Professional Documents

Culture Documents

Transcritical CO2 Booster System Brochure PDF

Transcritical CO2 Booster System Brochure PDF

Uploaded by

Vasti Diaz AguilarCopyright:

Available Formats

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- IWCF Equipment Sample Questions (Surface Stack)Document6 pagesIWCF Equipment Sample Questions (Surface Stack)Ogbadibo100% (2)

- T-680R, T-880R, T-1080R, T-680S, T-880S, T-1080S With Premium SR-3 HMI 55667-1-OPDocument132 pagesT-680R, T-880R, T-1080R, T-680S, T-880S, T-1080S With Premium SR-3 HMI 55667-1-OPJuan Miguel Marin Quintero100% (2)

- Installation Manual: Truck Edition (TSA, ESA and AP)Document72 pagesInstallation Manual: Truck Edition (TSA, ESA and AP)Vasti Diaz Aguilar100% (1)

- Frick Compressor Oils: 160-802 SPC (MAR 2009)Document4 pagesFrick Compressor Oils: 160-802 SPC (MAR 2009)Vasti Diaz AguilarNo ratings yet

- Fluor.: Specification-Upstream Piping Classification - Line Class 300 00-Common Overall-All AreasDocument35 pagesFluor.: Specification-Upstream Piping Classification - Line Class 300 00-Common Overall-All AreashapinefeNo ratings yet

- Range: Keeping The World FlowingDocument8 pagesRange: Keeping The World FlowingPiermarco ContrerasNo ratings yet

- RTAB 207 - 212 HA: Design To Perform, Built To LastDocument32 pagesRTAB 207 - 212 HA: Design To Perform, Built To LastloloNo ratings yet

- Go RangeDocument8 pagesGo RangePedro Vives MelendezNo ratings yet

- 28990-Turbinebypass Prds PDFDocument12 pages28990-Turbinebypass Prds PDFbuddhivasu100% (3)

- CpciiDocument4 pagesCpciiindrabayu ajiNo ratings yet

- CAT-CWS-1902 (McQuay VRA Added) PDFDocument36 pagesCAT-CWS-1902 (McQuay VRA Added) PDFIsmi IQasuNo ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Hightech BrochureDocument8 pagesHightech BrochureEken SariliNo ratings yet

- Screw Chiller CatalogueDocument24 pagesScrew Chiller CatalogueKamalMuralikumarNo ratings yet

- Valve Remote Control System - Anti Heeling System - Valve - ActuatorDocument12 pagesValve Remote Control System - Anti Heeling System - Valve - Actuatorcrackerz83No ratings yet

- 100 HP DatasheetDocument6 pages100 HP DatasheetPUNiiZIHIEIRNo ratings yet

- Voltas ChillerDocument126 pagesVoltas Chillerprafulb124No ratings yet

- KS-series 30-90kW WDocument3 pagesKS-series 30-90kW Wjuraj.horarNo ratings yet

- Catalog Chiller TraneDocument16 pagesCatalog Chiller TranePhạm ĐứcNo ratings yet

- 1 HydroelectricityDocument27 pages1 HydroelectricityAbhushan NeupaneNo ratings yet

- DRUVA O&G - Hydraulic - RegulatorDocument12 pagesDRUVA O&G - Hydraulic - RegulatormauroNo ratings yet

- CPC Manual BookDocument4 pagesCPC Manual BookPRAYETNONo ratings yet

- ActuatorDocument8 pagesActuatorMuhammed Ali PisuwalaNo ratings yet

- 5fc5275d6e1cd14138c012f5 - Matsui MC BrochureDocument4 pages5fc5275d6e1cd14138c012f5 - Matsui MC BrochurePedro Del AngelNo ratings yet

- Chiller o Enfriador Parker Hiross Bulice-03-EnDocument4 pagesChiller o Enfriador Parker Hiross Bulice-03-EnDaniel MarNo ratings yet

- Tescom-Topworx Flow MeasurementDocument18 pagesTescom-Topworx Flow MeasurementGrupoMecatrónicaNo ratings yet

- Brochure 7401Document2 pagesBrochure 7401Salman FayizNo ratings yet

- Pressure Independent Valves For Terminal Unit Applications: Cost Effective Solution With Maximum Energy SavingsDocument8 pagesPressure Independent Valves For Terminal Unit Applications: Cost Effective Solution With Maximum Energy SavingsDaniel FigueiredoNo ratings yet

- Marvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26Document37 pagesMarvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26lasNo ratings yet

- Techjet50 PDFDocument4 pagesTechjet50 PDFnitin kumarNo ratings yet

- Carrier 30rh-040Document16 pagesCarrier 30rh-040David MinerNo ratings yet

- BETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsDocument6 pagesBETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsVinothkumarNo ratings yet

- HVAC Brochure - 2016 PDFDocument2 pagesHVAC Brochure - 2016 PDFsanthoshnlNo ratings yet

