Professional Documents

Culture Documents

Astm G 8 PDF

Astm G 8 PDF

Uploaded by

FpainspectorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm G 8 PDF

Astm G 8 PDF

Uploaded by

FpainspectorCopyright:

Available Formats

4Tb Designation: G 8 - 96 AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken. PA 19428

Reprinted from the Annud B m k of ASTM Standards. Copyright ASTM

If not listed in the current cornbmed index, will appear in the next edition.

Standard Test Methods for

Cathodic Disbonding of Pipeline Coatings’

This standardisissuedunderthe fixed designation G 8; the number immediately following the designation indicates the year of

of last reapproval.A

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year

superscript epsilon ( 0 indicates an editorial change since the last revision or reapproval.

1. Scope either by means of a sacrificial magnesium anode or from an

1.1 These test methods cover accelerated procedures for impressed current system. The coating is perforated before

simultaneously determining comparative characteristics of starting the test.

insulating coating systems applied to steel pipe exterior for 3.1.1 In Method A, a magnesium anode is used with no

the purpose of preventing or mitigating corrosion that may electrical monitoring during the test period. The results are

occur in underground servicewhere the pipe willbe in determined by physical examination after the test period is

contact with inland soils and may or may not receive concluded.

cathodic protection. They are intended for use with samples 3.1.2 In Method B, either a magnesium anode or an

of coated pipe taken from commercial production and are impressed current system may be used.Electrical instrumen-

applicable to such samples when the coating is characterized tation is provided for measuring thecurrent in the cell

by function as an electrical bamer. circuit. The electrical potential is also measured, and upon

1.2 This test method is intended for testing coatings conclusion of the test period, the test specimen is physically

submerged or immersed in the test solution at room temper- examined.

ature. When it is impractical to submerge or immerse the test 3.1.3 In both test methods physical examination is con-

specimen, Test Method G 95 may be considered where the ducted by comparing the extent of loosened or disbonded

test cell is cemented tothe surface of the coated pipe coating at the perforations in the immersed area with extent

specimen. If higher temperatures are required, see Test of loosened or disbonded coating at a new test hole in the

Method G 42. If a specific test method is required with no coating made in an area that was not immersed.

options, see Test Method G 80.

1.3 The values stated in SI units to 3 significant decimals 4. Significance and Use

are to be regarded as the standard. The valuesgiven in 4. I Breaks or holidays in pipe coatings may expose the

parentheses are for information only. pipe to possible corrosion, since after a pipe has been

1.4 This standard does not purport to address all of the installed underground, the surrounding earthwill be more or

safety concerns, if any, associated with its use. Itisthe less moisture-bearing and it constitutes an effective eiectro-

responsibility of the user of this standard to establish appro- lyte. Damage to pipe coating is almost unavoidable during

priate safety and health practices and determine the applica- transportation and construction. Normal soil potentials as

bility of regulatory limitations prior to use. well as applied cathodic protection potentials may cause

loosening of the coating, beginning at holiday edges, in some

2. Referenced Documents cases increasing the apparent size of the holiday. Holidays

2.1 ASTM Standards: mayalso be caused by such potentials. While apparently

G 12 Test Method for Nondestructive Measurement of loosened coating and cathodic holidays may not result in

Film Thickness of Pipeline Coatings on Steel2 corrosion, this test provides accelerated conditions for loos-

G42 Test Method for Cathodic Disbonding of Pipeline ening to occur and therefore gives a measure of resistance of

Coatings Subjected to Elevated Temperatures’ coatings to this type of action.

G 80 Test Method for Specific Cathodic Disbonding of 4.2 The effects of the test may be evaluated by either

Pipeline Coatings2 physical examination or monitoring the current drawn by

G95 Test Method for Specific Cathodic Disbondment the test specimen and both of these two. Usually there is no

Test of Pipeline Coatings (Attached Cell Method)* correlation between the two methods of evaluation but both

methods are significant. Physical examination consists of

3. Summary of Test Methods assessing the effective contact of the coating with the metal

surface in terms ofobserved differences in the relative

3.1 Both of the two test methods described subject the adhesive bond. It isusually foundthatthe electrically

coating on the test specimen to electrical stress in a highly stressed area propagates from the holiday to a boundarjl

conductive, alkaline electrolyte. Electrical stress is obtained where the loosened coating leaves off for the more effective

contactor

bond attributed to

an original condition

* These test methods are under the jurisdiction of ASTM Committee Dl on throughout the specimen before electrical stressing was

PaintandRelatedCoatings,Materials,and Applications andarethe direct applied. Assumptions associated with test results include the

responsibility of Subcommittee DO1.48 on Durability of Pipeline Coating and following:

Linings. 4.2.1 Attempting to loosen or disbond the coating at a

Current edition approvedMay 10, 1996. Published July 1996.Originally

-

published as G 8 - 69 T. Last previous edition G 8 90. new test hole made in the coating in an area that was not

*Annual Book of ASTM Standards, Vol06.02. immersed represents maximum adhesion or bond as mea-

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

ASTM G B 96 0 7 5 9 5 1 0 0 5 8 7 5 5 3 bY3 m

SPECIMENSUPPORTED BY

DOWEL THRU HOLES IN

NON IMMERSED END

COATED CONNECTION

TO SPECIMEN

BOLTED TERMINAL LUG

CONNECTION

r----- HIGH-RESISTANCE

I

VOLTMETER

TEMPORARY WIRE

CONNECTIONS

REFERENCE

ELECTRODE

NONCONDUCTIVE

COVER

FACTORY SEALED

ANODE CONNECTION

INTENTIONAL HOLl DAY

MAGNESIUM ANOOE

TEST VESSEL

ELECTROLYTE

NOTE-Test hole made in non-imrnerred area atter testing not shown (seeFig. 5).

