Professional Documents

Culture Documents

Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data Sheet

Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data Sheet

Uploaded by

scottCopyright:

Available Formats

You might also like

- Ruling On DemurrerDocument8 pagesRuling On DemurrerTHROnlineNo ratings yet

- Sigmacover™ 620: Product Data SheetDocument5 pagesSigmacover™ 620: Product Data SheetAnonymous fvO1W3100% (1)

- Stud Bolt Coating - XYLAN - 10701Document3 pagesStud Bolt Coating - XYLAN - 10701scott100% (2)

- En 13889 (2003) +a1 (2008) (E) PDFDocument8 pagesEn 13889 (2003) +a1 (2008) (E) PDFscott50% (2)

- Sigmadur™ 188: Product Data SheetDocument5 pagesSigmadur™ 188: Product Data SheetkaleshNo ratings yet

- Sigmafast 155YDocument5 pagesSigmafast 155YStephen Francis BothelloNo ratings yet

- en-US 7605Document5 pagesen-US 7605Ha SonNo ratings yet

- New Guard Group: CoatingsDocument6 pagesNew Guard Group: CoatingsAryo WicaksonoNo ratings yet

- Sigmadur™ 550: Product Data SheetDocument5 pagesSigmadur™ 550: Product Data SheetAneesh Lie A YoungNo ratings yet

- Sigmacover 620Document5 pagesSigmacover 620praveenpatel.pp7143No ratings yet

- Sigmacover™ 620: Product Data SheetDocument5 pagesSigmacover™ 620: Product Data SheetMahmoud TahaNo ratings yet

- System 1 Second Coat DatasheetDocument6 pagesSystem 1 Second Coat DatasheetHossam EssawyNo ratings yet

- Sigmazinc 109hs PDFDocument5 pagesSigmazinc 109hs PDFAneesh Lie A YoungNo ratings yet

- System 11 DatasheetDocument5 pagesSystem 11 DatasheetHossam EssawyNo ratings yet

- Sigmadur 520 en-US - 7524 - AprobadoDocument6 pagesSigmadur 520 en-US - 7524 - AprobadoMiguel Puma SuclleNo ratings yet

- Sigmazinc™ 68 SP: Product Data SheetDocument5 pagesSigmazinc™ 68 SP: Product Data SheetStuart LemonNo ratings yet

- Amerlock® 400 GF / Sigmashield™ 400: Product Data SheetDocument5 pagesAmerlock® 400 GF / Sigmashield™ 400: Product Data SheetscottNo ratings yet

- Sigmafast 210. Product Data Sheet December 12, 2014 (Revision of April 1, 2013) DescriptionDocument5 pagesSigmafast 210. Product Data Sheet December 12, 2014 (Revision of April 1, 2013) Descriptionmoosa amerianNo ratings yet

- en-US 7791Document4 pagesen-US 7791امينNo ratings yet

- en-US 7537Document5 pagesen-US 7537pradnyeyNo ratings yet

- en-US 7466Document5 pagesen-US 7466RizckyAdhiprasetyoNo ratings yet

- System 1 & 11 Final Coat DatasheetDocument6 pagesSystem 1 & 11 Final Coat DatasheetHossam EssawyNo ratings yet

- Sigmacover 850 Sigmashield 880 HSDocument6 pagesSigmacover 850 Sigmashield 880 HSshahrimanNo ratings yet

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocument5 pagesSigmashield™ 880 / Amerlock® 880: Product Data Sheetjaime San Martin PulgarNo ratings yet

- Sigmadur™ 540: Product Data SheetDocument5 pagesSigmadur™ 540: Product Data SheetStuart LemonNo ratings yet

- Phenguard 935Document6 pagesPhenguard 935Trịnh Minh KhoaNo ratings yet

- Sigmacover 410Document6 pagesSigmacover 410Armanda SiryogiawanNo ratings yet

- Nova Guard 260 - InternalDocument6 pagesNova Guard 260 - InternalfaisalfaiNo ratings yet

- Phenguard™ 940: Product Data SheetDocument6 pagesPhenguard™ 940: Product Data SheetTrịnh Minh Khoa100% (1)

