Professional Documents

Culture Documents

Cement Sheath Stress Failure: K .... Goodwin, R .... Crook

Cement Sheath Stress Failure: K .... Goodwin, R .... Crook

Uploaded by

Greg CerrutiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Sheath Stress Failure: K .... Goodwin, R .... Crook

Cement Sheath Stress Failure: K .... Goodwin, R .... Crook

Uploaded by

Greg CerrutiCopyright:

Available Formats

Cement Sheath Stress Failure

K .... Goodwin, SPE, Mobil E&P Services Inc., and R.... Crook, SPE,

Halliburton Services Research Center

Summary. Observation of the sudden appearance of annular pressure in wells exposed to high temperature changes or excessive

internal casing pressure prompted a laboratory investigation to simulate conditions under which cement sheath failure could occur and

thereby define the causes, characteristics, and limits of the problem. Cement sheath failure is manifested by interzonal annular-fluid

movement and abnormally high annular pressure at some point behind the casing up to and at the surface. Cement sheath failure can

be observed in any producing area where excessive flowing temperatures exist at the surface or where excessive internal casing test

pressures are used. The detrimental effects of cement sheath failure are numerous and may include lost revenue from lost production,

potentially hazardous rig operations (especially when annular isolation loss creates shallow-water sands supercharged with gas), and

potentially hazardous producing operations. Exposure of steel casing to excessive temperature increases or internal test pressures causes

diametrical and circumferential casing expansion. This circumferential force creates a shearing force at the cement/casing interface,

causing failure at the cement/casing interface or radial fracturing of the cement sheath from the inner casing surface to the outer casing

(or borehole) surface.

Introduction

In several operating areas, annular-flow problems not attributable tended to ensure the mechanical integrity of the casing string. The

to common annular-flow-after-cementing definitions are experi- maximum internal test pressure generally will equal some percent-

enced. This paper is not intended to discuss short-term annular- age of rated casing burst pressure, assuming an equivalent annular

influx problems. Long-term annular-influx problems usually ex- pressure equal to a gradient of water, which decreases the assumed

perienced after a well begins producing represent a completely differential pressure created across the casing-wall thickness.

different set of circumstances. Long-term annular influx generally Cooke et al. 1 demonstrated that a cement column in the annu-

occurs after excessive casing test pressures once the cement sheath lus exhibits full hydrostatic pressure as long as the cement is in

has set and attained some compressive strength, or following ex- the liquid state but that, as the cement passes through the gel state

cessive temperature changes resulting from excessively high produc- and sets, the cement-column pressure can vary from 2 Ibm/gal to

ing temperatures or steam-injection temperatures. Long-term the equivalent formation pore pressure covered by the cement

annular influx has long been believed to be caused by either ce- column. Carter 2 and Burkowsky et al. 3 showed that the cement-

ment sheath failure or hydrostatic pressure loss in a channeled column hydrostatic pressure can be as low as 0 psi. These low pres-

(bypassed) mud column after the weighting material has settled out sure values generally occur when the cement sets in casing/casing

of the drilling mud. annuli, nonpermeable laboratory-test models, or openhole sections,

An extensive investigation was begun to determine the reasons with no pore pressure and no water available for the cement hydra-

for these long-term annular-flow phenomena. Analysis of cement- tion/hydrolysis reaction. Carter 2 demonstrated cement sheath

ing systems and well cementing techniques concentrated on the use failure in unsupported cases created by excessive internal casing

of "good cementing practices" (i.e., pipe movement; effective pressures causing diametrical, and subsequently circumferential,

casing centralization; sufficient circulation times and rates before expansion.

cementing for mud and hole conditioning; and sufficient volumes Assuming that the cement column represents a physical force (not

a hydraulic pressure) against the outer casing surface, the total in-

of water, washes, or spacers for hole cleaning). Such current ce-

ternal casing pressure (and the differential pressure across the casing-

ment sheath evaluation devices as fluid-compensated bond logs or

wall thickness) becomes the sum of the surface pressure plus the

ultrasonic-type logging devices were used to determine the pres- hydrostatic pressure of the casing fluid. Depending on the casing-

ence of primary cement channels. After analyzing only a relative- fluid density and depth, these differential pressures can range from

ly few problem wells, it became evident that something drastic had equal to the surface test pressure to as high as 20,000 psi at the

happened to the cement sheath in each well. In all the wells inves- bottom of the hole. This implies that cement sheath failure caused

tigated, clean cement was circulated to surface with no indication by excessive casing test pressures generally should occur some-

of lost circulation or fallback; however, the presence of a cement where in the bottom one-halfto three-quarters of the casing string,

sheath was not evident. creating zonal isolation loss over those intervals. Postcementing

The only evidence of cement in the annulus visible on the bond annular flow caused by this type of cement sheath failure generally

logs was an approximate 50% decrease in amplitude; no evidence is not evident at the surface, unless the differential test pressure

of casing or formation signal was visible on the microseismogram is sufficient to create sheath failure to the surface. If excessive casing

of the bond log. The presence of a cement sheath was extremely test pressures are conducted while the cement is gelled but not set,

difficult to prove on the ultrasonic logs as well. Without evidence casing expansion frequently will create a large microannulus be-

of a viable cement sheath on any of the logging devices, the exis- tween the casing and cement sheath, creating a flOW path to the

tence of a mud channel in the primary cement sheath was difficult surface.

