Professional Documents

Culture Documents

TABLE 8-4: V V Is The

TABLE 8-4: V V Is The

Uploaded by

Stephannie SyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TABLE 8-4: V V Is The

TABLE 8-4: V V Is The

Uploaded by

Stephannie SyCopyright:

Available Formats

TABLE 8– 4

Loss coefficients KL of various pipe components for turbulent flow (for use in the relation hL 5 KLV 2/(2g), where V is the

average velocity in the pipe that contains the component)*

Pipe Inlet

Reentrant: KL 5 0.80 Sharp-edged: KL 5 0.50 Well-rounded (r /D . 0.2): KL 5 0.03

(t ,, D and I < 0.1D) Slightly rounded (r /D 5 0.1): KL 5 0.12

(see Fig. 8–39)

V D V D V D

l t

Pipe Exit

Reentrant: KL 5 a Sharp-edged: KL 5 a Rounded: KL 5 a

V V V

Note: The kinetic energy correction factor is a 5 2 for fully developed laminar flow, and a < 1.05 for fully developed turbulent flow.

Sudden Expansion and Contraction (based on the velocity in the smaller-diameter pipe)

d2 2

Sudden expansion: KL 5 a a1 2 b

D2

0.6

V d D

0.4

KL for sudden

KL contraction

Sudden contraction: See chart.

0.2

0

0 0.2 0.4 0.6 0.8 1.0

D d V

d2/D2

Gradual Expansion and Contraction (based on the velocity in the smaller-diameter pipe)

Expansion (for u 5 20°): Contraction:

KL 5 0.30 for d/D 5 0.2 KL 5 0.02 for u 5 30°

KL 5 0.25 for d/D 5 0.4 KL 5 0.04 for u 5 45° D u d

V d u D V

KL 5 0.15 for d/D 5 0.6 KL 5 0.07 for u 5 60°

KL 5 0.10 for d/D 5 0.8

347-436_cengel_ch08.indd 377 12/18/12 1:52 PM

378

INTERNAL FLOW

TA B LE 8– 4 (CON C L UD ED )

Bends and Branches

90° smooth bend: 90° miter bend 90° miter bend 45° threaded elbow:

Flanged: KL 5 0.3 (without vanes): KL 5 1.1 (with vanes): KL 5 0.2 KL 5 0.4

Threaded: KL 5 0.9

45°

V V V V

180° return bend: Tee (branch flow): Tee (line flow): Threaded union:

Flanged: KL 5 0.2 Flanged: KL 5 1.0 Flanged: KL 5 0.2 KL 5 0.08

Threaded: KL 5 1.5 Threaded: KL 5 2.0 Threaded: KL 5 0.9

V

V V

Valves

Globe valve, fully open: KL 5 10 Gate valve, fully open: KL 5 0.2

1

Angle valve, fully open: KL 5 5 4 closed: KL 5 0.3

1

Ball valve, fully open: KL 5 0.05 2 closed: KL 5 2.1

3

Swing check valve: KL 5 2 4 closed: KL 5 17

* These are representative values for loss coefficients. Actual values strongly depend on the design and manufacture of the components and may differ from the

given values considerably (especially for valves). Actual manufacturer’s data should be used in the final design.

Head Pressure head converted Total

to velocity head head

KLV 2/2g Lost velocity head

V 21

2g V 22 /2g Remaining

P0 velocity head

rg

P1 Pressure P2 Remaining

rg head rg pressure head

1 2

Vena contracta

0 1 2

FIGURE 8–38

Graphical representation of flow

contraction and the associated head Separated

loss at a sharp-edged pipe inlet. flow

347-436_cengel_ch08.indd 378 12/18/12 1:52 PM

You might also like

- Activated Carbon Filter CalculationDocument2 pagesActivated Carbon Filter CalculationSiavash74% (27)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Heat-Transfer-Formula-Sheet Print PDFDocument28 pagesHeat-Transfer-Formula-Sheet Print PDFAz Zahra AzmiNo ratings yet

- Introduction To Cement Laboratory TestingDocument49 pagesIntroduction To Cement Laboratory TestingNico Walten80% (5)

- NTU Method Fundamentals of Heat and Mass Transfer Frank P IncroperaDocument9 pagesNTU Method Fundamentals of Heat and Mass Transfer Frank P IncroperaIgi Putra Moran PurbaNo ratings yet

- Loss Coefficient (KL)Document2 pagesLoss Coefficient (KL)Narin PaiboonNo ratings yet

- Loss Coefficients KLDocument2 pagesLoss Coefficients KLNicolHernandezNarvaezNo ratings yet