- 61af - 022 - 105 - P DataDocument16 pages61af - 022 - 105 - P DatasarcitoNo ratings yet

- Centrifugal Water ChillerDocument28 pagesCentrifugal Water ChillerCristian Andrés Pacó MoyaNo ratings yet

- Series R™ Helical Rotary Liquid Chillers: Product CatalogDocument140 pagesSeries R™ Helical Rotary Liquid Chillers: Product CataloggabyorNo ratings yet

- Ts Aec Truetemp Series Rev07 14 2016Document2 pagesTs Aec Truetemp Series Rev07 14 2016Alencar AnschutzNo ratings yet

- Marvair ComPac 01.18 Rev.20Document32 pagesMarvair ComPac 01.18 Rev.20Víctor RomeuNo ratings yet

- AwshcDocument9 pagesAwshcEduardo RivasNo ratings yet

- Aqualogic Toplotne PumpeDocument28 pagesAqualogic Toplotne PumpeAnonymous WNKDboSFlNo ratings yet

- 测试仪合集Document24 pages测试仪合集jackNo ratings yet

- c20 Ca 603 e - 10011999Document44 pagesc20 Ca 603 e - 10011999nazir305No ratings yet

- Cat 3520 Gas EngineDocument3 pagesCat 3520 Gas EngineJafarShojaNo ratings yet

- 30RAN-chiller SarmaafarinDocument21 pages30RAN-chiller SarmaafarinHosein SajadiNo ratings yet

- TAEevo Plus ENDocument2 pagesTAEevo Plus ENFardeen khanNo ratings yet

- PSD 30AW LR 3 1 CarrierDocument16 pagesPSD 30AW LR 3 1 CarrierVassilios KelessidisNo ratings yet

- Brochure Bettis Product Selection Guide Us en 83876 PDFDocument6 pagesBrochure Bettis Product Selection Guide Us en 83876 PDFIsidro RODRIGUEZ VILLEGASNo ratings yet

- 30RB - RQ 017 033 2009Document16 pages30RB - RQ 017 033 2009Kyriakos MichalakiNo ratings yet

- BellimoDocument2 pagesBellimoAliKarimliNo ratings yet

- Industrial Hospital Compressed Air SystemsDocument8 pagesIndustrial Hospital Compressed Air SystemsNagi AbdoNo ratings yet

- Chilleri Rhoss Tcee 105 140Document20 pagesChilleri Rhoss Tcee 105 140Sorin DiaconuNo ratings yet

- Weathermaker Single Package Rooftop Gas Heat/Electric Cooling Vertical Air Flow UnitDocument76 pagesWeathermaker Single Package Rooftop Gas Heat/Electric Cooling Vertical Air Flow UnitMohamed AmrNo ratings yet

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocument8 pages30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersHải TrầnNo ratings yet

- Ficha Técnica AB-QM USADocument18 pagesFicha Técnica AB-QM USAfernandoNo ratings yet

- SE Product Portfolio-MinDocument27 pagesSE Product Portfolio-MinSaurabh SahuNo ratings yet

- Continuous 1356 kVA 1431 kVA: GAS Generator SetDocument4 pagesContinuous 1356 kVA 1431 kVA: GAS Generator SetShwe Yaminn HtetNo ratings yet

- High-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic ModuleDocument16 pagesHigh-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic Modulekathy_es16No ratings yet

- 30RBRQ 039S 160S 0ipDocument17 pages30RBRQ 039S 160S 0ipMariano PeressuttiNo ratings yet

- Alfa Laval FCM One Gas: Fuel Conditioning System For ME-GI Dual-Fuel EnginesDocument2 pagesAlfa Laval FCM One Gas: Fuel Conditioning System For ME-GI Dual-Fuel EnginesSamo SpontanostNo ratings yet

- Market Leading Portfolio of Actuation TechnologiesDocument20 pagesMarket Leading Portfolio of Actuation Technologieskamala 123No ratings yet

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshNo ratings yet

- AdvantageDocument6 pagesAdvantageDavid_Allen_007No ratings yet

- Measurement and Safety Devices For Distribution and Power Transformers - Hitachi - ABB - Comem-Portfolio - Cat - EN-21-09-2020Document34 pagesMeasurement and Safety Devices For Distribution and Power Transformers - Hitachi - ABB - Comem-Portfolio - Cat - EN-21-09-2020neoph138No ratings yet

- CVT and CC - North American BrochureDocument8 pagesCVT and CC - North American Brochurejose dupimNo ratings yet

- Installation Accessories: Cap, PE, Black EDocument6 pagesInstallation Accessories: Cap, PE, Black EVasti Diaz AguilarNo ratings yet

- Control of Inverter CompressorsDocument7 pagesControl of Inverter CompressorsVasti Diaz AguilarNo ratings yet

- Faqe7073ka0 Secadora FrigidaireDocument8 pagesFaqe7073ka0 Secadora FrigidaireVasti Diaz AguilarNo ratings yet

