Professional Documents

Culture Documents

Mixer: Department of Chemical Engineering National Institute of Technology Rourkela

Mixer: Department of Chemical Engineering National Institute of Technology Rourkela

Uploaded by

Ankit LadhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mixer: Department of Chemical Engineering National Institute of Technology Rourkela

Mixer: Department of Chemical Engineering National Institute of Technology Rourkela

Uploaded by

Ankit LadhaCopyright:

Available Formats

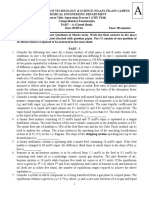

Department of Chemical Engineering

National Institute of Technology Rourkela

Process Plant Simulation Lab

Exercise-1

Simulations using DWSIM

1. Simulate a mixer in which 1000 kmol/h of Isobutane is mixed with 250 kmol/h of

Recycle stream having 60% Isobutane and 40 % Isobutene. The reactants are entering

at 25OC and 1 atm. Use Peng-Robinson thermodynamic package.

a. Find the flow rate and composition of the product.

b. Also report the thermodynamic properties like Enthalpy, Entropy and Gibbs

free energy of the reactants and product.

Isobutane =1000 kmol/h

Mixer

Product

Recycle- 250 kmol/h

Isobutane-60%

Isobutene-40%

2. In the above problem, heat the Isobutane stream to 150 OC before sending it to the

mixer using a heater. Compress the Recycle stream to 10 bar before sending it to the

mixer. Report the flow rate and composition of the product. Also report the

thermodynamic properties.

3. In problem 1, vary the flow rate of recycle stream by using sensitivity analysis tool

and report the flow rate of recycle stream so that the mixture composition is 95 %

isobutene and 5 % isobutene.

4. 1000 lb of toluene stream (S1) at 100 °F is mixed with ethylene stream (S2). The flow

rate of the ethylene stream which is at 50 °F is adjusted to achieve the desired

temperature of 85 °F at the mixer effluent. Both the input streams may be assumed to

be at a pressure of atm. Simulate the unit and find the flow rate of the stream S2.

5. 25,000 lb/hr of toluene is pumped from 75 °F and 30 psi to 570 psi. Simulate to

compute the capacity, the pump head, the exit temperature and horse power for (a) a

pump efficiency of 100% and (b) a pump efficiency of 75%.

You might also like

- CH138P WS 1.2 Geromo HALDocument11 pagesCH138P WS 1.2 Geromo HALLora Bell100% (1)

- CSTR Lab ReportDocument16 pagesCSTR Lab Reportleenzalal100% (5)

- Equilibrium.2 ExampleDocument14 pagesEquilibrium.2 Examplekindenew50% (2)

- Assignment Aspen PlusDocument8 pagesAssignment Aspen PlusVinayak PathakNo ratings yet

- Distillation Aspen HysysDocument66 pagesDistillation Aspen HysysCzarina MasicatNo ratings yet

- Alpha OlefinsDocument3 pagesAlpha OlefinsAnkit ModiNo ratings yet

- Aspen Sample Exam 1Document1 pageAspen Sample Exam 1muteiri2001No ratings yet

- Simulacion de Procesos Unidad 3Document8 pagesSimulacion de Procesos Unidad 3ChecoCastilloNo ratings yet

- Process Enginnering FundamentalsDocument65 pagesProcess Enginnering FundamentalsMeng KiatNo ratings yet

- Department of Chemical Engineering National Institute of Technology RourkelaDocument1 pageDepartment of Chemical Engineering National Institute of Technology RourkelaAnkit LadhaNo ratings yet

- Project No. 3 Case Study - Cumene Production Plant SimulationDocument3 pagesProject No. 3 Case Study - Cumene Production Plant SimulationRizal YansyahNo ratings yet

- Evaporation ProbDocument3 pagesEvaporation Probpenapple51100% (1)

- CHEMCAD Models 2Document33 pagesCHEMCAD Models 2Sheraz FiazNo ratings yet

- bài tập cuối kỳ 2Document17 pagesbài tập cuối kỳ 2KHÁNH VÕ ĐĂNGNo ratings yet

- Chapter 8 Evaporation-ExerciseDocument7 pagesChapter 8 Evaporation-ExerciseNguyễn QuangNo ratings yet

- Ejercicios Taller Parcial II Primera ParteDocument2 pagesEjercicios Taller Parcial II Primera ParteCarlos Alberto Bravo ReyesNo ratings yet

- Project Aspen VistaDocument4 pagesProject Aspen VistaMurrali Raj JeyagapalNo ratings yet

