Professional Documents

Culture Documents

Drying & Acid Distribution: Chlorine

Drying & Acid Distribution: Chlorine

Uploaded by

Darshan PatelCopyright:

Available Formats

You might also like

- COLIGWS5Document4 pagesCOLIGWS5Rishi Sinha25% (4)

- Scomi Mud Chemicals Cross Reference Table 2021-F48-C-M068Document35 pagesScomi Mud Chemicals Cross Reference Table 2021-F48-C-M068melvinkuri100% (4)

- Removal of Chloride Compounds PDFDocument7 pagesRemoval of Chloride Compounds PDFaaa100% (1)

- SCRsystemInstallationGuideLineDNOx2 V6.11 PDFDocument88 pagesSCRsystemInstallationGuideLineDNOx2 V6.11 PDFArnaldo Ribeiro67% (3)

- Chloride Management in Reformer Product StreamsDocument5 pagesChloride Management in Reformer Product StreamsAmda AmdaNo ratings yet

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignJyothi Jyotisha100% (1)

- BondingDocument17 pagesBondingericaNo ratings yet

- Hydrogen Processing: ChlorineDocument2 pagesHydrogen Processing: ChlorineDarshan PatelNo ratings yet

- Chlor Alkali TechnologyDocument14 pagesChlor Alkali TechnologyTinTin100% (1)

- GC PDFDocument28 pagesGC PDFccsllNo ratings yet

- GC PDFDocument28 pagesGC PDFccsllNo ratings yet

- CO&CCP Part2Document33 pagesCO&CCP Part2Aabhas UpadhyayaNo ratings yet

- Chloride Ball Valve FLVDocument7 pagesChloride Ball Valve FLVLenin MagañaNo ratings yet

- UK 2619 63 Revision 3Document35 pagesUK 2619 63 Revision 3Mohammed BariNo ratings yet

- AppBull Chlo1 08-11Document2 pagesAppBull Chlo1 08-11Darshan PatelNo ratings yet

- B زيد علاء شاكرDocument10 pagesB زيد علاء شاكرali ahmedNo ratings yet

- Chlor-Alkali ProcessDocument6 pagesChlor-Alkali ProcessEduardo Tonino Chavez Gaytan100% (1)

- Sitara Chemical InternshipDocument23 pagesSitara Chemical Internshipmuhammad uzairNo ratings yet

- Flat Rate Warranty Labor Schedule: Container Products EquipmentDocument11 pagesFlat Rate Warranty Labor Schedule: Container Products EquipmentHussain ShahNo ratings yet

- Gc/Ms Analysis of Pcbs in Waste Oil Using The Backflush Capability of The Agilent Quickswap AccessoryDocument6 pagesGc/Ms Analysis of Pcbs in Waste Oil Using The Backflush Capability of The Agilent Quickswap AccessoryKung KleeNo ratings yet

- Antifreeze CoolantDocument2 pagesAntifreeze CoolantbaroutesNo ratings yet

- Disponibilidad Shell SalitreDocument6 pagesDisponibilidad Shell Salitrediego.vanegasNo ratings yet

- Brochure 2021 Eka Chlorine Dioxide Generation SystemsDocument8 pagesBrochure 2021 Eka Chlorine Dioxide Generation SystemsirNo ratings yet

- Es Fleetguard Coolnat LT15070 SpesifcationDocument2 pagesEs Fleetguard Coolnat LT15070 SpesifcationahmedalgaloNo ratings yet

- Brochure-Chlorine Di-Oxide Generation and Dosing SystemDocument4 pagesBrochure-Chlorine Di-Oxide Generation and Dosing SystemsamirNo ratings yet

- Feldspar ProcessingDocument4 pagesFeldspar ProcessingaltipatlarNo ratings yet

- EIA Andhra SugarsDocument3 pagesEIA Andhra SugarsRavi PanaraNo ratings yet

- Gypsum ManifacturingDocument9 pagesGypsum ManifacturingpellazgusNo ratings yet

- Ressor FC Fitter-Dryer: Oct. 31, 1967 R. J. Brooks Etal 3,350,428Document10 pagesRessor FC Fitter-Dryer: Oct. 31, 1967 R. J. Brooks Etal 3,350,428Mato FaniNo ratings yet