FIG. 1 Test Assembly for Method A Using a Magnesium Anode

sured by the lifting technique used, and that the same lifting Dimensions of the vessel shall permit the following require-

technique can be used at a test hole that was immersed ments:

thereby providing a means of comparing relative resistance 5.1.1.1 Test specimens shall be suspended vertically in the

to lifting. vessel with at least 25.4-mm (1-in.) clearance from the

4.2.2 Any relatively lesser bonded area at the immersed bottom.

test holes in the coating was caused by electrical stressing and 5.1.1.2 Eachtest specimen shall be separated from the

was notattributable to an anomaly inthe application other specimens, from the anodes and from the walls of the

process. Ability to resist disbondment is a desired quality on test vessel by at least 38.1 mm (1.500 in.).

a comparative basis, but disbondment per se in this test is 5 . I . 1.3 Depth of electrolyte shall permit the test length of

not necessarily an adverse indication. The virtue of this test the specimen to be immersed as required in 7.4.

is that all dielectric type coatings now in common use will 5.1.1.4 If electrical monitoring is to be performed as

disbond to some degree thus providing a means of com- required in Method B, the reference electrode may be placed

paring one coating with another. Bond strength is more anywhere in the vessel, provided it is separated from the

important for proper functioning of some coatings than specimen and from the anode by not less than 38.1 mm

others and the samemeasured disbondment for two different (1 300 in.).

coating systems may not represent equivalent loss of con-o- 5.1.2 Magnesium Anode-The anode shall be made of a

sion protection. magnesium alloy having a solution potential of - 1.45 to

4.2.3 The amount of current in the test cell is a relative -1.55 V with respect to a CuCuS04 reference electrode in

indicator of the extent of areas requiring protection against the electrolyte given in 6.1. It shall have a surface area not

corrosion; however, the current density appearing in this test less than one third that of the total specimen area exposed ta

is much greater thanthat usually required for cathodic electrolyte (outside area exposed only). The anode shall be

protection in natural, inland soil environments. provided with a factory-sealed, 4107-cmil(14-gage Awg),

minimum, insulated copper wire. Anodes without a factory

5. Apparatus seal may be used if the magnesium extends above the cover.

5.1 Apparatus for Both Methods: 5.1.3 Cunnecfors-Wiring from anode to test specimen

5.1.1 Test Vessel-A nonconductingmaterial shall be shall be 4 107-cmil(14-gageAwg), minimum, insulated

used for the vessel or as a lining in a metallic vessel. copper. Attachment tothe test specimen shall be by sol-

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

G8

HIGH-RESISTANCE ventional drills of the required diameter. For use in pre-

VOLTMETER paring small-diameter pipe specimens such as 19.05 m m

(0.750 in.) nominal diameter pipe, the use of a drill modified

by substantially grinding away the sharp conepoint has been

found effective in preventing perforation of the metal wall of

the pipe. A sharp-pointed knife with a safe handle is required

for use in making physical examinations.

TERMINAL

5.1.5 High-Resistance Voltmeter, for direct current,

BOAR0 having an internal resistance of not less than 10 MR and

having a range from 0.01 to 5 V for measuring potential to

ALLIGATOR CLIP

OR KNIFE SW.

the reference electrode.

5.1.6 Reference Electrode, saturated CuCuS04 of conven-

tional glass or plastic tube with porous plug construction,

preferably not over 19.05 mm (0.750 in.) in diameter, having

a potential of -0.3 16 V withrespect to the standard

hydrogen electrode. A calomel electrode may be used, but

NONCONDUCTIVECOVER measurements made withit shall be converted tothe

I M M E R S I O NL I N E CuCuSO, reference for reporting by adding -0.072 V to the

REFERENCE ELECTRODE

observed reading.

5.1.7 Thickness Gage, for measuring coating thickness in

I N T E N T I O N A LH O L I D A Y accordance with Test Method G 12.

ELECTROLYTE

5.1.8 Thermometer, for measuring electrolyte tempera-

ture, general lab type, 1" subdivisions, 76.2 mm ( 3 in.)

TEST VESSEL immersion.

5.2 Additional Apparatus for Method B:

5.2. I High-Resistance Voltmeter, for direct current,

SPECIMEN having an internal resistance of not less than 10 MR and

MAGNESIUM

ANODE capable of measuring as low as 10 pV potential drop across a

shunt in the test cell circuit.