- Loss CoefDocument2 pagesLoss CoefJorgeNo ratings yet

- Lecturer Notes On Pipe Sizing BasicsDocument32 pagesLecturer Notes On Pipe Sizing BasicsTactical Blackhawk BatamNo ratings yet

- 08 Viscous FlowDocument40 pages08 Viscous FlowJohn DoeNo ratings yet

- Pressure DropDocument4 pagesPressure Dropmartin.rubenNo ratings yet

- CE212-1-Flow Through Pipes - 4 PDFDocument12 pagesCE212-1-Flow Through Pipes - 4 PDFKhalid KhattakNo ratings yet

- Circulating Fluidized Bed Boiler Design and OperationDocument9 pagesCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoNo ratings yet

- 2ph Dig Stab Wiring Diagram PDFDocument1 page2ph Dig Stab Wiring Diagram PDFrajuNo ratings yet

- Table A. Equivalent Length, (L/D) of Valves and Pipe FittingsDocument7 pagesTable A. Equivalent Length, (L/D) of Valves and Pipe Fittingst_i_f_anoNo ratings yet

- Engineering Drawing ReportDocument24 pagesEngineering Drawing ReportNHẬT HẢO ĐẶNGNo ratings yet

- Series: SpecificationDocument1 pageSeries: Specificationing.josephcapellanNo ratings yet

- Water Supply ComponentsDocument32 pagesWater Supply ComponentsMichael LangatNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Gilberto VidalNo ratings yet

- Vishay SIR464DP T1 GE3 DatasheetDocument7 pagesVishay SIR464DP T1 GE3 DatasheetEge YekkkNo ratings yet

- Kuhnke Rotary SolenoidDocument9 pagesKuhnke Rotary SolenoidSajjad HussainNo ratings yet

- Design of Water Pipe FlowsDocument1 pageDesign of Water Pipe Flowsphoneme79No ratings yet

- Power DissipationDocument23 pagesPower DissipationVidhya DsNo ratings yet

- Clutches Technical DataDocument7 pagesClutches Technical DataNicolás CarboniNo ratings yet

- Lecture 5 - Climper and Clamper CircuitDocument22 pagesLecture 5 - Climper and Clamper CircuitArifah HamidunNo ratings yet

- Subminiature Basic Switch D2SDocument7 pagesSubminiature Basic Switch D2SMuhamad PriyatnaNo ratings yet

- (Chapter 6) Examples PDFDocument6 pages(Chapter 6) Examples PDFKarwan GoodNo ratings yet

- Varistor para Luminarias Cree 20d - 1-3003069Document16 pagesVaristor para Luminarias Cree 20d - 1-3003069Gabriel SanjurNo ratings yet

- Lec. 8 Pipes PDFDocument40 pagesLec. 8 Pipes PDFسامر فؤاد الشخريتNo ratings yet

- Lecture14 Inverter DelayDocument31 pagesLecture14 Inverter Delay羅翊誠No ratings yet

- Final Exam AppendixDocument2 pagesFinal Exam AppendixGeorge AbdallahNo ratings yet

- 02 - SIM DN150 PN160 Valve 2 PDFDocument4 pages02 - SIM DN150 PN160 Valve 2 PDFunnicyriacNo ratings yet

- Water Supply ComponentsDocument32 pagesWater Supply ComponentsGerman Marte PepénNo ratings yet

- JEE Main 2019 Answer Key Solutions January 12 by Aakash PDFDocument56 pagesJEE Main 2019 Answer Key Solutions January 12 by Aakash PDFAbhinandan SinhaNo ratings yet

- 2Document31 pages2ammar.sNo ratings yet

- 1-Characteristics and Performances DefinitionDocument6 pages1-Characteristics and Performances DefinitionDN CoverNo ratings yet

- Answers & Solutions: For For For For For JEE (MAIN) - 2019Document27 pagesAnswers & Solutions: For For For For For JEE (MAIN) - 2019Manila NandaNo ratings yet

- Data Sheet: HEF40106B GatesDocument8 pagesData Sheet: HEF40106B GateserbesonribeiroNo ratings yet

- 02 - Victaulic FitinguriDocument6 pages02 - Victaulic FitinguriAlex AlexNo ratings yet

- Datasheet HEF74106BPDocument7 pagesDatasheet HEF74106BPBetsabeNo ratings yet

- Hydraulic Calculation Rev 0Document29 pagesHydraulic Calculation Rev 0Vigneswaran KumaranNo ratings yet

- Click To Add Text Click To Add TextDocument23 pagesClick To Add Text Click To Add TextNoor SabaNo ratings yet

