Professional Documents

Culture Documents

Prod-Fmea-01 Pfmea

Prod-Fmea-01 Pfmea

Uploaded by

umesh sengarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prod-Fmea-01 Pfmea

Prod-Fmea-01 Pfmea

Uploaded by

umesh sengarCopyright:

Available Formats

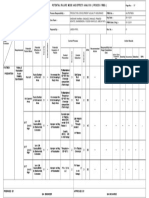

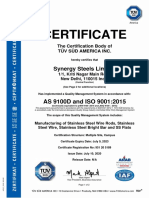

Synergy Steels Limited

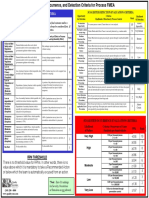

PROCESS FMEA

ITEM : Process Responsibility : Prepared By : FMEA No. : SSL/PFMEA/01

Model : Key Date : FMEA Date (Org) : Rev. / Date : 00/ 14.01.2019

Target RPN= 200

Core Team :

Potential Causes / Resp. &

Detect

Detect

Occur

Occur

Process Function Potential Failure Potential Effect (s) of Current Process Control Current Process Recommended Action

RPN

RPN

Sev

Sev

Mechanism of Target

Requirement Mode Failure (Prevention) Control (Detection) Action (s) Taken

Failures Comp.Date

Rolling Mill

Skilled Operator,

Display the DGM

Issues in rolling mill Continuous online

Size setting Improper Size Product Rejected 7 4 Standard Setup 2 56 standarad set up (Prodn),15th Completed 7 2 2 28

setup inspection by qualified

on the shop floor Feb'19

inspector

Senior furnace operators

Standardized furnace

Improper reheating with sufficient job

temperature set up for Display the DGM

Surface defects in furnace temperature, Bad knowledge,

Finished goods quality Product Rejected 8 3 various material grades, 3 72 standarad set up (Prodn),15th Completed 8 2 2 32

Material condition of mill passes. Visual inspection of

Strictly following the agreed on the shop floor Feb'19

passes by skilled

schedule for pass changes

operator

Improper setting , Poor

Regular calibration of Use EN 10088-3

condition of the UTM, Skilled Operator ,Automatic Sr. Manager

Tesnile testing of finished Tensile properties out UTM, Chemistry for chamistry &

Product Rejected 7 Improper 1 control of annealing furnace, 2 14 QC, 15th Completed 7 0 1 0

goods of tolerances validation by calibrate the

chemistry,Improper heat Standardized chemistry Feb'19

Spectrometer UTM machine

treatment

Temp. display of temp. Grade wise

Annealing

Variation in material Variation In Temp. of Auto Temp. Control controller/ regular temprature chart

Heat Treatment High / Low Temp. 6 1 2 12 Operater 15th Completed 6 1 1 6

properties Annealing Furnace available calibration of and WI available

Feb'19

thermocouples on shop floor

Visual inspection

Unskilled Operator , Regular Inspection as of every coils QC Line

Visual Inspection of Chances of passing of Skilled QC inspector

Defects in Product 3 Not able to detect the 3 per guidelines, 5 45 and work Inspecter 15 Completed 3 2 3 18

finished goods rejected Material Available

hidden defects instruction on th FEB'19

finishing area

Colour coding for coil Color Code chart

Coil QC Supervisor

Improper Marking Material Mixing 2 Un Skilled Operator 3 Skilled Operator identification, Hand held 7 42 on coil handling Completed 2 1 5 10

identification/traceability 15 th feb'19

Spectrometer and finishing area.

Skilled Operator , Stuffing Skilled operator Rachid Belt after Dispatch

Material damage during Un Skilled Operator, Bad

Improper Packing 8 3 the container with proper Supervision during 2 48 three line and last Supervisor Completed 8 2 1 16

Transit stuffing in the container

props & supports container stuffing line of coils 16th Feb'19

Packing & Dispatch

Ensure the loaded Dispatch

Check truck

vehicles leave SSL after Supervisor and

Improper transport Before entered and

Chances of Product Failure 8 Mishandling of material 3 Agreements with Transporter verifying that the loaded 2 48 Security Completed 8 2 1 16

activities material covered

material is in proper Incharge 15 th

with Tarpoline

condition Feb'19

You might also like

- DFMEA PFMEA Control Plan LinkagesDocument1 pageDFMEA PFMEA Control Plan LinkagesSaul Montiel100% (2)