- Sigmacover 410Document5 pagesSigmacover 410panji akbarNo ratings yet

- Sigmaguard™ 730: Product Data SheetDocument5 pagesSigmaguard™ 730: Product Data SheetMahmoud TahaNo ratings yet

- Sigmarine-28 Technical Data SheetDocument4 pagesSigmarine-28 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- PPG - Vigor ZN 302 SR - EnglishDocument5 pagesPPG - Vigor ZN 302 SR - EnglisherwinvillarNo ratings yet

- Sigmafast™ 210: Product Data SheetDocument5 pagesSigmafast™ 210: Product Data SheetJurgen En Mari BeckenbauerNo ratings yet

- Sigmadur 580Document6 pagesSigmadur 580CRISTIAN SILVIU IANUCNo ratings yet

- en-US 6823MEDocument5 pagesen-US 6823MEbaseet gazaliNo ratings yet

- External - PDSDocument10 pagesExternal - PDSfaisalfaiNo ratings yet

- Sigmafast 278 en-US - 6829 - AprobadoDocument5 pagesSigmafast 278 en-US - 6829 - AprobadoMiguel Puma SuclleNo ratings yet

- Phenguard™ 935: Product Data SheetDocument5 pagesPhenguard™ 935: Product Data SheetMahmoud TahaNo ratings yet

- novaguard 260Document6 pagesnovaguard 260jesus hernandezNo ratings yet

- Sigma Zinc 102en-US - 7702 PDFDocument5 pagesSigma Zinc 102en-US - 7702 PDFaselabollegalaNo ratings yet

- Sigma Zinc 102en-US - 7702Document5 pagesSigma Zinc 102en-US - 7702aselabollegalaNo ratings yet

- Sigmafast 278Document5 pagesSigmafast 278kaleshNo ratings yet

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocument5 pagesSigmashield™ 880 / Amerlock® 880: Product Data SheetIchsan RosidinNo ratings yet

- Amercoat 450 XDocument5 pagesAmercoat 450 XStephen Francis BothelloNo ratings yet

- Amer Coat 383 Sigma Fast TdsDocument5 pagesAmer Coat 383 Sigma Fast TdsVINAY SARDANo ratings yet

- Sigma Cover 256Document5 pagesSigma Cover 256Trịnh Minh KhoaNo ratings yet

- Sigmacover™ 456: Product Data SheetDocument6 pagesSigmacover™ 456: Product Data SheetscottNo ratings yet

- en-US 7743Document5 pagesen-US 7743Jose Manuel Guizado SolisNo ratings yet

- Speedhide® - 6-209 Series: Product Data SheetDocument5 pagesSpeedhide® - 6-209 Series: Product Data SheetGibbs PerNo ratings yet

- Sigmacover-456 Technical Data SheetDocument6 pagesSigmacover-456 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- en-US 7490Document5 pagesen-US 7490Movie LoverNo ratings yet

- Sigmatherm™ 540: Product Data SheetDocument4 pagesSigmatherm™ 540: Product Data Sheetali piNo ratings yet

- Amerlock 400al Sigmacover 400alDocument5 pagesAmerlock 400al Sigmacover 400alVijay KumarNo ratings yet

- Sigmaguard 730Document5 pagesSigmaguard 730Vijay KumarNo ratings yet

- Phenguard 930 (2018) PDFDocument5 pagesPhenguard 930 (2018) PDFkaleshNo ratings yet

- BASE EXTERNA SIGMACOVER 380 (BASE)Document5 pagesBASE EXTERNA SIGMACOVER 380 (BASE)aarones28No ratings yet

- Sigmafast™ 278 / Amercoat® 278: Product Data SheetDocument5 pagesSigmafast™ 278 / Amercoat® 278: Product Data SheetStuart LemonNo ratings yet

- Sigmaguard™ 730: Product Data SheetDocument5 pagesSigmaguard™ 730: Product Data SheetLjubomirSinđelićNo ratings yet

- PPG PDS Phenguard 935Document5 pagesPPG PDS Phenguard 935sanguripNo ratings yet

- Phenguard™ 935: Product Data SheetDocument6 pagesPhenguard™ 935: Product Data SheetMuthuKumarNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Hovair Systems: The Load M Oving Specia ListsDocument7 pagesHovair Systems: The Load M Oving Specia ListsscottNo ratings yet

