Professional Documents

Culture Documents

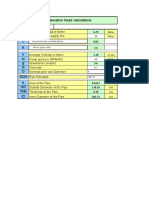

Assignment (6) Variable Control Charts

Assignment (6) Variable Control Charts

Uploaded by

Ahmed AymanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment (6) Variable Control Charts

Assignment (6) Variable Control Charts

Uploaded by

Ahmed AymanCopyright:

Available Formats

Alexandria University 4th Year - 2nd Semester (2016/2017)

Faculty of Engineering Quality Control

Production Engineering Department Exercise (6) – Date (22/4/2017)

Assignment (6)

Variable Control Charts

Question 1:

Consider the piston ring data in the table given below, estimate the process capability

assuming that the specifications limits are 74.00±0.035 mm., and then determine if the

process is under control or no?

Sample Observations

number (Readings)

1 74.030 74.002 74.019 73.992 74.008

2 73.995 73.992 74.000 74.011 74.004

3 73.988 74.024 74.021 74.005 74.002

4 74.002 73.996 73.993 74.015 74.009

5 73.992 74.007 74.015 73.989 74.014

6 74.009 73.994 73.997 73.985 73.993

7 73.995 74.006 73.994 74.000 74.005

8 73.985 74.003 73.993 74.015 73.988

9 74.008 73.995 74.009 74.005 74.004

10 73.998 74.000 73.990 74.007 73.995

11 73.993 73.998 73.994 73.995 73.990

12 74.004 74.000 74.007 74.000 73.996

13 73.983 74.002 73.998 73.997 74.012

14 74.006 73.967 73.994 74.000 73.984

15 74.012 74.014 73.998 73.999 74.007

16 74.000 73.984 74.005 73.998 73.996

17 73.994 74.012 73.986 74.005 74.000

18 74.006 74.010 74.018 74.003 74.000

19 73.984 74.002 74.003 74.005 73.997

20 74.000 74.010 74.013 74.020 74.003

Prof. Mohamed El Dardiry Eng. Ahmed Sobhi Eng. Nesma Page 1

Alexandria University 4th Year - 2nd Semester (2016/2017)

Faculty of Engineering Quality Control

Production Engineering Department Exercise (6) – Date (22/4/2017)

Assignment (6)

Variable Control Charts

Question 2:

Estimate the process capability by using Average and Range control charts for the

power supply voltage data given in the table below. The data given below shows the

difference between the observed reading on each unit and the nominal voltage value

times ten; that is, Xi = (observed voltage on unit i - 350 ) * 10.

If specifications are at 350±5 V, Calculate the process capability.

Sample Observations

number (Readings)

1 6 9 10 15

2 10 4 6 11

3 7 8 10 5

4 8 9 6 13

5 9 10 7 13

6 12 11 10 10

7 16 10 8 9

8 7 5 10 4

9 9 7 8 12

10 15 16 10 13

11 8 12 14 16

12 6 13 9 11

13 16 9 13 15

14 7 13 10 12

15 11 7 10 16

16 15 10 11 14

17 9 8 12 10

18 15 7 10 11

19 8 6 9 12

20 14 15 12 16

Prof. Mohamed El Dardiry Eng. Ahmed Sobhi Eng. Nesma Page 2

Alexandria University 4th Year - 2nd Semester (2016/2017)

Faculty of Engineering Quality Control

Production Engineering Department Exercise (6) – Date (22/4/2017)

Assignment (6)

Variable Control Charts

Question 3:

Perform analysis by using X-bar and R control charts for the data in the table given

below of a shaft to estimate, Is the manufacturing process is under control or not?.

Sample Average Range

number readings

1 34.5 3

2 34.2 4

3 31.6 4

4 31.5 4

5 35 5

6 34.1 6

7 32.6 4

8 33.8 3

9 34.8 7

10 33.6 8

11 31.9 3

12 31.6 9

13 35.4 8

14 34 6

15 31.1 5

16 34.9 7

17 33.5 4

18 31.7 3

19 34 8

20 34.8 5

During sampling process, each one contains 5 shafts.

Prof. Mohamed El Dardiry Eng. Ahmed Sobhi Eng. Nesma Page 3

Alexandria University 4th Year - 2nd Semester (2016/2017)

Faculty of Engineering Quality Control

Production Engineering Department Exercise (6) – Date (22/4/2017)

Assignment (6)

Variable Control Charts

Question 4:

Consider the hole diameter data in the table given below. The values reported are

deviations from the nominal size in µm.