- Failure Mode and Effects Analysis (Process Fmea)Document4 pagesFailure Mode and Effects Analysis (Process Fmea)kamlesh kuchekar100% (4)

- Plating FMEADocument1 pagePlating FMEAshiv jangale80% (5)

- PFMEA - StampingDocument8 pagesPFMEA - StampingNimesh Mehta67% (6)

- Sample FMEA - MachiningDocument20 pagesSample FMEA - MachiningHemantNo ratings yet

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyNo ratings yet

- 5m+1e Change Matrix SOPDocument2 pages5m+1e Change Matrix SOPGirdhar Sahu100% (1)

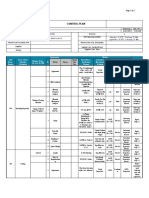

- Control PlanDocument3 pagesControl PlanSaravana Bharathy Reddy100% (2)

- CQI-11 Plating 20177Document24 pagesCQI-11 Plating 20177Jose Raul Aquino Herrera0% (1)

- System QSB First Step Fast Response PDFDocument19 pagesSystem QSB First Step Fast Response PDFPrabagarane RamachandranNo ratings yet

- Potential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyDocument6 pagesPotential Failure Mode and Effects Analysis (DESIGN FMEA) : Disk Brake Sub-AssemblyLuis Carlos SuarezNo ratings yet

- PFMEA OF ABB TankDocument12 pagesPFMEA OF ABB Tankrohit mathanker100% (3)

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- 6070634bea45a1f34b572c55 - CQI-9 4th Ed AMP 041021Document30 pages6070634bea45a1f34b572c55 - CQI-9 4th Ed AMP 041021harieduidNo ratings yet

- PPAP 4th. EditionDocument75 pagesPPAP 4th. EditionGilberto FloresNo ratings yet

- Fmea Sfe47.005 WeldingDocument8 pagesFmea Sfe47.005 Weldingkumaraswamy.kNo ratings yet

- IATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionDocument29 pagesIATF - International Automotive Task Force: Rules For Achieving and Maintaining IATF Recognition IATF Rules 5 EditionAkshay Singh kushwahNo ratings yet

- FMEA SampleDocument94 pagesFMEA SampleKaran MalhiNo ratings yet

- Hot ForgingDocument7 pagesHot ForgingPradeep Kumar BowmarajuNo ratings yet

- Apqp Matrix-Pin Post Side HingeDocument2 pagesApqp Matrix-Pin Post Side Hingeabhishek100% (1)

- FMEADocument55 pagesFMEAVijay Kumar100% (1)

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1No ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocument4 pagesMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (6)

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarNo ratings yet

- 4M Change Management Matrix-Rane NSK-signedDocument1 page4M Change Management Matrix-Rane NSK-signednitin rathoreNo ratings yet

- Layout Inspection Report XH5DR June 20 2012Document17 pagesLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj Rawat0% (1)

- Supplier Control Plan: Audit SummaryDocument2 pagesSupplier Control Plan: Audit SummaryRay ManNo ratings yet

- PFMEA ExampleDocument14 pagesPFMEA Examplekalebasveggie100% (1)

- PPAP GuidelinesDocument19 pagesPPAP GuidelinesmoezNo ratings yet

- Control Plan TrainingDocument20 pagesControl Plan TraininglittlekheongNo ratings yet

- 06) - Fmea For 11190722 - DDocument192 pages06) - Fmea For 11190722 - DMONISHRAJNo ratings yet

- Plating Control Plan-31 MARCH 09Document10 pagesPlating Control Plan-31 MARCH 09Rohtash fastner100% (1)

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- System Audit RequirementDocument37 pagesSystem Audit Requirementavinashbatra171% (7)

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDocument1 pageOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochNo ratings yet

- New PFMEADocument9 pagesNew PFMEAPuneet SharmaNo ratings yet

- 02 FMEA Training - How To DoDocument45 pages02 FMEA Training - How To DoRamkumar PerumalNo ratings yet

- Pfmea Process Failure Mode and Effects AnalysisDocument34 pagesPfmea Process Failure Mode and Effects AnalysisRizky SihabNo ratings yet

- Special Characteristics PDFDocument11 pagesSpecial Characteristics PDFKristof MCNo ratings yet

