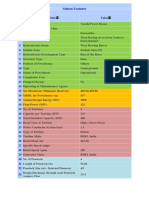

Professional Documents

Culture Documents

(2019) Design of Warehouse - Manoj Wagh PDF

(2019) Design of Warehouse - Manoj Wagh PDF

Uploaded by

Pavel ColladoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(2019) Design of Warehouse - Manoj Wagh PDF

(2019) Design of Warehouse - Manoj Wagh PDF

Uploaded by

Pavel ColladoCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/333579837

Design of warehouse

Article in Global Journal of Engineering Science and Research Management · June 2019

CITATIONS READS

0 62

1 author:

Manoj Wagh

Padmashri Dr. Vithalrao Vikhe Patil College of Engineering

15 PUBLICATIONS 41 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Treatment to Distillery Spent Wash using Electro-coagulation and Chitosan granules View project

3. To study the effect of Steel &polypropylenefibers on geopolymer concrete.Fibers View project

All content following this page was uploaded by Manoj Wagh on 03 June 2019.

The user has requested enhancement of the downloaded file.

International Journal of Research in Engineering, Science and Management 1011

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

Design of Warehouses

Vishal Dhawale1, Shubham Jadhav2, Krushna Gore3, Ganesh Dhobi4, Manoj Wagh5

1,2,3,4

Student, Dept. of Civil Engineering, Dr. Vithalrao VikhePatil College of Engineering, Ahmednagar, India

5

Associate Professor, Dept. of Civil Engg., Dr. Vithalrao VikhePatil College of Engineering, Ahmednagar, India

Abstract: In the 20th century, warehouses become one of the 2. Objectives

most important and critical parts in the supply chain system due

to the fact that it consumes a considerable part of logistics cost and The main objective of the study is the current status of

quality. India is agrarian country, in the country production of the Indian warehouses.

various crops is in large quantity. As there is various types of crops Recognize the need for warehousing.

production are taken, these crops are stored in various types of Designing and developing economical warehouse.

warehouses as per the requirement of the crops. In India, 50% of

storage capacity warehouses are required. The farmer produces a Increasing the life of storage products.

large amount of yield production, but storage facilities are Obtaining profit or revenue from the warehouse.

inadequate. Hence 30% losses of total yield production occur. It

affects the living standard of the farmer and the growth of the 3. Technical details and methods technical detail

country. This paper elaborate study between available constructed

warehouses and modified warehouse. Design proposal studied and The warehouse is constructed on 3678.43 m2; in spite built-

prepared. From the present study, the proposal is made which is up area of the warehouse is 1646.34 m2. Entire structure

economical and the design of an economic one is selected. predominantly consists of 20 numbers of Stacks each having

dimensioned 6.09 m ×9.14 m. It consists of One Office with

Keywords: warehouse; stack; truss, beam, column; foundation. tool Room and the Guard Room as per the standard dimension.

The total capacity of Warehouse is 3000 MT. The warehouse is

1. Introduction divided into two sections (150 MT of each stack) for proper

The research paper illustrates the basic information about the ventilation and circulation of air. Front facing opening (shutter)

warehouse and its basic need for the agricultural industry. The with a dimension of 2.44×3.05m is provided to loading and

warehouse provides a facility for agricultural crop and unloading the goods at the corner of each stack. The cantilever

agricultural products at the village and the district. The primary slab of 1.52m is provided throughout the shutter to protect from

aim of a warehouse is to assist the storage and movement of sunlight and rainwater. The isolated foundation is provided

goods from suppliers to the customer. Customer’s demand can below each column and step footing is provided below each

be fulfilled timely and cost-effective manner if a sufficient stack. Depth of footing is 1.5 m below the G.L. and base slab is

quantity of good quality warehouses is available. In order to provided 1m above G.L. The height of the column is 5.48 m

achieve it efficiently, we may have to hold stock, but this is not above G.L., each having dimensions 0.3 m ×0.3 m. The spacing

the main role of Indian warehouses. The basic aim is to of the column is 6 m c/c from the longer side and 5.94 m c/c

minimize the total cost of operation, and storage while from the shorter side. Plinth beam is provided parallel to the

providing the desired level of service. base slab, 1m above the G.L. The other 2 beams are provided at