Estimate the process capability by using X-bar and R control charts, if the specifications

are at 0±0.2 mm, and calculate the process capability.

Sample X1 X2 X3 X4 X5

number

1 -30 50 -20 10 30

2 0 50 -60 -20 30

3 -50 10 20 30 20

4 -10 10 30 -20 50

5 20 -40 50 20 10

6 0 0 40 -40 20

7 0 0 20 -20 10

8 70 -30 30 -10 0

9 0 0 20 -20 10

10 10 20 30 10 50

11 40 0 20 0 20

12 30 20 30 10 40

13 30 -30 0 10 10

14 30 -10 50 -10 -30

15 10 -10 50 40 0

16 0 0 30 -10 0

17 20 20 30 30 -20

18 10 -20 50 30 10

19 50 -10 40 20 0

20 50 0 0 30 0

Question 5:

A process is in control with µ= 75 and σ= 2. The process specifications limits are at

80±8. The sample size n = 5.

a. Estimate the process control chart limits.

b. Estimate the process capability.

Prof. Mohamed El Dardiry Eng. Ahmed Sobhi Eng. Nesma Page 4

You might also like

- Elementary Data Analysis (Statistics) - OUMDocument10 pagesElementary Data Analysis (Statistics) - OUMASHWIN 2629No ratings yet

- 966M / 972M / 980M / 982M Wheel Loaders: Global Service TrainingDocument22 pages966M / 972M / 980M / 982M Wheel Loaders: Global Service TrainingVictor Rodrigo Cortes YañezNo ratings yet

- How To Calculate CBR Value Using DCPT Result On SiteDocument5 pagesHow To Calculate CBR Value Using DCPT Result On SiteMartin100% (1)

- UTI BrochureDocument2 pagesUTI BrochureKaye de LeonNo ratings yet

- Comunicaciones Digitales Avanzadas DEBER 1 (Select Max. 10 Problems and Answer The Two Questions)Document3 pagesComunicaciones Digitales Avanzadas DEBER 1 (Select Max. 10 Problems and Answer The Two Questions)Cristian Sancho LopezNo ratings yet

- Variable Control Charts - 2Document5 pagesVariable Control Charts - 2Kareem MahdyNo ratings yet

- 792f4practice Assignment - Control ChartsDocument7 pages792f4practice Assignment - Control Chartsakanchaagarwal12047970% (1)

- 0 IE 2130E Tutorial Problems - 2017 - S2Document7 pages0 IE 2130E Tutorial Problems - 2017 - S2Denise Isebella LeeNo ratings yet

- Unit 1 - Activity 15 - Graphical Representation of Data TestDocument6 pagesUnit 1 - Activity 15 - Graphical Representation of Data TestNidhi VyasNo ratings yet

- Tensile TestDocument6 pagesTensile TestHadi Al-HajNo ratings yet

- Excel Worksheet - Session 3 - Section ADocument27 pagesExcel Worksheet - Session 3 - Section AABHISEK MAITYNo ratings yet

- AssignmentstatDocument5 pagesAssignmentstatAl ShahriarNo ratings yet

- แบบฝึกบท 6Document18 pagesแบบฝึกบท 6Patcharapon SukjumratNo ratings yet

- Chapter 8-Exercise 8.3Document34 pagesChapter 8-Exercise 8.3A R DHARANASHESHNo ratings yet

- Control Charts DataDocument11 pagesControl Charts DataIGNo ratings yet

- Ms - Excel Formula MatematikaDocument2 pagesMs - Excel Formula MatematikaYusi KoriyanaNo ratings yet

- Homework 2Document3 pagesHomework 2ayçaNo ratings yet

- Simple Sprint BacklogDocument2 pagesSimple Sprint Backlogcjpol34No ratings yet

- Simple Sprint BacklogDocument2 pagesSimple Sprint BacklogRajeev Kumar SainiNo ratings yet

- Pert CPMDocument4 pagesPert CPMTF TECH AND GAMINGNo ratings yet

- Lect 3Document11 pagesLect 3sertyuNo ratings yet

- Uji Validitas Dan ReliabilitasDocument4 pagesUji Validitas Dan ReliabilitasPapale PalpalrNo ratings yet

- General Directions:: User Guide For The Item Analysis Template © Balajadia 2014Document13 pagesGeneral Directions:: User Guide For The Item Analysis Template © Balajadia 2014Krystel Libu CastroNo ratings yet

