Professional Documents

Culture Documents

G65 Data Sheet: Properties

G65 Data Sheet: Properties

Uploaded by

Nicko RizqienggalCopyright:

Available Formats

You might also like

- Mine Plan - Nickel MiningDocument23 pagesMine Plan - Nickel Miningzainul fitriNo ratings yet

- Compare and Contrast Essay Between Two CountriesDocument3 pagesCompare and Contrast Essay Between Two CountriesAndi AminayaniNo ratings yet

- Lubricity Additives PDFDocument2 pagesLubricity Additives PDFNicko Rizqienggal50% (2)

- Lubricity Additives PDFDocument2 pagesLubricity Additives PDFNicko Rizqienggal50% (2)

- Mining Explained E-BookDocument18 pagesMining Explained E-BookHannans Reward Ltd89% (9)

- Glysantin G64 - Engine Coolant Concentrate PDFDocument6 pagesGlysantin G64 - Engine Coolant Concentrate PDFNicko RizqienggalNo ratings yet

- TDS Nuoc Lam Mat BASF Glysantin G 48 ENDocument5 pagesTDS Nuoc Lam Mat BASF Glysantin G 48 ENSPTC CORPNo ratings yet

- Antifriz Za Opel Od 2001 G30 G12+Document5 pagesAntifriz Za Opel Od 2001 G30 G12+DJORJENo ratings yet

- G40 Ready Mix Data Sheet: PropertiesDocument4 pagesG40 Ready Mix Data Sheet: Propertieswadi ajanaNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Penray 2798N Tech Data SheetDocument2 pagesPenray 2798N Tech Data SheetJuan MancipeNo ratings yet

- Technical Data Sheet - KrafftDocument2 pagesTechnical Data Sheet - Krafftcrili69No ratings yet

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- ShellDocument4 pagesShellMaboodNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- Polar Premiuim Long Life Pro TDS EngDocument4 pagesPolar Premiuim Long Life Pro TDS EngwesmaNo ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- VELVEX-Light White Oil / White Mineral Oils (Technical)Document4 pagesVELVEX-Light White Oil / White Mineral Oils (Technical)Varadrajan jothiNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Ago 50ppmDocument3 pagesAgo 50ppmanil divveNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

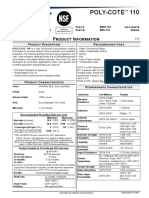

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- The Right For Your: Extended Life Extended LifeDocument2 pagesThe Right For Your: Extended Life Extended LifeSunny D bhoglaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- 1414059256wpdm - Stainless Steel Grade AISI 310Document2 pages1414059256wpdm - Stainless Steel Grade AISI 310Riian ApriansyahNo ratings yet

- Mortech Oil Series: High Quality, High Performance Bearing OilDocument1 pageMortech Oil Series: High Quality, High Performance Bearing OilZeko AlzogneyNo ratings yet

- White Oil PDS - TechnicalDocument2 pagesWhite Oil PDS - TechnicalArjunNo ratings yet

- Engen Premium EP SeriesDocument2 pagesEngen Premium EP SeriesNunoNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- SS316LNDocument4 pagesSS316LNsamruddhiNo ratings yet

- Alloy321 SpecSheetDocument2 pagesAlloy321 SpecSheetVinod tiwariNo ratings yet

- Coolant Plus 33 - TdsDocument2 pagesCoolant Plus 33 - TdsSandyNo ratings yet

- COrrosion Inhibitor BS 6580Document4 pagesCOrrosion Inhibitor BS 6580rizky andrianNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Castrol Alphasyn HTX RangeDocument2 pagesCastrol Alphasyn HTX RangeVusal HasanovNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- Ultra 10W-30Document2 pagesUltra 10W-30has003044No ratings yet

- Specification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541Document2 pagesSpecification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541ex4182No ratings yet

