Professional Documents

Culture Documents

Coco Panels PDF

Coco Panels PDF

Uploaded by

NEHA AGARWALOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coco Panels PDF

Coco Panels PDF

Uploaded by

NEHA AGARWALCopyright:

Available Formats

COCO PANELS Building Finishes BCT - V

Specifications of the finish

Governing factors behind the selection of a particular finish

Sub-categories/Types

These panels offer a 3D effect along with a warm and exotic

Natural Grain, Espresso Grain, White Patina, Grey Bliss, Antique look and feel.

Brown and Natural Bliss.

Brief Manufacturing Process

Image/Sketch

Seasoned pieces of bamboo and coconut shells are cut into per-

fectly measured geometrical shapes or patterns that are then

Quality Aspects

glued together using some solution (blackish brown in colour)

into larger plywood (6-8mm)panels in a tile format. A variety of Finishing of laying of bamboo and cocunut pieces ensures its

colours and textures are made possible by taking pieces from both quality.

Natural grain Installation

the inside and the outside of the shell and then painting or dyeing

the pieces. Maintenance Aspects

Properties Melamine Polishing to increase its durability and life.

Water absorption capacity max. is 30 wt % of coconut shell parti-

cle. Maximum compressive strength investigated was 88.0 MPa.

Available Sizes

Details/Junctions/Joineries

4FT X 2FT Thickness 12mm. Sizes are customizable as per custom- Joining of two panels is done through adhesives

er’s needs but that increases the cost. This size is convenient When using grout leave a spacing gap of 3mm between the tiles

to manufacture and is not too big because highlight is done over for the grout.

small portion, not very big area. Its processsing is costly, so pro-

Espresso grain If you are not using grout leave a spacing gap of 1 - 2mm Living room wall cladding

ducing bigger sizes won’t be affordable.

Other specifications or details if any

Applications Only water-based lacquers, adhesives and paints are used in

Used in interiors because it deterioates by water. These panels may not

be suitable for every application. They are best applied in a dry, venti-

Usage of the material from past till date

lated area.

Used on walls, door panels (mostly main gates), windows as a high- Not a very old material, new to market. Image/Sketch

lighter between veneer or laminates, aesthetic highlight in furniture. Came into market roughly 10 -12 years back.

Installation

Applied using adhesives (same as veneer and alminates). Recognition of the material after application

Nailed sometimes at some places for extra stability. White patina Background wall cladding

Looks like a wooden mosiac

Rates

200- 250/- per sq. ft.

1500-2500/- per sheet (4ft x 2ft)

Thickness 12mm Image/Sketch

Advantages/Disadvantages of using the finish

Advantages: Eco-friendly wall coverings, each panel is lightweight,

durable and easy to install. Disadvantages: Bamboo and coconut References

pieces sometimes fall out due to heat, and it deteriorates due to Grey Bliss https://materialdistrict.com/material/cocomosaic-coco-pan-

water.

els/

http://cocomosaic.com/wp-content/uploads/2018/04/

MG_0968_copy_grande.jpg

Samiksha Jain (18bar09), Neha Agarwal (18bar22), Anushka Goyal (18bar43), Radhika Atre(19bar207) IAPNU

You might also like

- Provincial Finals Intermediate: Pack #4Document9 pagesProvincial Finals Intermediate: Pack #4lin xu100% (1)

- Carpentry Canadian 3rd Edition Vogt Solutions ManualDocument11 pagesCarpentry Canadian 3rd Edition Vogt Solutions Manualalisonfernandezmerzigfkap100% (12)

- BS en Iso 11064-3-2000 - (2019-10-09 - 04-01-15 PM)Document48 pagesBS en Iso 11064-3-2000 - (2019-10-09 - 04-01-15 PM)SHAILENDRA100% (4)

- Engineering Economy Lecture4Document22 pagesEngineering Economy Lecture4Jaed Caraig0% (2)

- Exterior Finishes FinalDocument14 pagesExterior Finishes FinalAshish Marwha0% (1)

- Garden Mosaics: 19 Beautiful Projects to Make for Your GardenFrom EverandGarden Mosaics: 19 Beautiful Projects to Make for Your GardenRating: 5 out of 5 stars5/5 (2)

