Professional Documents

Culture Documents

Welder Monitoring Sheet

Welder Monitoring Sheet

Uploaded by

QC apollohxOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welder Monitoring Sheet

Welder Monitoring Sheet

Uploaded by

QC apollohxCopyright:

Available Formats

DOC No.

F/QAD/29

Rev.00

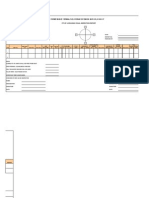

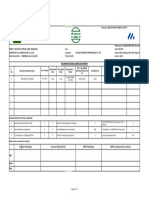

DATA MONITERING SHEET---WELDING PROCEDURE QUALIFICATION (PQR)TEST COUPON

RECORD

Owner AHEPL Welder Name Report No.

Client AHEPL Welder No. WPS No. PQR No:

Project Welder Qualification Electrode: :Batch No: Process GTAW with Argon gas (141)

Date Electrode :Batch No: 14175 Ar ( 100% pure Argon)

Material Specification EN AW Brand Name: Position

Thickness. Filler wire Root Gap

Test Coupon Yes Production Weld Filler Grade EN ISO 18273 S: Al 5183 Visual Examinati Root: Satisfacto Final Satisfactory

Size of the test coupon Filler wire size: Result: Satisfactory NO

Id,Joint N Joint Type & Size Preheat Temperature Interpass Temperature

Gas Flow Rate: 12-15LPM

Sl.No. Size of Weld Polarity Current Voltage Travel speed speed Run out Time Heat Input REMARKS

Electrode Layers A V mm/min sec/100mm (sec) (KJ/min)

Material Heat No./ Cast No.: Plate No. /Lot No./ Test No.

Material Heat No./ Cast No.: Plate No./ Lot No./Test No.:

1.The hard stamping details or marking on the test plates shall be recorded on the next page for both performance qualification and procedure qualification.

Joint dia

2.Weld Visual has been carried out as per (EN 17637) and found satisfactory.

SIGNATURE

NAME

DATE

PREPARED BY CHECKED BY WITTNESS BY

IWE/IWT

You might also like

- SEBF8034 - Valve and Valve Spring Specifications (1Document21 pagesSEBF8034 - Valve and Valve Spring Specifications (1mohamed aliNo ratings yet

- Welding Traceability Record 1Document1 pageWelding Traceability Record 1Alfian Imaduddin100% (1)

- QCF309 Welding Summary ReportDocument1 pageQCF309 Welding Summary Reportminhnn100% (5)

- Basic Fabrication Process FlowchartDocument2 pagesBasic Fabrication Process FlowchartGodwin A.udo-akan100% (1)

- Piping Welding Daily Quality Control and Inspection Report FormDocument1 pagePiping Welding Daily Quality Control and Inspection Report Formenels77100% (5)

- BS en 755-1-2016Document24 pagesBS en 755-1-2016QC apollohx50% (2)

- Rahu Ketu Komilla SuttonDocument5 pagesRahu Ketu Komilla Suttontmn2011100% (2)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Eicas Messages - Failures - B767 Passenger and Freighters Airplanes - (Only Reference)Document31 pagesEicas Messages - Failures - B767 Passenger and Freighters Airplanes - (Only Reference)Daniel Ospina100% (2)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- FIT UP ReportDocument2 pagesFIT UP Reportsiva8000No ratings yet

- Weld Map (17007 Ab)Document22 pagesWeld Map (17007 Ab)9913489806100% (2)

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportAbdullah Ansari100% (1)

- Fit-Up & Welding Visual Inspection ReportDocument11 pagesFit-Up & Welding Visual Inspection ReportRachel Flores71% (7)

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Welding Map & NDE Map JTBDocument7 pagesWelding Map & NDE Map JTBFarhan PutraNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Visual Inspection Report - During WeldingDocument1 pageVisual Inspection Report - During WeldingsurwaneNo ratings yet