- Ferolite Nam 32N1 PDFDocument2 pagesFerolite Nam 32N1 PDFMittapelly praveenNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Repsol Circulation 220Document1 pageRepsol Circulation 220ibrahim maulanaNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentMohammed Nuseir100% (1)

- Stainless Steel Grade AISI 321Document2 pagesStainless Steel Grade AISI 321Mitul Rawat100% (1)

- Xtreme 15W-40Document2 pagesXtreme 15W-40has003044No ratings yet

- Titanus EpDocument1 pageTitanus EpTAREK HAMADNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Foodmax Grease ALU M 2 - TDS - 263700401 - ENDocument2 pagesFoodmax Grease ALU M 2 - TDS - 263700401 - ENDeath HeartNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Optimus Turbine Oil 2Document1 pageOptimus Turbine Oil 2kennethNo ratings yet

- Ferolite Nam 32 Steel PDFDocument2 pagesFerolite Nam 32 Steel PDFMittapelly praveenNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- Super Tauro PAG: LubricantsDocument1 pageSuper Tauro PAG: LubricantsSaurav SharmaNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- Corrosion Inhibitor BS 6580: Data SheetDocument4 pagesCorrosion Inhibitor BS 6580: Data SheetNicko RizqienggalNo ratings yet

- 265 11001 01 Nordel Epdm Product Selection GuideDocument8 pages265 11001 01 Nordel Epdm Product Selection GuideNicko RizqienggalNo ratings yet

- Safety Data Sheet: Product Name: PB2400Document11 pagesSafety Data Sheet: Product Name: PB2400Nicko RizqienggalNo ratings yet

- Evaluasi Produksi 27072020Document2 pagesEvaluasi Produksi 27072020Nicko RizqienggalNo ratings yet

- Glysantin G64 - Engine Coolant Concentrate PDFDocument6 pagesGlysantin G64 - Engine Coolant Concentrate PDFNicko RizqienggalNo ratings yet

- Cargo Handling Sheet: Shell HVI 60Document4 pagesCargo Handling Sheet: Shell HVI 60Nicko RizqienggalNo ratings yet

- Bosch IP Camera BrochureDocument16 pagesBosch IP Camera BrochureNicko RizqienggalNo ratings yet

- Smooth Fluid Brochure PDFDocument2 pagesSmooth Fluid Brochure PDFNicko RizqienggalNo ratings yet

- US - C6 Alcohols - LIAL, ALCHEM, ISALCHEM - C9-C17 Alcohols PDFDocument9 pagesUS - C6 Alcohols - LIAL, ALCHEM, ISALCHEM - C9-C17 Alcohols PDFNicko Rizqienggal100% (1)

- Code Script Arduino Sensor LCDDocument5 pagesCode Script Arduino Sensor LCDNicko RizqienggalNo ratings yet

- Dae AnnDocument290 pagesDae AnnTICKER PORTNo ratings yet

- Bureau of Indian Standards (Central Marks Department-Iii)Document58 pagesBureau of Indian Standards (Central Marks Department-Iii)vinodNo ratings yet

- Physical Properties of MineralsDocument73 pagesPhysical Properties of MineralsNishant MeenaNo ratings yet

- ks3 Science 2008 Level 5 7 Paper 2Document28 pagesks3 Science 2008 Level 5 7 Paper 2A.K MonNo ratings yet

- JPID-Vol-04-Issue-01-Article06Document5 pagesJPID-Vol-04-Issue-01-Article06mahaNo ratings yet

- Physical Properties: Zinc Is ADocument2 pagesPhysical Properties: Zinc Is AVinod NairNo ratings yet

- ICSE Class 10 Chemistry Sample Papers 1 2021Document9 pagesICSE Class 10 Chemistry Sample Papers 1 2021Pranava Surya VedanthamNo ratings yet

- Powders: Thermal Spray Consumables GuideDocument28 pagesPowders: Thermal Spray Consumables Guidea.n.87711990No ratings yet

