Professional Documents

Culture Documents

Accounting Fo Material

Accounting Fo Material

Uploaded by

zahid khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accounting Fo Material

Accounting Fo Material

Uploaded by

zahid khanCopyright:

Available Formats

Cost Associated with Material

Purchase Ordering

• Purchase price • Documents

• All cost incurred in them to present • Delivery

location and condition

Holding Stock-out (NOT HAVING INVENTORY)

• Rent • Opportunity cost

• Damaged • Goodwill

• Theft

• Obsolete (out of date)

• Expired (not usable)

We should keep these costs as low as possible

There is one technique that will make these cost lower

Especially the cost of Ordering and Holding

How much to order at a time?

Ordering Quantity

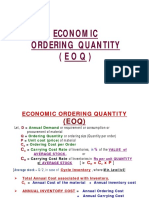

Economic Ordering Quantity (EOQ) (or compare)

The cost of holding and ordering are inversely related the decrease in one causes increase in another

For example the less you order the more orders you have to make (to decrease holding cost ordering

cost will increase)

The more units you order the less orders you have to make (to Decrease cost of ordering cost of holding

will increase)

The confusion is how many units to order exactly

Inversely Related : The increase of one cause the decrease in another

increase of cold causes decrease in ice-cream sold

Directly Related: The increase in one causes increase in another

Increase in heat cause increase in ice-cream sold

CH CO

Accounting fo Material Page 1

Given in exam

CO= Cost per order= $80/order

D= Annual demand = 2500

CH= Cost of holding/unit/year= $15/unit/year

((2*80*2500)/15))= 163 meaning that we should order 163 units

every time

2500/163=15.3374 orders

Accounting fo Material Page 2

Co=$10

Ch= $.10*12=$1.2/unit/year

D=5400unit

((2*10*5400)/1.2))=300

Total Cost of Holding TCH 200

Total cost of holding ( TCH)

Average inventory *CH

Average Inventory

Average inventory= OQ/2 200/2=100 units

100*$1.2=$120

300/2=150

150*$1.2=$180 TCH Total cost of holding (TCO)

Orders

Total Cost of Order TCO 5400/200=27 orders

Orders * CO 27*$10=$270.

Orders = D/OQ

$120+$270=$390

5400/300=18 orders

360

18*$10=$180 TCO

TCH 360/2*$1.2=$216

TCO 5400/360*$10=$150

Total cost 216+150=366

180+180=360

Accounting fo Material Page 3

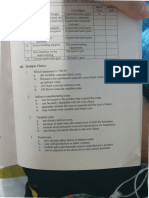

(B)

((2*32*1800)/4.5))=160

Assume there was no bulk discount

160 300

TCH 160/2*$4.5=$360 TCH 300/2*$4.5=$675

TCO 1800/160*$32=$360.00 TCO 1800/300*$32=$192

Purchase 1800*$25=$45000 Purchase 1800*$25=$45000.00

Total $360+$360+$45000=$45720 Total $675+192+$45000=$45867

Now let's consider discount

160

TCH 160/2*$4.5=$360 TCH 300/2*$4.5*98%=$661.5

TCO 1800/160*$32=$360.00 TCO 1800/300*$32=$192

Purchase 1800*$25=$45000 Purchase 1800*$25*98%=$44100

Total $360+$360+$45000=$45720 Total 661.5+192+44100=44953.5

45720-44953.5=766.5 less with bulk discount

We should always go with the EOQ but if there is change in purchases price or any

other cost because of quantity then we have to compare which gives us the lowest

cost

Accounting fo Material Page 4

When to order?

Reorder Level

The point in inventory level where the order is placed ( To avoid Stock out)

Why does stock out happen?

Main Reasons

1 Demand is more than expected.

2 Delivery of goods arrived late.

Reorder Level = Maximum Demand X Maximum Lead Time

(12+18)/2=15

95*18=1,710 ( C )

When inventory decreases to this level we should place an order

If inventory at any point is more than 2860 then it is not

good management

How much is too much inventory?

Maximum Inventory

This is the high level that inventory should not cross

Why inventory would be too much?

Reason

1 Demand was minimum

2 Order arrived earliest

Reorder level-(Min demand* Min Time)+OQ

1710 -(50 *12) +1750=2860

Accounting fo Material Page 5

How much is too little?

