0 9150 117 10160* 120

30 1.5 1.5 3.8 mm 250% 8650 118 10160* 121

0.2

1.9 5450 118 6860 121

1.5 9150 116 10160* 114

1.9 0.0 8650 117 10160 116

2.7 7100 120 9144 119

3.4 3.8 mm 250% 0.1 5600 122 7112 120

45 4.8 1.5 0.2 2550 123 3302 120

6.4 0.3 2050 123 2540 120

9.5 0.5 840 130 1067 125

12.7 510 134 635 130

Edge start recommended

19.1 200 143 254 138

* Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-13

TORCH SETUP

T45m shielded consumables

Air flowrate (scfh)

Aluminum Hot 320

English

Cold 360

Recommended Maximum

Torch-

Arc Pierce time Cut Cut

Material to-work Initial pierce Voltage Voltage

current delay Speed Speed

thickness distance height (V) (V)

(amps) (sec) (ipm) (ipm)

(in)

0.018 in

0.0 360 117 400* 120

(26 Ga)

0.060 in

30 0.06 0.15 in 250% 340 118 400* 121

(16 Ga)

0.2

0.075 in

215 118 270 121

(14 Ga)

0.060 in

360 116 400* 114

(16 Ga)

0.075 in

0.0 340 117 400* 116

(14 Ga)

0.105 in

280 120 360 119

(12 Ga)

0.135 in

0.15 in 250% 0.1 220 122 280 120

(10 Ga)

0.188 in

45 0.06 0.2 100 123 130 120

(3/16 in)

0.250 in

0.3 80 123 100 120

(1/4 in)

0.375 in

0.5 33 130 42 125

(3/8 in)

0.500 in

20 134 25 130

(1/2 in)

Edge start recommended

0.750 in

8 143 10 138

(3/4 in)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

3-14 powermax45 Service Manual

TORCH SETUP

T45m unshielded consumables

220717 220713 220718 220670 220669

Deflector Retaining cap Nozzle Swirl ring Electrode

Mild steel Air flowrate (lpm)

Metric Hot 151

Cold 165.2

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 9150 118 10160* 114

0.8 0.0 8650 118 10160* 116

30 2.0 5.0 mm 250%

0.9 8100 117 10160* 120

1.5 0.2 5800 113 7250 119

0.9 9650 118 10160* 110

1.5 0.0 8900 114 10160* 113

1.9 6100 114 7620 114

2.7 0.3 4450 116 5588 114

5.0 mm 250%

3.4 0.4 3400 118 4318 116

4.8 0.4 2150 118 2794 116

45 2.0

6.4 0.5 1500 118 1905 118

9.5 0.7 810 120 1016 118

12.7 510 130 635 124

15.9 280 132 356 126

Edge start recommended

19.1 200 138 254 132

25.4 100 145 127 140

* Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-15

TORCH SETUP

T45m unshielded consumables

Air flowrate (scfh)

Mild steel Hot 320

English

Cold 360

Recommended Maximum

Torch-

Arc Pierce time Cut Cut

Material to-work Initial pierce Voltage Voltage

current delay Speed Speed

thickness distance height (V) (V)

(amps) (sec) (ipm) (ipm)

(in)

0.018 in

360 118 400* 114

(26 Ga)

0.030 in

0.0 340 118 400* 116

(22 Ga)

30 0.08 0.2 in 250%

0.036 in

320 117 400* 120

(20 Ga)

0.060 in

0.2 225 113 285 119

(16 Ga)

0.036 in

380 118 400* 110

(20 Ga)

0.060 in

0.0 350 114 400* 113

(16 Ga)

0.075 in

240 114 300 114

(14 Ga)

0.105 in

0.3 175 116 220 114

(12 Ga)

0.2 in 250%

0.135 in

0.4 135 118 170 116

(10 Ga)

0.188 in

0.4 85 118 110 116

(3/16 in)

45 0.08

0.250 in

0.5 60 118 75 118

(1/4 in)

0.375 in

0.7 32 120 40 118

(3/8 in)

0.500 in

20 130 25 124

(1/2 in)

0.625 in

11 132 14 126

(5/8 in)

Edge start recommended

0.750 in

8 138 10 132

(3/4 in)