- ASTM A570 Steel Grade 50 PDFDocument1 pageASTM A570 Steel Grade 50 PDFranjitNo ratings yet

- A.ChemDocument23 pagesA.Chemmote rajuNo ratings yet

- Indian Mineral PolicyDocument9 pagesIndian Mineral PolicyLOKNATH SNo ratings yet

- Ni-Cr-Mo Vs Ti - Part1Document4 pagesNi-Cr-Mo Vs Ti - Part1mehboobNo ratings yet

- WX100 World Wide Fastener Standard PDFDocument16 pagesWX100 World Wide Fastener Standard PDFRico Malibiran100% (1)

- 7 Redox Reactions: Core CurriculumDocument2 pages7 Redox Reactions: Core CurriculumSumathi ShangkarNo ratings yet

- Effect OF Selenium ON THE Structure AND Properties OF Structural SteelDocument6 pagesEffect OF Selenium ON THE Structure AND Properties OF Structural Steelkrushna bansodeNo ratings yet

- 9 Notes For Use in Qualitative Analysis Test For Anions: © UCLES 2017 0620/05/SP/20Document2 pages9 Notes For Use in Qualitative Analysis Test For Anions: © UCLES 2017 0620/05/SP/20Mayur VanjaniNo ratings yet

- Phosphate InformationDocument2 pagesPhosphate InformationLimbaji shindeNo ratings yet

- Isasmelt: The ISASMELT Furnace Advantages of The ISASMELT Process History of The ProcessDocument18 pagesIsasmelt: The ISASMELT Furnace Advantages of The ISASMELT Process History of The ProcessHunNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.15 (WeldingDocument20 pagesModule 7 (Maintenance Practices) Sub Module 7.15 (WeldingInterogator5No ratings yet

- VIVA VOCE Questions FinalDocument5 pagesVIVA VOCE Questions FinalS.m. Chandrashekar100% (2)

- GBM307 13Document1 pageGBM307 13handriharyadiNo ratings yet

- Unit-III - Theory On The Metal Cutting OperationDocument217 pagesUnit-III - Theory On The Metal Cutting OperationKansath KamalNo ratings yet

- Class Handout: by Christy Runyan UsingDocument9 pagesClass Handout: by Christy Runyan UsingAndy NajeraNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- VHG Catalog For WebsiteDocument118 pagesVHG Catalog For WebsiteLuis Avit Medina QuispeNo ratings yet

- Minfc21931 Astm A29 Grade E52100Document3 pagesMinfc21931 Astm A29 Grade E52100suresh kumarNo ratings yet

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainNo ratings yet

G65 Data Sheet: Properties

G65 Data Sheet: Properties

Uploaded by

Nicko RizqienggalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G65 Data Sheet: Properties

G65 Data Sheet: Properties

Uploaded by

Nicko RizqienggalCopyright:

Available Formats

G65® Data Sheet

D/EVO 3105 e March 2019

Supersedes edition of April 2017

Page 1 of 6

GLYSANTIN® G65® is an engine coolant concentrate based on

ethylene glycol that needs to be diluted with water before use.

GLYSANTIN® G65® contains a corrosion inhibitor package based on

salts of organic acids, phosphate and silicate (PSi-OAT coolant).

GLYSANTIN® G65® is free from nitrites, amines and borates.

Properties

GLYSANTIN® G65® protects engines from corrosion, overheating and

frost. It effectively protects engines against corrosion.

GLYSANTIN® G65® protects engines with an elevated temperature

profile from the formation of deposits from flux and corrosion in the

cooling system with its vital ducts in engine block and cylinder head,

the radiator, the heater core and the water pump.

GLYSANTIN® G65® provides excellent cavitation protection and

protects also heavy-duty engines from pitting of the cylinder liners.