Indian economy is based on agriculture; In India agriculture the height of 2.74 m and 5.48 m above G.L. respectively. The

is the main source of livelihood for around 61% population of dimension of the beam is 0.3×0.3 m. The thickness of the wall

India [1, 3, 7, 9, 13]. So agriculture and agricultural growth is 0.3 m. Space is provided in front of stacks of 9.14 m, with

occupy a higher degree of importance in the development of the front space of 6.09 m. The thickness of the base slab is 0.3m.

country. In India, 50% of storage capacity warehouses are The span of truss is 30 m with 5 m height. Minimum 1 m of

required. The farmer produces a large amount of yield space is provided from the bottom of the truss. Asbestos sheets

production, but storage facilities are inadequate. Hence 30% of are provided for warehouse having thickness 6.00 mm, Overall

losses of total yield production occur. District Ahmednagar and size 1.05 m, land width - 1.01 m, Cover efficiency - 91%

its adjoining area are well known for its agricultural products

A. Methods

such as Bajra, Wheat, Cotton, Food grain, etc. After getting an

idea about the need of warehousing, Let us identify the different Data Collection: To finalize the capacity of

types of warehouses. In order to meet their requirement, various warehouse data of agriculture production has been

types of warehouses are available such as Private, Public, procured from Rahuri Krishi Vidyapeeth. (M. P. K.V.)

Government, Bonded, Co-operative, etc. Rahuri, District Ahmednagar, Maharashtra, India.

Data related to the topography of the area has been

collected from the survey of numerous warehouses.

International Journal of Research in Engineering, Science and Management 1012

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

Design of warehouse: To investigate data related to Percentage of tensile steel Pt =

Ast × 100

%

bd

warehouses such as capacity (dimension of a Shear strength of concrete (table 19 page 73 IS 456: 2000) If

warehouse) required for an operation is determined by τv < τc than no shear reinforcement is required

maximum quantity in tonnage and volume of supplies

stored and then govt. schemes, case study, ISO B. Design of Beam: [4,10,11]

standards, the problem in reality facing, the material Use M20 and Fe 415 Steel

used, various design methods. From the available data, The total load on beam (W) = Weight of

the production of food grain is 3000 metric tons. By wall + Self-weight of the beam

using density volume of wheat is calculated and from Design load for consideration (Factored

that, no. of bags is calculated. Further than using above load) = 1.5 × W

data size of clearly indicate that there is an acute The effective length of span = c/c

shortage of organized and good quality warehousing distance of column

and storage infrastructure in the country, for both, Factored moment

agricultural and non-agricultural commodities. (Mu) = (Wu x L.eff.)/8

For design production from data then the volume is Maximum shear

calculated, Area is decided that is the dimension. Wu x L.eff

(Vu) =

2

4. Design of truss ( A-Type Truss ) Check for singly or doubly reinforced

beam

A. Design of truss has been carried out as per the Is 875-

1987 part I, II, III. [2,5,12] Calculation of reinforcement

Check for shear

C. Design of column: [4,10,11]

Design of short column and long column.

If the ratio of effective length to its least lateral

dimension <12 then it is short column and if least

lateral dimension >12 then long columns.

Load Calculation Use M20 and Fe 415

Dead load, Live load, Wind load Load on each Colum due to truss

Load Combination Factored Load

1.5(D.L. + L.L.) Height of Column above G.L.

1.5(D.L. + W.L.) Leff. (Effective length), It is designed as an axially

1.2(D.L. +L.L. +W.L.) loaded short column.