- Fit Up & Weld VisualDocument2 pagesFit Up & Weld VisualBhanu Pratap ChoudhuryNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- Welding Log BookDocument1 pageWelding Log Booksamsurendran_mech4020No ratings yet

- Qualified Welders ListDocument3 pagesQualified Welders Listdav100% (1)

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- Daily Weld Fit-Up and Production Report (Field Weld) - Pipeline-Satr-W-2007Document5 pagesDaily Weld Fit-Up and Production Report (Field Weld) - Pipeline-Satr-W-2007smdriyazbasha100% (2)

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument4 pagesPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepNo ratings yet

- WPS Format For ASME IX - WQTDocument1 pageWPS Format For ASME IX - WQTThe Welding Inspections CommunityNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Welding ReportDocument52 pagesWelding ReportalidadNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Replace No.3 API Oil Separator Project: Daily Fitup ReportDocument20 pagesReplace No.3 API Oil Separator Project: Daily Fitup Reportsajay2010No ratings yet

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- WPS Form - A - ENGDocument1 pageWPS Form - A - ENGdavidemolNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

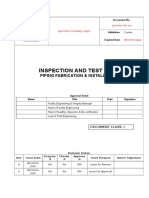

- Inspection and Test Plan: Piping Fabrication & InstallationDocument11 pagesInspection and Test Plan: Piping Fabrication & Installationmohd as shahiddin jafriNo ratings yet

- Welding Visual Inspection FormatDocument2 pagesWelding Visual Inspection Formatgst ajah100% (3)

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPQT SawDocument2 pagesWPQT Sawkiran144No ratings yet

- PQR Form (Welding)Document2 pagesPQR Form (Welding)jasmineammaNo ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- Daily Fit-Up/Welding Inspection ReportDocument7 pagesDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Welding TracebillityDocument15 pagesWelding TracebillityDeby Agung PratamaNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- E WPQ Witness FormatDocument1 pageE WPQ Witness FormatBalkishan DyavanapellyNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Summary of The Book One Minute Manager.Document9 pagesSummary of The Book One Minute Manager.QC apollohxNo ratings yet

- Large Damage RepairDocument2 pagesLarge Damage RepairQC apollohx100% (1)

- Hand-Tap BSPDocument1 pageHand-Tap BSPQC apollohxNo ratings yet

- Weld Defects TrainingDocument77 pagesWeld Defects TrainingQC apollohx100% (1)

- ANNEXURE FOR RT Testing 20.12.19Document1 pageANNEXURE FOR RT Testing 20.12.19QC apollohxNo ratings yet

- Apollo Heat Exchangers PVT LTD: SR - No. EN Ref - No. List of Standard For en 15085-2 Existing Version New VersionDocument1 pageApollo Heat Exchangers PVT LTD: SR - No. EN Ref - No. List of Standard For en 15085-2 Existing Version New VersionQC apollohxNo ratings yet

- Apollo Heat Exchangers PVT LTD: Testing Requirement As Per EN ISO 15614-2 RequirementsDocument1 pageApollo Heat Exchangers PVT LTD: Testing Requirement As Per EN ISO 15614-2 RequirementsQC apollohxNo ratings yet

- Apollo Heat Exchangers PVT LTD: SR - No. EN Ref - No. List of Standard For en 15085-2 Existing Version New VersionDocument1 pageApollo Heat Exchangers PVT LTD: SR - No. EN Ref - No. List of Standard For en 15085-2 Existing Version New VersionQC apollohxNo ratings yet

- ANNEXURE FOR Testing 20.12.19Document2 pagesANNEXURE FOR Testing 20.12.19QC apollohxNo ratings yet

- BS en 455-4-2009Document22 pagesBS en 455-4-2009QC apollohx100% (1)

- BS en 455-2-2015Document16 pagesBS en 455-2-2015QC apollohxNo ratings yet

- BS en 455-1-2000Document8 pagesBS en 455-1-2000QC apollohxNo ratings yet

- Ikr17 RulesDocument52 pagesIkr17 RulesAnandNo ratings yet

- Laguna Project 2013Document30 pagesLaguna Project 2013Ervin Aldaba BoadoNo ratings yet