GLYSANTIN® G65® fulfills the requirements of the following coolant

standards:

ASTM D3306, ASTM D4985, SAE J1034, ÖNORM V 5123, CUNA NC

956-16, PN-C40007:2000, AS 2108-2004, JIS K 2234:2006, SANS

1251:2005, GB 29743-2013 and BS 6580:2010.

GLYSANTIN® G65® is officially approved by:

DEUTZ DQC CC-14

Volkswagen Group TL 774-L / G12evo

(VW, Audi, Seat, Skoda,

Lamborghini, Bentley, Bugatti)

G65® Data Sheet

D/EVO 3105 e March 2019

Supersedes edition of April 2017

Page 2 of 6

Miscibility Since the special advantages of GLYSANTIN® G65® will only be

achieved when GLYSANTIN® G65® is used exclusively, mixing of

GLYSANTIN® G65® with other engine coolants is not recommended.

GLYSANTIN® G65® should be blended with water in a concentration

of 33 to 60% by volume prior to use. The usage of a 50/50 ratio for the

mixture of water and GLYSANTIN® G65® is generally recommended.

For preparation of the coolant it is recommended to use distilled or

deionized water. In most cases tap water is also appropriate.

Analysis values of the water may not exceed the following threshold

values:

Water hardness: 0 – 3.6 mmol/l

Chloride content: max 100 ppm

Sulfate content: max 100 ppm

Chemical nature Ethylene glycol with corrosion inhibitors

Appearance Clear liquid without solid contaminants

Physical data Density at 20 °C 1.124 – 1.128 g/cm³ DIN 51 757-4

Refractive index, 20°C 1.431 – 1.434 DIN 51 423-2

Boiling point min 163 °C ASTM D1120

Flash point min 120 °C DIN EN ISO 2592

pH value 8.4 – 8.9 ASTM D1287

pH value, 50 vol% 7.5 – 8.5 ASTM D1287

Reserve alkalinity 8.0 – 10.0 ml ASTM D1121

Water content max 5.0 % DIN 51 777-1

G65® Data Sheet

D/EVO 3105 e March 2019

Supersedes edition of April 2017

Page 3 of 6

Frost protection Freezing point ASTM D1177

50 vol% solution below -37 °C

33 vol% solution below -18 °C

Frost Protection of GLYSANTIN® G65®

0,00

-10,00

Temperature, °C

-20,00

-30,00

-40,00

Freezing Point ASTM D 1177

-50,00

-60,00

0 10 20 30 40 50 60

Concentration, Vol.%

Stability Inhibitor stability clear, no VW TL 774-L

after 168 h precipitation

Hard water stability clear, no VW PV 1426

after 10 days precipitation

Foaming characteristics 33 vol% solution max 50 ml / 3 s ASTM D1881

G65® Data Sheet

D/EVO 3105 e March 2019

Supersedes edition of April 2017

Page 4 of 6

Corrosion Test data

Glassware Corrosion Test ASTM D1384

Typical weight change ASTM D3306 limit

Metal specimen

mg mg

Copper 1 10 max

Solder -13 30 max

Brass 1 10 max

Steel 1 10 max

Cast iron 3 10 max

Cast aluminum 4 30 max

Simulated Service Corrosion ASTM D2570

Test

Typical weight change ASTM D3306 limit

Metal specimen

mg mg

Copper < 10 20 max

Solder < 30 60 max

Brass < 10 20 max

Steel < 10 20 max

Cast iron < 10 20 max

Cast aluminum < 10 60 max

Cavitation Erosion Corrosion ASTM D2809

Test Pump rating >8 8 min

Heat Transfer Corrosion Test ASTM D4340

Corrosion rate -0.07 mg/cm2/week 1.0 max

G65® Data Sheet

D/EVO 3105 e March 2019

Supersedes edition of April 2017

Page 5 of 6

Quality Control The above-listed data represent average values at the time of going to

press of this Data Sheet. They are intended as a guide to facilitate

handling and cannot be regarded as specified data. Specified product

data are issued as a separate product specification.