- bài-tập-cuối-kỳ môn KTPƯDocument17 pagesbài-tập-cuối-kỳ môn KTPƯSang HoàngNo ratings yet

- IV B. TECH (Chemical Engineering) I SemesterDocument14 pagesIV B. TECH (Chemical Engineering) I SemesterPiyush AmbulgekarNo ratings yet

- Assignment OneDocument2 pagesAssignment OneAbdi Bekele WakoNo ratings yet

- 3 - Prob PFR 11-12 23-35 English-1Document4 pages3 - Prob PFR 11-12 23-35 English-1Biniyam haileNo ratings yet

- ChE 195 Problem Set No. 2Document1 pageChE 195 Problem Set No. 2Jahz ChannelNo ratings yet

- Something Related To Catalysts.Document2 pagesSomething Related To Catalysts.Deepro BhattacharyaNo ratings yet

- Ayesha DesignDocument36 pagesAyesha DesignAbu BakarNo ratings yet

- TareaDocument3 pagesTareaAydee GarciaNo ratings yet

- Assignment Problems Batch I (R.No. 102117001 To 102117011)Document7 pagesAssignment Problems Batch I (R.No. 102117001 To 102117011)Nishanth ChandranNo ratings yet

- Exercise BM With Chemical ReactionDocument2 pagesExercise BM With Chemical ReactionSergio Rugerio TorresNo ratings yet

- Sheet 8 McCabe ThieleDocument2 pagesSheet 8 McCabe ThieleMohamed Fateem0% (1)

- Tutorial 2 DistillationDocument6 pagesTutorial 2 Distillationmaheema rimalNo ratings yet

- Group 3 - Acetone Production Via The Dehydrogenation of IPADocument7 pagesGroup 3 - Acetone Production Via The Dehydrogenation of IPAQuỳnh Như PhạmNo ratings yet

- Control of An Isomerization Column/Reactor Process: William L. LuybenDocument8 pagesControl of An Isomerization Column/Reactor Process: William L. LuybenMirko SusichNo ratings yet

- Department of Chemical Engineering National Institute of Technology RourkelaDocument1 pageDepartment of Chemical Engineering National Institute of Technology RourkelaAbhisek AgarwalNo ratings yet

- Tutorial 2Document2 pagesTutorial 2Aakash R RajwaniNo ratings yet

- 2 - Prob Batch 11-12 14-22 EnglishDocument3 pages2 - Prob Batch 11-12 14-22 EnglishAbiola AjiginniNo ratings yet

- Acetone ProductionDocument2 pagesAcetone ProductionpehweihaoNo ratings yet

- Ayırma İşlemleri SorularDocument9 pagesAyırma İşlemleri SorularElif Yaren Öztürk0% (1)

- Levenspiel C5 Problemas PDFDocument7 pagesLevenspiel C5 Problemas PDFbete_azmaveteNo ratings yet

- Assignment 2: (Subject: Ch.E. 401 Chemical Reactor Design) Related To CLO1Document4 pagesAssignment 2: (Subject: Ch.E. 401 Chemical Reactor Design) Related To CLO1imtiazNo ratings yet

- Assignment 4 (7332)Document8 pagesAssignment 4 (7332)Musa KaleemNo ratings yet

- Chemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Document6 pagesChemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Alfredo ZuñigaNo ratings yet

- Introduction To Chemical Engineering ThermodynamicDocument3 pagesIntroduction To Chemical Engineering ThermodynamicR SuyaoNo ratings yet

- Esterification of Acetic AcidDocument9 pagesEsterification of Acetic AcidMeiimeii Puri IqbalbalLzNo ratings yet

- Material Balance SheetDocument4 pagesMaterial Balance Sheetsyed waheed ul hasanNo ratings yet

- Tutorial 1Document2 pagesTutorial 1Yasrani RamliNo ratings yet

- If The Reactor Is Operated Isothermally at 150°C, How MuchDocument1 pageIf The Reactor Is Operated Isothermally at 150°C, How MuchJuan SalasNo ratings yet

- Problemario Entropía y ExergíaDocument2 pagesProblemario Entropía y ExergíaDIEGO ALFREDO ROSALES TORRESNo ratings yet

- Reaction Kinetics Sample ProblemsDocument1 pageReaction Kinetics Sample ProblemsBenedict MarzanNo ratings yet

- Simulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017Document5 pagesSimulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957No ratings yet

- EO in Sesame Seed Using TQDocument6 pagesEO in Sesame Seed Using TQMailinda Mega LorensNo ratings yet