to ascertain. With the understanding that full circulation was at- The magnitude of unsupported casing expansion 5 (Fig. 1) may

tained during primary cement placement, gas-cut cement is readi- be calculated as

ly identifiable on ultrasonic logging devices, cement particles cannot

Me=(tlpd~)/(Ehc)' ............................... (1)

enter formation-matrix permeability, and cement (once it has set)

does not magically disappear from the annulus, it was readily ap- where tlde=change in OD, tlp=change in pressure, E=Young's

parent that something had destroyed the cement sheath. Further in- modulus for steel, and hc=casing-wall thickness.

vestigations indicated that all these production casing strings had The casing ID also increases concurrent with casing expansion.

been exposed to either high internal test pressures or high surface The casing ID, d j , may be calculated after internal pressurization

flowing (or injection) temperatures. as

Typically, oil- or gas-well casing strings are pressure tested to d j =( {[7 , 854(tlde +de)2] -A tl/0.7854)O.5, ............. (2)

some value after the string has been cemented, or before drilling

out in the case of intermediate casings, and after the cement has where A 1 =original cross-sectional area, in. 2 . Eqs. 1 and 2 were

attained some compressive strength. These pressure tests are in- derived by Zinkham and Goodwin. 4

In some subject wells, annular surface pressure became evident

Copyright 1992 Society cif Petroleum Engineers only after a well had begun producing. This phenomenon was ob-

SPE Drilling Engineering, December 1992 291

12000 ~5 112" Inner Casing

,-""~'" ~

1000

"I Il / /

v v V

i-e- 13.375" (856 )

800

a; V 9625" (53.5")

0-

<I

600

/, I(j / V

-+-

.... 7" (29")

v ... 7" (38 6 )

V!J / /"

.... 55" (155#)

-e- 5S (23.5 6 ) 75/8" Outer Casing ~

400

v

~~v

I#) v

200

0

0.00 0.02 0.04 006 008 0.10 1== Inlet For Permeability

l>. 00 .in .. --:::--_~--1 Measurement

Fig. 1-Unsupported casing expansion vs. pressure. Hot Oil CirculatIOn ~ ----.l I

served where surface flowing temperatures were excessively high Fig. 2-Schematlc of the pressure-/temperature-change test

or in steamflood injection wells. In cases where annular flow (gas model.

or liquid) was measured and sampled at the surface, we determined

that the flow did not originate in the producing zone of interest, 1. At 0 psi in the 5lh-in. casing, measure the base permeability

but in other zones considerable distances above the primary produc- of the annular cement sheath to water.

ing zone. This implies that cement sheath failure occurs in the up- 2. Increase the inner (5lh-in.) casing pressure to 2,000 psi, record

per one-fourth to two-thirds of the casing string when failure is any pressure increase in the annulus, and then measure the perme-

caused by excessive temperature changes. In the case of shallow ability of the annulus to water.

steamfiood injection wells, however, cement sheath failure appears 3. Decrease the pressure on the inner casing to 0 psi, then meas-

to occur over the entire cemented interval. ure the permeability of the annulus to water.

This type of cement sheath failure was believed to result from 4. Repeat Steps 2 and 3 in 2,000-psi increments to a maximum

sheath stress cracking caused by diametrical and circumferential of 1O,000-psi inner casing pressure.

casing expansion from excessive temperature increases. Labora-

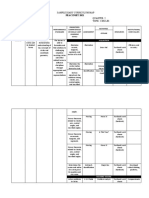

tory measurements of the cementing systems in these cases dem- Cement Systems

onstrated that compressive-strength retrogression accompanied by The cementing systems tested and their measured physical proper-

matrix-permeability increases caused by high temperatures (320 to ties are as follows.

500 0 P) was. not occurring. 1. System 1 contained a cement/siliceous material mixture, 30%

latex by weight of water (BWOW), 1.25% synthetic fluid:-Ioss ad-

T.st Mod.1 ditive, and 0.5% gelling agent mixed at 12.1Ibm!gal with 10.81

Fig. 2 is a schematic of the test model devised for laboratory meas- gal mix water/sack. The yield was 2.49 ft3/sack. The compres-

urements to determine the effects of excessive pressure or temper- sive strength of the system at the time of testing was 1,000 psi,

ature changes on cement sheaths in casing/casing annuli. A test E=0.69 x 10 6 , and Poisson's ratio was 0.42.

model was built for each test as it was taken to cement sheath failure, 2. System 2 contained a cement/pozzolan mixture, 10 Ibm silica

then was cut into four sections for visual observation and to photo- flour/sack, 30% latex BWOW, 2 gal/sack synthetic fluid-loss ad-

ditive, and 0.25% gelling agent mixed at 13.1 Ibm/gal with 6.48

graph the sheath. The model consisted of a 5lh-in., 23-lbm!ft in-

gal mix water/sack with a yield of 1.76 ft3/sack. The compres-

ner casing and a 7%-in., 29.7-lbm/ft outer casing with mounting

sive strength of the system at the time of testing was 2,500 psi,

plates welded at the top and bottom of the 7%-in. casing, leaving E=0.8 x 10 6 , and Poisson's ratio was 0.32.