1.000 in

4 145 5 140

(1 in)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

3-16 powermax45 Service Manual

TORCH SETUP

T45m unshielded consumables

Air flowrate (lpm)

Stainless steel Hot 151

Metric

Cold 165.2

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 9144 113 10160* 125

0.8 0.0 8128 115 10160* 128

30 2.0 5.0 mm 250%

0.9 7000 114 9000 125

1.5 0.2 3650 112 4800 118

0.9 8900 112 10160* 110

0.0

1.5 8100 115 10160* 113

1.9 0.1 7112 116 9144 114

2.7 0.3 4100 118 5080 116

5.0 mm 250%

3.4 0.4 2800 120 3556 118

45 2.0

4.8 0.5 1650 120 2032 118

6.4 0.6 1010 121 1270 118

9.5 0.8 610 125 762 120

12.7 355 130 457 126

Edge start recommended

19.1 175 133 229 138

* Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-17

TORCH SETUP

T45m unshielded consumables

Air flowrate (scfh)

Stainless steel Hot 320

English

Cold 360

Recommended Maximum

Torch-

Arc Pierce time

Material to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current delay

thickness distance height (ipm) (V) (ipm) (V)

(amps) (sec)

(in)

0.018 in

400* 113 400* 125

(26 Ga)

0.030 in

0.0 400* 115 400* 128

(22 Ga)

30 0.08 0.2 in 250%

0.036 in

345 114 345 125

(20 Ga)

0.060 in

0.2 145 112 180 118

(16 Ga)

0.036 in

350 112 400* 110

(20 Ga)

0.0

0.060 in

320 115 400* 113

(16 Ga)

0.075 in

0.1 280 116 360 114

(14 Ga)

0.105 in

0.3 160 118 200 116

(12 Ga)

0.2 in 250%

0.135 in

0.4 110 120 140 118

(10 Ga)

45 0.08

0.188 in

0.5 64 120 80 118

(3/16 in)

0.250 in

0.6 40 121 50 118

(1/4 in)

0.375 in

0.8 24 125 30 120

(3/8 in)

0.500 in

14 130 18 126

(1/2 in)

Edge start recommended

0.750 in

7 133 9 138

(3/4 in)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

3-18 powermax45 Service Manual

TORCH SETUP

T45m unshielded consumables

Air flowrate (lpm)

Aluminum Hot 151

Metric

Cold 165.2

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

1.2 0.0 8900 122 10160* 121

30 1.5 2.0 5.0 mm 250% 0.1 8100 120 10160* 118

1.9 0.2 5700 121 7100 119

1.5 8900 120 10160* 116

1.9 0.0 8100 120 10160* 116

2.7 7200 122 9144 118

3.4 5.0 mm 250% 0.1 5500 123 6858 118

45 4.8 2.0 0.3 2540 123 3175 118

6.4 0.3 1820 128 2286 124

9.5 0.5 710 130 914 124

12.7 510 131 635 125

Edge start recommended

19.1 200 148 254 143

* Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-19

TORCH SETUP

T45m unshielded consumables

Air flowrate (scfh)

Aluminum Hot 320

English

Cold 360

Recommended Maximum

Torch-

Arc Pierce time Cut Cut

Material to-work Initial pierce Voltage Voltage

current delay Speed Speed

thickness distance height (V) (V)

(amps) (sec) (ipm) (ipm)

(in)

0.018 in

0.0 350 122 400* 121

(26 Ga)

0.060 in

30 0.08 0.20 in 250% 0.1 320 120 400* 118

(16 Ga)

0.075 in

0.2 225 121 280 119

(14 Ga)

0.060 in

350 120 400* 116

(16 Ga)

0.075 in

0.0 320 120 400* 116

(14 Ga)

0.105 in

285 122 360 118

(12 Ga)

0.135 in

0.20 in 250% 0.1 215 123 270 118

(10 Ga)

0.188 in

45 0.08 0.3 100 123 125 118

(3/16 in)

0.250 in

0.3 72 128 90 124

(1/4 in)

0.375 in

0.5 28 130 36 124

(3/8 in)

0.500 in

20 131 25 125

(1/2 in)