- bài tập cuối kỳDocument14 pagesbài tập cuối kỳKHÁNH VÕ ĐĂNGNo ratings yet

- Thermodynamics 2 - Quiz #2 (Set A) : 1 1-k 1 K 2 1-k 2 KDocument2 pagesThermodynamics 2 - Quiz #2 (Set A) : 1 1-k 1 K 2 1-k 2 KCabagnot Piolo JuliusNo ratings yet

- EnzymeDocument4 pagesEnzymeAnilos Basanta100% (2)

- Assignment 1Document4 pagesAssignment 1CH030 Kamal ChavdaNo ratings yet

- Sample Collection and PreparationDocument5 pagesSample Collection and PreparationTheresa CostalesNo ratings yet

- Practical-2 Simulation of ReactorsDocument2 pagesPractical-2 Simulation of ReactorsniralNo ratings yet

- Che F244 1183 C 2015 2Document4 pagesChe F244 1183 C 2015 2shubhamNo ratings yet

- Single Stage Distillation: Che134P/CpmonterolaDocument40 pagesSingle Stage Distillation: Che134P/CpmonterolaConrad Monterola50% (2)

- ExercisesDocument13 pagesExercisesRajpriya GuptaNo ratings yet

- CRE IdocxDocument8 pagesCRE IdocxParth DesaiNo ratings yet

- 717CH1007 Ankit Kumar Ladha Exp4 Ball Mill - Effect of No. of Balls (G5)Document2 pages717CH1007 Ankit Kumar Ladha Exp4 Ball Mill - Effect of No. of Balls (G5)Ankit LadhaNo ratings yet

- 717CH1007 Ankit Kumar Ladha Exp5 Crushing Rolls (G5)Document3 pages717CH1007 Ankit Kumar Ladha Exp5 Crushing Rolls (G5)Ankit LadhaNo ratings yet

- 717CH1007 Ankit Kumar Ladha Exp3 Ball Mill - Effect of Time (G5)Document2 pages717CH1007 Ankit Kumar Ladha Exp3 Ball Mill - Effect of Time (G5)Ankit LadhaNo ratings yet

- 717CH1007 Ankit Kumar Ladha AFD TESTDocument6 pages717CH1007 Ankit Kumar Ladha AFD TESTAnkit LadhaNo ratings yet

- 717ch1007 Ankit Kumar Ladha 30.09.20 AssignmentDocument3 pages717ch1007 Ankit Kumar Ladha 30.09.20 AssignmentAnkit LadhaNo ratings yet

- 717CH1007 Afd Q2 End SemDocument2 pages717CH1007 Afd Q2 End SemAnkit LadhaNo ratings yet

- 717CH1007 - CH6233Document8 pages717CH1007 - CH6233Ankit LadhaNo ratings yet

- Chapter - 2. Exponents of Real NumbersDocument30 pagesChapter - 2. Exponents of Real NumbersAnkit LadhaNo ratings yet

- 717CH1007 - Assignment 1Document2 pages717CH1007 - Assignment 1Ankit LadhaNo ratings yet

- Chapter - 4. Algebraic IdentitiesDocument44 pagesChapter - 4. Algebraic IdentitiesAnkit LadhaNo ratings yet

- Chapter - 5. Factorization of Algebraic ExpressionsDocument36 pagesChapter - 5. Factorization of Algebraic ExpressionsAnkit LadhaNo ratings yet

- Chapter - 5. Factorization of Algebraic ExpressionsDocument36 pagesChapter - 5. Factorization of Algebraic ExpressionsAnkit LadhaNo ratings yet

- Chapter - 3. RationalisationDocument31 pagesChapter - 3. RationalisationAnkit LadhaNo ratings yet

- Chapter - 3. RationalisationDocument31 pagesChapter - 3. RationalisationAnkit LadhaNo ratings yet

- Chapter - 1. Number SystemDocument31 pagesChapter - 1. Number SystemAnkit LadhaNo ratings yet

- Department of Chemical Engineering National Institute of Technology RourkelaDocument1 pageDepartment of Chemical Engineering National Institute of Technology RourkelaAnkit LadhaNo ratings yet

- Re-Activation Process of MATLAB Individual Unlimited Campus License of Expiry Message Option 1: Possible Till 30 April (Today) MidnightDocument2 pagesRe-Activation Process of MATLAB Individual Unlimited Campus License of Expiry Message Option 1: Possible Till 30 April (Today) MidnightAnkit LadhaNo ratings yet

- Chapter - 1. Number SystemDocument31 pagesChapter - 1. Number SystemAnkit LadhaNo ratings yet

- Screen EffectivenessDocument7 pagesScreen EffectivenessAnkit LadhaNo ratings yet