5lh ft of annulus for the cement. A pad of steel wool was placed 3. System 3 was the same as System 2 without the latex at 13.1

in the bottom of the annulus for even distribution of water to the Ibm/gal. The compressive strength of the system at the time oftest-

annular cement sheath to test permeability. The cement system was ing was 2,000 psi, E=0.9 x 10 6 , and Poisson's ratio was 0.30.

mixed and pumped into the annulus. then cured at temperature by 4. System 4 contained Class H cement and 35% silica flour mixed

circulating hot (350 0 P) oil through the 5lh-in. casing. The annu- at 18 Ibm!gal. The compressive strength of the system at the time of

lus was maintained at 500 psi during the curing phase. Typically, testing was 9,600 psi, E=2.4x 10 6 , and Poisson's ratio was 0.11.

the temperature on the outside of the 7%-in. casing dropped by 35

to 40 o P. Test Results

Testing procedures after compressive-strength development within Figs. 3 through 5 show the test results. The first test, using Ce-

the cement sheath follow. ment System 1, reflects the presence of a siliceous, highly porous,

reactive filler material. As internal casing pressure was increased

0.03 -r---.--.---.-.----.-...,--,r-.----,-,---,r--, incrementally, the cement matrix permeability decreased incremen-

23,s so tally to 0 md at 8,OOO-psi inner casing pressure (Pig. 4). After sec-

tioning the test cell, we found that the cement had failed and was

0.02 in a liquid state with the consistency of putty. Subsequent labora-

!'

g . . . . .v / Sys m No 1

tory testing indicated that the putty-like material consisted of fully

I

0

0

0.01

hydrated cement, evidence that the cement system had been com-

pressed to total crystalline (structural) collapse during the test. The

remaining cement systems tested (Systems 2 through 4) show no

appreciable change in matrix permeability with increasing inner

casing pressure (Fig. 3).

10000 '2000

2000 4000 6000 8000 Fig. 5 illustrates changes in the integrity of the cement sheath,

Internal Casing Pressure, psi

representing measurements of the annular permeability to water after

the inner casing pressure had been bled to 0 psi following each in-

Fig. 3-Supported and unsupported casing-diameter ex-

cremental pressure increase. Because only System 1 exhibited a

pansion.

change in matrix permeability, increases in annular permeability

292 SPE Drilling Engineering, December 1992

80

0.3

.,

E

., 60 /

S .. tem <0. I E N. I

/

\ g

~

~ --r--....... yste No 2 ~ 40

/ ....../ / N .2

'\/ f.-- ....._r--..J.

"-.,.,... ~

a. j /

-

"'" -., Syst m No. /

20

~ ~ - - ---+--+--+syst m No ....... ~/ ..-' N 4

r-~I'--

o 2000 4000 6000 8000 10000

0

0 2000

---

4000 6000 8000 10000 12000

Internal Casing Pressure, psi Internal Casing Pressure, psI

Fig. 4-Annular permeability chart with Internal casing pres- Fig. 5-Annular permeability chart at O-psl Internal casing

sure Indicated. pressure.

must reflect creation of flow channels (stress cracks) within the ce- ported casing. Fig. 3 also illustrates a rnicroannulus that occurred

ment sheath structure. All the cement systems tested withstood the in the test of Cement System 2 with no subsequent change in casing

2,OOO-psi inner casing pressure cycle with minor stress fracture for- support up through 6,000-psi pressure cycling. System 2 is more

mation. Major stress fractures were observed after the 4,000-psi ductile than the other cements, although it started to develop minute

pressure cycle, and catastrophic stress fractures developed after the stress cracks during this portion of the test. System I, another duc-

6,000-psi pressure cycle. tile cement, also exhibited elastic behavior and provided full casing

During the inner casing pressure cycling as the cement sheath support until its catastrophic failure at 6,OOO-psi internal casing pres-

in the tests began to fail, annular pressure changes could be meas- sure. Systems 3 and 4, the more brittle cements, exhibited failure

ured to determine the supported casing diametrical changes for com- at the first test pressure (2,000 psi), although the total change in

parison with unsupported diametrical changes. Combining the inner casing diameter was not as severe as that of the elastic mate-

definition of bulk modulus of elasticity with the volumetric change rials after catastrophic failure.

in the annulus created by the internal casing pressure provides a From these tests, it appears that the higher-compressive-strength

solution for the resulting supported diameter of the inner casing. material (i.e., the more brittle cements) provided better casing

ds = ({[(.:1pIEb )O. 7854(d~ -dr)] +(0. 7854d~) support but lost the ability to seal the annulus at a much lower in-

ternal casing test pressure. After these cement systems fail catas-

-[0.7854(d~ -dr)]}/0.7854)O.5, ..................... (3) trophically, the slope of the line of diameter change should equal

where d 2 =outer casing ID (hole diameter), d l =original inner that of the unsupported casing. These magnitudes of casing expan-

casing 00, .:1p=change in internal casing pressure, V=original sion become even more significant when considering the size of

annular volume, and Eb=bulk Young's modulus. Eq. 3 was de- the rnicroannulus created, M/2, and during attempts to evaluate

rived by Zinkham and Goodwin. 4 a cement sheath with bond logging tools.