- EEEQ 221 Fluid Mechanics 7B - Notes For 2nd February 2018Document44 pagesEEEQ 221 Fluid Mechanics 7B - Notes For 2nd February 2018Ellie AwiNo ratings yet

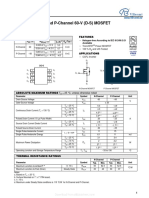

- N-And P-Channel 60-V (D-S) MOSFET: Features Product SummaryDocument14 pagesN-And P-Channel 60-V (D-S) MOSFET: Features Product SummaryJOHN BRICCO A. MATACSILNo ratings yet

- EX1008Document2 pagesEX1008igualdi53No ratings yet

- WK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Document4 pagesWK 450 540 Check Valve Type S: DM /min Up To 260 Up To 31,5 Mpa Ns 6 To 30Gizem MuhendislikNo ratings yet

- PractiCAM ReducersDocument1 pagePractiCAM Reducersalexcaron25No ratings yet

- Saturno 3 Counter EjectorDocument10 pagesSaturno 3 Counter Ejectorarmando olivaresNo ratings yet

- Schematic - How To Make A Current Booster Circuit - 2022-10-18Document1 pageSchematic - How To Make A Current Booster Circuit - 2022-10-18Jerry LeeNo ratings yet

- Uploads - Victaulic - Fittings Fichas - 10 c90 11 c45 100 cl90 110 cl45Document5 pagesUploads - Victaulic - Fittings Fichas - 10 c90 11 c45 100 cl90 110 cl45Gluno DelfinNo ratings yet

- Beam GravityDocument34 pagesBeam GravitycurlyjockeyNo ratings yet

- Atx 060Document2 pagesAtx 060TimmyJuriNo ratings yet

- Vector Groups TransformerDocument4 pagesVector Groups TransformerZahid Kazmi100% (1)

- Loss Coefficients For Pipe ComponentsDocument1 pageLoss Coefficients For Pipe Componentsjason403100% (1)

- Chapter 5: Incompressible Flow Over Finite WingsDocument54 pagesChapter 5: Incompressible Flow Over Finite WingsveeraraghavanNo ratings yet

- GTO Block Diagram FinalDocument2 pagesGTO Block Diagram Finalamit guinNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Anchor Insurance Brokerage Corporation: Co-Signer'S Information SheetDocument1 pageAnchor Insurance Brokerage Corporation: Co-Signer'S Information SheetStephannie SyNo ratings yet

- Revised 2Document61 pagesRevised 2Stephannie SyNo ratings yet

- Updated Content of E-PortfolioDocument1 pageUpdated Content of E-PortfolioStephannie SyNo ratings yet

- Midterm Exam 51047: Industrial Waste Management & ControlDocument6 pagesMidterm Exam 51047: Industrial Waste Management & ControlStephannie SyNo ratings yet

- Chapter 1 3Document25 pagesChapter 1 3Stephannie SyNo ratings yet

- Solid-Solid Separation: Screening: Particulate TechnologyDocument20 pagesSolid-Solid Separation: Screening: Particulate TechnologyStephannie SyNo ratings yet

- Chapter-6 Rotating-Equipment ACETONEDocument2 pagesChapter-6 Rotating-Equipment ACETONEStephannie SyNo ratings yet

- Chapter 7 and 8 - AcetoneDocument14 pagesChapter 7 and 8 - AcetoneStephannie SyNo ratings yet

- Liquid Liquid Extraction 1 Lecture PDFDocument35 pagesLiquid Liquid Extraction 1 Lecture PDFStephannie SyNo ratings yet

- Philippine Environmental Law: Toxic Substances and Hazardous and Nuclear Waste Control Act of 1990 Case StudiesDocument2 pagesPhilippine Environmental Law: Toxic Substances and Hazardous and Nuclear Waste Control Act of 1990 Case StudiesStephannie SyNo ratings yet

- Che Conduct-Of-Ethics Reviewer2020Document3 pagesChe Conduct-Of-Ethics Reviewer2020Stephannie SyNo ratings yet

- Rate of Combustion of Isopropyl AlcoholDocument8 pagesRate of Combustion of Isopropyl AlcoholStephannie SyNo ratings yet

- Benchmark Study - General Instructions: Subscription For Benchmark ParticipationDocument6 pagesBenchmark Study - General Instructions: Subscription For Benchmark ParticipationFrancisco Ribeiro FernandesNo ratings yet

- Manner-Maxwell and Boltzmann's View. However, Henry Poincare and His Co-Workers Were ofDocument5 pagesManner-Maxwell and Boltzmann's View. However, Henry Poincare and His Co-Workers Were ofneerajNo ratings yet