- Cubo 18Document21 pagesCubo 18Dago BiltonNo ratings yet

- Timber Rubberwood Sheets: Brief Manufacturing ProcessDocument5 pagesTimber Rubberwood Sheets: Brief Manufacturing ProcessNEHA AGARWALNo ratings yet

- Material Study: Wood Substitutes AND Applied Wall Finishes (STAGE 1)Document24 pagesMaterial Study: Wood Substitutes AND Applied Wall Finishes (STAGE 1)ABIRAMI K ANo ratings yet

- Madecentro Wood Catalog 2020Document36 pagesMadecentro Wood Catalog 2020ScribdTranslationsNo ratings yet

- Vetotouch Effects - Decorative Coating Brochure 2017 Website - en - 52Document4 pagesVetotouch Effects - Decorative Coating Brochure 2017 Website - en - 52SHAIK ASIMUDDINNo ratings yet

- 71bd00 Betopan Brosur TRDocument2 pages71bd00 Betopan Brosur TRJulius MuhimboNo ratings yet

- Building Materials and Assemblies: Finishes, Products and ComponentsDocument12 pagesBuilding Materials and Assemblies: Finishes, Products and ComponentsAlskduiNo ratings yet

- SikaCeram - 100 Basic PDFDocument3 pagesSikaCeram - 100 Basic PDFMoatz HamedNo ratings yet

- Building Materials To Be Used For Interior and ExteriorDocument11 pagesBuilding Materials To Be Used For Interior and Exteriorchiefassassin08No ratings yet

- Timber Product Stage 1Document68 pagesTimber Product Stage 1Ayush GuptaNo ratings yet

- BC NotesDocument78 pagesBC NotesKOMAKECH RONNIENo ratings yet

- VeneersDocument23 pagesVeneerssujana reddyNo ratings yet

- Cemcrete Wall Overview BrochureDocument19 pagesCemcrete Wall Overview BrochureJoão Athayde e MeloNo ratings yet

- 2021 Decoria Catalog KorDocument18 pages2021 Decoria Catalog Koriwcksa22No ratings yet

- Internal Cladding Installation GuidelinesDocument7 pagesInternal Cladding Installation GuidelinesShajit KumarNo ratings yet

- Market SurveyDocument3 pagesMarket SurveyreetNo ratings yet

- نموذج لمراحل حساب الكميات والمواصفاتDocument57 pagesنموذج لمراحل حساب الكميات والمواصفاتKhawla EbrhimNo ratings yet

- Wood and Its DerivativesDocument35 pagesWood and Its DerivativesA 04 Ankit SharmaNo ratings yet

- Tile Installation Products Series Part 1Document4 pagesTile Installation Products Series Part 1Malak HindiNo ratings yet

- Wall Treatments / FinishesDocument54 pagesWall Treatments / FinishesNirmal Kurnelius MarandiNo ratings yet

- Bamboo WoodDocument8 pagesBamboo WoodPerez CarlosNo ratings yet

- Bay15 16 PDFDocument23 pagesBay15 16 PDFBob CalebNo ratings yet

- 18nov21 ModularKitchenNotesDocument6 pages18nov21 ModularKitchenNotesNitesh BhosaleNo ratings yet

- Types of Modular KitchenDocument6 pagesTypes of Modular KitchenNitesh BhosaleNo ratings yet

- Bison: Think of An Application The Answer IsDocument2 pagesBison: Think of An Application The Answer IsVSMS8678No ratings yet

- Bison: Think of An Application The Answer IsDocument2 pagesBison: Think of An Application The Answer IsVSMS8678No ratings yet

- E-CATALOG TITANCOREDocument10 pagesE-CATALOG TITANCORESapto adi NugrohoNo ratings yet

- Particleboard Lec. 4Document10 pagesParticleboard Lec. 4aree.adelNo ratings yet

- Ficha Tecnica Arauco Melamina Ing 20abr 22Document4 pagesFicha Tecnica Arauco Melamina Ing 20abr 22Rosa Marie GreenNo ratings yet

- Quick Stone Catalogue 2014Document6 pagesQuick Stone Catalogue 2014api-255721233No ratings yet