Percentage Reinforced Pu = 0.40 fck Ac + 0.67 fyAsc.

Design of Slab: [4,10,11] Provision of lateral ties

Design of one-way slab and Two-way slab. Diameter not less than ø/4

Pitch: Not more than

As the ratio of length & width of all slabs is less than

Least lateral dimension = 300 mm or 16 × ømm

2, two-way slabs have been considered to design.

Use Steel Fe415 and Concrete Grade M20. D. Design of footing:

For Max. depth: Design of isolated footing.

Xu max= 0.48d Use M20 and Fe 415

Mu lim= 0.138 fck bd2 Calculation of Self Weight of Footing

For the area of steel : Calculation of the area of footing=

0.87 fyAstd (1 –Astbd

𝑀𝑢 = Total Load/Soil Bearing Capacity

fyfck)

area of one bar x 1000 Determination of the size of footing

Spacing of bars = Calculation of Soil Reaction for Factored Load

Ast

Vu= Soil pressure from shaded area = qu × B [{(B-b)/2} - d]

Maximum spacing for main reinforcement <3d or 300mm Assume 0.2% steel for M-20 concrete

(whichever is less) Minimum depth required

Check for shear τcbd = Vu

Wd x L

Shear force due to load Vu = Check for Bending:

2

Vu Mu lim. = 0.138 × fck bd2

Nominal shear stress τv =

bd Mu =qu (B – b)2/8 × B

International Journal of Research in Engineering, Science and Management 1013

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

Mu < Mu lim. modified warehouse.

Check for two way shear Farmer can be benefited and life style can be changed.

Perimeter of critical section = 4 × (b + d) Also problem of Farmer suicides can be overcome.

Calculation of Area of critical section By storing the goods in ware house quality of foods

Upward pressure

Two-way shear stress = can be preserved.

Area of critical section

Future need can be fulfilled at the time of famine or

Max. Shear stress permitted = 0.25√fck any other natural or manmade disaster.

1 –Ast x fy Maximum space and storage can have utilized with

Mu = 0.87 × fy × Ast × d [ ]

bd x fck minimum investment.

Calculation of Ast and spacing.

E. Design of Stack for Wheat Production [4, 6, 11] Acknowledgment

Total weight on soil = Total weight on foundation + 10% of We are honored to express my deep sense of gratitude

total weight of foundation towards our guide Dr. Manoj Wagh for his creative suggestions,

Total weight helpful discussion, unfailing advice, and constant

Width of foundation =

s.b.c encouragement during the project work. We consider ourselves

w [1−sin∅]2

Depth of foundation = × privileged to have worked under him, as we always share his

a×ρ [(1+sin∅)] 2

Depth of concrete slab: D = 𝛼 × √3𝑞/𝑀 vast Experience so generously and patiently in spite in his busy

wheat production = 3000 MT = 3000000 kg schedule. We sincerely appreciate the interactive help received

Density of wheat grain = 790 kg/m3 from him by the way of advice and suggestions. At the outset,

Area of one bag = (0.6x 0.9) m2 = 0.54 m2 we take this opportunity to express our sincere gratitude to Dr.

Thickness of one bag = 0.2 m Uday Naik, Principal, Dr. Vithalrao Vikhe Patil College of

mass of wheat grain Engineering, Vilad ghat Ahmednagar, for giving us an

Volume of wheat grain =

𝑑𝑒𝑛𝑠𝑖𝑡𝑦 𝑜𝑓 𝑤ℎ𝑒𝑎𝑡 opportunity to pursue our studies for the present work. We have

3000MT

= been always graced by our parents, their support and blessings

790

= 3797.46 m3 have driven our performance and success. We are grateful to

Volume of one bag = l x b x h= 06 x 0.9x0.2 our family their kind support and motivation have helped us to

= 0.108 m3 complete this work successfully.

volume of wheat grain

No. of. bag = Nomenclature

𝑣𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑜𝑛𝑒 𝑏𝑎𝑔

3797.46

= qu = factored load

0.108

= 35161.74 Mu= factored moment

= 35200 bags Fck= characteristics of strength of concrete

Size of stack = 6.09 m x 9.14 m = 55.66 m2 b= width of column

d= depth of section

5. Result B= width of footing

Fy=characteristics of strength of steel

The design of R.C.C. structured is done by Limit State

τc = shear stress in concrete

Theory.