Storage Stability GLYSANTIN® G65® has a shelf life of at least three years when stored

in originally closed, air-tight containers at temperatures of maximum

30 °C. Do not store in direct sunlight. Do not use galvanized containers

for storage.

Color GLYSANTIN® G65® is usually available in pink.

G65® Data Sheet

D/EVO 3105 e March 2019

Supersedes edition of April 2017

Page 6 of 6

Safety

When using this product, the information and advice given in our Safety

Data Sheet should be observed. Due attention should also be given to

the precautions necessary for handling chemicals

Note

The data contained in this publication are based on our current knowledge

and experience. In view of the many factors that may affect processing and

application of our product, these data do not relieve processors from

carrying out their own investigations and tests; neither do these data imply

any guarantee of certain properties, nor the suitability of the product for a

specific purpose. Any descriptions, drawings, photographs, data,

proportions, weights, etc. given herein may change without prior

information and do not constitute the agreed contractual quality of the

product. It is the responsibility of the recipient of our products to ensure

that any proprietary rights and existing laws and legislation are observed.

March 2019

www.glysantin.de

BASF SE

Fuel and Lubricant Solutions

67056 Ludwigshafen, Deutschland

®=registered trademark of BASF SE

You might also like

- Mine Plan - Nickel MiningDocument23 pagesMine Plan - Nickel Miningzainul fitriNo ratings yet

- Compare and Contrast Essay Between Two CountriesDocument3 pagesCompare and Contrast Essay Between Two CountriesAndi AminayaniNo ratings yet

- Lubricity Additives PDFDocument2 pagesLubricity Additives PDFNicko Rizqienggal50% (2)

- Lubricity Additives PDFDocument2 pagesLubricity Additives PDFNicko Rizqienggal50% (2)

- Mining Explained E-BookDocument18 pagesMining Explained E-BookHannans Reward Ltd89% (9)

- Glysantin G64 - Engine Coolant Concentrate PDFDocument6 pagesGlysantin G64 - Engine Coolant Concentrate PDFNicko RizqienggalNo ratings yet

- TDS Nuoc Lam Mat BASF Glysantin G 48 ENDocument5 pagesTDS Nuoc Lam Mat BASF Glysantin G 48 ENSPTC CORPNo ratings yet

- Antifriz Za Opel Od 2001 G30 G12+Document5 pagesAntifriz Za Opel Od 2001 G30 G12+DJORJENo ratings yet

- G40 Ready Mix Data Sheet: PropertiesDocument4 pagesG40 Ready Mix Data Sheet: Propertieswadi ajanaNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Penray 2798N Tech Data SheetDocument2 pagesPenray 2798N Tech Data SheetJuan MancipeNo ratings yet

- Technical Data Sheet - KrafftDocument2 pagesTechnical Data Sheet - Krafftcrili69No ratings yet

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- ShellDocument4 pagesShellMaboodNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- Polar Premiuim Long Life Pro TDS EngDocument4 pagesPolar Premiuim Long Life Pro TDS EngwesmaNo ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- VELVEX-Light White Oil / White Mineral Oils (Technical)Document4 pagesVELVEX-Light White Oil / White Mineral Oils (Technical)Varadrajan jothiNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Ago 50ppmDocument3 pagesAgo 50ppmanil divveNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- The Right For Your: Extended Life Extended LifeDocument2 pagesThe Right For Your: Extended Life Extended LifeSunny D bhoglaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- 1414059256wpdm - Stainless Steel Grade AISI 310Document2 pages1414059256wpdm - Stainless Steel Grade AISI 310Riian ApriansyahNo ratings yet

- Mortech Oil Series: High Quality, High Performance Bearing OilDocument1 pageMortech Oil Series: High Quality, High Performance Bearing OilZeko AlzogneyNo ratings yet