Fig. 3 illustrates the calculated inner-casing expansion resulting Permeability measurements were made in the annulus while pres-

from the support provided by each of the cement systems tested. sure testing the internal casing and after release of the internal casing

The 5~-in. casing line represents calculated expansion of nonsup- pressure to determine when the cement sheath failed. The permea-

Before Pressure Test Before Pressure Test

_ ...

After Pressure Test - - --- - After Pressure Test

Fig. 6-Cross section of Cement System 1 failure. Fig. 7-Cross section of Cement System 2 failure.

SPE Drilling Engineering, December 1992 293

bility measurements were made with water at a loo-psi !J.p. This These stress cracks result from the cement failure in tension, not

procedure measures the total annular permeability and the cement in compression. These changes in temperature do not occur near

sheath matrix permeability. Figs. 4 and 5 show these measurements; a producing zone but toward the surface, where significant differ-

Fig. 4 illustrates cement matrix permeability measurements dur- ential temperatures can occur (e.g., surface flowing temperature

ing application of internal casing pressure, and Fig. 5 illustrates less the normal geothermal temperature or steamflood inlet tem-

total annular permeability with no internal casing pressure. In Fig. perature less the normal geothermal temperature). Generally, the

4, the complete loss of matrix permeability in System 1 illustrates presence of the stress cracks in the cement sheath is not a problem

internal collapse of the cement system to a plastic material (total while the casing is expanded (e.g., while the well is flowing or

compressive failure to O-psi compressive strength). Subsequent tests during steam injection) as long as the cracks do not extend into the

indicated that System 1 was totally amorphous (hydrated cement). formation at a well-bonded interface. When the casing relaxes during

Fig. 5 dramatically illustrates when excessive stress cracking be- cooling, the cracks open sufficiently to permit annular flow. The

gan in the systems. Although System 4 did not fail as catastrophi- differential temperature, !J.T, required to create casing expansion

cally as the other systems, it still began to fail at the first internal equal to internal test pressure expansion may be defined as

pressure test at 2, ()()() psi. !J.T=(h w1 -hw2)/(Ohwl)' ............................ (4)

Figs. 6 through 9 illustrate the types of stress cracks observed

in the test models sectioned after each test. The crack direction ap- where hwl =original casing-wall thickness, hw2 = pressurized

parently may be determined by the greater value of tensile strength casing-wall thickness, and O=volumetric (cubical) expansion of

or shear-bond strength. In higher-tensile-strength cements, the steel, 2.07xlO- 5 in.lin.-oF.

cracks generally tended to generate either within the cement sys- Eq. 4 was derived by Zinkham and Goodwin. 4 This method was

tem or at the casing/cement interface and parallel to the inner casing used to generate Figs. 5 and Figs. 10 through 13.

surface until internal test pressures also exceeded the tensile strength.

The cracks then radiated toward the outer casing surface. In higher- Field Trials

shear-bond cements, the cracks radiated directly from the inner to Field testing was conducted with the same casing sizes and cements

the outer casing surface. previously used in the laboratory test model. Following placement

and curing of the cement in a well, the quality and quantity of the

Temperature cement sheath were measured with an ultrasonic cement-evaluation

Temperature changes in a flowing well also can create significant

casing-diameter increases. This expansion is cubical (volumetric).

The coefficient of cubic expansion of a solid is approximately three

times the linear coefficient. 5 The axial stresses created by the in-

creasing casing OD create stress cracks in the cement sheath much

as the previously described excessive inner casing pressure does.

Fig. 10-Expanslon of 51/z-ln. casing. temperature vs. pres-

Fig. l1-Expanslon of 7·ln. casing. temperature vs. pressure.

sure.

294 SPE Drilling Engineering, December 1992

500'---~~---r----~--~-----r--~ 500~--~-----r----~--~----~--~

400~--~r----+----+---~--~~--~ 400~----+-----~--~-----+~~~----~

300i---~r----+----+-~~~--~--~ 3004---~----~----~~-t~~4---~

<l

200i---~r----+~~~~~-----r----;

100~---'~~~-----r----+-~~~#~/f~t~

..It 1ft

o 2000 4000 6000 8000 10000 12000 o 2000 4000 6000 8000 10000 12000

6 P, PSi 6 P, psi

Fig. 12-Expanslon of 9%-ln. casing, temperature vs. pres- Fig. 13-Expanslon of 13%-ln. casing, temperatul'e vs. pres-

sure. sure.

device. One well was cemented with Cement Systems 3 and 4, and same type of failure has been observed on wells that used expend-

the other well was cemented with Cement System 2. In response able perforating guns to shoot high-density (8- to 12-shot/ft) pat-

to the results of the laboratory tests and to meet the necessities of terns with large holes (0.45 to 0.5 in.).

field operation, the casing was pressure tested with tubing and a 3. Generally, low-compressive-strength (500- to 1,000-psi) ce-

retrievable packer to isolate the lowest test pressure to the bottom ments are more ductile than other cements and can withstand the

end of the casing, subsequently increasing test pressures toward stress cycling. Also, ultrahigh-compressive-strength (> 12,OOO-psi)

the top of the well. An upper section of the first well contained cement can withstand stress cycling without cracking. One sugges-

Cement System 3, which had developed compressive strength in tion for circumventing the cracking problem is to use a low-density

the range of 2,000 psi, and Cement System 4, which had devel- cement slurry to cement the entire well (deleting the high-strength

tail slurry).

oped compressive strength in the range of 3,000 psi.