- Installation Procedure of Air-Conditioner Window and SplitDocument24 pagesInstallation Procedure of Air-Conditioner Window and SplitVasti Diaz AguilarNo ratings yet

- Chapter10 PDFDocument19 pagesChapter10 PDFVasti Diaz AguilarNo ratings yet

- Environmental Impact and Human Health Impact of Refrigeration & Air-ConditioningDocument18 pagesEnvironmental Impact and Human Health Impact of Refrigeration & Air-ConditioningVasti Diaz AguilarNo ratings yet

- Handling and Safety Issues of HC RefrigerantsDocument14 pagesHandling and Safety Issues of HC RefrigerantsVasti Diaz AguilarNo ratings yet

- Operator's Manual: TK 55666-1-OP (Rev. 2, 09/16)Document102 pagesOperator's Manual: TK 55666-1-OP (Rev. 2, 09/16)Vasti Diaz Aguilar100% (1)

- Handling of Hfcs RefrigerantsDocument8 pagesHandling of Hfcs RefrigerantsVasti Diaz AguilarNo ratings yet

- ARI STD 540 - EvapTempRangeDocument16 pagesARI STD 540 - EvapTempRangeVasti Diaz AguilarNo ratings yet

- No Symbol Term SI Unit Comment No Symbol Term SI Unit CommentDocument1 pageNo Symbol Term SI Unit Comment No Symbol Term SI Unit CommentVasti Diaz AguilarNo ratings yet

- Ttmm1: Compact Size, Big PerformanceDocument1 pageTtmm1: Compact Size, Big PerformanceVasti Diaz AguilarNo ratings yet

- 15 02 PDFDocument176 pages15 02 PDFVasti Diaz AguilarNo ratings yet

- Transcritical CO2 Booster System PT Poster PDFDocument1 pageTranscritical CO2 Booster System PT Poster PDFVasti Diaz AguilarNo ratings yet

- Marine Type Container Refrigeration Unit: Daikin Container LXE10E-A14 LXE10E-A15Document161 pagesMarine Type Container Refrigeration Unit: Daikin Container LXE10E-A14 LXE10E-A15Vasti Diaz AguilarNo ratings yet

- Liquid Level Controller EKC 347: ManualDocument16 pagesLiquid Level Controller EKC 347: ManualVasti Diaz AguilarNo ratings yet

- Valves, Controls and System Protectors For R-744: Efficiency and Reliability in CO ApplicationsDocument4 pagesValves, Controls and System Protectors For R-744: Efficiency and Reliability in CO ApplicationsVasti Diaz AguilarNo ratings yet

- Data Sheet Coils For Industrial Valves: Code No. 042N0185Document2 pagesData Sheet Coils For Industrial Valves: Code No. 042N0185Vasti Diaz AguilarNo ratings yet

- Triple Point: (Carbon Dioxide or CO)Document1 pageTriple Point: (Carbon Dioxide or CO)Vasti Diaz AguilarNo ratings yet

- Data Sheet Ejector PDFDocument2 pagesData Sheet Ejector PDFSuryaprakashNo ratings yet

- Surge TankDocument2 pagesSurge TankBilel MarkosNo ratings yet

- Power Source Air Conditioner (Before Aug. 2006 Production Except Thailand)Document1 pagePower Source Air Conditioner (Before Aug. 2006 Production Except Thailand)Ardina Praja MartantoNo ratings yet

- HP LP Bypass System (Turbine)Document9 pagesHP LP Bypass System (Turbine)Debasish Dewan67% (3)

- Circuit With Quick Exhaust Valves: #3 QEV #1B Qev #4 QEVDocument1 pageCircuit With Quick Exhaust Valves: #3 QEV #1B Qev #4 QEVRodo RequenaNo ratings yet

- Development of The FDP For Badra Oil Field in Iraq: LLC Gazpromneft Science & Technology CentreDocument28 pagesDevelopment of The FDP For Badra Oil Field in Iraq: LLC Gazpromneft Science & Technology Centreal_snow100% (1)

- Book 1Document9 pagesBook 1Prince NsikanNo ratings yet

- HvacDocument48 pagesHvacmohamed adelNo ratings yet

- Inst Sheet L2461Document44 pagesInst Sheet L2461RonaldNo ratings yet

- Fig. 3460 Ball Valve: ApplicationDocument2 pagesFig. 3460 Ball Valve: ApplicationDanielNo ratings yet

- Fluid Catalytic Cracking (FCC) : Main Air Blowers and Wet Gas Compressor TrainsDocument6 pagesFluid Catalytic Cracking (FCC) : Main Air Blowers and Wet Gas Compressor TrainsJaswindersingh BhatiaNo ratings yet

- Hydraulic Setting Tool Technical DatasheetDocument5 pagesHydraulic Setting Tool Technical DatasheetEvolution Oil ToolsNo ratings yet

- Unit Notes PDFDocument29 pagesUnit Notes PDFPrashant UbarhandeNo ratings yet

- DWS2510.03 Butterfly ValvesDocument6 pagesDWS2510.03 Butterfly ValvesCorneNo ratings yet

