Professional Documents

Culture Documents

Mobile - Scaffolds JSA

Mobile - Scaffolds JSA

Uploaded by

Bojie AbogadieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobile - Scaffolds JSA

Mobile - Scaffolds JSA

Uploaded by

Bojie AbogadieCopyright:

Available Formats

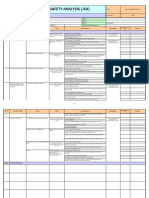

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

General planning Inadequate Injury due to • Insufficient skills

training, inexperience or (competency) to complete the

consultation, failure to provide required task correctly.

planning and or use appropriate • Inadequate consultation with

improvisation. equipment relevant employees.

• Competent person not used

for scaffold erection up to 4

metres in height.

• Certificated scaffolder not

used to erect scaffold in

excess of 4 metres in height

or where complex

configurations are involved.

Unstable scaffold Injury due to • Competent person not used

due to lack of scaffold collapse for scaffold erection up to 4

competency in or partial collapse. metres in height.

erection. • Certificated scaffolder not

used to erect scaffold where

the working platform exceeds

4 metres in height or if the

scaffold has cantilevers or

outriggers.

• Foundation or ground not

suitable for mobile scaffold.

• Different scaffold systems

mixed together. (mix and

match problems)

Overload of Collapse causing • Wrong type of scaffold used

scaffold fall from height. for the job.

components. • Scaffold components

overloaded beyond design

limits.

• Different scaffold systems

mixed together. (mix and

match problems).

Hazard identification tool for aluminium mobile scaffolding Page 1 of 10

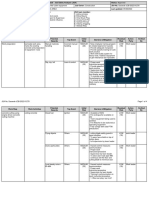

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Unstable or Injury due to • Instructions are not provided,

incorrect erection scaffold collapse or are not clear – print is too

of scaffold. or partial collapse. small and/or photocopy

cannot be accurately

followed.

• Scaffold poorly maintained by

supplier – colour coding

referred to in instructions is

not visible on components.

• Damaged scaffold.

Planning by Scaffold erected Electric shock or • Earth Leakage Switch not

Principal too close to power electrocution. installed on mains supply or

Contractor or lines or completed portable generator.

Subcontractor scaffold is moved • Working on or moving mobile

depending on too close to power scaffold too close to live

contract lines during use. power lines.

conditions • Scaffold components or

material handled are greater

than 4 metres in length.

• Scaffold component or

material contacts power lines.

Insulation (tiger tails) not in

place on power lines or wet

conditions makes them

ineffective.

• Strong wind causes power

lines to swing closer to work

area.

Erection of base Unsupported Frames fall over • Bracing or team member not

frames and frames being striking person used to support first frames.

bracing erected at ground erecting scaffold • Foundation not level or

level. or other person unsuitable for mobile scaffold.

close to the work • Castor wheels not adjusted

area. correctly or not locked.

Hazard identification tool for aluminium mobile scaffolding Page 2 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Incorrectly Fall from • Insufficient skills

assembled first completed (competency) to complete the

frames causing scaffold or fall required task.

unstable scaffold from scaffold • Instructions are not provided

base. during erection. or are not clear – print is too

small and/or photocopy

cannot be read.

• Scaffold poorly maintained –

colour coding referred to in

instructions is not visible on

components.

• Base frame assembled

upside down – castor wheels

will not fit correctly.

Erection of Climbing Scaffold tips over • Climbing up the outside of the

second level lightweight causing fall. frame causing scaffold to tip

frames and scaffold base sideways.

bracing frames during • Only one person used in

erection. frame erection.

• Foundation not level or

unsuitable for mobile scaffold.

Base frames not Instability/ • Scaffold distorts out of square

adequately braced collapse of base due to plan bracing being left

or supported. frames causing out.

fall. • Insufficient diagonal bracing

or bracing fixed incorrectly.

• Castor wheels not locked to

prevent movement or lock/s

broken.

• Foundation not level or

unsuitable for mobile scaffold.

• Castor wheels not adjusted

correctly when levelling the

base frames.

Hazard identification tool for aluminium mobile scaffolding Page 3 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Live power lines Electric shock • Earth Leakage Switch not

too close to work burns or installed on mains supply or

area. electrocution. portable generator.

• Working too close to live

power lines.

• Scaffold components or

materials handled are greater

than 4 metres in length.