- Emkarate RL-katalog Comparativo Otros Aceites DAVEDocument7 pagesEmkarate RL-katalog Comparativo Otros Aceites DAVEDiego Alejandro Villarejo EscobarNo ratings yet

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerDocument21 pagesRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185No ratings yet

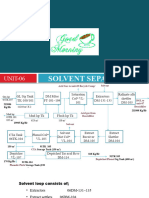

- Solvent Separation UNIT-06 - GOODDocument17 pagesSolvent Separation UNIT-06 - GOODAamir HasanNo ratings yet

- The SuCy Process SulfatosDocument18 pagesThe SuCy Process SulfatoslauramanjarresNo ratings yet

- Flat Rate Warranty Labor Schedule: Container Products EquipmentDocument11 pagesFlat Rate Warranty Labor Schedule: Container Products EquipmentJuan Pablo Muñoz CortezNo ratings yet

- GACL - Report MEET PDFDocument36 pagesGACL - Report MEET PDFMeet KhuntNo ratings yet

- 8.12 Sodium CarbonateDocument7 pages8.12 Sodium CarbonateDheeraj DheeruNo ratings yet

- Castrol BulletinDocument1 pageCastrol BulletinHarrier ESNo ratings yet

- Gacl Training ReportDocument35 pagesGacl Training ReportDhruvin Shah100% (1)

- PP Aaa PP1 132Document20 pagesPP Aaa PP1 132Rabah Amidi100% (1)

- Chevron - PDS - Compressor Oils - CapellaWF - v0519Document2 pagesChevron - PDS - Compressor Oils - CapellaWF - v0519Bekir ManavogluNo ratings yet

- Gas chlorinator-MTP1Document2 pagesGas chlorinator-MTP1Achira Chanaka PeirisNo ratings yet

- List VesselDocument3 pagesList Vesselfebriyan.saputraNo ratings yet

- Chlorine Treatment - ConvertiDocument16 pagesChlorine Treatment - ConvertiShaheen MansourNo ratings yet

- ProductDocument3 pagesProductRaymond ButialNo ratings yet

- Vinyl Chloride Production Powerpoint PDFDocument69 pagesVinyl Chloride Production Powerpoint PDFClash With KAINo ratings yet

- Sru OperationDocument15 pagesSru OperationM HayatNo ratings yet

- General Information: Shimrin® KBC & C2C-Kbc Classic & Coast 2 Coast Compliant Kandy Basecoat Factory PacksDocument3 pagesGeneral Information: Shimrin® KBC & C2C-Kbc Classic & Coast 2 Coast Compliant Kandy Basecoat Factory PacksrobertoNo ratings yet

- PP Aaa PP1 144Document39 pagesPP Aaa PP1 144Rabah AmidiNo ratings yet

- MN Derivatization Reagents GCDocument28 pagesMN Derivatization Reagents GCFatma MoustafaNo ratings yet

- ClO2 ProcessDocument27 pagesClO2 ProcessBenito de ProcesosNo ratings yet

- Corrosion Control at Ammonium Sulphate Plant-An Experience at Vizag SteelDocument9 pagesCorrosion Control at Ammonium Sulphate Plant-An Experience at Vizag Steelbhujakhia_748657110No ratings yet

- Tps 890 Class A B LJFDocument5 pagesTps 890 Class A B LJFKentNo ratings yet

- CPL PCL ReportDocument3 pagesCPL PCL Reportlisl.pietersenNo ratings yet

- Chlorsys: Electro-Chlorination PackageDocument8 pagesChlorsys: Electro-Chlorination Packagegkdora574No ratings yet

- Coolant OAT Bulletin LT32533Document2 pagesCoolant OAT Bulletin LT32533Castro RicardoNo ratings yet

- (CCS) Manual - Acclaim RSLC ColumnsDocument10 pages(CCS) Manual - Acclaim RSLC ColumnstamiaNo ratings yet

- Plant CapacityDocument1 pagePlant CapacityManjunath HrmNo ratings yet

- 20HDP Template SuCyProcess v0Document18 pages20HDP Template SuCyProcess v0Mario Cancino SerranoNo ratings yet