FIG. 2 Test Assembly for Method B Using a Magnesium Anode 5.2.2 Precision Wire-Wound Resistor, 1-52 2 1 %, 1-W

(minimum), to be used in the test cell circuit as a shunt for

dering, brazing, or bolting to the nonimmersed end, and the current.

place of attachment shallbe coated with an insulating 5.2.3 Volt-Ohm-Meter, for initial testing of apparent

material. A junction in the connecting wireis permitted, coating resistance.

provided thatit is made by means of a bolted pair of 5.2.4 Metallic Electrode, used temporarily with the volt-

terminal lugs soldered or mechanically crimped to clean wire ohm-meter to determine apparent initial holiday status of

ends. the test specimen.

5.1.4 Holiday Tools-Holidaysshallbe made with con- 5.2.5 Additional Connecting Wires, 4107-cmil(14-gage

NONCONDUCTIVECOVER

IMMERSION LINE

REFERENCE ELECTRODE

INTENTIONAL HOLIDAY

ELECTROLYTE

TEST VESSEL

IMPRESSEDCURRENT

ANOOE

FIG. 3 Test Assembly for Method B Using an Impressed Current with One Specimen

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

Set rectifier output voltoqa lo not RECTIFIER

oyer 3 volts; then trim eoch voltoqe

divider so tho1 A lo C rneOIurcl

I 5 volt,.

To measurecurrentuse terrninols A and 0

To rneosurt wollogsterminals

use A ond C #-REFERENCE ELECTRODE

V

FIG. 4 Modification of Method B (Fig. 3) Using Impressed Current to Test More than One Specimen

Awg), minimum, insulated copper. 6.3 Plywood or plastic material has been found suitable

5.2.6 Brass Studs, used at a terminal board,together with for the construction of test vessel covers and for the support

alligator clips or knifeswitches, for making and breaking through apertures of test specimens and electrodes. Wood

circuits. Alligatorclipsshall not be used toconnectto dowels introduced through holesin the topends oftest

electrodes or specimens at the top location of test cells. specimens havebeen found suitable for suspending test

5.2.7 Zero-Resistance Ammeter, capable of measuring specimens from the vessel cover.

direct current as low as 10 PA may be used in the alternative

method given in 9.1.3 and substituted for theapparatus 7. Test Specimen

described in 5.2.1 and 5.2.2.

7.1 The testspecimenshall be a representative piece of

5.2.8 Direct-Current Reclrfier, capable of supplying con-

*

stant voltage at a voltage of 1S O 0.01 V, as measured

production-coated pipe. One end shall be plugged or capped,

and sealed.

between the specimen and reference electrode.

7.2 One orthree holidays shall be made ineach specimen.

5.2.9 Impressed Current Anode, shall of

be the

Three holidays arerecommended.Recommendeddimen-

nonconsumable type provided with a factory sealed, insu-

sions are given in Fig. 5. A specimen with one holiday shall

lated copper wire.4 have it drilled in the middle of the immersedlength. If three

5.2.10 Voltage Divider, lOO-Q, 25-W rheostat, to be used holidays are used, they shall be drilled 120" apart with one in

if more than one specimen is to be tested as shown in Fig. 4.

the center and the other two at locations onefourththe

6. Reagent and Materials distance from top and bottom of the immersed test length.

6.1 The electrolyte shall consist of potable tap water with Each holiday shallbe drilled so that theangular cone point of

the drill will fullyenter thesteel wherethe cylindrical portion

the addition of 1 mass % of each of the following technical-

of the drill meets the steel surface.The drill diameter shall be

grade satls, calculated on an anhydrous basis: sodium chlo-

ride, sodium sulfate, and sodiumcarbonate. Usefreshly not less than three times the coating thickness, but it shall

prepared solution for each test. never be smaller than 6.35 mm (0.250 in.) in diameter. The

6.2 Materials for sealing the ends of coated pipespeci- steelwallof the pipe shall not be perforated. With small-

diameter pipes, wherethere is danger of perforating the pipe,

mens may consist of bituminous products, wax, epoxy, or

the holiday shall be started with a standard 60" cone point

other materials, including molded elastomeric or plastic end

caps. and finished with a drill thathas had a substantial portionof

the cone point groundaway.

NOTEI -Before making the holiday, see 8.1.

'Durion, a material found suitable for this purpose is available from Durion

Co., Inc., Dayton OH. 7.3 The end of the pipe whichwill protrude above the

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

NO SCALE

12.7 mm 10.5 i n I HOLE THRU

FOR W W E L SUPPORT

’ REFERENCE HOLE IN

ORILLED AFTER TE5

Dimension mm (in.)