• Tiger Tails (insulation) not in

place on power lines or wet

conditions make them

ineffective.

• High wind causes power lines

to swing closer to work area.

• Scaffold component strikes

and shatters unprotected light

bulb.

Scaffold used Scaffold topples • General height of the light

without following over causing a fall duty prefabricated aluminium

manufacturers from height. mobile scaffold exceeds three

instructions (e.g. times the minimum base

indoor or outdoor dimension (ref AS/NZS4576).

specifications). • e.g. a scaffold with base

dimensions of 2.4m x 1.8m

the height to the working

platform should be no more

than 5.4m.

• For a scaffold with a narrow

base width of less than 1.2m

the height of the light duty

prefabricated aluminium

mobile scaffold exceeds twice

the base width (ref AS4576).

• e.g. a scaffold with a base of

2.4m x 1.2m the height to the

working platform should be

no more than 2.4m.

Erection of Manual Handling. Sprains, strains • Only one person used to lift

working platform and fractures. platforms onto second level

frames.

Hazard identification tool for aluminium mobile scaffolding Page 4 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Split (uneven) Step backward off • Working platform installed

decks installed higher deck with split decks, i.e. both deck

onto second causing fall from platforms are not set at the

frames. height. same height.

Erection of edge Climbing on Scaffold moves • Only one person used in

protection, lightweight unexpectedly or frame erection.

ladder and scaffold base tips over causing • Foundation uneven or soft.

toeboards frames. fall. • Planks and ply or steel plates

not used where soft ground is

a problem.

Movement of Fall from • Castor wheels not locked to

scaffold tower. unprotected prevent movement whilst

working platform. edge protection is erected.

Edge protection Fall from the edge • Handrail not positioned 900 –

incomplete. of the working 1100mm above the working

platform. platform on all sides.

• No midrail or fenderboard

installed to all sides.

Ladder access Fall through • Hatch not closed or trapdoor

hatch (trap door) ladder access missing.

in working deck. hatch.

Hazard identification tool for aluminium mobile scaffolding Page 5 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Inappropriate Fall whilst gaining • Climbing up or down the

access to working access to working outside of the scaffold – no

deck. platform. ladder access.

• Ladder not positioned

internally and at the

appropriate angle 1:4 i.e. for

every 4 metres in height 1

metre out from the base.

• Ladder not secured at the top

and the bottom.

• Ladder does not project at

least 900 mm above the

working platform.

• Ladder does not access the

working platform through a

trapdoor.

• Ladder hung vertically off the

handrail or ledger on the

external or internal face of the

scaffold.

Unsecured tools Struck by falling • No fenderboards fitted to the

and/or equipment object. working platform.

lying on working • No exclusion zone around

platform. scaffold positioned in a public

or work area.

• Area around base of scaffold

not barricaded or bunted off.

Use of scaffold Vehicle or mobile Injury due to • Scaffold positioned too close

plant strikes scaffold collapse. to plant operating area.

scaffold. • Plant not operated in a

defined exclusion zone.

• Base of scaffold not

adequately protected from

impact e.g. concrete kerbs.

• “Spotter” not used to

supervise plant.

Hazard identification tool for aluminium mobile scaffolding Page 6 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Carrying out “hot Burns. • Fire extinguisher not

work” from the maintained or adjacent to

scaffold. work area on scaffold working

platform.

• Worker/s not trained in the

use of fire fighting equipment.

• Incorrect type of fire

extinguisher provided for the

required task.

• No PPE or incorrect PPE for

the required task.

Incomplete Fall from scaffold • Un-authorised removal of or

scaffold. frames or working interference with scaffold

platform. components.

• Scaffold not inspected by

competent person prior to

use.

• No isolation system for

incomplete scaffolds, e.g.

Danger tag warning signs not

in place.

• Incomplete edge protection to

working platform – no

Handrail, midrail, or

fenderboards.

Split (uneven) Step backward off • Working platform installed

decks installed higher deck with split decks, i.e. both deck

onto second causing fall from platforms are not set at the

frames. height. same height.

Scaffold left Scaffold accessed • Scaffold not barricaded to

unattended and by inexperienced prevent un-authorised use.

unsecured. person or scaffold Scaffold not secured to

falls onto person prevent movement e.g.

or object. during windy weather.

• Castor wheels not locked.