- Sigmacover™ 456: Product Data SheetDocument6 pagesSigmacover™ 456: Product Data SheetscottNo ratings yet

- Hovair Systems: The Load M Oving Specia ListsDocument1 pageHovair Systems: The Load M Oving Specia ListsscottNo ratings yet

- Sigmaprime® 200 Series: Product Data SheetDocument7 pagesSigmaprime® 200 Series: Product Data SheetscottNo ratings yet

- Amerlock® 400 GF / Sigmashield™ 400: Product Data SheetDocument5 pagesAmerlock® 400 GF / Sigmashield™ 400: Product Data SheetscottNo ratings yet

- Hovair Systems: The Load M Oving Specia ListsDocument1 pageHovair Systems: The Load M Oving Specia ListsscottNo ratings yet

- Overhead Lifting Devices Container Connectors and Tie Downs: All Types of Lifting EquipmentDocument2 pagesOverhead Lifting Devices Container Connectors and Tie Downs: All Types of Lifting EquipmentscottNo ratings yet

- Truck and Trailer Twist Lock Drawing CHTTL PDFDocument1 pageTruck and Trailer Twist Lock Drawing CHTTL PDFscottNo ratings yet

- Astm E23Document25 pagesAstm E23nemNo ratings yet

- STAHL - Sockets and Plugs 8570 8571 8575 8579 8581 PlugsAndSockets EK00 III enDocument12 pagesSTAHL - Sockets and Plugs 8570 8571 8575 8579 8581 PlugsAndSockets EK00 III enscottNo ratings yet

- Atlas 4140Document3 pagesAtlas 4140gio_flores_4No ratings yet

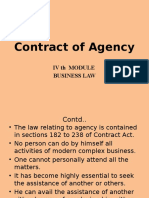

- Module IV Contract of AgencyDocument30 pagesModule IV Contract of AgencyAnish IyerNo ratings yet

- Kolshet Property Details FinalDocument7 pagesKolshet Property Details FinalMR ANIkETNo ratings yet

- C AE26 MODULE 2 Tax Laws and Tax AdministrationDocument6 pagesC AE26 MODULE 2 Tax Laws and Tax AdministrationBaek hyunNo ratings yet

- Overcoming Legal Challenges in ExtraditionDocument14 pagesOvercoming Legal Challenges in ExtraditionEnrique Paolo MendozaNo ratings yet

- 434 - DC Wadhwa v. State of BiharDocument11 pages434 - DC Wadhwa v. State of Biharharini s100% (1)

- Case Study - Contract Part 1Document5 pagesCase Study - Contract Part 1Như NgôNo ratings yet

- Tesla Lawsuit Rivian ResponseDocument20 pagesTesla Lawsuit Rivian ResponseSimon Alvarez100% (1)

- Zandueta v. Dela CostaDocument1 pageZandueta v. Dela CostaApril ValenciaNo ratings yet

- 1 PDFDocument1 page1 PDFAbhinav 007No ratings yet

- M.C. No. 06 - Amendment To Sec. 34 of The ORAOHRADocument2 pagesM.C. No. 06 - Amendment To Sec. 34 of The ORAOHRAmaroons_01No ratings yet

- G.R. No. 171905Document7 pagesG.R. No. 171905Joshua Buenaobra CapispisanNo ratings yet

- Course Outline 2Document13 pagesCourse Outline 2Ayush SrivastavaNo ratings yet

- Cariño v. Insular GovernmentDocument5 pagesCariño v. Insular GovernmentJuris PrudenceNo ratings yet

- Uprtmt '1court: JR - Epublic of TBT Bilippint!l FfiantlaDocument14 pagesUprtmt '1court: JR - Epublic of TBT Bilippint!l FfiantlaAngela AngelesNo ratings yet

- Cadila Healthcare Limited Vs Uniza Healthcare LLP DE202102032115541743COM797918Document7 pagesCadila Healthcare Limited Vs Uniza Healthcare LLP DE202102032115541743COM797918Siddharth soniNo ratings yet

- Deed of Family Settlement Between Rival ClaimantsDocument4 pagesDeed of Family Settlement Between Rival ClaimantsMahebub Ghante100% (1)