- Intec Copper Process December 20081Document20 pagesIntec Copper Process December 20081Miguel JackoNo ratings yet

- CR Catalogue 2014Document24 pagesCR Catalogue 2014Swar VikamshiNo ratings yet

- H P I C R I: Standart Torque Bolt MetriksDocument1 pageH P I C R I: Standart Torque Bolt MetriksRizal MerahNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Sandpiper Complete BrochureDocument35 pagesSandpiper Complete BrochureDarshan PatelNo ratings yet

- Eastman - Dimethylformamide (DMF)Document4 pagesEastman - Dimethylformamide (DMF)Darshan PatelNo ratings yet

- A - O D D P P: IR Perated Ouble Iaphragm UMP ErformanceDocument4 pagesA - O D D P P: IR Perated Ouble Iaphragm UMP ErformanceDarshan PatelNo ratings yet

- Pressure Drop in Gas PipelinesDocument38 pagesPressure Drop in Gas PipelinesDarshan Patel100% (2)

- Chlor Alkali Valve Figure Numbers Based On Chlorine Institute Pamphlet 6 Valve Service TableDocument2 pagesChlor Alkali Valve Figure Numbers Based On Chlorine Institute Pamphlet 6 Valve Service TableDarshan PatelNo ratings yet

- Bin Hopper Martindale PDFDocument1 pageBin Hopper Martindale PDFDarshan PatelNo ratings yet

- AppBull Chlo1 08-11Document2 pagesAppBull Chlo1 08-11Darshan PatelNo ratings yet

- Hydrogen Processing: ChlorineDocument2 pagesHydrogen Processing: ChlorineDarshan PatelNo ratings yet

- AppBull Chlo2 08-11Document2 pagesAppBull Chlo2 08-11Darshan PatelNo ratings yet

- BS 1710 1984 Pipeline Identification PDFDocument1 pageBS 1710 1984 Pipeline Identification PDFDarshan PatelNo ratings yet

- Guideline Chlorine Gas Pipeline 10032019 RevisedDocument40 pagesGuideline Chlorine Gas Pipeline 10032019 RevisedDarshan PatelNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev 01Document4 pagesPressure Safety Valve Sizing Calculation Rev 01Darshan PatelNo ratings yet

- ChemchartDocument14 pagesChemchartDarshan PatelNo ratings yet

- Blackmer LPG PumpsDocument8 pagesBlackmer LPG PumpsDarshan PatelNo ratings yet

- Solving Vessel Equations PDFDocument5 pagesSolving Vessel Equations PDFDarshan PatelNo ratings yet

- VivaDocument24 pagesVivaVignesh KNo ratings yet

- Chemistry Journal Chjv06i06p0596Document18 pagesChemistry Journal Chjv06i06p0596Meysam BayazidiNo ratings yet

- Dissipation FactorDocument2 pagesDissipation FactorrodgerNo ratings yet

- ChemFlyer-CST DeclarationOfConformity-Food v3.0.1 enDocument1 pageChemFlyer-CST DeclarationOfConformity-Food v3.0.1 enDiego OrtegaNo ratings yet

- Nozzles Data-SheetDocument9 pagesNozzles Data-SheetMawada RashedNo ratings yet

- Paper - Diki Wahyudi - Politeknik Negeri BandungDocument6 pagesPaper - Diki Wahyudi - Politeknik Negeri BandungDiq TalkNo ratings yet

- Industrial Training at ISGEC Heavy Engineering Corporation HaryanaDocument32 pagesIndustrial Training at ISGEC Heavy Engineering Corporation HaryanaashvaniNo ratings yet

- Solids, Liquids and Gases.: - Complete The Spaces in The Table BelowDocument8 pagesSolids, Liquids and Gases.: - Complete The Spaces in The Table BelowAmelia AuclairNo ratings yet

- PPPi - Company Profile 2022Document82 pagesPPPi - Company Profile 2022Jeff T.No ratings yet

- Chapter 2-Gravimetric MethodsDocument13 pagesChapter 2-Gravimetric MethodsMilesNo ratings yet