- Ejercicio 4: Individuo Distancia CM R Obs Cuadrilla R Esp R Area (cm2) PDocument5 pagesEjercicio 4: Individuo Distancia CM R Obs Cuadrilla R Esp R Area (cm2) PDavidGutierrezNo ratings yet

- Petunjuk: Ujian Kompetensi Dasar I Program Pascasarjana Teknik Industri Universitas Sebelas MaretDocument4 pagesPetunjuk: Ujian Kompetensi Dasar I Program Pascasarjana Teknik Industri Universitas Sebelas MaretriadNo ratings yet

- Engineering Data AnalysisDocument13 pagesEngineering Data AnalysisJohn CastilloNo ratings yet

- MG311 ExamDocument4 pagesMG311 ExamTetzNo ratings yet

- Kitchen Civil Engineering - DCPT TESTDocument11 pagesKitchen Civil Engineering - DCPT TESTPranoto Budi UtomoNo ratings yet

- AlexProcessingDocument10 pagesAlexProcessingStephanie AnitaNo ratings yet

- 320 Series Excavators - Intro - EN - SLD-CalloutsDocument28 pages320 Series Excavators - Intro - EN - SLD-CalloutsShova MuhammadNo ratings yet

- Test Cases For Decision Coverage and Modified Condition - Decision CoverageDocument71 pagesTest Cases For Decision Coverage and Modified Condition - Decision CoverageTuyen DinhNo ratings yet

- EEE 603 - 3rd Examiner MarksDocument1 pageEEE 603 - 3rd Examiner MarksSajib TalebNo ratings yet

- Historical Time (Days) For Delivery Partners S.no Partner1 Partner2 Partner1 Partner2Document8 pagesHistorical Time (Days) For Delivery Partners S.no Partner1 Partner2 Partner1 Partner2suraj dhruvNo ratings yet

- IE-431, Assignment-6, TEAM-10Document26 pagesIE-431, Assignment-6, TEAM-10Mohammad KashifNo ratings yet

- Assignment 1Document3 pagesAssignment 1nurul_edah89No ratings yet

- Full RosaDocument30 pagesFull RosaAyub KasyfiNo ratings yet

- Olahdata DBN Dan DBPDocument18 pagesOlahdata DBN Dan DBPYusuf RPNo ratings yet

- VLSI - CO - PO MatrixDocument103 pagesVLSI - CO - PO Matrixramesh471No ratings yet

- Sheet 6 The Assignment ProblemDocument2 pagesSheet 6 The Assignment ProblemMohamed MostafaNo ratings yet

- Tutorial Questions Managing Quality: Observation Sample 1 2 3 4 5 6 7 8Document5 pagesTutorial Questions Managing Quality: Observation Sample 1 2 3 4 5 6 7 8lianliang0% (1)

- Causal FactorsDocument15 pagesCausal FactorsNIJESHNo ratings yet

- Format Penilaian Bleef TestDocument4 pagesFormat Penilaian Bleef TestFristian Chayyi100% (1)

- Block Gauges - احمد نادر إبراهيم الغوانمةDocument10 pagesBlock Gauges - احمد نادر إبراهيم الغوانمةG. Dancer GhNo ratings yet

- SU2 - AlexProcessing NEWDocument5 pagesSU2 - AlexProcessing NEWjaketan456No ratings yet

- Creep TestDocument5 pagesCreep TestRockerss RockerssNo ratings yet

- Additional Homework ProblemsDocument5 pagesAdditional Homework ProblemsSivaMarojuNo ratings yet

- Tinh PT Time - Cru - ShanksDocument11 pagesTinh PT Time - Cru - ShanksNguyễn HưởngNo ratings yet

- Exercise Chapter 5-Past Year Exam QuestionDocument2 pagesExercise Chapter 5-Past Year Exam QuestionDeelah MawarNo ratings yet

- Method of Image Encryption by Using Scrambling and Slant TransformDocument6 pagesMethod of Image Encryption by Using Scrambling and Slant Transformeditor ijeratNo ratings yet

- General Directions:: Guide For InterpretationDocument10 pagesGeneral Directions:: Guide For InterpretationMary Grace Ortega-Dela RosaNo ratings yet

- 'Bisection Method': FunctionDocument13 pages'Bisection Method': FunctionJeann Mae CascañoNo ratings yet

- IPE-3714 Quality Management Sessional: An Experiment On Development of A Control ChartDocument12 pagesIPE-3714 Quality Management Sessional: An Experiment On Development of A Control ChartNazrul IslamNo ratings yet