τv= nominal shear stress

All the slabs are designed as two way Slabs, by the

𝑎= angle of repose

method provided by IS 456: 2000.

𝜌 =density of soil

It is evident that load in a slab below office is so less,

s.b. c. = safe bearing capacity

that slab was safe in all aspects with the minimum

∅ = angle of reposse

reinforcement as per IS 456: 2000.

M= modulus of rupture

The Reinforcement is 1.61 % in the slab below Stacks.

Beams are designed individually as fixed beams with References

doubly and singly reinforced of 300 mm × 300 mm.

[1] Bramhankar E.B. (1968) Problems of warehousing agricultural products

Columns are designed as Axially Loaded Short with special reference to the warehousing corporation in India, Pune

Column of dimension 300 mm × 300 mm. University, Ph.D. Thesis.

The isolated footing was provided of a maximum size of 2.2 [2] B.C. Punmia, Ashok Kumar Jain, Arun Kumar Jain, “Design of Steel

Structure,” Laxmi Publishing Company.

m × 2.2 m and safe bearing capacity of the soil is 150 KN/m2. [3] FAO Agricultural services bulletin no. 109 (1994), “Grain storage

technique, evolution and trend in developing countries.”

6. Conclusion [4] IS 456:2000 Indian Standard Code of practice for Plain & Reinforced

Concrete.

The life span of stored goods enhanced by design of [5] IS 875:1987 Code of practice for Design of Load for Building & Structure

(Part 1 – Dead Load, Part 2 – Imposed Load and Part 3 – Wind Load)

International Journal of Research in Engineering, Science and Management 1014

Volume-2, Issue-5, May-2019

www.ijresm.com | ISSN (Online): 2581-5792

[6] IS 4082:1996 Stacking and Storage of Construction Materials and

Components at Site.

[7] Mamta Barnwal (2006) Warehousing Infrastructure: Empowering the

Agricultural Sector, The ICFAI University press (2006).

[8] Nveen Prakash (2008) Negotiable Warehouse Receipts: Concept &

Implementation warehousing. The Warehousing (Development &

Regulation) Act 2007: Issues & Challenges, FICCI New Delhi.

[9] Pattanaik B.B. (2008) The warehousing (development and regulation)

Act: Impact on agribusiness, FICCI New Delhi.

[10] S.S. Bhavikatti, “R.C.C. Theory & Design,” New Age International

Publishers.

[11] SP 16. Indian Standard Codes of Design Aids for Reinforced Concrete.

[12] SP 38. Handbook of Typified Designs for Structures with Steel Roof

Truss.

[13] Saxena J.P. (2003) warehouse management and inventory control.

View publication stats

You might also like

- (2004) Supplier Management Handbook - James L. BossertDocument308 pages(2004) Supplier Management Handbook - James L. BossertPavel Collado100% (2)

- (2020) Product Management. Building A Product Strategy - Teg GrenagerDocument22 pages(2020) Product Management. Building A Product Strategy - Teg GrenagerPavel Collado100% (3)

- Strategic Planning Foundations - Mike FigliuoloDocument36 pagesStrategic Planning Foundations - Mike FigliuoloPavel ColladoNo ratings yet

- EIRI Project Reports MagazineDocument21 pagesEIRI Project Reports MagazineeiribooksNo ratings yet

- R FP Ramgarh SewerageDocument56 pagesR FP Ramgarh SewerageWapcos LimitedNo ratings yet