- Molecular Dynamics Simulations of The Elastic Properties of Polymer/carbon Nanotube CompositesDocument9 pagesMolecular Dynamics Simulations of The Elastic Properties of Polymer/carbon Nanotube CompositesQuantum KnotsNo ratings yet

- Solved With COMSOL Multiphysics 4.4 TinDocument14 pagesSolved With COMSOL Multiphysics 4.4 TinEdgar MurilloNo ratings yet

- Plate and Frame FiltrationDocument11 pagesPlate and Frame FiltrationQuenneBelocuraNo ratings yet

- Cotter and Sleeve JointDocument17 pagesCotter and Sleeve JointNishit Karkar100% (2)

- Flux Cored Wire LincolnDocument6 pagesFlux Cored Wire LincolnAlexander Saavedra MambuscayNo ratings yet

- Msds PVC ReonDocument2 pagesMsds PVC ReongudasanNo ratings yet

- Bamboo As Building MaterialDocument30 pagesBamboo As Building MaterialKkarthik100% (1)

- Organic Chemistry Keywords - 1. Crossword Answers.Document2 pagesOrganic Chemistry Keywords - 1. Crossword Answers.sjNo ratings yet

- BXCD4545 - Revd BXCD4545 DatasheetDocument9 pagesBXCD4545 - Revd BXCD4545 DatasheetpedroanjoNo ratings yet

- SS 1.4313Document2 pagesSS 1.4313mechkashanNo ratings yet

- DS125NSSUGARR2Document1 pageDS125NSSUGARR2Frandika PrimayogaNo ratings yet

- Catloge 321Document184 pagesCatloge 321Muhammad WaseemNo ratings yet

- Multiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyDocument109 pagesMultiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyLong BuiNo ratings yet

- Agricultural Applications For Pine-Based BioCharDocument542 pagesAgricultural Applications For Pine-Based BioCharcarbonbrokers100% (1)

- Determination of Gold in Bullion by Cupellation: Standard Test Methods ForDocument5 pagesDetermination of Gold in Bullion by Cupellation: Standard Test Methods ForMark JurichNo ratings yet

- Quotation For RO MembraneDocument15 pagesQuotation For RO MembraneKELVIN TECHNOLOGIESNo ratings yet

- Ebook Powder CoatingDocument27 pagesEbook Powder Coatinggcldesign100% (1)

Drying & Acid Distribution: Chlorine

Drying & Acid Distribution: Chlorine

Uploaded by

Darshan PatelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drying & Acid Distribution: Chlorine

Drying & Acid Distribution: Chlorine

Uploaded by

Darshan PatelCopyright:

Available Formats

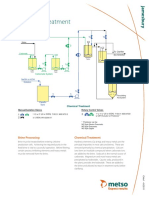

APPLICATION REPORT

jamesbury

Chlorine

Drying & Acid Distribution

Dry Chlorine

to

4 Compression

Demister

SC 3

2

Storage

Wet

Chlorine

SC

SC SC 2

Spent

Acid

SC

2

SC SC SC 1 1 2

2 H2SO4 Distribution

H2SO4 Storage

2

Storage

Chlorine Drying & Acid Distribution

Automated or Rotary Control

Manual/Isolation Valves

1 2" & 3" (50 & 80DN) 7150 31 2235 XTZ1 2 2" & 3" (50 & 80DN) 7150 31 2235 XTZ1

w/ VPVL Actuator

3 2" (50DN) 7150C 31 2271 XTZ1

4 4" - 18" (100 – 450DN) 815LC 11 2271 XZ

w/ QPX Actuator w/ Positioner *

* Positioner can be:

NE Style Electro Pneumatic

NP Style Pneumatic

ND Style Digital

Chlorine Processing Drying

The second phase for drying Cl2 gas from the cooling Cooled Cl2 gas entering the drying columns has some

system is to contact it with concentrated H2S04. This moisture eliminated by the cooling and chilling process.

occurs in a series of columns. Additional drying occurs as moisture in the Cl2 gas is

absorbed by 96% H2S04.

Chlo3 • 8/2011

APPLICATION REPORT

Drying (Con’t.)