Minimum Level

This is the low level that inventory shouldn't decrease from.

If It does find contingencies( Alternative).

Reorder Level -(Average use x Average time)

1710 -(75 * 15)=585

How much to order : Ordering Quantity 1750

When to order: Reorder Level 1710

How much is too much : Maximum Level 2860

How much is too little : Minimum Level 585

2860

1710

585

Accounting fo Material Page 6

(A)

Physical Inventory= Free inventory+ Customer orders - Supplier orders

physical

Free Inventory= Inventory available for sales

Physical Inventory - Customer orders + Suppliers orders = Free Inventory

1750 -16250 + 27500 = 13000

Physical Inventory: Inventory physically available in warehouse

Free inventory+ Customer orders - Supplier orders = Physical Inventory

13000 +16250 -27500 = 1750 (A )

On Customer orders: Inventory that we have sold but not yet taken by customers

Physical Inventory + Supplier Orders - Free inventory = Customer orders

1750 +27500 -13000 = 16250

On Supplier Order: Inventory bought but not yet arrived (on the way )

Customer orders - Physical Inventory +Free inventory =Supplier Orders

16250 -1750 +13000 = 27500

Accounting fo Material Page 7

Safety/Buffer Stock: Inventory kept in separate location for emergencies not used regularly

(D)

( D)

15*10%=1.5

((2*20*12500)/1.5))=577 ( A)

When CO reduce= OQ reduce= Avg inventory reduce= Ch reduce

(D)

(10+15)/2=12.5

(C )

Reorder Level

Max use * Max time 14000

520*15=7,800

7800

Maximum Level

Reorder Level-(Min Use*Min Time) + OQ 2800

7800-(180*10)+8000=14000

Minimum Level

Reorder Level-(Avg Use*Avg Time)

7800-(400*12.5)=2800

Accounting fo Material Page 8

500+(2000/2)=1500 average inventory

1500*$2=$3000 ( C)

.10*12=1.2

((2*10*5400)/1.2)=300 (D )

Buffer stock+(OQ/2)= Average Inventory

Reverse the formula

Average Inventory *CH

?+(6000/2)=3400

3400-3000=400 (A)

To prove

400+(6000/2)=3400

In question 6.12

?+(2000/2)=1500 average inventory

1500-1000=500

Accounting fo Material Page 9

((2*100*1225)/8)=175 (A )

Re-order Level = 130*26=3,380

(20+26)/2=23 Max level

Reorder Level-(Min use* min time) +OQ

3380 -(60 *20 )+4000=6180 ( B )

Min Level

3380-(23*100)=1080

1250000/.00125=31623 ( C )

(2*125*5000)/.0025*(1-5000/10000))

( C)

Accounting fo Material Page 10

R=4000

D=2000

Co=50

Ch=.001

((2*50*2000)/.001*(1-2000/4000)) 200000/.0005 =20000

R=4000 20000/4000=5

D=2000

Co=$50

Ch=$.001

1) 4000-2000=2000

2) 2000+4000-2000=4000

3) 4000+4000-2000=6000

4) 6000+4000-2000=8000

5) 8000+4000-2000=10000

6) 10000-2000=8000

7) 8000-2000=6000

8) 6000-2000=4000

9) 4000-2000=2000

10) 2000-2000=0

11) 4000-2000=2000

12) 2000+4000-2000=4000

13) 4000+4000-2000=6000

14) 6000+4000-2000=8000

15) 8000+4000-2000=10000

16) 10000-2000=8000

17) 8000-2000=6000

18) 6000-2000=4000

19) 4000-2000=2000

20) 2000-2000=0

Accounting fo Material Page 11

Documents

Material Requisition Note : To request materials (mostly from store)

Material Transfer Note : To evidence transfer of material

Purchase Requisition Note : To request purchase of material (mostly to purchasing/procurement department )

Request for Quotation (RFQ) : Asking suppliers to send their quotations

Quotation: A price list

Estimate: An estimate of total cost

Purchase Order : To request sales (to supplier)

for customer

Sales Order: To request sales (from customer)

for supplier

Goods Delivery Note (GDN): A confirmation that goods have been delivered

Goods Received Note (GRN): A confirmation that goods have been Received

Invoice/Bill: Shows how much payment has to be made for a transactions (for credit sales)