- Introduction To Contract Act 1872Document52 pagesIntroduction To Contract Act 1872Aakash ChhabraNo ratings yet

- Lim v. CA, G.R. No. 91114, September 25, 1992 282-283: Virtua1aw LibraryDocument3 pagesLim v. CA, G.R. No. 91114, September 25, 1992 282-283: Virtua1aw LibraryTootsie GuzmaNo ratings yet

- West Bengal Waqf Rules 2022Document66 pagesWest Bengal Waqf Rules 2022MOSTAFIJUR RAHMANNo ratings yet

- DR Journal JanFeb 2022Document59 pagesDR Journal JanFeb 2022Zola MlobiNo ratings yet

- Manila Bulletin Publishing Corporation-ManualDocument13 pagesManila Bulletin Publishing Corporation-ManualMoises CalastravoNo ratings yet

- NSIC Chick ListDocument5 pagesNSIC Chick ListVRS MANPOWER AND SECURITY SERVICE PVT LTDNo ratings yet

- Constitutional Development of India Upsc Notes 23Document6 pagesConstitutional Development of India Upsc Notes 23Deshiha SNo ratings yet

- Ch2 Responsibility in EngineeringDocument22 pagesCh2 Responsibility in EngineeringZain AliNo ratings yet

- Calendar of Activities 2022 2023Document2 pagesCalendar of Activities 2022 2023CMLC learning centerNo ratings yet

- Template For Phil Iri Pre Test 2019Document13 pagesTemplate For Phil Iri Pre Test 2019Kim Bautista MallariNo ratings yet

- Dwnload Full Communicating at Work Principles and Practices For Business 11th Edition Adler Test Bank PDFDocument35 pagesDwnload Full Communicating at Work Principles and Practices For Business 11th Edition Adler Test Bank PDFjaniswoodsersi100% (13)

- 15 TUCP vs. NHADocument7 pages15 TUCP vs. NHAchristopher d. balubayanNo ratings yet

- ESC Application Form-QUINONESDocument3 pagesESC Application Form-QUINONESXylene Kate SmithNo ratings yet

Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data Sheet

Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data Sheet

Uploaded by

scottOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data Sheet

Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data Sheet

Uploaded by

scottCopyright:

Available Formats

PRODUCT DATA SHEET December 12, 2014 (Revision of June 1, 2012)

SIGMALINE™ 780 / PHENGUARD™ SUBSEA 780

DESCRIPTION

Two-component, amine adduct-cured phenolic epoxy finish

PRINCIPAL CHARACTERISTICS

• Finish coat for coating system, used for the protection of subsea equipment

• Bright color to assist location by ROV

• Excellent resistance to seawater immersion

• Very good corrosion control

• Excellent high-temperature resistance in immersed conditions

• Good application properties, resulting in a smooth surface

• Easy to clean

COLOR AND GLOSS LEVEL

• RAL 1004, RAL 1018, RAL 2004 (other colors available on request)

• Eggshell

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.7 kg/l (14.2 lb/US gal)

Volume solids 66 ± 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 300.0 g/kg

Recommended dry film thickness 100 µm (4.0 mils)

Theoretical spreading rate 6.6 m²/l for 100 µm (265 ft²/US gal for 4.0 mils)

Dry to touch 2 hours

Overcoating Interval Minimum: 24 hours

Maximum: 21 days

Full cure after See curing table

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

Ref. 7580 Page 1/4

PRODUCT DATA SHEET December 12, 2014 (Revision of June 1, 2012)

SIGMALINE™ 780 / PHENGUARD™ SUBSEA 780

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Substrate conditions

• Previous coat of approved coating must be dry and free from any contamination

• Substrate must be perfectly dry before and during application of SIGMALINE 780

Substrate temperature and application conditions

• Substrate temperature during application and curing should be above 10°C (50°F)

• Substrate temperature during application should be at least 3°C (5°F) above dew point

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 88:12

• The temperature of the paint should preferably be above 15°C (59°F), otherwise extra thinner may be required to obtain

application viscosity

• Adding too much thinner results in reduced sag resistance and slower cure

• Thinner should be added after mixing the components

Pot life

4 hours at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Air spray

Recommended thinner

THINNER 91-92

Volume of thinner

2 - 10%, depending on required thickness and application conditions

Nozzle orifice

2.0 mm (approx. 0.079 in)