- Reviewer For FinalsDocument10 pagesReviewer For FinalsKenneth CanoNo ratings yet

- Types of Modular KitchenDocument6 pagesTypes of Modular KitchenNitesh BhosaleNo ratings yet

- Mortar Mix - Coloured DatasheetDocument3 pagesMortar Mix - Coloured DatasheetHIMANSHU SRIVASTAVANo ratings yet

- Wall PanelDocument6 pagesWall PanelRuel ElidoNo ratings yet

- MDF (Medium Density Fibreboard) Made by A Process Which Glues WoodDocument3 pagesMDF (Medium Density Fibreboard) Made by A Process Which Glues WoodJensenNo ratings yet

- FSC Bamboo Composite Products: WWW - Eva-Last - Co.zaDocument8 pagesFSC Bamboo Composite Products: WWW - Eva-Last - Co.zaBrandon Jay HeukelmanNo ratings yet

- Wall Finishes: Building MaterialsDocument29 pagesWall Finishes: Building Materialspallavi maheshwariNo ratings yet

- Interlock Pages en 24Document28 pagesInterlock Pages en 24ybc29533No ratings yet

- Floor FinishesDocument68 pagesFloor FinishesMian Afzaal 72No ratings yet

- 04 Building BoardsDocument25 pages04 Building BoardsArchitect ArtistaNo ratings yet

- Disadvantages of WPC BoardDocument32 pagesDisadvantages of WPC BoardvidhiNo ratings yet

- Bison Panel Cement Bonded Particle BoardDocument16 pagesBison Panel Cement Bonded Particle BoardafifkadriNo ratings yet

- Materials and Finishes PDFDocument65 pagesMaterials and Finishes PDFSunilNo ratings yet

- The Advantages and Disadvantages of Particle BoardDocument2 pagesThe Advantages and Disadvantages of Particle Boardpoosa annupriyaNo ratings yet

- BMC Assignment S5 (HARDBOARD&GLULAM)Document19 pagesBMC Assignment S5 (HARDBOARD&GLULAM)Ebin JoyNo ratings yet

- Veneer, Particle Board, Plywood, Fiber BoardDocument23 pagesVeneer, Particle Board, Plywood, Fiber BoardRatnesh PatelNo ratings yet

- Eco-Boards: A Green Building Material From Residues and WasteDocument26 pagesEco-Boards: A Green Building Material From Residues and WasteJaybesNo ratings yet

- BCT Wooden PanellingDocument14 pagesBCT Wooden PanellingDevershi BisaniNo ratings yet

- Panelling RakDocument30 pagesPanelling Raksameen rizviNo ratings yet

- 3m VHB Selection GuideDocument4 pages3m VHB Selection GuideamenstoNo ratings yet

- Material Case StudyDocument9 pagesMaterial Case StudyLol FunnyNo ratings yet

- Resene Acrylic Undercoat: General PurposeDocument2 pagesResene Acrylic Undercoat: General PurposeAlexNo ratings yet

- FinishesDocument4 pagesFinishesFaye SerranoNo ratings yet

- Bharati Vidyapeeth College of Architecture: Interior Design IDocument24 pagesBharati Vidyapeeth College of Architecture: Interior Design IGlory ChhajedNo ratings yet

- Cemcrete Mortar Mix BrochureDocument3 pagesCemcrete Mortar Mix BrochureHIMANSHU SRIVASTAVANo ratings yet

- FlooringDocument57 pagesFlooringGayatri SharmaNo ratings yet

- Timber m2Document47 pagesTimber m2Ankur SharmaNo ratings yet

- 30.9.2020laminate Floring FinalDocument8 pages30.9.2020laminate Floring FinalNEHA AGARWALNo ratings yet

- Timber Rubberwood Sheets: Brief Manufacturing Process 1. Sawing 1.1 1.2Document5 pagesTimber Rubberwood Sheets: Brief Manufacturing Process 1. Sawing 1.1 1.2NEHA AGARWALNo ratings yet

- Timber Rubberwood Sheets: Brief Manufacturing ProcessDocument5 pagesTimber Rubberwood Sheets: Brief Manufacturing ProcessNEHA AGARWALNo ratings yet