Sales Receipt: shows that payment for a sale has been received ( for cash sales)

Remittance Advice: States reasons for payments

Credit Note/(memo): It shows that receivables has been credited (decrease) Dr Sales Cr TR

Debit Note/(memo): It shows that payables has been debited (decrease) DR TP Cr Purchases

Accounting fo Material Page 12

Choose

between

them

Accounting fo Material Page 13

Accounting fo Material Page 14

Find reorder level

Minimum level

Maximum level

Accounting fo Material Page 15

You might also like

- CH18 Test Bank Problems1Document3 pagesCH18 Test Bank Problems1Vinzon de Guzman100% (1)

- Accenture Building Shared Service CentersDocument13 pagesAccenture Building Shared Service Centersselsuj100% (2)

- PTC FlexPLMDocument13 pagesPTC FlexPLMPrachi AgrawalNo ratings yet

- Accounting For MaterialDocument7 pagesAccounting For Materialzahid khanNo ratings yet

- Inventory ModelsDocument38 pagesInventory ModelsAngela MenesesNo ratings yet

- MSC 705 Lecture 10Document19 pagesMSC 705 Lecture 10nusratpte07No ratings yet

- Assignment #3 InventoryDocument13 pagesAssignment #3 InventoryAnkit SainiNo ratings yet

- Inventory Control ModelDocument11 pagesInventory Control ModelMd Aulad Hossain100% (1)

- Inventory Management (2021)Document8 pagesInventory Management (2021)JustyNo ratings yet

- Inventory ValuationDocument4 pagesInventory ValuationMary AmoNo ratings yet

- SOLUTION#01:: WorkingDocument9 pagesSOLUTION#01:: Workingsameed iqbalNo ratings yet

- Inventory Management A&BDocument17 pagesInventory Management A&BAb PiousNo ratings yet

- Material Assignment PDFDocument21 pagesMaterial Assignment PDFjoeyNo ratings yet

- PPC Unit V EOQ Problems - MK 01Document3 pagesPPC Unit V EOQ Problems - MK 01Kannan Muthusamy100% (3)

- InventorymDocument7 pagesInventorymstudentofmmNo ratings yet

- 1 Eoq PDFDocument12 pages1 Eoq PDFLyber Pereira100% (1)

- Fallsem2017-18 Bmt2013 TH Sjt601 Vl2017181002989 Reference Material I Course Matrl-3 SCM JPM F Sem 2017-18Document39 pagesFallsem2017-18 Bmt2013 TH Sjt601 Vl2017181002989 Reference Material I Course Matrl-3 SCM JPM F Sem 2017-18Pulkit JainNo ratings yet

- Pertemuan 2 InventoryDocument33 pagesPertemuan 2 InventoryYulia Pratama Umbu DonguNo ratings yet

- Chapter 8 MowenDocument25 pagesChapter 8 MowenRosamae PialaneNo ratings yet

- Dodrio Doorknob Design CompanyDocument8 pagesDodrio Doorknob Design Companyloyd aradaNo ratings yet

- Ma 2 Group 6 Chap 2Document6 pagesMa 2 Group 6 Chap 2An Nguyen Thai HongNo ratings yet

- Unit 2Document25 pagesUnit 2din zahurNo ratings yet

- SOLUTIONS To Pricing DecisionDocument4 pagesSOLUTIONS To Pricing DecisioncookiesNo ratings yet

- 9 Stock ValuationDocument15 pages9 Stock ValuationDayaan ANo ratings yet

- Final ExamDocument9 pagesFinal ExamWaizin KyawNo ratings yet

- Problem 8-35 Hansen Mowen Cornerstone of Managerial AccountingDocument4 pagesProblem 8-35 Hansen Mowen Cornerstone of Managerial Accountingwiwit_karyantiNo ratings yet

- Purchase Cost 480,000.00Document9 pagesPurchase Cost 480,000.00Charisse Aro YcongNo ratings yet

- Inventory Model: by The End of This Topic, You Should Be Able ToDocument14 pagesInventory Model: by The End of This Topic, You Should Be Able ToHaider Abdul QadirNo ratings yet

- Cost Accounting Assignment - VivekDocument49 pagesCost Accounting Assignment - VivekJackson JoseNo ratings yet