- F40 561 End Suction Pumps IOIDocument16 pagesF40 561 End Suction Pumps IOIAUX PRESUPUESTONo ratings yet

- What Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?Document11 pagesWhat Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?MOHAMED ABD ELGHANYNo ratings yet

- Jet Engine Report - MergedDocument16 pagesJet Engine Report - MergedMohamed Abo BakrNo ratings yet

- Expansion Joints NOTESDocument21 pagesExpansion Joints NOTESKvvPrasadNo ratings yet

- Blast Furnace Fuguai List (Abnormality, Minor Defects List)Document138 pagesBlast Furnace Fuguai List (Abnormality, Minor Defects List)Blast Furnace Control RoomNo ratings yet

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- Floating and Trunnion Ball Valves PDFDocument15 pagesFloating and Trunnion Ball Valves PDFAlienshowNo ratings yet

- Hydraulic Lab 1Document11 pagesHydraulic Lab 1pokok assam100% (1)

- Effect of Stacking Conditions On Performance of A Centrifugal PumpDocument8 pagesEffect of Stacking Conditions On Performance of A Centrifugal Pumpalper yeterNo ratings yet

- LG Multi V 5 2017 - 086-096Document1 pageLG Multi V 5 2017 - 086-096Ahmed Salah Abd EL-WahedNo ratings yet

- Compressor SurgeDocument5 pagesCompressor Surges1308b100% (2)

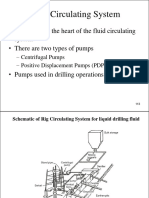

- Fluid Circulating System: - Mud Pump Is The Heart of The Fluid Circulating System - There Are Two Types of PumpsDocument46 pagesFluid Circulating System: - Mud Pump Is The Heart of The Fluid Circulating System - There Are Two Types of PumpsFreddy Mendoza CoronelNo ratings yet

- Manual AIRE ACONDICIONADO General AOHA24LALL PDFDocument26 pagesManual AIRE ACONDICIONADO General AOHA24LALL PDFjackskeletonNo ratings yet

- GRDU-EG-PRC-09-008-A1 - CommentsDocument1 pageGRDU-EG-PRC-09-008-A1 - CommentsHermenegildo ZolaNo ratings yet

Transcritical CO2 Booster System Brochure PDF

Transcritical CO2 Booster System Brochure PDF

Uploaded by

Vasti Diaz AguilarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transcritical CO2 Booster System Brochure PDF

Transcritical CO2 Booster System Brochure PDF

Uploaded by

Vasti Diaz AguilarCopyright:

Available Formats

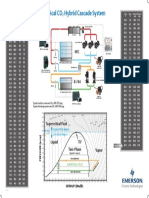

Transcritical CO2 booster system

A natural solution for supermarket refrigeration

2013ECT-41 R2 (4/15) Emerson, Copeland, Copeland Scroll, and CoreSense are trademarks of Emerson Electric Co. or one of its affiliated companies. ©2015 Emerson Climate Technologies, Inc. All rights reserved.

2013ECT-41 R2.indd 1-2 4/15/2015 11:37:47 AM

CX/EX Valve High Pressure Controller Copeland™ 4MTLS Compressors Valves, Controls and System Protectors

Emerson’s patented valve design is ideally suited for The high pressure controller is an integral part of Emerson’s The superior design of Copeland transcritical CO2 Emerson Climate Technologies has developed a new range of

R-744 (CO2) applications due to: transcritical control system as it is critical to control the high compressors includes: valves, controls and system protectors that fulfills the require-

• Gate port design provides fast reaction and intermediate pressure for proper system operation. The • Optimized refrigerant flow and heat transfer for superior ments of all common CO2 applications. Emerson offerings

speed and linear flow capacity high pressure controller features: efficiency include oil controls, filter driers, moisture indicators, solenoid

• Subcritical and transcritical mode of operation valves, check valves, ball valves, pressure controls and trans-

• Wide and accurate capacity range (10-100%) • Balanced design and valving for industry leading sound, mitters. Trust an experienced leader to provide high quality

based on temperature vibration & discharge pulse

• Direct coupling of motor and valve for high reliability components to keep your system running at peak efficiency.