4. Loss of annular control of gas or water also has been observed

Comparison of the evaluation logs of Systems 3 and 4 (Figs. 14

in cases of excessively high surface flowing temperatures or steam-

and 15) before and after being subjected to 12,150-psi internal flood injection. Where pumping low-density, low-compressive-

casing pressure (surface pressure plus casing-fluid hydrostatic pres- strength cements was possible, the cracking problem practically was

sure) demonstrates that the more brittle system (System 4) failed, eliminated.

while the more ductile system (System 3) remained intact. 5. Cement sheath stress cracking as a result of excessive tem-

Another casing string was cemented with commercial lightweight perature changes generally occurs in the upper one-third to one-

cement containing silica flour and 20 vol % latex. To date, the well half of the well.

has been pressure tested, but no evaluation logs have been run for

definitive effects of the pressure tests on the more ductile cement Methodology

sheath. Eq. 2 solves for the new casing ID following expansion. The method

involves subtracting the cross-sectional area of the steel (which does

Conclusions not change) from the expanded-OD cross-sectional area, which de-

1. Casing expansions created by excessive internal casing pres- fines the new ID cross-sectional area of the expanded casing.

sures can create radial stress cracks in the set cement in the annu- Eq. 3 combines the classic definition of the Eb equation with the

lus. These cracks, which cause loss of annular zonal isolation, annular-volume change caused by increased casing OD measured

generally are created in the lower one-quarter to one-third of the during testing. An average bulk modulus of elasticity for cement

well. is 1.51x10 5 .

2. Typical causes of such cracks include pressure testing the Eq. 4 assumes that the casing expansion caused by increased tem-

casing after the cement has attained high compressive strength. The perature is equal to casing expansion caused by internal pressure

9 5/S"' Casing 13 3/S"' Casing

500 600~---4-----r----~--~-----r--~

400 ./ 5004---~ __---+----+---~--~~--~

300 / /' 400;---~r----+----;---~~7'~--~

<l

200

~ V <l

V P.

~

43. .# 1ft

~ 53 . .#/ft

100 100~--~~~~-----+----~--~+-~~

V

V'

o

o 2000 4000 6000 8000 10000 12000 2000 4000 6000 8000 10000 12000

6 P, psi 6 P, psi

Fig. 14-Acoustlc Impedance log showing Transducer 2 track Fig. 15-Acoustlc Impedance log showing Transducer 2 track

before and after pressure testing casing, Cement System 3. before and after pressure testing casing, Cement System 4.

SPE Drilling Engineering, December 1992 295

d2 = outer casing OD (hole diameter), L, in.

Authors E = Young's modulus for steel, mlU2

K.... Goodwin Is Eb = bulk Young's modulus, m/U2, psi

an associate drill- he = casing-wall thickness, L, in.

Ing engineering ad- hwl = original casing-wall thickness, L, in.

viser with Mobil hw2 = pressurized casing-wall thickness, L, in.

E&P Services Inc. p = internal casing pressure, m/U2, psi

In Dallas. Before

joining Mobil In T = differential temperature, T

1985, he was em- V = original annular volume, L3, in. 3

ployed by Dowell o = volumetric (cubical) expansion of steel, 2.07 x 10- 5

and Western Co. of in.lin.-oF

North America.

Goodwin Crook During his career,

Acknowledgments

he has worked In

the laboratory and field In stimulation, cementing, and lost We thank the managements of Mobil E&P Services Inc. and Hal-

circulation. His Interests Include remedial cementing and ce- liburton Services for permission to publish this paper. The help of

ment sheath evaluation, and he currently teaches cement- all persons concerned with the project is deeply appreciated.

Ing courses, conducts remedial cementing and cement sheath

evaluation seminars, and provides technical assistance In

these areas worldwide. He holds a BS degree In chemistry

References

from Northwestern State U. Goodwin, a 25-year SPE mem- 1. Cooke, C.E., Kluck, M.P., and Medrano, R.: "Field Measurements

ber, served on the 1990-91 Forum Series Committee and cur- of Annular Pressure and Temperature During Primary Cementing," JPT

rently Is a Short Course Instructor. Ronald ... Crook is a (Aug. 1983) 1429-38.

research engineer and technical team leader for the Appli- 2. Carter, L.G.: "Effect of Bore-Hole Stresses on Set Cement," MS the-

cations Research Group at Halliburton Services Research sis, U. of Oklahoma, Norman, OK (1968).