The H2S04 is stored on-site in companion facilities and flows

through the columns counter to the Cl2 gas. As the Cl2 moves

through the drying process, it dries the Cl2 gas to a level of 50

ppm. At the same time, H2S04 becomes dilute exiting a spent

acid at 70% - 80% H2S04. The spent acid contains Cl2 and is

subjected to dechlorination process before reconcentration or

disposal.

The dry Cl2 gas exists in the last column at 50 ppm. Cl2 at

this moisture level is not corrosive to ferrous metals.

Valve Requirements

Sulfuric acid is at ambient conditions and 45 psi (3 bar). The

distribution is through 2" – 3" (50 – 80DN) line size with

automated and manual valves situated at control points on

tanks (2 ) and manual valves on pump and tank isolation

(1 ). Carbon steel valves with alloy trim are the preferred

materials.

Automated valves are equipped with actuators, solenoids,

communication terminals and an on-off beacon.

Cl2 is compressed in the next phase but between the

drying column and compression, the Cl2 is filtered through a

demister. There is a 2" (50DN) flanged manual drain valve

(3 ) on the demister and a high-performance butterfly

modulating control valve (4 ) regulating Cl2 gas to the

compression process.

Metso Solution

Modulating control valves include QPX spring return

diaphragm actuator with positioner and accessories as

specified.

The information provided in this bulletin is advisory in nature, and is intended as a guideline only.

For specific circumstances and more detailed information, please consult with Metso.

Metso Automation Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-11301 Vantaa, Finland.

Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA.

Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500- Iporanga, 18087-101, Sorocaba-São Paulo

Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748/49

Asia Pacific, 20 Kallang Avenue, Lobby B, #06-00, PICO Creative Centre, Singapore 339411, Singapore.

Tel. +65 6511 1011. Fax +65 6250 0830

China, 19/F, the Exchange Beijing, No. 118, Jianguo Lu Yi, Chaoyang Dist, 100022 Beijing, China.

Tel. +86-10-6566-6600. Fax +86-10-6566-2575

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai,

United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/automation

You might also like

- COLIGWS5Document4 pagesCOLIGWS5Rishi Sinha25% (4)

- Scomi Mud Chemicals Cross Reference Table 2021-F48-C-M068Document35 pagesScomi Mud Chemicals Cross Reference Table 2021-F48-C-M068melvinkuri100% (4)

- Removal of Chloride Compounds PDFDocument7 pagesRemoval of Chloride Compounds PDFaaa100% (1)

- SCRsystemInstallationGuideLineDNOx2 V6.11 PDFDocument88 pagesSCRsystemInstallationGuideLineDNOx2 V6.11 PDFArnaldo Ribeiro67% (3)

- Chloride Management in Reformer Product StreamsDocument5 pagesChloride Management in Reformer Product StreamsAmda AmdaNo ratings yet

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignJyothi Jyotisha100% (1)

- BondingDocument17 pagesBondingericaNo ratings yet

- Hydrogen Processing: ChlorineDocument2 pagesHydrogen Processing: ChlorineDarshan PatelNo ratings yet

- Chlor Alkali TechnologyDocument14 pagesChlor Alkali TechnologyTinTin100% (1)

- GC PDFDocument28 pagesGC PDFccsllNo ratings yet

- GC PDFDocument28 pagesGC PDFccsllNo ratings yet

- CO&CCP Part2Document33 pagesCO&CCP Part2Aabhas UpadhyayaNo ratings yet

- Chloride Ball Valve FLVDocument7 pagesChloride Ball Valve FLVLenin MagañaNo ratings yet

- UK 2619 63 Revision 3Document35 pagesUK 2619 63 Revision 3Mohammed BariNo ratings yet

- AppBull Chlo1 08-11Document2 pagesAppBull Chlo1 08-11Darshan PatelNo ratings yet

- B زيد علاء شاكرDocument10 pagesB زيد علاء شاكرali ahmedNo ratings yet

- Chlor-Alkali ProcessDocument6 pagesChlor-Alkali ProcessEduardo Tonino Chavez Gaytan100% (1)