- White Oil PDS - TechnicalDocument2 pagesWhite Oil PDS - TechnicalArjunNo ratings yet

- Engen Premium EP SeriesDocument2 pagesEngen Premium EP SeriesNunoNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- SS316LNDocument4 pagesSS316LNsamruddhiNo ratings yet

- Alloy321 SpecSheetDocument2 pagesAlloy321 SpecSheetVinod tiwariNo ratings yet

- Coolant Plus 33 - TdsDocument2 pagesCoolant Plus 33 - TdsSandyNo ratings yet

- COrrosion Inhibitor BS 6580Document4 pagesCOrrosion Inhibitor BS 6580rizky andrianNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Castrol Alphasyn HTX RangeDocument2 pagesCastrol Alphasyn HTX RangeVusal HasanovNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- Ultra 10W-30Document2 pagesUltra 10W-30has003044No ratings yet

- Specification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541Document2 pagesSpecification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541ex4182No ratings yet

- Ferolite Nam 32N1 PDFDocument2 pagesFerolite Nam 32N1 PDFMittapelly praveenNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Repsol Circulation 220Document1 pageRepsol Circulation 220ibrahim maulanaNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentMohammed Nuseir100% (1)

- Stainless Steel Grade AISI 321Document2 pagesStainless Steel Grade AISI 321Mitul Rawat100% (1)

- Xtreme 15W-40Document2 pagesXtreme 15W-40has003044No ratings yet

- Titanus EpDocument1 pageTitanus EpTAREK HAMADNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Foodmax Grease ALU M 2 - TDS - 263700401 - ENDocument2 pagesFoodmax Grease ALU M 2 - TDS - 263700401 - ENDeath HeartNo ratings yet

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoNo ratings yet

- Optimus Turbine Oil 2Document1 pageOptimus Turbine Oil 2kennethNo ratings yet

- Ferolite Nam 32 Steel PDFDocument2 pagesFerolite Nam 32 Steel PDFMittapelly praveenNo ratings yet

- FOB Extra Duty Gear Oil TDSW 815913 - 815914Document3 pagesFOB Extra Duty Gear Oil TDSW 815913 - 815914Elwin arifinNo ratings yet

- Super Tauro PAG: LubricantsDocument1 pageSuper Tauro PAG: LubricantsSaurav SharmaNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- Corrosion Inhibitor BS 6580: Data SheetDocument4 pagesCorrosion Inhibitor BS 6580: Data SheetNicko RizqienggalNo ratings yet

- 265 11001 01 Nordel Epdm Product Selection GuideDocument8 pages265 11001 01 Nordel Epdm Product Selection GuideNicko RizqienggalNo ratings yet

- Safety Data Sheet: Product Name: PB2400Document11 pagesSafety Data Sheet: Product Name: PB2400Nicko RizqienggalNo ratings yet

- Evaluasi Produksi 27072020Document2 pagesEvaluasi Produksi 27072020Nicko RizqienggalNo ratings yet

- Glysantin G64 - Engine Coolant Concentrate PDFDocument6 pagesGlysantin G64 - Engine Coolant Concentrate PDFNicko RizqienggalNo ratings yet

- Cargo Handling Sheet: Shell HVI 60Document4 pagesCargo Handling Sheet: Shell HVI 60Nicko RizqienggalNo ratings yet

- Bosch IP Camera BrochureDocument16 pagesBosch IP Camera BrochureNicko RizqienggalNo ratings yet

- Smooth Fluid Brochure PDFDocument2 pagesSmooth Fluid Brochure PDFNicko RizqienggalNo ratings yet

- US - C6 Alcohols - LIAL, ALCHEM, ISALCHEM - C9-C17 Alcohols PDFDocument9 pagesUS - C6 Alcohols - LIAL, ALCHEM, ISALCHEM - C9-C17 Alcohols PDFNicko Rizqienggal100% (1)