- K L K L K L: Moisture Barrier (MB) Shell (S) Thermal Liner (TL) 1 MM 1 MMDocument1 pageK L K L K L: Moisture Barrier (MB) Shell (S) Thermal Liner (TL) 1 MM 1 MMCarlos Gonzalez ValarezoNo ratings yet

- On The Theoretical Link Between Design Parameters and Performance in Cross Flow Fans A Numerical and Experimental Study 2005 Computers and FluidsDocument18 pagesOn The Theoretical Link Between Design Parameters and Performance in Cross Flow Fans A Numerical and Experimental Study 2005 Computers and Fluidsankushanks2591No ratings yet

- DEm Lab ManualDocument59 pagesDEm Lab ManualO.p. BrarNo ratings yet

- Joule's Apparatus IPDocument31 pagesJoule's Apparatus IP--MsKahokoHino--No ratings yet

- CHE S204 Chapter 9 Unsteady State Heat Transfer G1Document11 pagesCHE S204 Chapter 9 Unsteady State Heat Transfer G1Fawziyyah AgboolaNo ratings yet

- Design of Mega Column With Several Encased Steel Profiles For Combined Compressonand Bending - Plumiecs - Journal PDFDocument27 pagesDesign of Mega Column With Several Encased Steel Profiles For Combined Compressonand Bending - Plumiecs - Journal PDFPrapa KaranNo ratings yet

- Section PropertiesDocument93 pagesSection PropertiesNiranjanAryanNo ratings yet

- Aluminium Rail Roof Top (R1)Document2 pagesAluminium Rail Roof Top (R1)krishna kumarNo ratings yet

- Universal Tensile Testing Machine: Assoc. Prof. Dr. El-Hadi, AhmedDocument1 pageUniversal Tensile Testing Machine: Assoc. Prof. Dr. El-Hadi, AhmedMathias NsimbeNo ratings yet

- Kajian Sambungan Balok Kayu Bangkirai Dengan Claw Nail PlateDocument15 pagesKajian Sambungan Balok Kayu Bangkirai Dengan Claw Nail Plateabidah fitraNo ratings yet

- Sign Convention of Plate Element Stresses and MomentsDocument2 pagesSign Convention of Plate Element Stresses and MomentsNikhil Poriya100% (1)

- Reactor Particle SizeDocument4 pagesReactor Particle SizeArmas Alexis100% (1)

- Specific Heat Capacities of AirDocument13 pagesSpecific Heat Capacities of AirNguyen ChuyenNo ratings yet

- Eng1460 TT1 Solutions Fa11Document7 pagesEng1460 TT1 Solutions Fa11Favelax895No ratings yet

- HX FC Cal C1 8423 00 001Document133 pagesHX FC Cal C1 8423 00 001bongNo ratings yet

- Heriot-Watt University: 3 Year Mechanical Engineering LaboratoryDocument7 pagesHeriot-Watt University: 3 Year Mechanical Engineering LaboratoryTom chambetNo ratings yet

- Immediate Settlement CalculationsDocument4 pagesImmediate Settlement CalculationsgeminexNo ratings yet

- Basic Aerodynamics - Lecture Notes 1-22 - 5th Aeronautical Engineering Review Course Manila, - StudocuDocument1 pageBasic Aerodynamics - Lecture Notes 1-22 - 5th Aeronautical Engineering Review Course Manila, - StudocuSantos MaineNo ratings yet

- Aerodynamics in CarsDocument20 pagesAerodynamics in CarsSagar KnNo ratings yet

- Process Hazards Communicator: Title Process Hazards Testing Capability at IPDO Process Safety LabDocument4 pagesProcess Hazards Communicator: Title Process Hazards Testing Capability at IPDO Process Safety LabsaikiranNo ratings yet

- Spec. No. E) CRX75C: Orion Machinery Co., LTDDocument5 pagesSpec. No. E) CRX75C: Orion Machinery Co., LTDHa CongNo ratings yet

- Friction Loss.Document1 pageFriction Loss.JhonJairoMurilloVelezNo ratings yet

- Static Equipment Diploma Module 2: Pressure Vessels: Activities Week 2Document7 pagesStatic Equipment Diploma Module 2: Pressure Vessels: Activities Week 2Valesh MonisNo ratings yet

- Thermodynamic Evaluation and Optimization of The (Na SO + K SO + Na S O + K S O) SystemDocument16 pagesThermodynamic Evaluation and Optimization of The (Na SO + K SO + Na S O + K S O) SystemJhoselin Guisela ContrerasNo ratings yet

- Department of Mathematics: Guide To Optional ModulesDocument36 pagesDepartment of Mathematics: Guide To Optional ModulesMike AntonyNo ratings yet