- Sitara Chemical InternshipDocument23 pagesSitara Chemical Internshipmuhammad uzairNo ratings yet

- Flat Rate Warranty Labor Schedule: Container Products EquipmentDocument11 pagesFlat Rate Warranty Labor Schedule: Container Products EquipmentHussain ShahNo ratings yet

- Gc/Ms Analysis of Pcbs in Waste Oil Using The Backflush Capability of The Agilent Quickswap AccessoryDocument6 pagesGc/Ms Analysis of Pcbs in Waste Oil Using The Backflush Capability of The Agilent Quickswap AccessoryKung KleeNo ratings yet

- Antifreeze CoolantDocument2 pagesAntifreeze CoolantbaroutesNo ratings yet

- Disponibilidad Shell SalitreDocument6 pagesDisponibilidad Shell Salitrediego.vanegasNo ratings yet

- Brochure 2021 Eka Chlorine Dioxide Generation SystemsDocument8 pagesBrochure 2021 Eka Chlorine Dioxide Generation SystemsirNo ratings yet

- Es Fleetguard Coolnat LT15070 SpesifcationDocument2 pagesEs Fleetguard Coolnat LT15070 SpesifcationahmedalgaloNo ratings yet

- Brochure-Chlorine Di-Oxide Generation and Dosing SystemDocument4 pagesBrochure-Chlorine Di-Oxide Generation and Dosing SystemsamirNo ratings yet

- Feldspar ProcessingDocument4 pagesFeldspar ProcessingaltipatlarNo ratings yet

- EIA Andhra SugarsDocument3 pagesEIA Andhra SugarsRavi PanaraNo ratings yet

- Gypsum ManifacturingDocument9 pagesGypsum ManifacturingpellazgusNo ratings yet

- Ressor FC Fitter-Dryer: Oct. 31, 1967 R. J. Brooks Etal 3,350,428Document10 pagesRessor FC Fitter-Dryer: Oct. 31, 1967 R. J. Brooks Etal 3,350,428Mato FaniNo ratings yet

- Emkarate RL-katalog Comparativo Otros Aceites DAVEDocument7 pagesEmkarate RL-katalog Comparativo Otros Aceites DAVEDiego Alejandro Villarejo EscobarNo ratings yet

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerDocument21 pagesRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185No ratings yet

- Solvent Separation UNIT-06 - GOODDocument17 pagesSolvent Separation UNIT-06 - GOODAamir HasanNo ratings yet

- The SuCy Process SulfatosDocument18 pagesThe SuCy Process SulfatoslauramanjarresNo ratings yet

- Flat Rate Warranty Labor Schedule: Container Products EquipmentDocument11 pagesFlat Rate Warranty Labor Schedule: Container Products EquipmentJuan Pablo Muñoz CortezNo ratings yet

- GACL - Report MEET PDFDocument36 pagesGACL - Report MEET PDFMeet KhuntNo ratings yet

- 8.12 Sodium CarbonateDocument7 pages8.12 Sodium CarbonateDheeraj DheeruNo ratings yet

- Castrol BulletinDocument1 pageCastrol BulletinHarrier ESNo ratings yet

- Gacl Training ReportDocument35 pagesGacl Training ReportDhruvin Shah100% (1)

- PP Aaa PP1 132Document20 pagesPP Aaa PP1 132Rabah Amidi100% (1)

- Chevron - PDS - Compressor Oils - CapellaWF - v0519Document2 pagesChevron - PDS - Compressor Oils - CapellaWF - v0519Bekir ManavogluNo ratings yet

- Gas chlorinator-MTP1Document2 pagesGas chlorinator-MTP1Achira Chanaka PeirisNo ratings yet

- List VesselDocument3 pagesList Vesselfebriyan.saputraNo ratings yet

- Chlorine Treatment - ConvertiDocument16 pagesChlorine Treatment - ConvertiShaheen MansourNo ratings yet

- ProductDocument3 pagesProductRaymond ButialNo ratings yet

- Vinyl Chloride Production Powerpoint PDFDocument69 pagesVinyl Chloride Production Powerpoint PDFClash With KAINo ratings yet