- Final J ComponentreviewDocument23 pagesFinal J ComponentreviewjayeshNo ratings yet

- Analysis and Design of Cooling Tower Using Staad Pro: Mini Project ReportDocument40 pagesAnalysis and Design of Cooling Tower Using Staad Pro: Mini Project ReportMohammed Murtuza100% (1)

- Salient FeaturesDocument3 pagesSalient FeaturesAnonymous ESZmDGNo ratings yet

- RCC Corrosion PDFDocument126 pagesRCC Corrosion PDFPreitee Ranjan PradhanNo ratings yet

- NICMAR GPQS-11 - Construction TechnologyDocument11 pagesNICMAR GPQS-11 - Construction TechnologyshajbabyNo ratings yet

- Grey Water Recycling With Corn Cob As An Adsorbent: T Janani Dr. J.S.Sudarsan K PrasannaDocument21 pagesGrey Water Recycling With Corn Cob As An Adsorbent: T Janani Dr. J.S.Sudarsan K PrasannaxubopifNo ratings yet

- Pranahita Chevella Jurala Lift Irrigation SchemesDocument29 pagesPranahita Chevella Jurala Lift Irrigation SchemesBhaskar ReddyNo ratings yet

- Alis Flow ChartDocument1 pageAlis Flow ChartMahesh KumarNo ratings yet

- Seismic Analysis of Overhead Circular Water TanksDocument10 pagesSeismic Analysis of Overhead Circular Water TanksGiurcanas Andrei0% (1)

- Is 6926 1996Document15 pagesIs 6926 1996rajenkoleyNo ratings yet

- KoldamDocument13 pagesKoldamHarpreet SinghNo ratings yet

- Codeofpracticefor Designandconstructionof MachinefoundationsDocument6 pagesCodeofpracticefor Designandconstructionof MachinefoundationsMalar ManoharanNo ratings yet

- Leach PitDocument4 pagesLeach PitDebdulal SamantaNo ratings yet

- Srisailam HPSDocument4 pagesSrisailam HPSN. Sasidhar100% (1)

- Final WSS and New Tank Project ReportDocument43 pagesFinal WSS and New Tank Project Reportprachi_borkar100% (4)

- GSDA Jalsandharan ManualDocument66 pagesGSDA Jalsandharan ManualAbhishekKumarSinhaNo ratings yet

- Approved Guidelines For Evaluation of ProposalsDocument13 pagesApproved Guidelines For Evaluation of ProposalsAbdullah Al JubayerNo ratings yet

- Percolation - Tank DesignDocument25 pagesPercolation - Tank DesignSanthosh Kumar Baswa100% (1)

- Oaqøhv VLRJ VKSJ Ysiu Okys Blikr Flfyumj Fof'Kf"V: HKKJRH EkudDocument9 pagesOaqøhv VLRJ VKSJ Ysiu Okys Blikr Flfyumj Fof'Kf"V: HKKJRH EkudVijayaNo ratings yet

- WTT For Shivmurti by Abhay GuptaDocument38 pagesWTT For Shivmurti by Abhay GuptacdmaaNo ratings yet

- Nabard Rural GodownDocument33 pagesNabard Rural Godownvenkatesh996667% (3)

- QS - BasicsDocument20 pagesQS - BasicsPanyam Babu ShivanandNo ratings yet

- Deep Beam DesignDocument6 pagesDeep Beam DesignMohanraj VenuNo ratings yet

- Drip Design at SolDocument13 pagesDrip Design at SolVan BGNo ratings yet

- SDMF Question Paper 1Document2 pagesSDMF Question Paper 1G. SASIDHARA KURUPNo ratings yet

- Drain Design MetricDocument31 pagesDrain Design MetricEmre MermerNo ratings yet

- Design PDF BommakurDocument113 pagesDesign PDF BommakurRama KrishnaNo ratings yet