A 490.22 f 12.7 (19.300 i 0.500)

B 245.11 f 12.7 ( 9.650 f 0.500)

C 120.65 f 6.35 ( 4.750 f 0.250)

D 114.3 f 6.35 ( 4.500 f 0.250)

E 233.363, min ( 9.1875, min)

F 19.05, min ( 0.750, min)

G 762, min (30, min)

FIG. 5 RecommendedI 1Dimensions for Specimen

immersion line shallbe provided with suitable supporting electrode. Measure the apparent resistance in ohms, making

means and aseparate wire connection for electrical purposes, two determinations: one with the specimen connected to the

soldered, brazed, or bolted to the pipe. The protruding end, positive terminal of the multimeter; andone with the

including hanger and wire connections, shallbe protected specimen connected to the negative terminal.

and sealed with an insulating coating material. 8.1.2 Disconnect the specimen from the multimeter but

7.4 The specimen test area shall consist of the area leave it immersed for 15 min. Then, measure the resistance

between the edge of the bottom end seal and the immersion again as in 8.1.1.

line. The bottom endseal area shall not be considered part of 8.1.3 A significant decrease in either resistance reading

the area tested. Any suitable diameter and specimen length after 15 min will indicate a flaw in the coating or end-cap

of pipe may be used, but the immersed area shall be not less seal.Reject the specimen if the flawis identified inthe

than 23 227 mm2 (36 in2). An area of 92 900 mm2 ( 1 ft’) coating. If the flaw is in the end-cap seal, it may be repaired

has been found preferable when convenient. and the resistance remeasured as in 8.1.1 and 8.1.2.

8.1.4 The lowest resistance after 15 min of immersion

8. Specimen Preparation shall be not less than 1000 MR but a stable reading below

8.1 Before making artificial holidays, verify the continuity 1000 MQ may not indicate a flaw and the specimen may be

of the coating and the effectiveness of the end-cap seal as used for test. All resistance measurements shall be reported

follows: in the results.

8.1.1 Immerse the test specimen and a metallic electrode 8.2 Record initial holiday diameter(s).

in the electrolyte. Connect one terminal of the multimeter to 8.3 Measure and record theminimumandmaximum

the test specimen andtheother terminal to the metallic coating thickness in accordance with Test Method G 12, and

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

Data Sheet and Report, Part I,for Method A and Method B Cathodlc Diabonding of Plpellne Coatings

1. Specimen

2. Pipe:

O.D. mrn (in.) mm (in.) Wall Length rnrn (in.)

Mfgr. API

3. Coating:

Name, No.

Mfgr.

Application method

APplhtM

Thickness. mm (in.)

Max. Top Middle BonM

4. Test:

arted Date

Test mm2 (in.2)

Top Middle Bottom Average

Initial h d i a y dia. rnm (in.)

Final unsealed area rnrnz (in.?

(-) Initial holiday area mrn2 (in.?

= Net disbonded area mm2 (in.2)

Disbonded Equivalent Circle Diametermmz (in.2)

5 . Preliminaryverification

Largest Disbonded Equivalent Circle Diameter

Verification of coating continuity before starting test perSec. 7.6

IECD)

. . does not exceed

Group Spontaneous Holidays

Megohms

mm in. Trial Polarity

Initial

After 15 rnin.

A 12.7 0.50 None

Plus

0 25.4 1.Initial

oo None

Minus

C 38.1 1.50 NOne

Plus

2.00 D 50.8 None

Minus Final

E than

More

than

More Any

50.8 2.00

6. Rectifier Current:

If rectifier current was not continuous indicate interrupted time (rnin., hrs.):

FIG. ,6 Suggested Form, Part I, for Use in Presenting Data for One Specimen Method A and Bethod B

the thickness where each holiday is made. be - 1.45 V to - 1.55 V with respect to a CuCuSO, reference

electrode. Use the instrument described in 5.1.5.

9. Procedure for Method A 9.2 Duration of the test period shall be 30 days. Option-

9.1 Immerse the test specimen in the electrolyte and ally, other test periods such as 60 or 90 days may be used.

connect it totheanode as shown inFig. 1. Position the 9.3

An examination shall be performed immediately

middle or single holiday so that it faces away from the anode. upon termination of the test period as follows:

Space the anode with respect to test specimens as described 9.3.1At the end of the test period, disassemble the cell

in5.1.1.Mark the correct immersion level of the test and rinse the test area withwarm tap water. Immediately

specimen with a grease pencil and maintain by daily addi- wipe the sample dry and visually examine the entire test area

tions of potable water as required. Perform the test at for any evidence of unintentional holidays and loosening of

electrolyte temperature of 21 to 25°C (70 to 77°F). coating at the edge of all holidays, including the intentional

9.1.1 In order to ascertain that the test cell is functioning, holiday, and record coating condition, for example, color,

measure the potential between test specimen and a reference blisters, cracking, crazing, adhering deposits, etc.

electrode immediately after starting the test and immediately 9.3.2 Drill a new reference holiday in the coating in an

before terminating it. Usetemporary connections and instru- area that was not immersed. Follow thesame drilling

mentation, as shown in Fig. 1. The potential measured shall procedure as described in 7.2.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

Data Sheet and Report, Part II, for Method B Cathodic Disbonding of Pipeline Coatings

toring, Electrical B Ohms Initial + -

Elapsed days of Potential to Ref., V mV E2 - AveraglB Values on 1

Date and Actual I,. pA

Test, To El €2

E, = A€* v I 11, PA

I

Change, Start to Termination: Forspecimen:

the

per Initial Holiday: Av

FIG. 7 Suggested Form, Part II, for Use in Presenting Data for One Specimen, Method B