- Ex Mi1Document8 pagesEx Mi1220h0367No ratings yet

- Module 4Document42 pagesModule 4Gagan Deep SinghNo ratings yet

- Units Remaining in Ending InventoryDocument4 pagesUnits Remaining in Ending InventoryQuynh Cao PhuongNo ratings yet

- Economic Order QuantityDocument4 pagesEconomic Order QuantityhakikNo ratings yet

- Basic EOQ Model: Trial and Error MethodDocument7 pagesBasic EOQ Model: Trial and Error MethodROCKYNo ratings yet

- Tugas Chapter 8Document8 pagesTugas Chapter 8wiwit_karyantiNo ratings yet

- Problem CH 7 Hansen Mowen Cornerstone of Managerial AccountingDocument8 pagesProblem CH 7 Hansen Mowen Cornerstone of Managerial Accountingwiwit_karyantiNo ratings yet

- Logistics - Case Study Chapter 8 - Question 4Document3 pagesLogistics - Case Study Chapter 8 - Question 4Phan Thị Hương TrâmNo ratings yet

- Quantity DiscountDocument22 pagesQuantity Discountkevin royNo ratings yet

- L&SCM Review Final SolutionDocument9 pagesL&SCM Review Final SolutionmytinhszNo ratings yet

- Industrial Engineering by S K Mondal.0003Document70 pagesIndustrial Engineering by S K Mondal.0003tirupatiNo ratings yet

- (GROUP 1) Logistics-Inventory-Case 3Document4 pages(GROUP 1) Logistics-Inventory-Case 3K59 Huynh Kim NganNo ratings yet

- 03b Inventory Management - EOQ With Discount, Reorder PointDocument13 pages03b Inventory Management - EOQ With Discount, Reorder PointSophia Bianca DaytoNo ratings yet

- Managerial Accounting 6th Edition Jiambalvo Solutions ManualDocument24 pagesManagerial Accounting 6th Edition Jiambalvo Solutions Manualgenevievetruong9ajpr100% (30)

- EOQ and ABC Analysis: Economic Order QuantityDocument21 pagesEOQ and ABC Analysis: Economic Order QuantityHitesh Kumar SharmaNo ratings yet

- Accounting 2022 U2 P1Document12 pagesAccounting 2022 U2 P1Abby GailNo ratings yet

- Salazar TP Cost Acct GDocument3 pagesSalazar TP Cost Acct GDong RoselloNo ratings yet

- BruhDocument15 pagesBruhspaghettisaucerersNo ratings yet

- P1 Solution CMA JUNE 2020Document5 pagesP1 Solution CMA JUNE 2020Awal ShekNo ratings yet

- EOQ Model: Ken HomaDocument18 pagesEOQ Model: Ken HomatohemaNo ratings yet

- Answer - Case 1Document10 pagesAnswer - Case 1EVI MARIA SIBUEANo ratings yet

- Inventory C3Document22 pagesInventory C3quynhtrang01.lscNo ratings yet

- University of Finance and MarketingDocument8 pagesUniversity of Finance and MarketingQuế Phương NguyễnNo ratings yet

- Inventory Systems For Independent DemandDocument4 pagesInventory Systems For Independent DemandCharice Anne VillamarinNo ratings yet

- Acct 260 CHAPTER 8Document25 pagesAcct 260 CHAPTER 8John Guy0% (1)

- Extra+question+ Lina+Ballerina +memoDocument2 pagesExtra+question+ Lina+Ballerina +memondzalo050822No ratings yet

- Economic Order Quantity (EOQ)Document18 pagesEconomic Order Quantity (EOQ)DHARMENDRA SHAHNo ratings yet

- She 3Document7 pagesShe 3cynthia bansilNo ratings yet

- 5 AprilDocument6 pages5 AprilShiza MahamNo ratings yet

- Visual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsFrom EverandVisual Financial Accounting for You: Greatly Modified Chess Positions as Financial and Accounting ConceptsNo ratings yet

- Consumer Behavior Chap 1&2Document16 pagesConsumer Behavior Chap 1&2Ilma GirmaNo ratings yet

- Evaluating A Company's Website (Reading Materials)Document18 pagesEvaluating A Company's Website (Reading Materials)Hằng PhạmNo ratings yet