- Code Script Arduino Sensor LCDDocument5 pagesCode Script Arduino Sensor LCDNicko RizqienggalNo ratings yet

- Dae AnnDocument290 pagesDae AnnTICKER PORTNo ratings yet

- Bureau of Indian Standards (Central Marks Department-Iii)Document58 pagesBureau of Indian Standards (Central Marks Department-Iii)vinodNo ratings yet

- Physical Properties of MineralsDocument73 pagesPhysical Properties of MineralsNishant MeenaNo ratings yet

- ks3 Science 2008 Level 5 7 Paper 2Document28 pagesks3 Science 2008 Level 5 7 Paper 2A.K MonNo ratings yet

- JPID-Vol-04-Issue-01-Article06Document5 pagesJPID-Vol-04-Issue-01-Article06mahaNo ratings yet

- Physical Properties: Zinc Is ADocument2 pagesPhysical Properties: Zinc Is AVinod NairNo ratings yet

- ICSE Class 10 Chemistry Sample Papers 1 2021Document9 pagesICSE Class 10 Chemistry Sample Papers 1 2021Pranava Surya VedanthamNo ratings yet

- Powders: Thermal Spray Consumables GuideDocument28 pagesPowders: Thermal Spray Consumables Guidea.n.87711990No ratings yet

- ASTM A570 Steel Grade 50 PDFDocument1 pageASTM A570 Steel Grade 50 PDFranjitNo ratings yet

- A.ChemDocument23 pagesA.Chemmote rajuNo ratings yet

- Indian Mineral PolicyDocument9 pagesIndian Mineral PolicyLOKNATH SNo ratings yet

- Ni-Cr-Mo Vs Ti - Part1Document4 pagesNi-Cr-Mo Vs Ti - Part1mehboobNo ratings yet

- WX100 World Wide Fastener Standard PDFDocument16 pagesWX100 World Wide Fastener Standard PDFRico Malibiran100% (1)

- 7 Redox Reactions: Core CurriculumDocument2 pages7 Redox Reactions: Core CurriculumSumathi ShangkarNo ratings yet

- Effect OF Selenium ON THE Structure AND Properties OF Structural SteelDocument6 pagesEffect OF Selenium ON THE Structure AND Properties OF Structural Steelkrushna bansodeNo ratings yet

- 9 Notes For Use in Qualitative Analysis Test For Anions: © UCLES 2017 0620/05/SP/20Document2 pages9 Notes For Use in Qualitative Analysis Test For Anions: © UCLES 2017 0620/05/SP/20Mayur VanjaniNo ratings yet

- Phosphate InformationDocument2 pagesPhosphate InformationLimbaji shindeNo ratings yet

- Isasmelt: The ISASMELT Furnace Advantages of The ISASMELT Process History of The ProcessDocument18 pagesIsasmelt: The ISASMELT Furnace Advantages of The ISASMELT Process History of The ProcessHunNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.15 (WeldingDocument20 pagesModule 7 (Maintenance Practices) Sub Module 7.15 (WeldingInterogator5No ratings yet

- VIVA VOCE Questions FinalDocument5 pagesVIVA VOCE Questions FinalS.m. Chandrashekar100% (2)

- GBM307 13Document1 pageGBM307 13handriharyadiNo ratings yet

- Unit-III - Theory On The Metal Cutting OperationDocument217 pagesUnit-III - Theory On The Metal Cutting OperationKansath KamalNo ratings yet

- Class Handout: by Christy Runyan UsingDocument9 pagesClass Handout: by Christy Runyan UsingAndy NajeraNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- VHG Catalog For WebsiteDocument118 pagesVHG Catalog For WebsiteLuis Avit Medina QuispeNo ratings yet

- Minfc21931 Astm A29 Grade E52100Document3 pagesMinfc21931 Astm A29 Grade E52100suresh kumarNo ratings yet

- Welding A Cast IronDocument9 pagesWelding A Cast Ironjatin jainNo ratings yet