- SSRDocument38 pagesSSRsudarsancivilNo ratings yet

- Kaleshwaram Project-Skms - Reach-1: Name of The WorkDocument7 pagesKaleshwaram Project-Skms - Reach-1: Name of The Workbhagyaraju100% (1)

- Components Design of Hoisting Mechanism of 5 Tonne Eot CraneDocument6 pagesComponents Design of Hoisting Mechanism of 5 Tonne Eot CraneRahman Listanto100% (1)

- Soil Report of Mini Stadium KathmanduDocument88 pagesSoil Report of Mini Stadium KathmanduSudan ShakyaNo ratings yet

- Balancing Tank PDFDocument482 pagesBalancing Tank PDFSudeepa SumanasekaraNo ratings yet

- Pres Sure M Ain 7.65 0 K M: TUNNEL FROM KM 7.900 TO KM 8.250 (350M)Document1 pagePres Sure M Ain 7.65 0 K M: TUNNEL FROM KM 7.900 TO KM 8.250 (350M)Rama KrishnaNo ratings yet

- Design of PumpDocument4 pagesDesign of PumpTajamul HussainNo ratings yet

- Bhimgoda BarrageDocument2 pagesBhimgoda BarrageLuojisi CilNo ratings yet

- Simplified Design Method For Piled Raft Foundations: Geotechnical Special Publication May 2014Document11 pagesSimplified Design Method For Piled Raft Foundations: Geotechnical Special Publication May 2014le ingénieurNo ratings yet

- Bridge Girder Design of An EOT Crane Structure - A CAD ApproachDocument5 pagesBridge Girder Design of An EOT Crane Structure - A CAD ApproachChristian Oribe CastilloNo ratings yet

- List of Files (AD2-CANALS) FinalDocument33 pagesList of Files (AD2-CANALS) FinalnidhisasidharanNo ratings yet

- Public Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inDocument10 pagesPublic Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inSanthosh BabuNo ratings yet

- Prasadpur: Detailed Project Report FOR Ground Water BasedDocument76 pagesPrasadpur: Detailed Project Report FOR Ground Water BasedSk Faridul ChoiceNo ratings yet

- Built Up Area Basis MaterialDocument2 pagesBuilt Up Area Basis MaterialHossen Ali MollahNo ratings yet

- Is 5822 1994Document18 pagesIs 5822 1994aquibzafarNo ratings yet

- GID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringDocument6 pagesGID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringAkash SharmaNo ratings yet

- 54M Height RCC Chimney General ArrangementDocument3 pages54M Height RCC Chimney General ArrangementMoorthy SSIDCNo ratings yet

- Project Report Modify PDFDocument24 pagesProject Report Modify PDFTasmay EnterprisesNo ratings yet

- IS 9178 - Part 3 PDFDocument75 pagesIS 9178 - Part 3 PDFSOURAVNo ratings yet

- Bid Document of 4th B LiftDocument670 pagesBid Document of 4th B LiftSuresh Kumar100% (1)

- Information of Terminated Work of M/s Gurinder Singh Contractor Kandi Canal Circle HoshiarpurDocument8 pagesInformation of Terminated Work of M/s Gurinder Singh Contractor Kandi Canal Circle HoshiarpurManjit SinghNo ratings yet

- Unit 3 Tension Members: StructureDocument28 pagesUnit 3 Tension Members: StructureRaj BakhtaniNo ratings yet

- Dhauliganga ProjectDocument2 pagesDhauliganga ProjectAntra Chowdhury100% (1)

- Underground Works in VietNam-B.DDocument42 pagesUnderground Works in VietNam-B.Dapi-3714473No ratings yet

- Sardar Sarovar Narmada DamDocument32 pagesSardar Sarovar Narmada DamBindu SravaniNo ratings yet