• High pressure valve control based on gas cooler • Operating pressure up to 1740 psig (120 bar)

• Ceramic slide for minimal wear

outlet temperature to ensure optimum efficiency

• Positive shut-off valve during transcritical operation • Standstill pressures of 1958 psig (135 bar) high side and

• Corrosion resistant stainless steel body 957 psig (66 bar) low side

• Bypass valve control maintains flash tank

• Maximum working pressure: CX 1740 psig (120 bar) pressure to provide pressure drop across • Onboard CoreSense™ electronics that prevent problems

EX 870 psig (60 bar) evaporator expansion valves before they occur

The CX valve is recommend for the high pressure valve and • Optional heat reclaim mode • Variable speed rated from 30-60 Hz Commander HSK Inverter Drive

the EX valve acts as the expansion valve for the medium and The UL approved compressors were subjected to rigorous

The E2 module constantly communicates to the high The variable speed HSK provides the precision control

low temperature loads. The bypass valve can be either the durability testing to ensure peak performance over their

pressure controller allowing users to manage and monitor needed for the dynamic operating conditions present in a

CX or EX valve depending on the design pressure required. entire life.

all aspects of the high pressure controller. transcritical CO2 booster system. The HSK is capable of:

XM678 Case Controller • Variable speed control of the medium temperature

The XM case controller manages all aspects of a transcritical compressors from 30-60 Hz

refrigeration case including lights, fans, defrost, heaters and • Gas cooler fan speed control by single pressure control

expansion valve (superheat) control with the following or two sensor temperature difference control

capabilities:

The Commander HSK inverter drive is simple to use, compact,

• Stepper valve control and communicates via Modbus to the E2 controller.

• Embedded intelligence for tight temperature control

• Standard, demand or pulse defrost available E2 Controller

• On-board relays, communications and integrated The E2 complete facility controller has been updated to

power supply include complete CO2 refrigeration control as a standard

• Optional display for configuration and status feature in the E2 Rx. In the CO2 transcritical booster system,

the E2 controller is responsible for:

The XM case controller is fully integrated with the E2

supervisory controller making set point changes and status • Synchronized compressor staging for the low and

checks user friendly. medium temp racks

• Condenser/gas cooler control based on ambient

temperatures and system pressures

• Supervisory platform for the XM case control, the high

pressure controller, Copeland 4MTLS compressors and

HSK variable speed drives

The E2 controller provides status, logging and alarm infor-

mation, both on site and via a remote software interface.

Services Copeland Scroll™ ZO Compressors

The ZO range of Copeland Scroll compressors based on

Emerson provides a variety of field and remote services that

Emerson’s compliant scroll design feature:

are ideal for R-744 (CO2) systems.

• Axial and radial compliance for improved liquid and

• Onsite commissioning services for proper startup

debris handling

• Remote monitoring services ensure optimum perfor-

mance and mitigate potential failures • Low sound and vibration

• Alarm management assist with sorting, analyzing and • High volumetric efficiency

resolving any alarm conditions • Operating pressure up to 580 psig (40 bar)

• Energy monitoring and setpoint management ensure • Standstill pressure of 624 psig (43 bar) high side and

maximum efficiency years after installation 406 psig (28 bar) low side

• Emerson’s smart dispatch reduces operating costs Precision machined scrolls wear-in over time, so you can

associated with untimely and insignificant alarms expect better performance with increased run time. Digital

Contact your Emerson representative with your R-744 (CO2) modulation is also available providing 10-100% capacity and

service needs to see how we can assist. superior system operation.

2013ECT-41 R2.indd 3-4 4/15/2015 11:38:14 AM

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- IWCF Equipment Sample Questions (Surface Stack)Document6 pagesIWCF Equipment Sample Questions (Surface Stack)Ogbadibo100% (2)

- T-680R, T-880R, T-1080R, T-680S, T-880S, T-1080S With Premium SR-3 HMI 55667-1-OPDocument132 pagesT-680R, T-880R, T-1080R, T-680S, T-880S, T-1080S With Premium SR-3 HMI 55667-1-OPJuan Miguel Marin Quintero100% (2)

- Installation Manual: Truck Edition (TSA, ESA and AP)Document72 pagesInstallation Manual: Truck Edition (TSA, ESA and AP)Vasti Diaz Aguilar100% (1)

- Frick Compressor Oils: 160-802 SPC (MAR 2009)Document4 pagesFrick Compressor Oils: 160-802 SPC (MAR 2009)Vasti Diaz AguilarNo ratings yet

- Fluor.: Specification-Upstream Piping Classification - Line Class 300 00-Common Overall-All AreasDocument35 pagesFluor.: Specification-Upstream Piping Classification - Line Class 300 00-Common Overall-All AreashapinefeNo ratings yet

- Range: Keeping The World FlowingDocument8 pagesRange: Keeping The World FlowingPiermarco ContrerasNo ratings yet

- RTAB 207 - 212 HA: Design To Perform, Built To LastDocument32 pagesRTAB 207 - 212 HA: Design To Perform, Built To LastloloNo ratings yet

- Go RangeDocument8 pagesGo RangePedro Vives MelendezNo ratings yet

- 28990-Turbinebypass Prds PDFDocument12 pages28990-Turbinebypass Prds PDFbuddhivasu100% (3)

- CpciiDocument4 pagesCpciiindrabayu ajiNo ratings yet

- CAT-CWS-1902 (McQuay VRA Added) PDFDocument36 pagesCAT-CWS-1902 (McQuay VRA Added) PDFIsmi IQasuNo ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Hightech BrochureDocument8 pagesHightech BrochureEken SariliNo ratings yet