Edge start recommended

0.750 in

8 148 10 143

(3/4 in)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

3-20 powermax45 Service Manual

TORCH SETUP

T30v (Powermax30) 30 A consumables

220569 220483 220480 220479 220478

Optional deflector Retaining cap Nozzle Swirl ring Electrode

Mild steel Air flowrate (lpm)

Metric

Hot 131.2

Cold 146.3

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 8900 105 10160* 98

0.8 0.0 8100 102 10160* 103

0.9 7100 101 8900 100

30 1.5 0.5 2.5 mm 500% 0.2 4450 97 5600 100

1.9 3050 98 3800 97

2.7 0.4 2050 96 2550 96

3.4 1270 100 1650 101

* Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

powermax45 Service Manual 3-21

TORCH SETUP

T30v (Powermax30) 30 A consumables Air flowrate (scfh)

Mild steel Hot 280

English Cold 310

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (ipm) (V) (ipm) (V)

(amps) (in) (sec)

(in)

0.018

350 105 400* 98

(26 Ga)

0.030

0.0 320 102 400* 103

(22 Ga)

0.036

280 101 350 100

(20 Ga)

0.060

30 0.02 0.1 in 500% 0.2 175 97 220 100

(16 Ga)

0.075

120 98 150 97

(14 Ga)

0.105

0.4 80 96 100 96

(12 Ga)

0.135

50 100 65 101

(10 Ga)

T30v (Powermax30) 30 A consumables Air flowrate (lpm)

Stainless steel Hot 131.2

Metric Cold 146.3

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 8900 103 10160* 102

0.8 0.0 8100 98 10160* 100

0.9 7600 97 6850 98

30 1.5 0.5 2.5 mm 500% 0.2 3800 99 4800 98

1.9 2800 101 3450 97

2.7 0.4 1500 101 1900 98

3.4 1150 102 1400 97

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm or 10160 mm/min).

3-22 powermax45 Service Manual

TORCH SETUP

T30v (Powermax30) 30 A consumables Air flowrate (scfh)

Stainless steel Hot 280

English Cold 310

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (ipm) (V) (ipm) (V)

(amps) (in) (sec)

(in)

0.018

350 103 400* 102

(26 Ga)

0.030

0.0 320 98 400* 100

(22 Ga)

0.036

300 97 380 98

(20 Ga)

0.060

30 0.02 0.1 in 500% 0.2 150 99 190 98

(16 Ga)

0.075

110 101 135 97

(14 Ga)

0.105

0.4 60 101 75 98

(12 Ga)

0.135

45 102 55 97

(10 Ga)

T30v (Powermax30) 30 A consumables Air flowrate (lpm)

Aluminum Hot 131.2

Metric Cold 146.3

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (mm/min) (V) (mm/min) (V)

(amps) (mm) (sec)

(mm)

0.5 8100 107 10160* 105

0.8 0.0 6100 104 7650 103

30 0.9 0.5 2.5 mm 500% 4800 104 6100 103

1.5 3700 103 4550 103

0.2

1.9 2400 101 3050 101

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm or 10160 mm/min).

powermax45 Service Manual 3-23

TORCH SETUP

T30v (Powermax30) 30 A consumables Air flowrate (scfh)

Aluminum Hot 280

English Cold 310

Recommended Maximum

Torch-

Arc Material Pierce time

to-work Initial pierce Cut Speed Voltage Cut Speed Voltage

current thickness delay

distance height (ipm) (V) (ipm) (V)

(amps) (in) (sec)

(in)

0.036

320 107 400* 105

(20 Ga)

0.060

0.0 240 104 300 103

(16 Ga)

0.075

30 0.02 0.10 in 500% 190 104 240 103

(14 Ga)

0.105

145 103 180 103

(12 Ga)

0.2

0.135

95 101 120 101

(10 Ga)

* Maximum cut speed is limited by the test table’s maximum speed (400 ipm).

Align the torch

Mount the machine torch perpendicular to the workpiece in order to get a vertical cut. Use a square to align the torch at

0° and 90°.