- Sickle PlateDocument8 pagesSickle PlatepitamberNo ratings yet

- Bs5950 Calculation Decking SheetDocument6 pagesBs5950 Calculation Decking SheetKho C Ahl100% (1)

- Round and Rectangular Duct Structural DesignDocument1 pageRound and Rectangular Duct Structural DesignkiranNo ratings yet

- Common Retaining Walls: Dr. Mohammed E. Haque, P.E. Retaining WallsDocument18 pagesCommon Retaining Walls: Dr. Mohammed E. Haque, P.E. Retaining WallsandyhrNo ratings yet

- Ijresm V2 I5 262Document5 pagesIjresm V2 I5 262Sara AminNo ratings yet

- Study On Structural Analysis and Design of RCC Bin: AbstractDocument10 pagesStudy On Structural Analysis and Design of RCC Bin: AbstractRian RievandaNo ratings yet

- Global Edition Chapter Two: Company and Marketing Strategy Partnering To Build Customer RelationshipsDocument31 pagesGlobal Edition Chapter Two: Company and Marketing Strategy Partnering To Build Customer RelationshipsPavel ColladoNo ratings yet

- (2015) Mayhem. A Hands-On Case Playing Activity For Teaching Porter's Five Forces To Undergraduate Business Students - Rachel C. WilsonDocument12 pages(2015) Mayhem. A Hands-On Case Playing Activity For Teaching Porter's Five Forces To Undergraduate Business Students - Rachel C. WilsonPavel ColladoNo ratings yet

- Standard Work For Leaders - YescoDocument43 pagesStandard Work For Leaders - YescoPavel Collado100% (3)

- Cost Estimation of Machined Parts Within An Aerospace Supply Chain - P. WatsonDocument10 pagesCost Estimation of Machined Parts Within An Aerospace Supply Chain - P. WatsonPavel ColladoNo ratings yet

- Should Porters Five Forces Have Value in Businesses Today?: April 2020Document7 pagesShould Porters Five Forces Have Value in Businesses Today?: April 2020Pavel ColladoNo ratings yet

- Application of Porter's Five Forces Model in Battery Manufacturing Industries of BangladeshDocument6 pagesApplication of Porter's Five Forces Model in Battery Manufacturing Industries of BangladeshPavel ColladoNo ratings yet

- (2013) VP Supply Chain 90 Day PlanDocument4 pages(2013) VP Supply Chain 90 Day PlanPavel ColladoNo ratings yet

- Designing Growth Strategies - Anil GuptaDocument19 pagesDesigning Growth Strategies - Anil GuptaPavel ColladoNo ratings yet

- Pestel Analysis Political FactorsDocument4 pagesPestel Analysis Political FactorsPavel ColladoNo ratings yet

- (2004) Integrating Planning Into Production Scheduling. A Formal View - Roman BartákDocument10 pages(2004) Integrating Planning Into Production Scheduling. A Formal View - Roman BartákPavel ColladoNo ratings yet

- Five Forces Framework: January 2016Document8 pagesFive Forces Framework: January 2016Pavel ColladoNo ratings yet

- Modulestrategic Management For Hospitality and EventsDocument4 pagesModulestrategic Management For Hospitality and EventsPavel ColladoNo ratings yet

- Design of Intze Tank in Perspective of Revision of IS: 3370Document5 pagesDesign of Intze Tank in Perspective of Revision of IS: 3370Innovative Research PublicationsNo ratings yet

- Data Sheet Tolerance For Concrete SurfacesDocument10 pagesData Sheet Tolerance For Concrete SurfacesPedro RYNo ratings yet

- Design of Isolated FootingDocument366 pagesDesign of Isolated FootingkarthiksampNo ratings yet

- AISC Seismic Design-Module4-Eccentrically Braced FramesDocument134 pagesAISC Seismic Design-Module4-Eccentrically Braced FramesMiguel A Zuñiga100% (2)