9.3.3 Make radial 45" cuts through the coating inter- determining the potential drop across the 1-R resistor perma-

secting at the center of both the intentional holiday and the nently installed in the test cell circuit with the multimeter

reference holiday with a sharp, thin-bladed knife. Take care described in 5.2.1. The voltage reading will be numerically

to ensure that coating is cut completely through to the steel equal to amperes.

substrate. NOTE3-An alternative method of measuring current demand may

9.3.4 Attemptto lift the coating at both the reference be used by means of the instrument described in 5.2.4. In this method,

holiday and the intentionalholiday with the point of a sharp, the wire connection between test specimen and anode is temporarily

thin-bladed knife. Use the bond at thereference holiday as a broken and a zero-resistance ammeter temporarily interposed between

reference for judging the quality of the bond at the inten- the specimen and the anode. Reconnect the specimen to the anode with

tional holiday. Measure and record the total area of the connector wire as soon as this measurement is completed.

disbonded coating at the intentional holiday. 10.1.4 Measure E,, the polarized potential, involts. Do

NOTE2-The use of a transparent film havinga grid laid out insmall this with the multimeter described in 5.1.5 connected

squares such as 2.54 mm (0.1 in.) on a side has been found useful. The between the test specimen andthe reference electrode as

film is placedagainst the unsealed area and theboundary of the unsealed follows:

area traced on the grid, The area is then obtained by counting the 10.1.4.1 Disconnect the anode from the test specimen

squares within the bonded area. whileclosely observing the multimeter. As the instrument

pointer falls, it will dwell significantly at the polarized value

10. Procedure for Method B before receding further. The dwell point is E,. If a CuCuS04

10.1 In addition tothe procedure given in Section 9, electrode is used, immerse only temporarily.

monitor the progressof the testelectrically in accordance 10.2 Electrical Monitoring Schedule:

with the schedule given in 10.2 as follows: 10.2.1 Electrical measurements at the start of the test are

10.1.1 If a magnesium anode is to be used, install the test defined as the average of measurements taken on the second

assembly shown in Fig. 2. If impressed current for a single and third days after immersion. Measurements may be taken

specimen is to be used, install the test assembly shown in Fig. on the day of immersion in order to ascertain functioning of

3;if more than one specimen is to be tested, use the the test cell, but such measurements are not to be used in

modification shown in Fig. 4. calculating the change in characteristics from start to target

10.1.2 Measure E2, the stress potential in volts between dates in the conduct of the test.

test specimen and reference electrode, with a multimeter 10.2.2 Make electrical measurements at the start of a test

without disconnecting the anodefrom the test specimen. Use and ona target date after 30 days.The test may be continued

the instrument described in 5.1.5. If a CuCuSO, electrode is for 60 or 90-day targets with intermediate and corresponding

used, immerse only temporarily. electrical measurements.

10.1.3 Measure I , , thecurrentdemand in amperes, by 10.2.3 Take electrical measurements for intermediate

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

A S T M G B 96 = 0759530 0587559 Ob1

G8

target dates and for the terminal date on 2 successive days average change per holiday may be reported for 1 1 -2.3.1.

prior toand including the target date.The averageof 1 1.2.4 Any interrupted time of the rectifier current.

readings taken on the 2 days is defined as the target date

measurement. 12. Precision and Bias

10.2.4 Rectifier current shall be continuous. Any inter- 12.1 Precision data are limited to two adjacent specimens

ruptions must be reported. taken from the same production-coated pipe and assume

11. Report (see Figs. 6 and 7): that the production process was uniform with respect to pipe

surface condition and coating material. Specimens that were

11.1 The report for Method A shall include the following not adjacent in the as-produced condition or were taken

information: from different lengths ofpipe may represent differing process

1I . 1.1 Complete identification of the test specimen, in- conditions. The following data should be used for judging the

cluding: acceptability of results: (These precision data are approxima-

1 1.1.1.1 Name and code number of the coating, tions based on limited data, but they provide a reasonable

11.1.1.2 Size and wall thickness of pipe, basis for judging the significance of results.)

1 1.1.1.3 Source, production date,and production run 12.2 Method A:

number, 12.2.1 Repeatability-Duplicate results by the same

1 1.1.1.4 Minimum-maximum coating thickness, average worker should not be considered suspect unless they differ by

thickness and the thickness at the holiday, more than 12.7 mm (0.5 in.) in value ECD in accordance

1 1.1.1.5 Immersed area, with the following equation:

1 1.1.1.6 Size and number of initial holidays, and

1 1.1.1.7 Resistance measurements verifying continuity of ECD = (A/0.7SS)1/2

the coating and effectiveness of the end cap seal as required where:

in 8.1. A = unsealed area developed from 1 artificial holiday,

1 1.1.2 Dates of starting and terminating test. mm2 (in.2).

1 1.1.3 Tally of areas that have been found unsealed on the 12.2.2 Reproducibility-The results reported by one labo-

terminal date. Areas may be reported in square millimetres ratory should not be considered suspect unless they differ

(square inches) or millimetres (inches) of equivalent circle from those of another laboratory by more than 25 mm (1 in.)

diameter of the area, or both. If more than one holiday was for value ECD in the equation given in 12.2.1.

used, the area per holiday may be reported as an average. 12.3 Method B:

NOTE4-Equivalent Circle Diameter (ECD)is obtained from the 12.3.1

Repeatability-Duplicate results by the same

formula: worker should not be considered suspect unless they differ by

ECD = (A/0.785)'/2 more than unity in the negative characteristic of the loga-

where: rithm of the current demand in amperes.