Hazard identification tool for aluminium mobile scaffolding Page 7 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Moving scaffold Moving scaffold to Scaffold topples • Failure to descend from

to new location a new location. over resulting in a scaffold and re-position from

fall. the base of scaffold.

• Moving scaffold whilst a

person is still positioned aloft

on the working platform, e.g.

grasping overhead roof

trusses to pull scaffold along.

• Scaffold moved onto bitumen

or other soft surface causing

castor wheels to subside.

• Planks and ply or steel plates

not used where soft ground is

a problem.

• Scaffold too close to an

exposed edge or penetration,

i.e. within 1 metre.

Electrical supply Electric shock • Earth Leakage Switch not

too close to work burns or installed on mains supply or

area. electrocution. portable generator.

• New work area not inspected

for electrical hazards.

• Working too close to live

power line, check for danger

zones.

• Scaffold components are

greater than 4 metres in

length.

• Insulation - Tiger Tails not in

place over power lines.

• Strong wind causes power

lines to swing closer to the

work area.

• Scaffold component strikes

and shatters unprotected light

bulb.

Hazard identification tool for aluminium mobile scaffolding Page 8 of 10

Hazard identification tool – Aluminium mobile scaffolding

Job activity What can harm What can happen Causes which need to be

(Tasks) you (Hazards) (Risks) managed (Controlled)

Dismantling Scaffold Fall from scaffold. • Un-authorised removal of or

and/or alteration incomplete or interference with scaffold

partly dismantled. components.

• Scaffold not inspected by

competent person prior to

use.

• Isolation system for

incomplete scaffold, e.g.

danger tag or warning signs,

not in place.

Unstable or Injury due to • Insufficient skills

incorrect scaffold collapse. (competency) to complete the

dismantling of required task.

scaffold. • Instructions are not provided

or are not clear – print is too

small and/or photocopy

cannot be accurately

followed.

• Scaffold poorly maintained by

supplier – colour coding

referred to in instructions is

not visible on components.

Inappropriate Scaffold collapse • Competent person not used

alterations to or fall from for scaffold alteration.

scaffold. scaffold. • Certificated scaffolder not

used for complex alteration,

e.g. cantilever or outrigger.

• Scaffold not inspected by

competent person prior to

use.

• Isolation system for

incomplete scaffold, e.g.

danger tag or warning signs,

not in place.

Hazard identification tool for aluminium mobile scaffolding Page 9 of 10

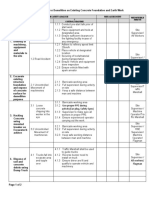

Check-list for Lightweight Aluminium Mobile Scaffolds

Clear of electrical hazards

during erection and use

Only light duty work carried out

Handrail at correct height

Ladder projects minimum

900mm above deck

Midrail at correct height

Ladder across trapdoor

operational

Toeboard fitted

Deck at suitable working height All end clip mechanisms in place

Full platform for working deck

Diagonal bracing secured

All standard joints firmly fitted

Ladder placed at correct angle

All standards (uprights) plumb

Ladder correctly fixed at base

Plan brace as low as possible

Castor locking device Base frame in square and level

operational

Castor adjustment device

Ladder clear of the ground operational

Foundation suitable – level and

firm

Source: Adapted from

diagram by Instant Access

At all times refer to manufacturers

recommendations

W:\POLICYS\WPARTY\CISAC\Hazard Profiles\from Construction Team\HazProfAlumScafWA.doc

Hazard identification tool for aluminium mobile scaffolding Page 10 of 10

You might also like

- Concrete & Form Work: Job Safety Analysis Pouring ConcreteDocument1 pageConcrete & Form Work: Job Safety Analysis Pouring ConcreteHortencio Samuel100% (4)

- JSA Wall and Ceiling PanelsDocument5 pagesJSA Wall and Ceiling PanelsPAVANKUMAR67% (6)

- Risk Assessment For Demolition WorksDocument5 pagesRisk Assessment For Demolition Worksappu pocom3100% (4)

- Risk Assessment - Use of Mobile Crane & Boom TruckDocument3 pagesRisk Assessment - Use of Mobile Crane & Boom TruckSarfraz Randhawa100% (5)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- TEIPL-JSA-058 Carpentry Wood WorkDocument3 pagesTEIPL-JSA-058 Carpentry Wood Workba ratnaparkheNo ratings yet