Nozzle pressure

0.3 MPa (approx. 3 Bar; 44 p.s.i.)

Ref. 7580 Page 2/4

PRODUCT DATA SHEET December 12, 2014 (Revision of June 1, 2012)

SIGMALINE™ 780 / PHENGUARD™ SUBSEA 780

Airless spray

Recommended thinner

THINNER 91-92

Volume of thinner

2 - 10%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.46 – 0.53 mm (0.018 – 0.021 in)

Nozzle pressure

15.0 MPa (approx. 150 bar; 2176 p.s.i.)

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

100 µm (4.0 mils) 6.6 m²/l (265 ft²/US gal)

Overcoating interval for DFT up to 100 µm (4.0 mils)

Overcoating with... Interval 10°C (50°F) 15°C (59°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

itself Minimum 36 hours 32 hours 24 hours 16 hours 12 hours

Maximum 28 days 25 days 21 days 14 days 7 days

Note: Surface should be dry and free from any contamination

Curing time for DFT up to 100 μm (4.0 mils)

Substrate temperature Dry to handle Full cure

10°C (50°F) 16 hours 5 days

15°C (59°F) 12 hours 4 days

20°C (68°F) 8 hours 3 days

30°C (86°F) 6 hours 48 hours

Note: Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and

1434)

Ref. 7580 Page 3/4

PRODUCT DATA SHEET December 12, 2014 (Revision of June 1, 2012)

SIGMALINE™ 780 / PHENGUARD™ SUBSEA 780

Pot life (at application viscosity)

Mixed product temperature Pot life

10°C (50°F) 6 hours

15°C (59°F) 5 hours

20°C (68°F) 4 hours

25°C (77°F) 3 hours

30°C (86°F) 1.5 hours

35°C (95°F) 1 hour

40°C (104°F) 30 minutes

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact between

the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any

third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN

LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG. Any claim under this

warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the

delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to

be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or suggestions relating to the use of the PPG product, whether in

technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The product and related information is designed for users having the requisite knowledge

and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no

control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such

use or the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This

sheet supersedes all previous versions and it is the Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at

www.ppgpmc.com. The English text of this sheet shall prevail over any translation thereof.

The PPG Logo, Bringing innovation to the surface., and all other trademarks herein are property of the PPG group of companies.

Ref. 7580 Page 4/4

You might also like

- Ruling On DemurrerDocument8 pagesRuling On DemurrerTHROnlineNo ratings yet

- Sigmacover™ 620: Product Data SheetDocument5 pagesSigmacover™ 620: Product Data SheetAnonymous fvO1W3100% (1)

- Stud Bolt Coating - XYLAN - 10701Document3 pagesStud Bolt Coating - XYLAN - 10701scott100% (2)

- En 13889 (2003) +a1 (2008) (E) PDFDocument8 pagesEn 13889 (2003) +a1 (2008) (E) PDFscott50% (2)

- Sigmadur™ 188: Product Data SheetDocument5 pagesSigmadur™ 188: Product Data SheetkaleshNo ratings yet

- Sigmafast 155YDocument5 pagesSigmafast 155YStephen Francis BothelloNo ratings yet

- en-US 7605Document5 pagesen-US 7605Ha SonNo ratings yet

- New Guard Group: CoatingsDocument6 pagesNew Guard Group: CoatingsAryo WicaksonoNo ratings yet

- Sigmadur™ 550: Product Data SheetDocument5 pagesSigmadur™ 550: Product Data SheetAneesh Lie A YoungNo ratings yet

- Sigmacover 620Document5 pagesSigmacover 620praveenpatel.pp7143No ratings yet

- Sigmacover™ 620: Product Data SheetDocument5 pagesSigmacover™ 620: Product Data SheetMahmoud TahaNo ratings yet

- System 1 Second Coat DatasheetDocument6 pagesSystem 1 Second Coat DatasheetHossam EssawyNo ratings yet

- Sigmazinc 109hs PDFDocument5 pagesSigmazinc 109hs PDFAneesh Lie A YoungNo ratings yet

- System 11 DatasheetDocument5 pagesSystem 11 DatasheetHossam EssawyNo ratings yet