Torch

0°

90°

3-24 powermax45 Service Manual

You might also like

- Man NR20Document68 pagesMan NR20DP75% (8)

- An Analysis of Indicators Disclosed in Corporate Sustainability Reports PDFDocument16 pagesAn Analysis of Indicators Disclosed in Corporate Sustainability Reports PDFRahul PramaniNo ratings yet

- Annulus Vent Monitoring System For Flexible RisersDocument4 pagesAnnulus Vent Monitoring System For Flexible RisersConnor Sailor100% (1)

- Bryan Burgess For Oberlin City CouncilDocument2 pagesBryan Burgess For Oberlin City CouncilThe Morning JournalNo ratings yet

- (UL ANSI: FR-4.0) Conventional FR-4: Features ApplicationsDocument2 pages(UL ANSI: FR-4.0) Conventional FR-4: Features ApplicationsNOUREDDINE ELHAMRINo ratings yet

- A18 A19 CylinderDocument4 pagesA18 A19 CylinderBiswanath LenkaNo ratings yet

- A16 A17 CylinderDocument7 pagesA16 A17 Cylinderjaneesh RNo ratings yet

- A18 A19 CylinderDocument4 pagesA18 A19 CylinderkarthikNo ratings yet

- SBPT Catalogue DC CouplingDocument11 pagesSBPT Catalogue DC CouplingEserNo ratings yet

- Stackup - CN TDS 1911 03 S1000H S1000HBDocument2 pagesStackup - CN TDS 1911 03 S1000H S1000HBMuhamad Sayid Akil MhsAkilNo ratings yet

- Datasheet-Sandvik-12r11-En-V2020-08-27 14 - 00 Version 1Document5 pagesDatasheet-Sandvik-12r11-En-V2020-08-27 14 - 00 Version 1Kashish0% (1)

- Transmotec Datasheet SDS80120ADocument1 pageTransmotec Datasheet SDS80120Asaxadi4814No ratings yet

- Air Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesDocument4 pagesAir Cylinder: Series A10, A11 AIR CYLINDERS Double Acting (Ø32 - 100) MM FeaturesBiswanath LenkaNo ratings yet

- Pile Design For AXIAL Forces Final CheckDocument4 pagesPile Design For AXIAL Forces Final CheckramesNo ratings yet

- MTO MuruganDocument2 pagesMTO MuruganBala SubramaniNo ratings yet

- Elmwood Temperatursicherung Eng TdsDocument6 pagesElmwood Temperatursicherung Eng TdsSebastianSimonNo ratings yet

- (Carbon Steel Air Plasma / Air Shield Cutting) Lead 15.3mDocument2 pages(Carbon Steel Air Plasma / Air Shield Cutting) Lead 15.3mNaser SulimanNo ratings yet

- Ancon EdjPro EPHIMini Edge Lifting SystemDocument2 pagesAncon EdjPro EPHIMini Edge Lifting SystemsashilaNo ratings yet

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- Using The Cut Charts: Torch SetupDocument30 pagesUsing The Cut Charts: Torch Setupjuan esteban RestrepoNo ratings yet

- PressedDocument46 pagesPressedsameh aboulsoudNo ratings yet

- Quotation: Machine FeaturesDocument5 pagesQuotation: Machine FeaturesZakhamaNo ratings yet

- Crosby 198Document1 pageCrosby 198oscar_jfrNo ratings yet

- Am 45HP SeriesDocument1 pageAm 45HP Serieskardelen aygunNo ratings yet

- Toptherm Roof-Mounted Fans: Air Throughput 400 - 800 M /HDocument1 pageToptherm Roof-Mounted Fans: Air Throughput 400 - 800 M /HMahasweta MitraNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- TornilleriaDocument26 pagesTornilleriacorpSIG corpSIGNo ratings yet

- 3 Slickline CapabilitiesDocument14 pages3 Slickline CapabilitiesHedi ChhidiNo ratings yet

- Data Sheet: P6Smb SeriesDocument4 pagesData Sheet: P6Smb SeriesZiritt Duran DavidNo ratings yet

- Shoulder Plugs GasketsDocument1 pageShoulder Plugs GasketssergioteroNo ratings yet

- Spit Epomax: Zinc Coated Steel (Standard Anchorage)Document12 pagesSpit Epomax: Zinc Coated Steel (Standard Anchorage)Sudhakar KrishnamurthyNo ratings yet