- Humanities 5 Paragraph EssayDocument5 pagesHumanities 5 Paragraph EssayAnonymous CMBZnGNNo ratings yet

- Full Paper-Dakov - Belev-IABSE Prague 2022Document5 pagesFull Paper-Dakov - Belev-IABSE Prague 2022Borislav BelevNo ratings yet

- Full Scale AnalysisDocument43 pagesFull Scale Analysispaulogud6170No ratings yet

- Stability Analysis and Design of Steel-Concrete Composite Columns PDFDocument19 pagesStability Analysis and Design of Steel-Concrete Composite Columns PDFDarsHan MoHanNo ratings yet

- Urban Renewal of The Sadar Bazaar Area in Pune CantonmentDocument7 pagesUrban Renewal of The Sadar Bazaar Area in Pune CantonmentPrajitha Jinachandran T KNo ratings yet

- Design of Reinforced Concrete Structural ElementsDocument8 pagesDesign of Reinforced Concrete Structural ElementsSuson DhitalNo ratings yet

- Compression Members: Version 2 CE IIT, KharagpurDocument19 pagesCompression Members: Version 2 CE IIT, KharagpurSandesh KumarNo ratings yet

- Column Analogy Method PDFDocument2 pagesColumn Analogy Method PDFHeather0% (1)

- Verification Manual Staad Fundation V8iDocument507 pagesVerification Manual Staad Fundation V8ijesus40100% (1)

- ACI 550R Design RecommDocument8 pagesACI 550R Design Recommyushi liNo ratings yet

- Eval 5 Review Nov 2020Document5 pagesEval 5 Review Nov 2020criscab12345No ratings yet

- Experimental Study On Voided Biaxial Slab and Its ApplicationDocument5 pagesExperimental Study On Voided Biaxial Slab and Its ApplicationEditor IJTSRDNo ratings yet

- 03 Loads On StructuresDocument19 pages03 Loads On StructuresDaniela EmbornalNo ratings yet

- Form WorkDocument25 pagesForm Workbalacads100% (1)

- IntercolumniationDocument4 pagesIntercolumniationJean-ClaudeNo ratings yet

- Steel Design Example I.7Document14 pagesSteel Design Example I.7edwardNo ratings yet

- Concrete Forms Product CatalogDocument86 pagesConcrete Forms Product CatalogLucas Michael LuzziNo ratings yet

- International Journal of Solids and Structures Volume 2 Issue 2 1966 (Doi 10.1016/0020-7683 (66) 90018-7) Jacques Heyman - The Stone Skeleton PDFDocument43 pagesInternational Journal of Solids and Structures Volume 2 Issue 2 1966 (Doi 10.1016/0020-7683 (66) 90018-7) Jacques Heyman - The Stone Skeleton PDFManuelPérezNo ratings yet

- Pinned Base Plate-ECPLUS DesignDocument2 pagesPinned Base Plate-ECPLUS DesignNivarNo ratings yet

- Lesson 11 Short ColumnsDocument13 pagesLesson 11 Short ColumnsRomel DecenillaNo ratings yet

- Entrance Arch With GateDocument3 pagesEntrance Arch With Gatelifelinegroups nilNo ratings yet

- Flat SlabsDocument21 pagesFlat Slabsnazish AbidNo ratings yet

- Tall Buildings and Their Foundations - Three ExamplesDocument11 pagesTall Buildings and Their Foundations - Three ExamplesNadya PriciliaNo ratings yet

- Ag. Engg. Syllabus B.Tech V To VIII Sem PDFDocument34 pagesAg. Engg. Syllabus B.Tech V To VIII Sem PDFSHIVDUTT KHATRINo ratings yet

- Deep Soil Mixing Hesap PDFDocument12 pagesDeep Soil Mixing Hesap PDFBilal AlpaydınNo ratings yet

- Cme 2003 PDFDocument16 pagesCme 2003 PDFNg Chee PengNo ratings yet