- Lean Manufacturing, Just in Time and Kanban: Case Study of Toyota Production System (TPS)Document5 pagesLean Manufacturing, Just in Time and Kanban: Case Study of Toyota Production System (TPS)MASHIUR RAHMANNo ratings yet

- MM-ELEC101: Brand ManagementDocument4 pagesMM-ELEC101: Brand ManagementJean Pearl PazNo ratings yet

- KSS SlidesDocument15 pagesKSS SlidesNimra ShahzadNo ratings yet

- BRC Packaging System Start Up Guide Sample 2020Document14 pagesBRC Packaging System Start Up Guide Sample 2020jai soniNo ratings yet

- Análisis de La Disposición de Los Desechos Sólidos y Generacion de Biogas en El Relleno Sanitario de Ambato, EcuadorDocument19 pagesAnálisis de La Disposición de Los Desechos Sólidos y Generacion de Biogas en El Relleno Sanitario de Ambato, EcuadorMARCELA RAMOS PALLARESNo ratings yet

- Software Engineering - NotesDocument172 pagesSoftware Engineering - NotesJASPER WESSLY100% (4)

- Green Supply Chain Pulp Dan Kertas: Perancangan Model Pengukuran KinerjaDocument10 pagesGreen Supply Chain Pulp Dan Kertas: Perancangan Model Pengukuran KinerjaMuhammad ZulfaNo ratings yet

- Unit 5 - Metals and AlloysDocument6 pagesUnit 5 - Metals and AlloysDanielle AdelanteNo ratings yet

- Mgt211 Quiz File SOLVEDDocument30 pagesMgt211 Quiz File SOLVEDAman KhanNo ratings yet

- BMKT6111 Brand and Marketing A: Rosebank CollegeDocument48 pagesBMKT6111 Brand and Marketing A: Rosebank CollegeNtokozo Hakeem MalgasNo ratings yet

- Sales Management & Business Development Group 3Document3 pagesSales Management & Business Development Group 3abhishek bhOoTnANo ratings yet

- Krispy Kreme IFE and EFEDocument2 pagesKrispy Kreme IFE and EFEJayanara May S. CapulongNo ratings yet

- Etom Process To Manitor and Corelat Iptv Qos in ImsDocument20 pagesEtom Process To Manitor and Corelat Iptv Qos in ImsijngnNo ratings yet

- Lesson Six Price PromotionsDocument17 pagesLesson Six Price Promotionsyng guesNo ratings yet

- Room Clean : Room The Thesa FDocument6 pagesRoom Clean : Room The Thesa FDRLNNo ratings yet

- XII Ch12 Linear Programming Remesh HssliveDocument24 pagesXII Ch12 Linear Programming Remesh HssliveRanit MukherjeeNo ratings yet

- SAE1045Document2 pagesSAE1045novale.basura2906100% (1)

- Marketing Planning - Strategy and Tactics For The Renault CLIO Simon ANTOINEDocument14 pagesMarketing Planning - Strategy and Tactics For The Renault CLIO Simon ANTOINEsimon.antoine793No ratings yet

- Tib BW ConceptsDocument105 pagesTib BW Conceptsmoliveira_rjNo ratings yet

- Procedure - PreservationDocument4 pagesProcedure - PreservationJeff DrewNo ratings yet

- PSGM 1 FinalDocument70 pagesPSGM 1 FinalpriyadhimamNo ratings yet

- Quality of SocksDocument13 pagesQuality of SocksHamad HRNo ratings yet

- Contents 01 A Leader in Process Automation 09 Inplant Total Solution 13 Typical Projects 19 Corporate Social Responsibility 20 Where To Find UsDocument12 pagesContents 01 A Leader in Process Automation 09 Inplant Total Solution 13 Typical Projects 19 Corporate Social Responsibility 20 Where To Find UsNauman ZafarNo ratings yet

- Social CRM ThesisDocument7 pagesSocial CRM Thesispamelacalusonewark100% (2)

- Defect Analysis On Production of Bolt With Nut Case of EthiopianDocument22 pagesDefect Analysis On Production of Bolt With Nut Case of EthiopianUrgie KuNo ratings yet

- Meucci Digital, Inc.: Author Date To Summarize Employee Information For The HR Department at Meucci Digital, IncDocument7 pagesMeucci Digital, Inc.: Author Date To Summarize Employee Information For The HR Department at Meucci Digital, IncSachi JoshiNo ratings yet