- Screw Chiller CatalogueDocument24 pagesScrew Chiller CatalogueKamalMuralikumarNo ratings yet

- Valve Remote Control System - Anti Heeling System - Valve - ActuatorDocument12 pagesValve Remote Control System - Anti Heeling System - Valve - Actuatorcrackerz83No ratings yet

- 100 HP DatasheetDocument6 pages100 HP DatasheetPUNiiZIHIEIRNo ratings yet

- Voltas ChillerDocument126 pagesVoltas Chillerprafulb124No ratings yet

- KS-series 30-90kW WDocument3 pagesKS-series 30-90kW Wjuraj.horarNo ratings yet

- Catalog Chiller TraneDocument16 pagesCatalog Chiller TranePhạm ĐứcNo ratings yet

- 1 HydroelectricityDocument27 pages1 HydroelectricityAbhushan NeupaneNo ratings yet

- DRUVA O&G - Hydraulic - RegulatorDocument12 pagesDRUVA O&G - Hydraulic - RegulatormauroNo ratings yet

- CPC Manual BookDocument4 pagesCPC Manual BookPRAYETNONo ratings yet

- ActuatorDocument8 pagesActuatorMuhammed Ali PisuwalaNo ratings yet

- 5fc5275d6e1cd14138c012f5 - Matsui MC BrochureDocument4 pages5fc5275d6e1cd14138c012f5 - Matsui MC BrochurePedro Del AngelNo ratings yet

- Chiller o Enfriador Parker Hiross Bulice-03-EnDocument4 pagesChiller o Enfriador Parker Hiross Bulice-03-EnDaniel MarNo ratings yet

- Tescom-Topworx Flow MeasurementDocument18 pagesTescom-Topworx Flow MeasurementGrupoMecatrónicaNo ratings yet

- Brochure 7401Document2 pagesBrochure 7401Salman FayizNo ratings yet

- Pressure Independent Valves For Terminal Unit Applications: Cost Effective Solution With Maximum Energy SavingsDocument8 pagesPressure Independent Valves For Terminal Unit Applications: Cost Effective Solution With Maximum Energy SavingsDaniel FigueiredoNo ratings yet

- Marvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26Document37 pagesMarvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26lasNo ratings yet

- Techjet50 PDFDocument4 pagesTechjet50 PDFnitin kumarNo ratings yet

- Carrier 30rh-040Document16 pagesCarrier 30rh-040David MinerNo ratings yet

- BETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsDocument6 pagesBETTIS Product Selection Guide: A Complete Offering of Valve Automation SolutionsVinothkumarNo ratings yet

- HVAC Brochure - 2016 PDFDocument2 pagesHVAC Brochure - 2016 PDFsanthoshnlNo ratings yet

- 61af - 022 - 105 - P DataDocument16 pages61af - 022 - 105 - P DatasarcitoNo ratings yet

- Centrifugal Water ChillerDocument28 pagesCentrifugal Water ChillerCristian Andrés Pacó MoyaNo ratings yet

- Series R™ Helical Rotary Liquid Chillers: Product CatalogDocument140 pagesSeries R™ Helical Rotary Liquid Chillers: Product CataloggabyorNo ratings yet

- Ts Aec Truetemp Series Rev07 14 2016Document2 pagesTs Aec Truetemp Series Rev07 14 2016Alencar AnschutzNo ratings yet

- Marvair ComPac 01.18 Rev.20Document32 pagesMarvair ComPac 01.18 Rev.20Víctor RomeuNo ratings yet

- AwshcDocument9 pagesAwshcEduardo RivasNo ratings yet

- Aqualogic Toplotne PumpeDocument28 pagesAqualogic Toplotne PumpeAnonymous WNKDboSFlNo ratings yet

- 测试仪合集Document24 pages测试仪合集jackNo ratings yet

- c20 Ca 603 e - 10011999Document44 pagesc20 Ca 603 e - 10011999nazir305No ratings yet

- Cat 3520 Gas EngineDocument3 pagesCat 3520 Gas EngineJafarShojaNo ratings yet

- 30RAN-chiller SarmaafarinDocument21 pages30RAN-chiller SarmaafarinHosein SajadiNo ratings yet

- TAEevo Plus ENDocument2 pagesTAEevo Plus ENFardeen khanNo ratings yet

- PSD 30AW LR 3 1 CarrierDocument16 pagesPSD 30AW LR 3 1 CarrierVassilios KelessidisNo ratings yet

- Brochure Bettis Product Selection Guide Us en 83876 PDFDocument6 pagesBrochure Bettis Product Selection Guide Us en 83876 PDFIsidro RODRIGUEZ VILLEGASNo ratings yet

- 30RB - RQ 017 033 2009Document16 pages30RB - RQ 017 033 2009Kyriakos MichalakiNo ratings yet

- BellimoDocument2 pagesBellimoAliKarimliNo ratings yet

- Industrial Hospital Compressed Air SystemsDocument8 pagesIndustrial Hospital Compressed Air SystemsNagi AbdoNo ratings yet