A = area of holiday, mm2 (in.*)

12.3.1.1 Duplicate results by the same worker should not

1 1.1.4 Other information that may be pertinent. be considered suspect unless they differ by more than 12.7

I 1.2 The report for Method B shall include the following: mm (0.5 in.) in the value of ECD as described in 12.2.1.

1 1.2.1 The data required in the report for Method A,

12.3.2 Reproducibility-The results reported by one labo-

11.2.2 The relative resistances of the test specimen in ratory should not be considered suspect unless theydiffer

ohms before the artificial holiday was made as described in from those of another laboratory by more than unity in the

8.1.4, and negative characteristic of the logarithm of the current de-

11.2.3 The results of starting, intermediate, and terminal mand in amperes.

electrical measurements. Report the following measure- 12.3.2.1 The results reported by one laboratory should

ments: not be considered suspect unless they differ from those of

11.2.3.1 Currentdemand in microamperes, or negative another laboratory by more than 25 mm (1 in.) in the value

characteristic of the logarithm of the current in amperes, or of ECD as described in 12.2.1.

both,

I 1.2.3.2 The value of A E = E2 - E , in volts, and 13. Keywords

11.2.3.3 Change from start to termination for values 13.1 ambient bonding; cathodic disbonding; pipeline

1 1.2.3.1 and 1 1.2.3.2. If more than one holiday was used the coatings

The American Society for Testing and Materials takes no position respecting the validity of any patent rights assetted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard Is sub/ect to revlsion at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarrers. Your comments will receive careful consideratlon at a meetlng of the responsible

technical committee, which you may aftend. If you feel that your comments have not recelved a fair hearing you shouid make your

views known to the ASTM Committee on Standards, 1 0 0 Barr Harbor Drive, West Conshohmken, PA 19428.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

You might also like

- That Time I Got Reincarnated As A Slime, Vol. 15Document468 pagesThat Time I Got Reincarnated As A Slime, Vol. 15Phil50% (2)

- CSM 10423RDocument53 pagesCSM 10423RWyllton CandidoNo ratings yet

- Relations and Functions Performance TaskDocument8 pagesRelations and Functions Performance Taskapi-242221534100% (1)

- C840 373465 1 PDFDocument18 pagesC840 373465 1 PDFibrahimNo ratings yet

- A Broken Wave-Lionel EsherDocument39 pagesA Broken Wave-Lionel EsherChristian NoetzlyNo ratings yet

- For Hino: Tics Pump Electrical Part Resistance Value ListDocument35 pagesFor Hino: Tics Pump Electrical Part Resistance Value Listfersky90% (10)

- Professor Dr Francesco Capasso, Professor Dr Timothy S. Gaginella, Professor Dr Giuliano Grandolini, Professor Dr Angelo a. Izzo (Auth.)-Phytotherapy_ a Quick Reference to Herbal Medicine-Springer-VerDocument413 pagesProfessor Dr Francesco Capasso, Professor Dr Timothy S. Gaginella, Professor Dr Giuliano Grandolini, Professor Dr Angelo a. Izzo (Auth.)-Phytotherapy_ a Quick Reference to Herbal Medicine-Springer-VerJesus Ignacio Briceño PrietoNo ratings yet

- ASTM G42 Cathodic Disbonment TestDocument8 pagesASTM G42 Cathodic Disbonment TestDuy Linh NguyenNo ratings yet

- Astn D 3681 - 01 PDFDocument8 pagesAstn D 3681 - 01 PDFrajesh makwanaNo ratings yet

- Cathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Document4 pagesCathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)Fernando Berrospi GarayNo ratings yet

- C 1002 - 00 QzewmditmdaDocument4 pagesC 1002 - 00 QzewmditmdaHumberto GutierrezNo ratings yet

- Nuclear Containment FailuresDocument10 pagesNuclear Containment FailuresskdonaldsNo ratings yet

- ASTM D4708 - 12 Purchased VersionDocument3 pagesASTM D4708 - 12 Purchased VersionnishanthNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Quenched-and-Tempered, Chromium-Molybdenum, and Chromium - Molybdenum-VanadiumDocument4 pagesPressure Vessel Plates, Alloy Steel, Quenched-and-Tempered, Chromium-Molybdenum, and Chromium - Molybdenum-VanadiumJosé Ramón Gutierrez100% (1)

- Astm A0490Document7 pagesAstm A0490ndt_inspectorNo ratings yet

- Coating Application Standard No. 7: Applying Thin Film Coatings To ConcreteDocument9 pagesCoating Application Standard No. 7: Applying Thin Film Coatings To Concretevanessa7aponteNo ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- Immersion Testing of Industrial Protective Coatings: Standard Practice ForDocument6 pagesImmersion Testing of Industrial Protective Coatings: Standard Practice ForJhon Jeiwer SantosNo ratings yet