- Sru OperationDocument15 pagesSru OperationM HayatNo ratings yet

- General Information: Shimrin® KBC & C2C-Kbc Classic & Coast 2 Coast Compliant Kandy Basecoat Factory PacksDocument3 pagesGeneral Information: Shimrin® KBC & C2C-Kbc Classic & Coast 2 Coast Compliant Kandy Basecoat Factory PacksrobertoNo ratings yet

- PP Aaa PP1 144Document39 pagesPP Aaa PP1 144Rabah AmidiNo ratings yet

- MN Derivatization Reagents GCDocument28 pagesMN Derivatization Reagents GCFatma MoustafaNo ratings yet

- ClO2 ProcessDocument27 pagesClO2 ProcessBenito de ProcesosNo ratings yet

- Corrosion Control at Ammonium Sulphate Plant-An Experience at Vizag SteelDocument9 pagesCorrosion Control at Ammonium Sulphate Plant-An Experience at Vizag Steelbhujakhia_748657110No ratings yet

- Tps 890 Class A B LJFDocument5 pagesTps 890 Class A B LJFKentNo ratings yet

- CPL PCL ReportDocument3 pagesCPL PCL Reportlisl.pietersenNo ratings yet

- Chlorsys: Electro-Chlorination PackageDocument8 pagesChlorsys: Electro-Chlorination Packagegkdora574No ratings yet

- Coolant OAT Bulletin LT32533Document2 pagesCoolant OAT Bulletin LT32533Castro RicardoNo ratings yet

- (CCS) Manual - Acclaim RSLC ColumnsDocument10 pages(CCS) Manual - Acclaim RSLC ColumnstamiaNo ratings yet

- Plant CapacityDocument1 pagePlant CapacityManjunath HrmNo ratings yet

- 20HDP Template SuCyProcess v0Document18 pages20HDP Template SuCyProcess v0Mario Cancino SerranoNo ratings yet

- Intec Copper Process December 20081Document20 pagesIntec Copper Process December 20081Miguel JackoNo ratings yet

- CR Catalogue 2014Document24 pagesCR Catalogue 2014Swar VikamshiNo ratings yet

- H P I C R I: Standart Torque Bolt MetriksDocument1 pageH P I C R I: Standart Torque Bolt MetriksRizal MerahNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Sandpiper Complete BrochureDocument35 pagesSandpiper Complete BrochureDarshan PatelNo ratings yet

- Eastman - Dimethylformamide (DMF)Document4 pagesEastman - Dimethylformamide (DMF)Darshan PatelNo ratings yet

- A - O D D P P: IR Perated Ouble Iaphragm UMP ErformanceDocument4 pagesA - O D D P P: IR Perated Ouble Iaphragm UMP ErformanceDarshan PatelNo ratings yet

- Pressure Drop in Gas PipelinesDocument38 pagesPressure Drop in Gas PipelinesDarshan Patel100% (2)

- Chlor Alkali Valve Figure Numbers Based On Chlorine Institute Pamphlet 6 Valve Service TableDocument2 pagesChlor Alkali Valve Figure Numbers Based On Chlorine Institute Pamphlet 6 Valve Service TableDarshan PatelNo ratings yet

- Bin Hopper Martindale PDFDocument1 pageBin Hopper Martindale PDFDarshan PatelNo ratings yet

- AppBull Chlo1 08-11Document2 pagesAppBull Chlo1 08-11Darshan PatelNo ratings yet

- Hydrogen Processing: ChlorineDocument2 pagesHydrogen Processing: ChlorineDarshan PatelNo ratings yet

- AppBull Chlo2 08-11Document2 pagesAppBull Chlo2 08-11Darshan PatelNo ratings yet

- BS 1710 1984 Pipeline Identification PDFDocument1 pageBS 1710 1984 Pipeline Identification PDFDarshan PatelNo ratings yet

- Guideline Chlorine Gas Pipeline 10032019 RevisedDocument40 pagesGuideline Chlorine Gas Pipeline 10032019 RevisedDarshan PatelNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev 01Document4 pagesPressure Safety Valve Sizing Calculation Rev 01Darshan PatelNo ratings yet