- Chilleri Rhoss Tcee 105 140Document20 pagesChilleri Rhoss Tcee 105 140Sorin DiaconuNo ratings yet

- Weathermaker Single Package Rooftop Gas Heat/Electric Cooling Vertical Air Flow UnitDocument76 pagesWeathermaker Single Package Rooftop Gas Heat/Electric Cooling Vertical Air Flow UnitMohamed AmrNo ratings yet

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocument8 pages30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersHải TrầnNo ratings yet

- Ficha Técnica AB-QM USADocument18 pagesFicha Técnica AB-QM USAfernandoNo ratings yet

- SE Product Portfolio-MinDocument27 pagesSE Product Portfolio-MinSaurabh SahuNo ratings yet

- Continuous 1356 kVA 1431 kVA: GAS Generator SetDocument4 pagesContinuous 1356 kVA 1431 kVA: GAS Generator SetShwe Yaminn HtetNo ratings yet

- High-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic ModuleDocument16 pagesHigh-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic Modulekathy_es16No ratings yet

- 30RBRQ 039S 160S 0ipDocument17 pages30RBRQ 039S 160S 0ipMariano PeressuttiNo ratings yet

- Alfa Laval FCM One Gas: Fuel Conditioning System For ME-GI Dual-Fuel EnginesDocument2 pagesAlfa Laval FCM One Gas: Fuel Conditioning System For ME-GI Dual-Fuel EnginesSamo SpontanostNo ratings yet

- Market Leading Portfolio of Actuation TechnologiesDocument20 pagesMarket Leading Portfolio of Actuation Technologieskamala 123No ratings yet

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshNo ratings yet

- AdvantageDocument6 pagesAdvantageDavid_Allen_007No ratings yet

- Measurement and Safety Devices For Distribution and Power Transformers - Hitachi - ABB - Comem-Portfolio - Cat - EN-21-09-2020Document34 pagesMeasurement and Safety Devices For Distribution and Power Transformers - Hitachi - ABB - Comem-Portfolio - Cat - EN-21-09-2020neoph138No ratings yet

- CVT and CC - North American BrochureDocument8 pagesCVT and CC - North American Brochurejose dupimNo ratings yet

- Installation Accessories: Cap, PE, Black EDocument6 pagesInstallation Accessories: Cap, PE, Black EVasti Diaz AguilarNo ratings yet

- Control of Inverter CompressorsDocument7 pagesControl of Inverter CompressorsVasti Diaz AguilarNo ratings yet

- Faqe7073ka0 Secadora FrigidaireDocument8 pagesFaqe7073ka0 Secadora FrigidaireVasti Diaz AguilarNo ratings yet

- Installation Procedure of Air-Conditioner Window and SplitDocument24 pagesInstallation Procedure of Air-Conditioner Window and SplitVasti Diaz AguilarNo ratings yet

- Chapter10 PDFDocument19 pagesChapter10 PDFVasti Diaz AguilarNo ratings yet

- Environmental Impact and Human Health Impact of Refrigeration & Air-ConditioningDocument18 pagesEnvironmental Impact and Human Health Impact of Refrigeration & Air-ConditioningVasti Diaz AguilarNo ratings yet

- Handling and Safety Issues of HC RefrigerantsDocument14 pagesHandling and Safety Issues of HC RefrigerantsVasti Diaz AguilarNo ratings yet

- Operator's Manual: TK 55666-1-OP (Rev. 2, 09/16)Document102 pagesOperator's Manual: TK 55666-1-OP (Rev. 2, 09/16)Vasti Diaz Aguilar100% (1)

- Handling of Hfcs RefrigerantsDocument8 pagesHandling of Hfcs RefrigerantsVasti Diaz AguilarNo ratings yet

- ARI STD 540 - EvapTempRangeDocument16 pagesARI STD 540 - EvapTempRangeVasti Diaz AguilarNo ratings yet

- No Symbol Term SI Unit Comment No Symbol Term SI Unit CommentDocument1 pageNo Symbol Term SI Unit Comment No Symbol Term SI Unit CommentVasti Diaz AguilarNo ratings yet

- Ttmm1: Compact Size, Big PerformanceDocument1 pageTtmm1: Compact Size, Big PerformanceVasti Diaz AguilarNo ratings yet

- 15 02 PDFDocument176 pages15 02 PDFVasti Diaz AguilarNo ratings yet

- Transcritical CO2 Booster System PT Poster PDFDocument1 pageTranscritical CO2 Booster System PT Poster PDFVasti Diaz AguilarNo ratings yet

- Marine Type Container Refrigeration Unit: Daikin Container LXE10E-A14 LXE10E-A15Document161 pagesMarine Type Container Refrigeration Unit: Daikin Container LXE10E-A14 LXE10E-A15Vasti Diaz AguilarNo ratings yet