- Sigmadur 520 en-US - 7524 - AprobadoDocument6 pagesSigmadur 520 en-US - 7524 - AprobadoMiguel Puma SuclleNo ratings yet

- Sigmazinc™ 68 SP: Product Data SheetDocument5 pagesSigmazinc™ 68 SP: Product Data SheetStuart LemonNo ratings yet

- Amerlock® 400 GF / Sigmashield™ 400: Product Data SheetDocument5 pagesAmerlock® 400 GF / Sigmashield™ 400: Product Data SheetscottNo ratings yet

- Sigmafast 210. Product Data Sheet December 12, 2014 (Revision of April 1, 2013) DescriptionDocument5 pagesSigmafast 210. Product Data Sheet December 12, 2014 (Revision of April 1, 2013) Descriptionmoosa amerianNo ratings yet

- en-US 7791Document4 pagesen-US 7791امينNo ratings yet

- en-US 7537Document5 pagesen-US 7537pradnyeyNo ratings yet

- en-US 7466Document5 pagesen-US 7466RizckyAdhiprasetyoNo ratings yet

- System 1 & 11 Final Coat DatasheetDocument6 pagesSystem 1 & 11 Final Coat DatasheetHossam EssawyNo ratings yet

- Sigmacover 850 Sigmashield 880 HSDocument6 pagesSigmacover 850 Sigmashield 880 HSshahrimanNo ratings yet

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocument5 pagesSigmashield™ 880 / Amerlock® 880: Product Data Sheetjaime San Martin PulgarNo ratings yet

- Sigmadur™ 540: Product Data SheetDocument5 pagesSigmadur™ 540: Product Data SheetStuart LemonNo ratings yet

- Phenguard 935Document6 pagesPhenguard 935Trịnh Minh KhoaNo ratings yet

- Sigmacover 410Document6 pagesSigmacover 410Armanda SiryogiawanNo ratings yet

- Nova Guard 260 - InternalDocument6 pagesNova Guard 260 - InternalfaisalfaiNo ratings yet

- Phenguard™ 940: Product Data SheetDocument6 pagesPhenguard™ 940: Product Data SheetTrịnh Minh Khoa100% (1)

- Sigmacover 410Document5 pagesSigmacover 410panji akbarNo ratings yet

- Sigmaguard™ 730: Product Data SheetDocument5 pagesSigmaguard™ 730: Product Data SheetMahmoud TahaNo ratings yet

- Sigmarine-28 Technical Data SheetDocument4 pagesSigmarine-28 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- PPG - Vigor ZN 302 SR - EnglishDocument5 pagesPPG - Vigor ZN 302 SR - EnglisherwinvillarNo ratings yet

- Sigmafast™ 210: Product Data SheetDocument5 pagesSigmafast™ 210: Product Data SheetJurgen En Mari BeckenbauerNo ratings yet

- Sigmadur 580Document6 pagesSigmadur 580CRISTIAN SILVIU IANUCNo ratings yet

- en-US 6823MEDocument5 pagesen-US 6823MEbaseet gazaliNo ratings yet

- External - PDSDocument10 pagesExternal - PDSfaisalfaiNo ratings yet

- Sigmafast 278 en-US - 6829 - AprobadoDocument5 pagesSigmafast 278 en-US - 6829 - AprobadoMiguel Puma SuclleNo ratings yet

- Phenguard™ 935: Product Data SheetDocument5 pagesPhenguard™ 935: Product Data SheetMahmoud TahaNo ratings yet

- novaguard 260Document6 pagesnovaguard 260jesus hernandezNo ratings yet

- Sigma Zinc 102en-US - 7702 PDFDocument5 pagesSigma Zinc 102en-US - 7702 PDFaselabollegalaNo ratings yet

- Sigma Zinc 102en-US - 7702Document5 pagesSigma Zinc 102en-US - 7702aselabollegalaNo ratings yet

- Sigmafast 278Document5 pagesSigmafast 278kaleshNo ratings yet

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocument5 pagesSigmashield™ 880 / Amerlock® 880: Product Data SheetIchsan RosidinNo ratings yet

- Amercoat 450 XDocument5 pagesAmercoat 450 XStephen Francis BothelloNo ratings yet