- Entech TPE Resin Datasheet 1Document4 pagesEntech TPE Resin Datasheet 1Ermin CisicNo ratings yet

- Achteck CatalogueDocument8 pagesAchteck CatalogueManas D SinghNo ratings yet

- Lit Circpac HP DataDocument2 pagesLit Circpac HP Databillel limaneNo ratings yet

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- Info EN755 9Document19 pagesInfo EN755 9Don JonesNo ratings yet

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Document1 pageRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNo ratings yet

- Key Features: Internal Mount Flange Facing Machine 12 - 60" (305 - 1525mm)Document3 pagesKey Features: Internal Mount Flange Facing Machine 12 - 60" (305 - 1525mm)DI DINo ratings yet

- Specification: EN9 - 070M55: Hollowbar - Co.zaDocument3 pagesSpecification: EN9 - 070M55: Hollowbar - Co.zaAnantha RamanNo ratings yet

- Brosure Kabel NA2XSYDocument5 pagesBrosure Kabel NA2XSYcandra handarsenNo ratings yet

- TAC-F - v1.1-OmegaAir - EngDocument12 pagesTAC-F - v1.1-OmegaAir - EngMột Lằn QuangNo ratings yet

- A25 A26 CylinderDocument5 pagesA25 A26 CylinderBiswanath LenkaNo ratings yet

- 18 EN 14509:2013 AVCP3: Declared Performance For Trapezoidal - KS1000/2000 RW 0818Document1 page18 EN 14509:2013 AVCP3: Declared Performance For Trapezoidal - KS1000/2000 RW 0818Far AwayNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- A16 A17 CylinderDocument7 pagesA16 A17 CylinderkarthikNo ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- 1PH8133-3AF02-2AA1-Z U60+X01 Datasheet enDocument1 page1PH8133-3AF02-2AA1-Z U60+X01 Datasheet enMohamad RagabNo ratings yet

- HPR XD Cut ChartsDocument46 pagesHPR XD Cut ChartsMunavir Ibnu KhaderNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- THHN TCDocument5 pagesTHHN TCjuan pablo castro gallegoNo ratings yet

- Blince OMR Hydraulic MotorDocument10 pagesBlince OMR Hydraulic MotorJoaquin CarvajalNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- LMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceDocument2 pagesLMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceTrong Hung NguyenNo ratings yet

- Actuators Complet RDocument44 pagesActuators Complet RAhmed ElkashifNo ratings yet

- ZF25ADocument4 pagesZF25A1380485No ratings yet

- Datasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1Document5 pagesDatasheet-Sandvik-9ru10-En-V2021-08-16 09 - 55 Version 1aceinsteinNo ratings yet

- 1N2970-1N3015B, 1N3993-1N4000A: 10 Watt Zener DiodesDocument5 pages1N2970-1N3015B, 1N3993-1N4000A: 10 Watt Zener DiodesAndres GalvezNo ratings yet

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNo ratings yet

- Flowserve Mark100 PesoDocument8 pagesFlowserve Mark100 PesoAnderson SiqueiraNo ratings yet

- X-Enp (Metal Deck Nail)Document10 pagesX-Enp (Metal Deck Nail)jojo_323No ratings yet

- Unitherm Cat 2210 Pre Insulated TubingDocument2 pagesUnitherm Cat 2210 Pre Insulated TubingSebas FaustoNo ratings yet

- HT Cable Sizing Calculation - Annexure - 1 - EtapDocument1 pageHT Cable Sizing Calculation - Annexure - 1 - Etapvenkatesh.gandhi91No ratings yet

- 2 PDFDocument1 page2 PDFabbas ahmedNo ratings yet

- A Pic Real Time Clock Ic RTC Using The ds1307 - Compress PDFDocument6 pagesA Pic Real Time Clock Ic RTC Using The ds1307 - Compress PDFabbas ahmedNo ratings yet

- Designing Smart Multipurpose Digital Clock Using RDocument5 pagesDesigning Smart Multipurpose Digital Clock Using Rabbas ahmedNo ratings yet

- Terms of Use - PlayrixDocument5 pagesTerms of Use - Playrixabbas ahmedNo ratings yet

- Universal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - UsDocument1 pageUniversal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - Usabbas ahmedNo ratings yet