- Liquid Level Controller EKC 347: ManualDocument16 pagesLiquid Level Controller EKC 347: ManualVasti Diaz AguilarNo ratings yet

- Valves, Controls and System Protectors For R-744: Efficiency and Reliability in CO ApplicationsDocument4 pagesValves, Controls and System Protectors For R-744: Efficiency and Reliability in CO ApplicationsVasti Diaz AguilarNo ratings yet

- Data Sheet Coils For Industrial Valves: Code No. 042N0185Document2 pagesData Sheet Coils For Industrial Valves: Code No. 042N0185Vasti Diaz AguilarNo ratings yet

- Triple Point: (Carbon Dioxide or CO)Document1 pageTriple Point: (Carbon Dioxide or CO)Vasti Diaz AguilarNo ratings yet

- Data Sheet Ejector PDFDocument2 pagesData Sheet Ejector PDFSuryaprakashNo ratings yet

- Surge TankDocument2 pagesSurge TankBilel MarkosNo ratings yet

- Power Source Air Conditioner (Before Aug. 2006 Production Except Thailand)Document1 pagePower Source Air Conditioner (Before Aug. 2006 Production Except Thailand)Ardina Praja MartantoNo ratings yet

- HP LP Bypass System (Turbine)Document9 pagesHP LP Bypass System (Turbine)Debasish Dewan67% (3)

- Circuit With Quick Exhaust Valves: #3 QEV #1B Qev #4 QEVDocument1 pageCircuit With Quick Exhaust Valves: #3 QEV #1B Qev #4 QEVRodo RequenaNo ratings yet

- Development of The FDP For Badra Oil Field in Iraq: LLC Gazpromneft Science & Technology CentreDocument28 pagesDevelopment of The FDP For Badra Oil Field in Iraq: LLC Gazpromneft Science & Technology Centreal_snow100% (1)

- Book 1Document9 pagesBook 1Prince NsikanNo ratings yet

- HvacDocument48 pagesHvacmohamed adelNo ratings yet

- Inst Sheet L2461Document44 pagesInst Sheet L2461RonaldNo ratings yet

- Fig. 3460 Ball Valve: ApplicationDocument2 pagesFig. 3460 Ball Valve: ApplicationDanielNo ratings yet

- Fluid Catalytic Cracking (FCC) : Main Air Blowers and Wet Gas Compressor TrainsDocument6 pagesFluid Catalytic Cracking (FCC) : Main Air Blowers and Wet Gas Compressor TrainsJaswindersingh BhatiaNo ratings yet

- Hydraulic Setting Tool Technical DatasheetDocument5 pagesHydraulic Setting Tool Technical DatasheetEvolution Oil ToolsNo ratings yet

- Unit Notes PDFDocument29 pagesUnit Notes PDFPrashant UbarhandeNo ratings yet

- DWS2510.03 Butterfly ValvesDocument6 pagesDWS2510.03 Butterfly ValvesCorneNo ratings yet

- F40 561 End Suction Pumps IOIDocument16 pagesF40 561 End Suction Pumps IOIAUX PRESUPUESTONo ratings yet

- What Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?Document11 pagesWhat Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?MOHAMED ABD ELGHANYNo ratings yet

- Jet Engine Report - MergedDocument16 pagesJet Engine Report - MergedMohamed Abo BakrNo ratings yet

- Expansion Joints NOTESDocument21 pagesExpansion Joints NOTESKvvPrasadNo ratings yet

- Blast Furnace Fuguai List (Abnormality, Minor Defects List)Document138 pagesBlast Furnace Fuguai List (Abnormality, Minor Defects List)Blast Furnace Control RoomNo ratings yet

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- Floating and Trunnion Ball Valves PDFDocument15 pagesFloating and Trunnion Ball Valves PDFAlienshowNo ratings yet

- Hydraulic Lab 1Document11 pagesHydraulic Lab 1pokok assam100% (1)

- Effect of Stacking Conditions On Performance of A Centrifugal PumpDocument8 pagesEffect of Stacking Conditions On Performance of A Centrifugal Pumpalper yeterNo ratings yet

- LG Multi V 5 2017 - 086-096Document1 pageLG Multi V 5 2017 - 086-096Ahmed Salah Abd EL-WahedNo ratings yet

- Compressor SurgeDocument5 pagesCompressor Surges1308b100% (2)

- Fluid Circulating System: - Mud Pump Is The Heart of The Fluid Circulating System - There Are Two Types of PumpsDocument46 pagesFluid Circulating System: - Mud Pump Is The Heart of The Fluid Circulating System - There Are Two Types of PumpsFreddy Mendoza CoronelNo ratings yet

- Manual AIRE ACONDICIONADO General AOHA24LALL PDFDocument26 pagesManual AIRE ACONDICIONADO General AOHA24LALL PDFjackskeletonNo ratings yet

- GRDU-EG-PRC-09-008-A1 - CommentsDocument1 pageGRDU-EG-PRC-09-008-A1 - CommentsHermenegildo ZolaNo ratings yet