- Amer Coat 383 Sigma Fast TdsDocument5 pagesAmer Coat 383 Sigma Fast TdsVINAY SARDANo ratings yet

- Sigma Cover 256Document5 pagesSigma Cover 256Trịnh Minh KhoaNo ratings yet

- Sigmacover™ 456: Product Data SheetDocument6 pagesSigmacover™ 456: Product Data SheetscottNo ratings yet

- en-US 7743Document5 pagesen-US 7743Jose Manuel Guizado SolisNo ratings yet

- Speedhide® - 6-209 Series: Product Data SheetDocument5 pagesSpeedhide® - 6-209 Series: Product Data SheetGibbs PerNo ratings yet

- Sigmacover-456 Technical Data SheetDocument6 pagesSigmacover-456 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- en-US 7490Document5 pagesen-US 7490Movie LoverNo ratings yet

- Sigmatherm™ 540: Product Data SheetDocument4 pagesSigmatherm™ 540: Product Data Sheetali piNo ratings yet

- Amerlock 400al Sigmacover 400alDocument5 pagesAmerlock 400al Sigmacover 400alVijay KumarNo ratings yet

- Sigmaguard 730Document5 pagesSigmaguard 730Vijay KumarNo ratings yet

- Phenguard 930 (2018) PDFDocument5 pagesPhenguard 930 (2018) PDFkaleshNo ratings yet

- BASE EXTERNA SIGMACOVER 380 (BASE)Document5 pagesBASE EXTERNA SIGMACOVER 380 (BASE)aarones28No ratings yet

- Sigmafast™ 278 / Amercoat® 278: Product Data SheetDocument5 pagesSigmafast™ 278 / Amercoat® 278: Product Data SheetStuart LemonNo ratings yet

- Sigmaguard™ 730: Product Data SheetDocument5 pagesSigmaguard™ 730: Product Data SheetLjubomirSinđelićNo ratings yet

- PPG PDS Phenguard 935Document5 pagesPPG PDS Phenguard 935sanguripNo ratings yet

- Phenguard™ 935: Product Data SheetDocument6 pagesPhenguard™ 935: Product Data SheetMuthuKumarNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Hovair Systems: The Load M Oving Specia ListsDocument7 pagesHovair Systems: The Load M Oving Specia ListsscottNo ratings yet

- Sigmacover™ 456: Product Data SheetDocument6 pagesSigmacover™ 456: Product Data SheetscottNo ratings yet

- Hovair Systems: The Load M Oving Specia ListsDocument1 pageHovair Systems: The Load M Oving Specia ListsscottNo ratings yet

- Sigmaprime® 200 Series: Product Data SheetDocument7 pagesSigmaprime® 200 Series: Product Data SheetscottNo ratings yet

- Amerlock® 400 GF / Sigmashield™ 400: Product Data SheetDocument5 pagesAmerlock® 400 GF / Sigmashield™ 400: Product Data SheetscottNo ratings yet

- Hovair Systems: The Load M Oving Specia ListsDocument1 pageHovair Systems: The Load M Oving Specia ListsscottNo ratings yet

- Overhead Lifting Devices Container Connectors and Tie Downs: All Types of Lifting EquipmentDocument2 pagesOverhead Lifting Devices Container Connectors and Tie Downs: All Types of Lifting EquipmentscottNo ratings yet

- Truck and Trailer Twist Lock Drawing CHTTL PDFDocument1 pageTruck and Trailer Twist Lock Drawing CHTTL PDFscottNo ratings yet

- Astm E23Document25 pagesAstm E23nemNo ratings yet

- STAHL - Sockets and Plugs 8570 8571 8575 8579 8581 PlugsAndSockets EK00 III enDocument12 pagesSTAHL - Sockets and Plugs 8570 8571 8575 8579 8581 PlugsAndSockets EK00 III enscottNo ratings yet

- Atlas 4140Document3 pagesAtlas 4140gio_flores_4No ratings yet

- Module IV Contract of AgencyDocument30 pagesModule IV Contract of AgencyAnish IyerNo ratings yet

- Kolshet Property Details FinalDocument7 pagesKolshet Property Details FinalMR ANIkETNo ratings yet