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- C&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFDocument4 pagesC&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFNajman Hamdi100% (3)

- JSA For Plaster WorkDocument8 pagesJSA For Plaster WorkZakeer Shaikh100% (1)

- JSA For Concrete PouringDocument8 pagesJSA For Concrete Pouringfayaz fayazhotmail.com100% (1)

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- JSA-003 Excavation & BackfillingDocument3 pagesJSA-003 Excavation & Backfillingba ratnaparkhe100% (1)

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Raman SawNo ratings yet

- Jsa For Steel ErectionDocument7 pagesJsa For Steel ErectionRajuNo ratings yet

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- 9.JSA For Night Work Activity - Rev 01Document7 pages9.JSA For Night Work Activity - Rev 01ibrahim80% (10)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- JSA For Concrete, Brecking, ExavationDocument6 pagesJSA For Concrete, Brecking, ExavationBinay0% (1)

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Design of CorbelDocument9 pagesDesign of Corbelalurabhilash1No ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal Pattanayak100% (2)

- Jsa For Brick WorkDocument4 pagesJsa For Brick WorkSushil Kumar YadavNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement WorkDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement Workba ratnaparkhe67% (3)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Chain Pulley Block JsaDocument2 pagesChain Pulley Block JsaAKBAR ALINo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- Hira Plastering Finishing WorkDocument2 pagesHira Plastering Finishing WorkDwitikrushna Rout0% (2)

- HIRA, TCS-ACP Sheet FixingDocument2 pagesHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- JSA For Concrete PouringDocument1 pageJSA For Concrete PouringHSE fahadNo ratings yet

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- JSA For Brick WorkDocument3 pagesJSA For Brick Workwahyu nugroho71% (7)

- JSA For HILTIDocument3 pagesJSA For HILTIMohammed Minhaj100% (1)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- JSA For Installation of Out Door UnitsDocument4 pagesJSA For Installation of Out Door UnitsMohammed MinhajNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (2)

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn Bhd100% (1)

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- Jsa For Cutting, Grinding and Welding For GulfconDocument3 pagesJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- Jsa For Applying Bituminous Roof Treatment On BuildingsDocument3 pagesJsa For Applying Bituminous Roof Treatment On BuildingsMohammed Minhaj100% (1)

- Scaffold HiracDocument15 pagesScaffold HiracSafety JosephNo ratings yet

- Defensive DrivingDocument23 pagesDefensive DrivingBojie AbogadieNo ratings yet

- RKform300pkg InstruxOnly PDFDocument1 pageRKform300pkg InstruxOnly PDFBojie AbogadieNo ratings yet

- Sample HSE Plan XXDocument37 pagesSample HSE Plan XXBojie Abogadie100% (1)

- HSE Business PlanDocument32 pagesHSE Business PlanBojie AbogadieNo ratings yet

- Training & CompetenceDocument20 pagesTraining & CompetenceBojie AbogadieNo ratings yet

- Cal/Osha Pocket Guide For The Construction IndustryDocument91 pagesCal/Osha Pocket Guide For The Construction IndustryBojie AbogadieNo ratings yet

- Slip Test - Board Retaining Coupler PDFDocument1 pageSlip Test - Board Retaining Coupler PDFBojie AbogadieNo ratings yet

- Alarkan-Perf Helmet Certificate PDFDocument3 pagesAlarkan-Perf Helmet Certificate PDFBojie AbogadieNo ratings yet

- Load Test - Base Jack PDFDocument1 pageLoad Test - Base Jack PDFBojie AbogadieNo ratings yet

- Steel Wire Rope PDFDocument1 pageSteel Wire Rope PDFBojie AbogadieNo ratings yet

- Helmet-Alarkan - Data Sheet of Helmet 20160830Document1 pageHelmet-Alarkan - Data Sheet of Helmet 20160830Bojie AbogadieNo ratings yet

- Delta Plus - Harness PDFDocument3 pagesDelta Plus - Harness PDFBojie AbogadieNo ratings yet

- Gin Wheel OperationDocument13 pagesGin Wheel OperationBojie AbogadieNo ratings yet

- Glossary of Roofing TermsDocument47 pagesGlossary of Roofing Termslilia_jNo ratings yet