- ChemchartDocument14 pagesChemchartDarshan PatelNo ratings yet

- Blackmer LPG PumpsDocument8 pagesBlackmer LPG PumpsDarshan PatelNo ratings yet

- Solving Vessel Equations PDFDocument5 pagesSolving Vessel Equations PDFDarshan PatelNo ratings yet

- VivaDocument24 pagesVivaVignesh KNo ratings yet

- Chemistry Journal Chjv06i06p0596Document18 pagesChemistry Journal Chjv06i06p0596Meysam BayazidiNo ratings yet

- Dissipation FactorDocument2 pagesDissipation FactorrodgerNo ratings yet

- ChemFlyer-CST DeclarationOfConformity-Food v3.0.1 enDocument1 pageChemFlyer-CST DeclarationOfConformity-Food v3.0.1 enDiego OrtegaNo ratings yet

- Nozzles Data-SheetDocument9 pagesNozzles Data-SheetMawada RashedNo ratings yet

- Paper - Diki Wahyudi - Politeknik Negeri BandungDocument6 pagesPaper - Diki Wahyudi - Politeknik Negeri BandungDiq TalkNo ratings yet

- Industrial Training at ISGEC Heavy Engineering Corporation HaryanaDocument32 pagesIndustrial Training at ISGEC Heavy Engineering Corporation HaryanaashvaniNo ratings yet

- Solids, Liquids and Gases.: - Complete The Spaces in The Table BelowDocument8 pagesSolids, Liquids and Gases.: - Complete The Spaces in The Table BelowAmelia AuclairNo ratings yet

- PPPi - Company Profile 2022Document82 pagesPPPi - Company Profile 2022Jeff T.No ratings yet

- Chapter 2-Gravimetric MethodsDocument13 pagesChapter 2-Gravimetric MethodsMilesNo ratings yet

- Molecular Dynamics Simulations of The Elastic Properties of Polymer/carbon Nanotube CompositesDocument9 pagesMolecular Dynamics Simulations of The Elastic Properties of Polymer/carbon Nanotube CompositesQuantum KnotsNo ratings yet

- Solved With COMSOL Multiphysics 4.4 TinDocument14 pagesSolved With COMSOL Multiphysics 4.4 TinEdgar MurilloNo ratings yet

- Plate and Frame FiltrationDocument11 pagesPlate and Frame FiltrationQuenneBelocuraNo ratings yet

- Cotter and Sleeve JointDocument17 pagesCotter and Sleeve JointNishit Karkar100% (2)

- Flux Cored Wire LincolnDocument6 pagesFlux Cored Wire LincolnAlexander Saavedra MambuscayNo ratings yet

- Msds PVC ReonDocument2 pagesMsds PVC ReongudasanNo ratings yet

- Bamboo As Building MaterialDocument30 pagesBamboo As Building MaterialKkarthik100% (1)

- Organic Chemistry Keywords - 1. Crossword Answers.Document2 pagesOrganic Chemistry Keywords - 1. Crossword Answers.sjNo ratings yet

- BXCD4545 - Revd BXCD4545 DatasheetDocument9 pagesBXCD4545 - Revd BXCD4545 DatasheetpedroanjoNo ratings yet

- SS 1.4313Document2 pagesSS 1.4313mechkashanNo ratings yet

- DS125NSSUGARR2Document1 pageDS125NSSUGARR2Frandika PrimayogaNo ratings yet

- Catloge 321Document184 pagesCatloge 321Muhammad WaseemNo ratings yet

- Multiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyDocument109 pagesMultiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyLong BuiNo ratings yet

- Agricultural Applications For Pine-Based BioCharDocument542 pagesAgricultural Applications For Pine-Based BioCharcarbonbrokers100% (1)

- Determination of Gold in Bullion by Cupellation: Standard Test Methods ForDocument5 pagesDetermination of Gold in Bullion by Cupellation: Standard Test Methods ForMark JurichNo ratings yet

- Quotation For RO MembraneDocument15 pagesQuotation For RO MembraneKELVIN TECHNOLOGIESNo ratings yet

- Ebook Powder CoatingDocument27 pagesEbook Powder Coatinggcldesign100% (1)