- 18bar022 - PLUMBING - NEHA AGARWALDocument2 pages18bar022 - PLUMBING - NEHA AGARWALNEHA AGARWALNo ratings yet

- 18bar022 - Extra Low Voltage System - Neha AgarwalDocument2 pages18bar022 - Extra Low Voltage System - Neha AgarwalNEHA AGARWALNo ratings yet

- 11.2 - Introduction To Particle Physics - Physics LibreTexts PDFDocument4 pages11.2 - Introduction To Particle Physics - Physics LibreTexts PDFpappuNo ratings yet

- Road Signage and MarkingsDocument8 pagesRoad Signage and MarkingsNimako MichaelNo ratings yet

- Power TransformersDocument4 pagesPower TransformerssabrahimaNo ratings yet

- Ecube 9Document13 pagesEcube 9Ishaan JindalNo ratings yet

- GrundfosDocument16 pagesGrundfosKarthick SarathyNo ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- Fundamentals of Modern Optics: LecturerDocument5 pagesFundamentals of Modern Optics: LecturervulkkanNo ratings yet

- Radial Fan Conical Vs Parallel Impeller Casing AnalysisDocument10 pagesRadial Fan Conical Vs Parallel Impeller Casing AnalysisvirgilioNo ratings yet

- DC SimpDocument3 pagesDC SimpNikhil HiremathNo ratings yet

- Pert and CPMDocument11 pagesPert and CPMbotchNo ratings yet

- TO Bus Rapid Transit (BRT) System: Hemant TiwariDocument48 pagesTO Bus Rapid Transit (BRT) System: Hemant TiwariHemant Tiwari100% (2)

- Direct and Indirect Tax:: GST IntroductionDocument12 pagesDirect and Indirect Tax:: GST IntroductionDdaksh KumarNo ratings yet

- MNRE 29 Jun 2021 PPA ExtensionDocument1 pageMNRE 29 Jun 2021 PPA Extensionharsha kunturNo ratings yet

- Corrosion Probe TypeDocument26 pagesCorrosion Probe TypeFirman MuttaqinNo ratings yet

- The Pentagon Bio-Weapons - Dilyana - BGDocument34 pagesThe Pentagon Bio-Weapons - Dilyana - BGOn The PathNo ratings yet

- ChirdsDocument5 pagesChirdsWise FidelityNo ratings yet

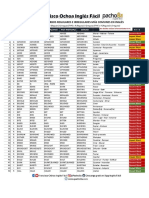

- Listado de Verbos Regulares E Irregulares Más Comunes en InglésDocument8 pagesListado de Verbos Regulares E Irregulares Más Comunes en InglésLogo DesingNo ratings yet

- Wheel of The YearDocument7 pagesWheel of The YearFabricioFernandezNo ratings yet

- María Herrera-Sobek - The Mexican Corrido - A Feminist Analysis-Indiana University Press (1990)Document164 pagesMaría Herrera-Sobek - The Mexican Corrido - A Feminist Analysis-Indiana University Press (1990)juanosuarez9009No ratings yet

- JKR Geotechnical SpecificationDocument9 pagesJKR Geotechnical SpecificationSousei No Keroberos100% (1)

- Designing A Bionic ArmDocument5 pagesDesigning A Bionic ArmSanrasniNo ratings yet

- Affordability and Subsidies in Public Urban Transport - World BankDocument53 pagesAffordability and Subsidies in Public Urban Transport - World Bankchequeado100% (2)

- Fcnyabwihntend4 PDFDocument11 pagesFcnyabwihntend4 PDFFasihNawazNo ratings yet

- ECO #10 - 6th Dec, 2012Document2 pagesECO #10 - 6th Dec, 2012adoptnegotiatorNo ratings yet

- Dwnload Full Entrepreneurship Successfully Launching New Ventures Ma 4th Edition Bruce Test Bank PDFDocument36 pagesDwnload Full Entrepreneurship Successfully Launching New Ventures Ma 4th Edition Bruce Test Bank PDFferiacassant100% (14)

- Production For Consultants v34 - Upload VersionDocument270 pagesProduction For Consultants v34 - Upload VersionsubquangaddNo ratings yet