- Rohtas Fasteners Pvt. LTD.: Defect Matrix-Bolt Cylinder Head SR. Ok Part Defect Reject Part ImageDocument4 pagesRohtas Fasteners Pvt. LTD.: Defect Matrix-Bolt Cylinder Head SR. Ok Part Defect Reject Part ImageVandana MehraNo ratings yet

- CQI 9 Internal Audit Observations 07.04.11Document2 pagesCQI 9 Internal Audit Observations 07.04.11Asif AliNo ratings yet

- 01 - APQP Training Material PDFDocument62 pages01 - APQP Training Material PDFMohit SinghNo ratings yet

- PFD - Example..Document4 pagesPFD - Example..lalit GuptaNo ratings yet

- FMEA - Landi Ranzo180908Document6 pagesFMEA - Landi Ranzo180908sanqutbi100% (1)

- MBO CQI 11 2020 2nd EditionDocument81 pagesMBO CQI 11 2020 2nd EditionHoang TanNo ratings yet

- Route Card Implementation (In In-House and Supplier)Document10 pagesRoute Card Implementation (In In-House and Supplier)Manoharar RNo ratings yet

- APQP Timing PlanDocument2 pagesAPQP Timing PlandanielsasikumarNo ratings yet

- Guideline 4M Change MatrixDocument3 pagesGuideline 4M Change MatrixAman JasujaNo ratings yet

- Process SheetDocument8 pagesProcess SheetSuraj RawatNo ratings yet

- Potential Failure Mode and Effects AnalysisDocument1 pagePotential Failure Mode and Effects AnalysisNatarajan GopalaswamyNo ratings yet

- Emmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Document1 pageEmmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Satya PalNo ratings yet

- Potential Failure Mode and Effects Analysis (Design)Document12 pagesPotential Failure Mode and Effects Analysis (Design)PiyushNo ratings yet

- Potential Failure Mode and Effects Analysis (Design FMEA)Document12 pagesPotential Failure Mode and Effects Analysis (Design FMEA)sachNo ratings yet

- Potential Failure Mode and Effects Analysis (Process Fmea)Document4 pagesPotential Failure Mode and Effects Analysis (Process Fmea)Mahmoud KhalifaNo ratings yet

- Blank PFMEADocument1 pageBlank PFMEAEdgar Lopez RiveraNo ratings yet

- dFMEA 4th Edition BlankDocument1 pagedFMEA 4th Edition BlankTom@GGCNo ratings yet

- EN# EN Name SAE UNS DIN Carbon SteelsDocument16 pagesEN# EN Name SAE UNS DIN Carbon Steelsumesh sengarNo ratings yet

- Carpenter Stainless Type 430: IdentificationDocument4 pagesCarpenter Stainless Type 430: Identificationumesh sengarNo ratings yet

- Certificate: AS 9100D and ISO 9001:2015Document2 pagesCertificate: AS 9100D and ISO 9001:2015umesh sengarNo ratings yet

- F08.2.2-8 Assesment Supplier InglesDocument15 pagesF08.2.2-8 Assesment Supplier Inglesumesh sengarNo ratings yet

- Pending Mechanical Testing Report Prasum MetalDocument1 pagePending Mechanical Testing Report Prasum Metalumesh sengarNo ratings yet

- Questionnaire For Suppliers Selection: Steel & Trucks, S.A. de C.V. / Stamping Steel & Trucks S.A. de C.VDocument3 pagesQuestionnaire For Suppliers Selection: Steel & Trucks, S.A. de C.V. / Stamping Steel & Trucks S.A. de C.Vumesh sengarNo ratings yet

- F08.2.2-8 Assesment Supplier InglesDocument15 pagesF08.2.2-8 Assesment Supplier Inglesumesh sengarNo ratings yet

- National Assembly of Vietnam - Socialist Republic of Vietnam Independence - Freedom - HappinessDocument24 pagesNational Assembly of Vietnam - Socialist Republic of Vietnam Independence - Freedom - HappinesskhavihongNo ratings yet

- Newspapers VocabularyDocument2 pagesNewspapers Vocabularyali bettaniNo ratings yet

- Faculty Motivation PowerPoint 21Document27 pagesFaculty Motivation PowerPoint 21Prasad ShahNo ratings yet