Center in Duncan, OK. His research Interests are In squeeze 3. Burkowsky, M., Ott, H., and Schillinger, H.: "Cemented Pipe-in-Pipe

cementing, the use of spacers and flushes, new cementing Casing Strings Solved Field Problems," World Oil (Oct. 1981) 143-47.

materials, large-scale displacement of drilling fluids, and prac- 4. Zinkham, R.E. and Goodwin, R.J.: "Burst Resistance of Pipe Cement-

tices related to devlated-wellbore cementing. He also has con- ed Into the Earth," JPT (Sept. 1962) 1033-40.

ducted field studies associated with downhole temperature 5. Handbook of Chemistry and Physics, 36th edition, Chemical Rubber Pub-

measurements and geothermal cementing. He holds a BS lishing Co. (1954-55) 2066.

degree In chemical engineering from Oklahoma State U. Crook

served on the program committees for the 1989-91 SPElIADC

Drilling Conferences and on a Technical Program Commit-

51 Metric Conversion Factors

tee for the 1990 Annual Meeting. ft x 3.048* E-Ol m

ft3 x 2.831685 E-02 m3

OF (OF - 32/1.8) °C

increases. All that remains is setting the casing-pressure expansion

method equal to the temperature expansion method and solving for gal x 3.785412 E-03 m3

the change in temperature required to produce an equivalent ex- in. x 2.54* E+OO cm

pansion value. in. 3 x 1.638706 E+Ol cm 3

Ibm x 4.535924 E-Ol kg

Nomenclature md x 9.869233 E-04 Ilm 2

psi x 6.894757 E+OO kPa

Al = original cross-sectional area, L2, in.

de = OD, L, in. • Conversion factor is exact. SPEDE

di = ID, L, in. Original SPE manuscript received for review Sept. 2, 1990. Revised manuscript received

June 15, 1992. Paper accepted for publication April 30, 1992. Paper (SPE 20453) first

d s = supported OD, L, in. presented at the 1990 SPE Annual Technical Conference and Exhibition held in New

d l = original inner casing OD, L, in. Orleans, Sept. 23-26.

296 SPE Drilling Engineering, December 1992

You might also like

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Chapter 3 The Equipment of Naturally Flowing Wells-1Document24 pagesChapter 3 The Equipment of Naturally Flowing Wells-1stanlnleybuduka100% (1)

- Elastics Properties of Matter (2 Hours)Document31 pagesElastics Properties of Matter (2 Hours)evergarden33100% (1)

- A Seminar Report On Rover Mission .1Document23 pagesA Seminar Report On Rover Mission .1monster gaming100% (1)

- Cement Sheath Stress FailureDocument6 pagesCement Sheath Stress FailureQutluq CaferzadeNo ratings yet

- Well Cementing 13cap IDocument43 pagesWell Cementing 13cap IWill OrtizNo ratings yet

- Economides 1987Document3 pagesEconomides 1987p9nwz2vj85No ratings yet

- Hole02 PDFDocument7 pagesHole02 PDFAri MustakdirNo ratings yet

- Use of Expandable Cement Slurries To Prevent Sustained Casing PressureDocument6 pagesUse of Expandable Cement Slurries To Prevent Sustained Casing Pressurehammadi8muhammedNo ratings yet

- Chapter 1+Casing+12Feb18Document47 pagesChapter 1+Casing+12Feb18Mohamad ZakwanNo ratings yet

- Estiramiento CasingDocument13 pagesEstiramiento CasingFrancisco RoccaNo ratings yet

- Oil Well CasingDocument5 pagesOil Well Casingragbrown_512No ratings yet

- Design and Construction Problems of A "Big Inch" Outfall: Carlo Avanzini and Pierantonio QuiriciDocument8 pagesDesign and Construction Problems of A "Big Inch" Outfall: Carlo Avanzini and Pierantonio Quiricijean miguel oscorima celisNo ratings yet

- Pipe Sticks SupportDocument8 pagesPipe Sticks SupportAmitNo ratings yet

- Construction and Building Materials: Yingbo Zhang, Weibiao Wang, Yue ZhuDocument7 pagesConstruction and Building Materials: Yingbo Zhang, Weibiao Wang, Yue ZhuVictor Ahumada MatosNo ratings yet

- Globe Valve Lab ReportDocument8 pagesGlobe Valve Lab ReportPeterJohn32No ratings yet

- Casing Design: Drilling ReportDocument10 pagesCasing Design: Drilling Reportمحمد علي كريم شكر100% (1)

- A Study of Pressure Safety Valve Response Times Under Transient OverpressuresDocument9 pagesA Study of Pressure Safety Valve Response Times Under Transient OverpressuresLeo MilojevićNo ratings yet

- Spe 168321 MS PDFDocument9 pagesSpe 168321 MS PDFJoshua SitorusNo ratings yet

- Fishing Time-Decision MakingDocument6 pagesFishing Time-Decision MakingJorgito AriasNo ratings yet

- Wellbore BroachingDocument22 pagesWellbore BroachingrahimovfuadNo ratings yet

- 21SPTE313 - Lecture 7Document47 pages21SPTE313 - Lecture 7Mohamed SolimanNo ratings yet