- Universal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - UsDocument1 pageUniversal Power Supply (Dc/Ac) With Function Generator: Lucas Nülle GMBH Page 1/1 WWW - Lucas-Nuelle - Usabbas ahmedNo ratings yet

- CD4060BMS: Pinout FeaturesDocument9 pagesCD4060BMS: Pinout Featuresabbas ahmedNo ratings yet

- LM 3914Document8 pagesLM 3914abbas ahmedNo ratings yet

- Content Handbook of Energy and Economic Statistics of Indonesia 2020Document111 pagesContent Handbook of Energy and Economic Statistics of Indonesia 2020Fabiola Marella PardedeNo ratings yet

- Chinese Standrad Pipe FittingsDocument79 pagesChinese Standrad Pipe FittingsDinh Nguyen DaoNo ratings yet

- Quality You Expect: Advantages at A GlanceDocument2 pagesQuality You Expect: Advantages at A GlanceNooruddin DeroNo ratings yet

- Ni-CD Battery Charger SpecificationDocument18 pagesNi-CD Battery Charger SpecificationAdrianne DouglasNo ratings yet

- Indian Standards ListDocument1 pageIndian Standards ListRaju ShresthaNo ratings yet

- Technical Note: I - Subject: Analysis, Measurement and Checking of BatteriesDocument7 pagesTechnical Note: I - Subject: Analysis, Measurement and Checking of Batteriesmebarki aberraoufNo ratings yet

- 6PH04 June 2011Document24 pages6PH04 June 2011areyouthere92No ratings yet

- Dynamics Chapter 7Document118 pagesDynamics Chapter 7Hisyammudin RoslanNo ratings yet

- Q.no 1. For Thermal Analysis, The Field Variable IsDocument128 pagesQ.no 1. For Thermal Analysis, The Field Variable IsAMOL JAGTAPNo ratings yet

- BD418 External - Annunciator - BTTY ANN 003 FiplexDocument1 pageBD418 External - Annunciator - BTTY ANN 003 Fiplexculeros1No ratings yet

- Electron Affinity: Atom MoleculeDocument3 pagesElectron Affinity: Atom MoleculeMj Sebastian GuadalupeNo ratings yet

- Product - Services CatalogDocument72 pagesProduct - Services CatalogFonc KitaNo ratings yet

- CombinedSci Chem Bio 5078 Y23 SyDocument56 pagesCombinedSci Chem Bio 5078 Y23 SykaboomzxcNo ratings yet

- Longitudinal Butt Joint Circumferential Lap Joint For Boiler ShellDocument3 pagesLongitudinal Butt Joint Circumferential Lap Joint For Boiler ShellAlvin Tung Kwong ChoongNo ratings yet

- Emergency LightDocument46 pagesEmergency Lightfunkisanju1No ratings yet

- Plates PDFDocument57 pagesPlates PDFÁlvaro Serrano100% (1)

- Geophysics and Medical PhysicsDocument5 pagesGeophysics and Medical PhysicsjanetpriscillaNo ratings yet

- PDS Lubrizol-6950pDocument4 pagesPDS Lubrizol-6950pBurcu Taşçı100% (1)

- CV Kadji Wolieu OMDocument2 pagesCV Kadji Wolieu OMkadjididieNo ratings yet

- Methods For The Reduction of Line LossesDocument5 pagesMethods For The Reduction of Line Lossesapi-232121477No ratings yet

- Product Identification Number - IngersollrandDocument6 pagesProduct Identification Number - Ingersollrandandy habibiNo ratings yet

- Cold Water SystemsDocument31 pagesCold Water Systemsjools100No ratings yet

- NEMA Contactors & StartersDocument148 pagesNEMA Contactors & Startersingreyes7No ratings yet

- M12 Plunger Pump Data: Forged ISO Drawing SpecificationsDocument4 pagesM12 Plunger Pump Data: Forged ISO Drawing SpecificationsAlfonso Alberto ArguelloNo ratings yet

- Hydrogen For TransportationDocument5 pagesHydrogen For Transportationrussell_hodgesNo ratings yet

- Control Panel PDFDocument18 pagesControl Panel PDFhector100% (1)