- Group Assignment PBA - LatestDocument8 pagesGroup Assignment PBA - Latests221220786No ratings yet

- CE - 323 Transportation Engineering II LaboratoryDocument16 pagesCE - 323 Transportation Engineering II Laboratorytushar gautamNo ratings yet

- FM1 Assessrep 12Document6 pagesFM1 Assessrep 12carsonauNo ratings yet

- Bab Iv Pengolahan Dan Analisis DataDocument19 pagesBab Iv Pengolahan Dan Analisis DataAndi FajarNo ratings yet

- Control Chart Math ExercisesDocument2 pagesControl Chart Math ExercisesNazmul Haque ParthibNo ratings yet

- Structure To UseDocument5 pagesStructure To UseTC ScarbangsNo ratings yet

- Analysis and ResultDocument3 pagesAnalysis and ResultNur HazwaniNo ratings yet

- Total 371,893,460.0 0 100.0 0Document2 pagesTotal 371,893,460.0 0 100.0 0Osamafaktafinish NdruruNo ratings yet

- Proceedings of the 41st International Conference on Advanced Ceramics and CompositesFrom EverandProceedings of the 41st International Conference on Advanced Ceramics and CompositesJonathan SalemNo ratings yet

- Random Feature: Karim Gaber Ahmed El-NaggarDocument21 pagesRandom Feature: Karim Gaber Ahmed El-NaggarAhmed AymanNo ratings yet

- 5-Acceleration Head Calculation SheetDocument2 pages5-Acceleration Head Calculation SheetAhmed Ayman0% (1)

- 1 - 2 Definitions and Modes of FailureDocument10 pages1 - 2 Definitions and Modes of FailureAhmed AymanNo ratings yet

- 6-Air Receiver CALCULATIONDocument3 pages6-Air Receiver CALCULATIONAhmed AymanNo ratings yet

- Random Feature: Karim Gaber Ahmed El-NaggarDocument22 pagesRandom Feature: Karim Gaber Ahmed El-NaggarAhmed AymanNo ratings yet

- 4 - Pressure Vessel - Wall Thickness Calculations - EvalDocument15 pages4 - Pressure Vessel - Wall Thickness Calculations - EvalAhmed Ayman100% (1)

- Flow Regime: - Heat Ex Performance Failure (Counter Flow Check)Document30 pagesFlow Regime: - Heat Ex Performance Failure (Counter Flow Check)Ahmed AymanNo ratings yet

- Fatigue FailureDocument8 pagesFatigue FailureAhmed AymanNo ratings yet

- Corrosion: Corrosion Fatigue. Classification of Corrosion ProcessesDocument6 pagesCorrosion: Corrosion Fatigue. Classification of Corrosion ProcessesAhmed AymanNo ratings yet

- Fracture MechanicsDocument14 pagesFracture MechanicsAhmed AymanNo ratings yet

- Sheet 2-Simulation Probability StatisticsDocument2 pagesSheet 2-Simulation Probability StatisticsAhmed AymanNo ratings yet

- General Practice in Failure Analysis PDFDocument12 pagesGeneral Practice in Failure Analysis PDFAhmed AymanNo ratings yet

- Reject The Hypothesis H: HistogramDocument1 pageReject The Hypothesis H: HistogramAhmed AymanNo ratings yet

- Iso 899 1 2017 en PDFDocument8 pagesIso 899 1 2017 en PDFAhmed AymanNo ratings yet

- Creep Resitance Materials 789Document9 pagesCreep Resitance Materials 789Ahmed AymanNo ratings yet

- Sample No x1 x2 x3 x4 x5 X Bar RangeDocument4 pagesSample No x1 x2 x3 x4 x5 X Bar RangeAhmed AymanNo ratings yet

- Creep Resistant Mg-Al-Ca Alloys: Computational Thermodynamics and Experimental InvestigationDocument5 pagesCreep Resistant Mg-Al-Ca Alloys: Computational Thermodynamics and Experimental InvestigationAhmed AymanNo ratings yet

- Project Proposal FormDocument1 pageProject Proposal FormAhmed AymanNo ratings yet

- No. 1 Activity T (Days) C (LE) TC (Days) C (LE)Document5 pagesNo. 1 Activity T (Days) C (LE) TC (Days) C (LE)Ahmed AymanNo ratings yet

- (Open This Document in 'Page Layout' View!) : TABLE 14: Poisson DistributionDocument10 pages(Open This Document in 'Page Layout' View!) : TABLE 14: Poisson DistributionAhmed AymanNo ratings yet