- Maleki-Frigaard2017 Article PrimaryCementingOfOilAndGasWelDocument30 pagesMaleki-Frigaard2017 Article PrimaryCementingOfOilAndGasWelNasim KazemiNo ratings yet

- Tutorial - Casing Design Plus Answers Rev 2Document3 pagesTutorial - Casing Design Plus Answers Rev 2Solomon BalemeziNo ratings yet

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziNo ratings yet

- Simulation of The Drop Impact Test For Moulded Thermoplastic ContainersDocument21 pagesSimulation of The Drop Impact Test For Moulded Thermoplastic ContainersIlham MaulanaNo ratings yet

- 8429 PaDocument7 pages8429 Pabaraa odayNo ratings yet

- Properties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Document10 pagesProperties of Anchor Grouts in A Confined State A D Barley Ice Conference London March 1997Kenny CasillaNo ratings yet

- Lesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-ObjectiveDocument8 pagesLesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-Objectivemister pogiNo ratings yet

- A Study of Cement-Pipe BondDocument5 pagesA Study of Cement-Pipe BondQutluq CaferzadeNo ratings yet

- Simulacro Sábado 13 de NoviembreDocument20 pagesSimulacro Sábado 13 de NoviembreNo HernaNo ratings yet

- The Science of Oil and Gas Well Construction: Senior EditorDocument2 pagesThe Science of Oil and Gas Well Construction: Senior EditorlakhanmukhtiarNo ratings yet

- Chapter No. 05 Casing and CementingDocument20 pagesChapter No. 05 Casing and CementingHassan AkbarNo ratings yet

- P12 Lewin FinalDocument12 pagesP12 Lewin Finaljulio aliaga villegasNo ratings yet

- Moore (1974) Swab and Surge Pressures (Drilling Practices Manual)Document12 pagesMoore (1974) Swab and Surge Pressures (Drilling Practices Manual)James BourneNo ratings yet

- Drilling FluidsDocument19 pagesDrilling FluidsBenjamin HaganNo ratings yet

- Schleiss External Water Pressure (E)Document10 pagesSchleiss External Water Pressure (E)Naresh ANo ratings yet

- FreeseDocument15 pagesFreeseBrandon HaleNo ratings yet

- Driven Piles OE4624Document63 pagesDriven Piles OE4624Suneel MatchalaNo ratings yet

- Wellheads and CasingDocument101 pagesWellheads and CasingnaefmubarakNo ratings yet

- Guia de Montaje Monitores MindrayDocument4 pagesGuia de Montaje Monitores MindrayLuis SanchezNo ratings yet

- OTC 13994 Brutus Export Pipelines - Improvement Opportunities and Challenges in Deepwater Pipeline InstallationDocument12 pagesOTC 13994 Brutus Export Pipelines - Improvement Opportunities and Challenges in Deepwater Pipeline InstallationBalan14No ratings yet

- Bin and Hopper Design LectureDocument73 pagesBin and Hopper Design LectureGanesh.MahendraNo ratings yet

- Well CompletionDocument82 pagesWell CompletionFlorian Ananias ByarugabaNo ratings yet

- SPE 146721-Ceramic Screens, An Innovative Milestone in Sand ControlDocument5 pagesSPE 146721-Ceramic Screens, An Innovative Milestone in Sand ControlamrNo ratings yet

- SPE/IADC 119296 Zonal Isolation Achieved in Kashagan Field Through Integrated ApproachDocument11 pagesSPE/IADC 119296 Zonal Isolation Achieved in Kashagan Field Through Integrated ApproachPAOLA ANDREA DUARTE PRADANo ratings yet

- Well Testing StudyDocument29 pagesWell Testing StudyDavid LutmangNo ratings yet

- Choi 2011Document14 pagesChoi 2011Anonymous wywR96jbNo ratings yet

- Cementing: Cement Cement Casing Shoe Casing StringDocument1 pageCementing: Cement Cement Casing Shoe Casing StringBakhtyar AhmedNo ratings yet

- SPE - Management of Well Integrity During Production OperationsDocument6 pagesSPE - Management of Well Integrity During Production OperationsdrexalvesNo ratings yet

- Abrasion - Erosion in Stilling BasinsDocument6 pagesAbrasion - Erosion in Stilling BasinsTansel YılmazNo ratings yet

- The Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosDocument12 pagesThe Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosVishal100% (1)

- Water HammerDocument9 pagesWater Hammeratamed32100% (1)

- The Application of The Reelwell Drilling MethodDocument7 pagesThe Application of The Reelwell Drilling Methodraj kumarNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- EPST Usermanual Autotune AST ZT V3.3.2 20170313 PDFDocument56 pagesEPST Usermanual Autotune AST ZT V3.3.2 20170313 PDFGreg CerrutiNo ratings yet

- ElectroProject Soft Torque Brochure PDFDocument4 pagesElectroProject Soft Torque Brochure PDFGreg CerrutiNo ratings yet

- EPST System Configurations 4.0 PDFDocument5 pagesEPST System Configurations 4.0 PDFGreg CerrutiNo ratings yet

- The Relationship of Thickening Time, Gel Strength, and Compressive Strength of Oilwell CementsDocument10 pagesThe Relationship of Thickening Time, Gel Strength, and Compressive Strength of Oilwell CementsGreg Cerruti100% (1)