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceDocument3 pagesFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- Zinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForDocument5 pagesZinc Coating (Hot-Dip) On Iron and Steel Hardware: Standard Specification ForMd. Main UddinNo ratings yet

- Astm A53Document22 pagesAstm A53Cristina ZamoraNo ratings yet

- ASTM B557 10 Standard Test MethodDocument15 pagesASTM B557 10 Standard Test MethodmehmetNo ratings yet

- Nace Withdrawn Standards PDFDocument2 pagesNace Withdrawn Standards PDFyusbelis0% (1)

- Astm B117 1973Document3 pagesAstm B117 1973prasad4ucherukuri11No ratings yet

- D 5141 AstmDocument4 pagesD 5141 AstmJordan ReyesNo ratings yet

- C 1047 - 99 QzewndcDocument3 pagesC 1047 - 99 QzewndcGarcia ManuelNo ratings yet

- Astm C868-02 PDFDocument4 pagesAstm C868-02 PDFIan HsuNo ratings yet

- Astm G33Document3 pagesAstm G33Vikash YadavNo ratings yet

- Porosity in Metallic Coatings by Humid Sulfur Vapor ("Flowers-of-Sulfur")Document5 pagesPorosity in Metallic Coatings by Humid Sulfur Vapor ("Flowers-of-Sulfur")ROHITNo ratings yet

- C 1063 - 03 QzewnjmDocument9 pagesC 1063 - 03 QzewnjmGarcia ManuelNo ratings yet

- Protective Coatings: Classification NotesDocument10 pagesProtective Coatings: Classification NotesIslam FawzyNo ratings yet

- CANDE A Versatile Soil-Structure Design and Analysis Computer ProgramDocument7 pagesCANDE A Versatile Soil-Structure Design and Analysis Computer ProgramVietanh PhungNo ratings yet

- Asphalt-Rubber Binder: Standard Specification ForDocument4 pagesAsphalt-Rubber Binder: Standard Specification FordsamotoNo ratings yet

- Astm F 679-03Document6 pagesAstm F 679-03JORGE ARTURO TORIBIO HUERTA100% (1)

- Astm CDocument3 pagesAstm CLuis MarcosNo ratings yet

- Astm C591 - 22Document10 pagesAstm C591 - 22sgjsevenpNo ratings yet

- Polyethylene (PE) Plastic Tubing: Standard Specification ForDocument7 pagesPolyethylene (PE) Plastic Tubing: Standard Specification ForHernando Andrés Ramírez GilNo ratings yet

- ASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsDocument4 pagesASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsArmaghan ShiekhNo ratings yet

- Astm D4496Document5 pagesAstm D4496Sampath WeragodaNo ratings yet

- A498Document13 pagesA498rgi178No ratings yet

- Astm D1895 17Document4 pagesAstm D1895 17Sonia Goncalves100% (1)

- C24Document5 pagesC24maria tNo ratings yet

- Softening Point of Pitches (Cube-in-Water Method) : Standard Test Method ForDocument4 pagesSoftening Point of Pitches (Cube-in-Water Method) : Standard Test Method FordanicyrNo ratings yet

- D3171 1166550-1Document11 pagesD3171 1166550-1khudhayer1970No ratings yet

- NACE TR21473-2024 In-Situ Coating of Steel Pipelines Via PiggingDocument16 pagesNACE TR21473-2024 In-Situ Coating of Steel Pipelines Via Piggingahugandkiss77071No ratings yet

- Evaluating Coatings For High Temperature Service: Standard Test Methods ForDocument3 pagesEvaluating Coatings For High Temperature Service: Standard Test Methods ForFernando Berrospi Garay100% (1)

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDocument6 pagesNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification Forsharon blushteinNo ratings yet

- Standard Test Method For Coefficient of Linear Thermal Expansion of Plastics Between 30°C and 30°C With A Vitreous Silica Dilatometer 1Document6 pagesStandard Test Method For Coefficient of Linear Thermal Expansion of Plastics Between 30°C and 30°C With A Vitreous Silica Dilatometer 1Gaurav KumarNo ratings yet

- Astm G42 - 11 PDFDocument8 pagesAstm G42 - 11 PDFJavier Celada100% (1)

- Astm d2444 21 落锤试验机标准Document10 pagesAstm d2444 21 落锤试验机标准Avin WangNo ratings yet

- ASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFDocument5 pagesASTEM D955 00 - Standard Test Method of Measuring Shrinkage From Mold Dimensions of Thermoplastics PDFAndre Rodriguez SpirimNo ratings yet

- Astm D365Document3 pagesAstm D365Frank LeeNo ratings yet

- 3LPE Coating Performance in IranDocument3 pages3LPE Coating Performance in IranJorge Suarez100% (1)

- An Imaging Technique To Measure Rust Creepage at Scribe On Coated Test Panels Subjected To Corrosive EnvironmentsDocument4 pagesAn Imaging Technique To Measure Rust Creepage at Scribe On Coated Test Panels Subjected To Corrosive EnvironmentsAlejandro 20No ratings yet

- A 872 - 91 R02 Qtg3mi05mviwmgDocument3 pagesA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdNo ratings yet