- C AE26 MODULE 2 Tax Laws and Tax AdministrationDocument6 pagesC AE26 MODULE 2 Tax Laws and Tax AdministrationBaek hyunNo ratings yet

- Overcoming Legal Challenges in ExtraditionDocument14 pagesOvercoming Legal Challenges in ExtraditionEnrique Paolo MendozaNo ratings yet

- 434 - DC Wadhwa v. State of BiharDocument11 pages434 - DC Wadhwa v. State of Biharharini s100% (1)

- Case Study - Contract Part 1Document5 pagesCase Study - Contract Part 1Như NgôNo ratings yet

- Tesla Lawsuit Rivian ResponseDocument20 pagesTesla Lawsuit Rivian ResponseSimon Alvarez100% (1)

- Zandueta v. Dela CostaDocument1 pageZandueta v. Dela CostaApril ValenciaNo ratings yet

- 1 PDFDocument1 page1 PDFAbhinav 007No ratings yet

- M.C. No. 06 - Amendment To Sec. 34 of The ORAOHRADocument2 pagesM.C. No. 06 - Amendment To Sec. 34 of The ORAOHRAmaroons_01No ratings yet

- G.R. No. 171905Document7 pagesG.R. No. 171905Joshua Buenaobra CapispisanNo ratings yet

- Course Outline 2Document13 pagesCourse Outline 2Ayush SrivastavaNo ratings yet

- Cariño v. Insular GovernmentDocument5 pagesCariño v. Insular GovernmentJuris PrudenceNo ratings yet

- Uprtmt '1court: JR - Epublic of TBT Bilippint!l FfiantlaDocument14 pagesUprtmt '1court: JR - Epublic of TBT Bilippint!l FfiantlaAngela AngelesNo ratings yet

- Cadila Healthcare Limited Vs Uniza Healthcare LLP DE202102032115541743COM797918Document7 pagesCadila Healthcare Limited Vs Uniza Healthcare LLP DE202102032115541743COM797918Siddharth soniNo ratings yet

- Deed of Family Settlement Between Rival ClaimantsDocument4 pagesDeed of Family Settlement Between Rival ClaimantsMahebub Ghante100% (1)

- Introduction To Contract Act 1872Document52 pagesIntroduction To Contract Act 1872Aakash ChhabraNo ratings yet

- Lim v. CA, G.R. No. 91114, September 25, 1992 282-283: Virtua1aw LibraryDocument3 pagesLim v. CA, G.R. No. 91114, September 25, 1992 282-283: Virtua1aw LibraryTootsie GuzmaNo ratings yet

- West Bengal Waqf Rules 2022Document66 pagesWest Bengal Waqf Rules 2022MOSTAFIJUR RAHMANNo ratings yet

- DR Journal JanFeb 2022Document59 pagesDR Journal JanFeb 2022Zola MlobiNo ratings yet

- Manila Bulletin Publishing Corporation-ManualDocument13 pagesManila Bulletin Publishing Corporation-ManualMoises CalastravoNo ratings yet

- NSIC Chick ListDocument5 pagesNSIC Chick ListVRS MANPOWER AND SECURITY SERVICE PVT LTDNo ratings yet

- Constitutional Development of India Upsc Notes 23Document6 pagesConstitutional Development of India Upsc Notes 23Deshiha SNo ratings yet

- Ch2 Responsibility in EngineeringDocument22 pagesCh2 Responsibility in EngineeringZain AliNo ratings yet

- Calendar of Activities 2022 2023Document2 pagesCalendar of Activities 2022 2023CMLC learning centerNo ratings yet

- Template For Phil Iri Pre Test 2019Document13 pagesTemplate For Phil Iri Pre Test 2019Kim Bautista MallariNo ratings yet

- Dwnload Full Communicating at Work Principles and Practices For Business 11th Edition Adler Test Bank PDFDocument35 pagesDwnload Full Communicating at Work Principles and Practices For Business 11th Edition Adler Test Bank PDFjaniswoodsersi100% (13)

- 15 TUCP vs. NHADocument7 pages15 TUCP vs. NHAchristopher d. balubayanNo ratings yet

- ESC Application Form-QUINONESDocument3 pagesESC Application Form-QUINONESXylene Kate SmithNo ratings yet