- ScienceDocument233 pagesScienceGrace Lu-angNo ratings yet

- Digital Marketing-Prof Krishanu-Session 5Document52 pagesDigital Marketing-Prof Krishanu-Session 5Shubham AroraNo ratings yet

- Ub VmoDocument4 pagesUb VmoChristian Dave Tad-awanNo ratings yet

- Incentives and CompensationDocument2 pagesIncentives and CompensationGasai YunoNo ratings yet

- Training Needs Assessment: A Systematic ApproachDocument20 pagesTraining Needs Assessment: A Systematic Approachpkumarjothi6433No ratings yet

- Skillup: Learn Now. Transform Tomorrow. Grow ForeverDocument14 pagesSkillup: Learn Now. Transform Tomorrow. Grow ForeverMahesh KumarNo ratings yet

- Regional Integration in Industrial Development in ECOWAS by Bitrus Kyangmah Samaila, BSC, MSC, MBA in View, University of Maiduguri, Nigeria.Document9 pagesRegional Integration in Industrial Development in ECOWAS by Bitrus Kyangmah Samaila, BSC, MSC, MBA in View, University of Maiduguri, Nigeria.BitrusNo ratings yet

- 9 Planning Tools and Techniques PDFDocument33 pages9 Planning Tools and Techniques PDFJae Anne SarabiaNo ratings yet

- Zayed Mohdhar Abed Mohsin Abadi: Test Information تﺎﻣوﻠﻌﻣ رﺎﺑﺗﺧﻻاDocument1 pageZayed Mohdhar Abed Mohsin Abadi: Test Information تﺎﻣوﻠﻌﻣ رﺎﺑﺗﺧﻻاadelNo ratings yet

- An Educational Ministry of The Jesus Christ, The Refiner's Fire ChurchDocument2 pagesAn Educational Ministry of The Jesus Christ, The Refiner's Fire ChurchIhla Katrina Reyes TubiganNo ratings yet

- Ty Bba-Ib Final ProjectDocument39 pagesTy Bba-Ib Final ProjectMohit Burad100% (1)

- Agent of Socialization MeDocument1 pageAgent of Socialization Meapi-428326058No ratings yet

- ResearchDocument52 pagesResearchmaryjoy furtonNo ratings yet

- Soal ErDocument5 pagesSoal ErDella cahya sariNo ratings yet

- LTP Legal ResearchDocument4 pagesLTP Legal ResearchNiharika GumasteNo ratings yet

- Instructional Learning Plan: Marvin Ace J. Sencio Mathematics Grade 7Document2 pagesInstructional Learning Plan: Marvin Ace J. Sencio Mathematics Grade 7Roy Allan T. RamoNo ratings yet

- Course Catalogue CCEEDocument3 pagesCourse Catalogue CCEEimad2050No ratings yet

- Time Table Level 5 - 10Document1 pageTime Table Level 5 - 10Babar KhanNo ratings yet

- Independent University, Bangladesh: Summer 2013 Semester Courses and Class ScheduleDocument47 pagesIndependent University, Bangladesh: Summer 2013 Semester Courses and Class ScheduleMd Sharif HossainNo ratings yet

- Cavdur 2018 Lean Service System Design A Simulation-Based VSM Case StudyDocument20 pagesCavdur 2018 Lean Service System Design A Simulation-Based VSM Case Studyapostolos thomasNo ratings yet

- 14 Principles OF Scientific Management BY Henry FayolDocument19 pages14 Principles OF Scientific Management BY Henry FayolShweta ShrivastavaNo ratings yet

- Maki's AssignmentDocument2 pagesMaki's AssignmentAna Luna AdolfoNo ratings yet

- 3 Act Tasks 3rd GradeDocument3 pages3 Act Tasks 3rd GradeKati RawnNo ratings yet

- 11 Steps To Successful Farm MarketingDocument6 pages11 Steps To Successful Farm MarketingLekh RajNo ratings yet

- Market AnalysisDocument2 pagesMarket AnalysisRia GayleNo ratings yet

- Project TopicDocument7 pagesProject TopicmehmudNo ratings yet

- Book of Best Practices Trauma and The Role of Mental Health in Post-Conflict RecoveryDocument383 pagesBook of Best Practices Trauma and The Role of Mental Health in Post-Conflict RecoveryDiego Salcedo AvilaNo ratings yet