- C73Document2 pagesC73reefreefNo ratings yet

- Astm A111Document3 pagesAstm A111deivisbtsNo ratings yet

- ASTM G 9-07 Standard Test Method For Water Penetration Into Pipeline Coatings1Document4 pagesASTM G 9-07 Standard Test Method For Water Penetration Into Pipeline Coatings1daempi100% (1)

- D 1780 - 99 Rde3odaDocument4 pagesD 1780 - 99 Rde3odaMarceloNo ratings yet

- Aws C2Document8 pagesAws C2dehamanezNo ratings yet

- Astm E96.9061 PDFDocument8 pagesAstm E96.9061 PDFgaso99No ratings yet

- C795Document3 pagesC795dinhtung2210No ratings yet

- Astm G 8Document9 pagesAstm G 8José Uriel Javier TorresNo ratings yet

- Cathodic Disbonding of Pipeline Coatings: Standard Test Methods ForDocument9 pagesCathodic Disbonding of Pipeline Coatings: Standard Test Methods FormarciobispoalmeidaNo ratings yet

- IMMI Grant NotificationDocument4 pagesIMMI Grant NotificationAngeline GarciaNo ratings yet

- Zosi Wireless NVR & Monitor SystemDocument60 pagesZosi Wireless NVR & Monitor SystemJose RamirezNo ratings yet

- Basic Accounting - Final ExaminationDocument5 pagesBasic Accounting - Final ExaminationLaira Diana RamosNo ratings yet

- Matrix - An IntroductionDocument10 pagesMatrix - An IntroductionMajid AbNo ratings yet

- LinkBelt 108H5Document20 pagesLinkBelt 108H5amirNo ratings yet

- Yeastar P-Series PBX System Datasheet enDocument7 pagesYeastar P-Series PBX System Datasheet enYemen BrokerNo ratings yet

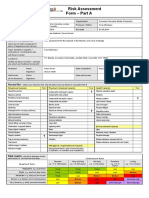

- Risk AssessmentDocument2 pagesRisk AssessmentFaraiMbudaya0% (1)

- The Verb To BeDocument1 pageThe Verb To Bek.havleovaNo ratings yet

- QUESTION - PAPER TemplateDocument4 pagesQUESTION - PAPER TemplaterajkalamaeroNo ratings yet

- Classes and Objects: © 2017 Wipro Confidential 1Document35 pagesClasses and Objects: © 2017 Wipro Confidential 1Preethi A ECENo ratings yet

- Cyber SOCDocument9 pagesCyber SOCTrần Trung HiếuNo ratings yet

- Analytical Modeling of Gate-All-Around Junctionless Transistor Based Biosensors For Detection of Neutral Biomolecule SpeciesDocument9 pagesAnalytical Modeling of Gate-All-Around Junctionless Transistor Based Biosensors For Detection of Neutral Biomolecule SpeciesamitNo ratings yet

- Modification and Characterization of PolypropyleneDocument7 pagesModification and Characterization of PolypropyleneSaba MalikNo ratings yet

- Syllabusbtechec1 PDFDocument107 pagesSyllabusbtechec1 PDFAmol AmollNo ratings yet

- Bài Tập Các Loại Mệnh ĐềDocument17 pagesBài Tập Các Loại Mệnh ĐềCường PhạmNo ratings yet

- Panasonic hc-vx870 hc-vx878 hc-v770 hc-v777 Series SMDocument71 pagesPanasonic hc-vx870 hc-vx878 hc-v770 hc-v777 Series SMhector mirandaNo ratings yet

- Series HDocument6 pagesSeries HAviation World100% (3)

- The Cost of Goods Sold For The Month of December: Excel Professional Services, IncDocument4 pagesThe Cost of Goods Sold For The Month of December: Excel Professional Services, IncmatildaNo ratings yet

- HRM Section A and C Case HHUPD-1-3Document3 pagesHRM Section A and C Case HHUPD-1-3vijay kumarNo ratings yet

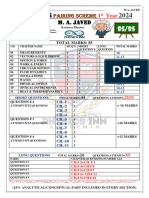

- Pairing Scheme 1st Year 2024 BY PHYSICS INN ACDEMIA M.A. JAVEDDocument1 pagePairing Scheme 1st Year 2024 BY PHYSICS INN ACDEMIA M.A. JAVEDabdull phyNo ratings yet

- Ixys P-Channel Power Mosfets and Applications Abdus Sattar, Kyoung-Wook Seok, Ixan0064Document14 pagesIxys P-Channel Power Mosfets and Applications Abdus Sattar, Kyoung-Wook Seok, Ixan0064Kikuvi JohnNo ratings yet

- Typical Details of Switchyard RequirementDocument364 pagesTypical Details of Switchyard RequirementEspro100% (1)

- Query ManualDocument37 pagesQuery ManualstraNo ratings yet

- Sobha LTD Q2 FY 2020 21 Investor PresentationDocument47 pagesSobha LTD Q2 FY 2020 21 Investor PresentationAdarsh Reddy GuthaNo ratings yet

- Fruit Juice IndustryDocument11 pagesFruit Juice IndustryArlene GutierrezNo ratings yet