- Colt Presentation - Smoke and Environmental Ventilation of Multi-Storey Buildings Using ShaftsDocument54 pagesColt Presentation - Smoke and Environmental Ventilation of Multi-Storey Buildings Using ShaftsNenad MutavdzicNo ratings yet

- ESO Port Facilities and Baywalk ExtensionDocument3 pagesESO Port Facilities and Baywalk ExtensionSharmaine MercadoNo ratings yet

- PIP IndexDocument46 pagesPIP Indexcui jackyNo ratings yet

- LimconDocument12 pagesLimconharishram123456No ratings yet

- Reference: AASHTO Guide For The Design of Pavement Structures, 1993Document25 pagesReference: AASHTO Guide For The Design of Pavement Structures, 1993Kevin SotoNo ratings yet

- Vision Mission Objectives: Ordinary Portland Cement 43 Grade Cement (OPC 43 Grade)Document2 pagesVision Mission Objectives: Ordinary Portland Cement 43 Grade Cement (OPC 43 Grade)M. HaripriyaNo ratings yet

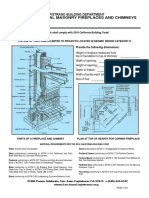

- Residential Masonry Fireplaces and ChimneysDocument5 pagesResidential Masonry Fireplaces and Chimneysmami chanNo ratings yet

- Cable T SpecsDocument8 pagesCable T Specsdr reNo ratings yet

- Abel Zenebe Negash: +251-9-24-30-41-14 +251-9-11-10-78-00 +251-9-11-96-13-29 E-MailDocument3 pagesAbel Zenebe Negash: +251-9-24-30-41-14 +251-9-11-10-78-00 +251-9-11-96-13-29 E-MailfayoNo ratings yet

- Understanding Sour Service Performace of Coiled TubingDocument12 pagesUnderstanding Sour Service Performace of Coiled TubingMubeenNo ratings yet

- Canada Stormwater Management Guidelines - HalifaxDocument282 pagesCanada Stormwater Management Guidelines - HalifaxFree Rain Garden Manuals100% (1)

- Frontier Works Organisattion (Fwo)Document2 pagesFrontier Works Organisattion (Fwo)Shahrukh Shaikh50% (2)

- Basics of Concrete Repair and Structural StrengtheningDocument65 pagesBasics of Concrete Repair and Structural StrengtheningEdmond ChowNo ratings yet

- Manual Servicio Refrigerador Daewoo Erf-384aDocument56 pagesManual Servicio Refrigerador Daewoo Erf-384aevalencia4808100% (1)

- Caltrans Standard Plans, 2015Document27 pagesCaltrans Standard Plans, 2015Afolabi OladunniNo ratings yet

- Gate Valve: Typical Use Valve ConstructionDocument4 pagesGate Valve: Typical Use Valve ConstructionCegrow Ber BersabalNo ratings yet

- Deluge PosterDocument1 pageDeluge PosterAhamed KyanaNo ratings yet

- Design Standard: ASME VIII / API 520: Design of Safety ValvesDocument27 pagesDesign Standard: ASME VIII / API 520: Design of Safety ValvesMoe MozhganNo ratings yet

- Different Types of FoundationDocument30 pagesDifferent Types of Foundationsmodi_92No ratings yet

- Chapter 3 STR 3 Beams Shear BondDocument8 pagesChapter 3 STR 3 Beams Shear BonddaniNo ratings yet

- FE Geotech Eng PDFDocument5 pagesFE Geotech Eng PDFgrNo ratings yet

- Steel Profile CatalogDocument32 pagesSteel Profile CatalogBilgehanNo ratings yet

- Kaiyuan CatalogDocument6 pagesKaiyuan CatalogGogyNo ratings yet

- Stone Masonry (Training Element and Technical Guide For SPWP Workers Booklet 3)Document86 pagesStone Masonry (Training Element and Technical Guide For SPWP Workers Booklet 3)Wubetie MengistNo ratings yet

- TF 10-8-22Document1 pageTF 10-8-22SanjayNo ratings yet

- Unitor CO2 Hoses DiagramDocument9 pagesUnitor CO2 Hoses DiagramPrasad BangaruNo ratings yet

- Bs 534Document26 pagesBs 534Lucian Chitu75% (4)

- Triple B Stadium Statement of Claim F March 4 2015Document27 pagesTriple B Stadium Statement of Claim F March 4 2015ChrisDcaNo ratings yet