- Sheet 05Document1 pageSheet 05Ahmed AymanNo ratings yet

- Quiz A7la Mesa 3al F5adDocument3 pagesQuiz A7la Mesa 3al F5adAhmed AymanNo ratings yet

- Variable Control ChartsDocument1 pageVariable Control ChartsAhmed AymanNo ratings yet

- (Open This Document in 'Page Layout' View!) : TABLE 14: Poisson DistributionDocument10 pages(Open This Document in 'Page Layout' View!) : TABLE 14: Poisson DistributionAhmed AymanNo ratings yet

- List SuperpowerDocument20 pagesList SuperpowerRezaNo ratings yet

- F A M X B.: Triangular Distribution (FromDocument2 pagesF A M X B.: Triangular Distribution (Fromspyros_peiraiasNo ratings yet

- Electrical Conductivity of Aqueous SolutionsDocument1 pageElectrical Conductivity of Aqueous SolutionsTing-Ting PanNo ratings yet

- Jillian Gaviani FSC Booth DesignDocument7 pagesJillian Gaviani FSC Booth DesignMuthana JalladNo ratings yet

- Fortinet Wireless Product MatrixDocument9 pagesFortinet Wireless Product MatrixDiegoJaraEsquivelNo ratings yet

- Cable and Tension StructuresDocument17 pagesCable and Tension StructuresplatasturNo ratings yet

- Advanced Monolithic Systems: 800ma Low Dropout Voltage RegulatorDocument8 pagesAdvanced Monolithic Systems: 800ma Low Dropout Voltage RegulatorTahar BenacherineNo ratings yet

- Readers Theater For Grade OneDocument9 pagesReaders Theater For Grade OneglaidzNo ratings yet

- Rms Polytechnic: Prepared By: Priyanka PatelDocument35 pagesRms Polytechnic: Prepared By: Priyanka PatelBhaumik ParmarNo ratings yet

- Indofood Case Study WEBDocument2 pagesIndofood Case Study WEBRiduan LieNo ratings yet

- Magnet Motor Unit Exam Review KeyDocument4 pagesMagnet Motor Unit Exam Review Keyapi-110202130No ratings yet

- Acg01 IntroDocument34 pagesAcg01 IntroGiang T.C. TranNo ratings yet

- Apply Good Dispensing Principles - NEW-1Document49 pagesApply Good Dispensing Principles - NEW-1abelashe2No ratings yet

- GP MCQ 6Document4 pagesGP MCQ 6Marta MoreiraNo ratings yet

- Site Installation Standard - Ver 20200706Document179 pagesSite Installation Standard - Ver 20200706Kyaw Kyaw WinNo ratings yet

- A Innovative Business IdeaDocument24 pagesA Innovative Business IdeaMohammad Mamun BhuiyanNo ratings yet

- Fluidization Laboratory of SaskatchewanDocument4 pagesFluidization Laboratory of SaskatchewanTae Vorachit UmnuaypornNo ratings yet

- 00-30juni 2023 Data Stok FLDocument98 pages00-30juni 2023 Data Stok FLSunaryo AryandaNo ratings yet

- Fault CodesDocument6 pagesFault CodesAnonymous zF4syKOrJNo ratings yet

- Loughborough Junction Minutes 16 February 2009Document5 pagesLoughborough Junction Minutes 16 February 2009Loughborough JunctionNo ratings yet

- 1st MonthlyDocument70 pages1st MonthlyajlsaysonNo ratings yet

- Lecture 11 Energy Transport With Energy DissipationDocument16 pagesLecture 11 Energy Transport With Energy DissipationFarahin Burhan100% (1)

- Method 207 Ammonia in Air EmissionDocument49 pagesMethod 207 Ammonia in Air Emissionsalma ghaniNo ratings yet

- B.ing 2Document3 pagesB.ing 2Dwi purwitasariNo ratings yet

- Spirited Away - Film of The Fantastic and Evolving Japanese Folk SymbolsDocument25 pagesSpirited Away - Film of The Fantastic and Evolving Japanese Folk Symbolscv JunksNo ratings yet

- K 512472Document2 pagesK 512472Daniel ManoleNo ratings yet

- World's TallestDocument6 pagesWorld's TallestMaryNo ratings yet

- Техническая документация B2412S-1WR2 PDFDocument6 pagesТехническая документация B2412S-1WR2 PDFИльнур ТагировNo ratings yet