- Quantum Magnets - A Brief OverviewDocument36 pagesQuantum Magnets - A Brief OverviewSubhajit SarkarNo ratings yet

- 9701 s08 Ms 2Document6 pages9701 s08 Ms 2Hubbak KhanNo ratings yet

- Design of Cond TrapDocument7 pagesDesign of Cond TrapgtdprasadNo ratings yet

- Blends, Glide Flooded Evaporators: DefinitionsDocument4 pagesBlends, Glide Flooded Evaporators: DefinitionszhyhhNo ratings yet

- CIRCULAR INLINE FANS - Rotech Inc.Document2 pagesCIRCULAR INLINE FANS - Rotech Inc.ABCDNo ratings yet

- MCT D ManualDocument25 pagesMCT D ManualAmit KumarNo ratings yet

- PSV Data Sheets: Customer NameDocument4 pagesPSV Data Sheets: Customer NameImmanuelNo ratings yet

- Gas Tanker Operation Manual (Refrigerated)Document263 pagesGas Tanker Operation Manual (Refrigerated)Paing Saying SoeNo ratings yet

- pppcr11 15seDocument124 pagespppcr11 15seLiv Edwards29% (7)

- Manual 8010 Serie 3 19 e 2Document78 pagesManual 8010 Serie 3 19 e 2Nelutu LapadatuNo ratings yet

- FINs & NCRsDocument5 pagesFINs & NCRsRaj KiranNo ratings yet

- Three Phase Transformer Connections and BasicsDocument8 pagesThree Phase Transformer Connections and BasicsKarthick RathinasamyNo ratings yet

- Energy Changes in Chemical Reactions Exothermic Reaction Is One That Releases Energy in The Form of Heat orDocument3 pagesEnergy Changes in Chemical Reactions Exothermic Reaction Is One That Releases Energy in The Form of Heat ormark bendanoNo ratings yet

- Unicorn Energy Healing System EnglishDocument15 pagesUnicorn Energy Healing System EnglishJose Marinho100% (1)

- Hindalco Integrated Annual Report 2020 21Document264 pagesHindalco Integrated Annual Report 2020 21NchdhrfNo ratings yet

- ELTFT01 Prueb SWG Panel PIPDocument25 pagesELTFT01 Prueb SWG Panel PIPJAVIJHPNo ratings yet

- E 563 - 97 - Rtu2my1sruqDocument4 pagesE 563 - 97 - Rtu2my1sruqgrats_singcoNo ratings yet

- High Power Fiber Lasers A ReviewDocument23 pagesHigh Power Fiber Lasers A ReviewNikita ToropovNo ratings yet

- E9 InspectionRecorderDocument14 pagesE9 InspectionRecordercristiNo ratings yet

- RM BV Manual PDFDocument9 pagesRM BV Manual PDFjaydspainNo ratings yet

- MEP 003A Dual With Trailer Organizational Intermediate Direct Support and General Support Maintenance Repair Parts and Special Tools List TM 5 6115 633 14& PDocument160 pagesMEP 003A Dual With Trailer Organizational Intermediate Direct Support and General Support Maintenance Repair Parts and Special Tools List TM 5 6115 633 14& PGreenMountainGenerators100% (1)

- Spesifikasi TeknisDocument3 pagesSpesifikasi TeknisMuhammad YassirNo ratings yet

- Instructions For Use CONNEX Cable Connector Size 3 and 3/SDocument36 pagesInstructions For Use CONNEX Cable Connector Size 3 and 3/SJonathan FuentesNo ratings yet

- Essential Pharma Documents: 1205: SolutionDocument14 pagesEssential Pharma Documents: 1205: SolutionSudhakar KuppireddyNo ratings yet

- 06 02 00 1FT PDFDocument2 pages06 02 00 1FT PDFRam MugeshNo ratings yet