- SPE/IADC-173037-MS Recent Advances in Soft Torque Rotary SystemsDocument12 pagesSPE/IADC-173037-MS Recent Advances in Soft Torque Rotary SystemsGreg CerrutiNo ratings yet

- SPE/IADC-194135-MS A Novel Mechanical Tool For Annular Cement VerificationDocument15 pagesSPE/IADC-194135-MS A Novel Mechanical Tool For Annular Cement VerificationGreg CerrutiNo ratings yet

- STR-M - Horizontal End Wall Hooks Construct Detail For 8-Inch CMU Special Shear WallsDocument1 pageSTR-M - Horizontal End Wall Hooks Construct Detail For 8-Inch CMU Special Shear WallsFWICIPNo ratings yet

- Manual Nonlinear Time History AnalysisDocument18 pagesManual Nonlinear Time History AnalysisSOO愛.No ratings yet

- Nstruction Sensor ST24Document5 pagesNstruction Sensor ST24Gabriel TanaseNo ratings yet

- Andhra University: List of Appearing SubjectsDocument1 pageAndhra University: List of Appearing SubjectsSri Sai Degree College BobbiliNo ratings yet

- Ows Calculations Revised 01Document3 pagesOws Calculations Revised 01Hilary AbaratuNo ratings yet

- Mathematics Project 1) Quadratic Equations in One Variable: Algebra Latin Square EquationDocument2 pagesMathematics Project 1) Quadratic Equations in One Variable: Algebra Latin Square Equationsachin DesardaNo ratings yet

- Class 5Document16 pagesClass 5Talha SarmadNo ratings yet

- Aquamid Aql40: Domo Engineering Plastics GMBHDocument3 pagesAquamid Aql40: Domo Engineering Plastics GMBHbobNo ratings yet

- Sample Diary Curriculum Map Subject: Mathematics Quarter: 2 Grade Level: 10 Topic: CirclesDocument5 pagesSample Diary Curriculum Map Subject: Mathematics Quarter: 2 Grade Level: 10 Topic: Circleschristen manatadNo ratings yet

- MCQ Questions and Solutions With ExplanationsDocument4 pagesMCQ Questions and Solutions With ExplanationsManishNo ratings yet

- Mini ProjectDocument7 pagesMini ProjectMolly KayeNo ratings yet

- Coefficient of Friction, Rolling Resistance, Air Resistance, AerodynamicsDocument1 pageCoefficient of Friction, Rolling Resistance, Air Resistance, AerodynamicsHasanNo ratings yet

- TutorDocument3 pagesTutorJake Role GusiNo ratings yet

- Madanapalle Institute of Technology & Science: Madanapalle (Ugc-Autonomous) WWW - Mits.ac - inDocument41 pagesMadanapalle Institute of Technology & Science: Madanapalle (Ugc-Autonomous) WWW - Mits.ac - inShanmuga KumarNo ratings yet

- Lucas Bulbs Stare ŽarniceDocument11 pagesLucas Bulbs Stare ŽarniceD. R. RajkichNo ratings yet

- TFG - TOMAS MARTINEZ - Espacios de Curvatura ConstanteDocument55 pagesTFG - TOMAS MARTINEZ - Espacios de Curvatura ConstanteJuaNNo ratings yet

- Motion in Straight LineDocument34 pagesMotion in Straight LineSubscriber SpNo ratings yet

- Djokoto 2019Document7 pagesDjokoto 2019Oleksii BalitskyiNo ratings yet

- Journal of Constructional Steel Research: Boshan Chen, Krishanu Roy, Asraf Uzzaman, Gary Raftery, James B.P. LimDocument22 pagesJournal of Constructional Steel Research: Boshan Chen, Krishanu Roy, Asraf Uzzaman, Gary Raftery, James B.P. LimLidya DewiNo ratings yet

- CAL-1-012-C-0011 Exhaust Stack 1 Foundation and Structure Rev ADocument24 pagesCAL-1-012-C-0011 Exhaust Stack 1 Foundation and Structure Rev AmutadiNo ratings yet

- BTECH Mechanical Engineering SyllabusDocument150 pagesBTECH Mechanical Engineering SyllabusCynicNo ratings yet

- Assignment 10Document2 pagesAssignment 10Kyle LuNo ratings yet

- 10.1 Material Properties, Development, and Splice LengthsDocument12 pages10.1 Material Properties, Development, and Splice LengthsjoshuaNo ratings yet

- Foundations of Robot Motion: 1.1 Degrees of Freedom of A Rigid BodyDocument4 pagesFoundations of Robot Motion: 1.1 Degrees of Freedom of A Rigid BodyBhushan RaneNo ratings yet

- CV (LATEST) UsamaDocument8 pagesCV (LATEST) UsamaSardar Usama YousafNo ratings yet

- 03.direct Shear and Punching Shear TestDocument4 pages03.direct Shear and Punching Shear TestKhizar SardarNo ratings yet

- Billirurbim ErmaDocument3 pagesBillirurbim ErmaomarNo ratings yet

- DBR CavityDocument20 pagesDBR CavitySabri TraderNo ratings yet