Professional Documents

Culture Documents

Zero Plastics Poster

Zero Plastics Poster

Uploaded by

Karafton IndiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zero Plastics Poster

Zero Plastics Poster

Uploaded by

Karafton IndiaCopyright:

Available Formats

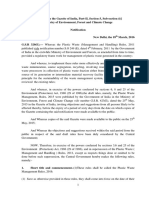

WORKING

ZERO PLASTIC WASTE

4% LOSSES

SOLUTION

8%

TOWARDS A

14% COLLECTED FO

CASCADED

R REC

RECYCLING 2% CLOSED-LOOP RECYCLING

YC

LING

IMPROVED RECYCLING TECHNOLOGIES

98% 78 14% INCINERATED

CHEMICAL RECYCLING MECHANICAL RECYCLING

SMART SORTING TECHNOLOGIES

Problem: The variety of plastics make it

FROM NON- MILLION

40% GOES TO LANDFILL difficult to identify polymer types.

RECYLED TONNES Where mechanical Effective separation and

SOURCES ANNUAL PLASTIC recycling fails, polymer cleaning technologies OPTICAL SORTING

PACKAGING PRODUCTION* 32% LEAKS TO ENVI

types (in mixed recycling) preserve the integrity of

RONMENT

*Global figures for 2013 Optical sorting technologies

can be chemically polymer types – resulting in

14% of plastics are collected for can recognise polymer types

separated at a a higher quality recycled

by illuminating the material

r

recycling (4% is lost, 8% is recycled to

a

molecular level. products that can be recycled

ye

and analysing the reflection

lower value plastics and only 2% in multiple times.

ch

spectrum.

00

ea

closed-loop recycling). ly

3

mi l

llio lo ba MARKER TECHNOLOGY

n to g

nnes of lastic crea ted This uses markers that can be

p quickly and easily scanned by

sorting machinery. These might

UK PLASTICS CONSUMPTION BENEFITS OF PLASTIC include printed barcodes,

44% packaging Versatile, durable, light, easily shaped, fluorescent labels and invisible

strong, inexpensive and able to be sterile. chemical markers.

7% automotive,

High quality

5% electrical and electronic plastics will allow for

24% building and construction cleaner, more efficient

20% other energy

recovery

through

incineration.

FOSSIL FUELS NEW CHEMISTRY Change behaviour – reduce Problem: Reducing leakage COMPOSTABLE PACKAGING

Problem: 90% of plastics are derived leakage, cut use of from 32% to 1% still results in

Problem: Plastic single-use plastics, one million tonnes of plastic material Problem: Many

from fossil fuel sources.

Sources: UKRI, Ellen MacArthur Foundation

Solution: Use organic sources such quality degrades increase reuse, increase entering natural systems. ‘biodegradable’

as algae, cellulose and starch. during recycling, uptake of recycling. Solution: Greater adoption of items are only such

many plastics can bio-benign materials would limit under laboratory,

Plastics can be only be recycled environmental damage. or industrial

manufactured from once. conditions.

hydrocarbons derived Solution: Develop a new ‘super’ polymer – a high-quality,

from recaptured high-value plastic that can be recycled multiple times. HARNESSING BEASTIES Solution: Develop truly biodegradable, or

greenhouse gases. compostable plastics based on organic

UKRI scientists

NEW JOINING TECHNOLOGY LIGHTWEIGHT PLASTIC have been

feedstocks.

Problem: working with an MARINE

Problem: Use of glues,

MONO MATERIAL PACKAGING screws and clips complicates Unnecessary enzyme that has DEGRADABILITY

the sorting process. plastic volume. been shown to Problem: Most

Infographic: BEN GILLILAND

Problem: Packaging made

up of multiple plastic Solution: Develop Solution: break down biodegradable plastics

types is hard to recycle. bio-inspired glues that break Reduce wall plastics in landfills. Wax moth merely fragment in the

Solution: Design down to allow for easy thickness and larvae have also been shown to be environment –

packaging made of single plastics separation. Design mono material reinforce with ribs – greatly able to digest plastic bags and increasing microplastics in the oceans.

type plastics (mono packaging with components that snap together reducing the volume of plastic scientists have also identified a Solution: Develop truly marine

materials). – requiring no glue or screws. in the product. plastic-eating bacteria. degradable plastics.

You might also like

- Miele Combi Oven H6200BM - Eng ManualDocument112 pagesMiele Combi Oven H6200BM - Eng ManualAmy LiNo ratings yet

- Eis Fareast Fuel PDFDocument50 pagesEis Fareast Fuel PDFricchrist dela cruzNo ratings yet

- Environmental and Social Management Plan (ESMP) and Mitigating Measures For Eligible Sub-Projects Under The KC-NCDDPDocument11 pagesEnvironmental and Social Management Plan (ESMP) and Mitigating Measures For Eligible Sub-Projects Under The KC-NCDDPmich100% (1)

- Process Design BasisDocument6 pagesProcess Design BasisMufleh Idris100% (3)

- Science Centres For 21st Century SchoolsDocument28 pagesScience Centres For 21st Century SchoolsSimon Crook100% (2)

- QMRE Business Plan Digital PDFDocument50 pagesQMRE Business Plan Digital PDFSourabh WaghNo ratings yet

- Drawstring Linen Shorts Tutorial and Free PatternDocument20 pagesDrawstring Linen Shorts Tutorial and Free PatternheloisaNo ratings yet

- Web Science Centre For Doctoral Training 2017-2018 Research BookletDocument114 pagesWeb Science Centre For Doctoral Training 2017-2018 Research BookletAnonymous iSSViANo ratings yet

- 18.introduction To A Large-Scale Biogas Plant in A Dairy FarmDocument4 pages18.introduction To A Large-Scale Biogas Plant in A Dairy FarmAndre SitohangNo ratings yet

- Research Methods - Grants Ver 1.1Document93 pagesResearch Methods - Grants Ver 1.1meghraj01No ratings yet

- Circular EconomyDocument4 pagesCircular EconomyAnna Samchuk100% (1)

- Magic BusDocument29 pagesMagic BusAshworth Vaz100% (1)

- Going PaperlessDocument56 pagesGoing Paperlessjoseline kenmoeNo ratings yet

- Smart Cities - Deloitte NCCDocument13 pagesSmart Cities - Deloitte NCCRahul BajajNo ratings yet

- Infographic Tetra RecartDocument1 pageInfographic Tetra RecartvizmarghNo ratings yet

- Paper Task Force ReportDocument249 pagesPaper Task Force ReportHeadyMcGeeNo ratings yet

- Guidance and Criteria For Safe RecyclingDocument37 pagesGuidance and Criteria For Safe RecyclingSundar MoorthiNo ratings yet

- Sustainable Mobility The Route of Tires Through The Circular EconomymodelDocument14 pagesSustainable Mobility The Route of Tires Through The Circular Economymodelgutha manikantaNo ratings yet

- TI-Finding - & - Reducing - Waste - in - Plastics Processing - (GG277)Document51 pagesTI-Finding - & - Reducing - Waste - in - Plastics Processing - (GG277)NormanBates100% (1)

- Packaging in A Circular EconomyDocument110 pagesPackaging in A Circular EconomyDaniela MincaNo ratings yet

- Cognitive Smart Healthcare For Pathology Detection and MonitoringDocument9 pagesCognitive Smart Healthcare For Pathology Detection and MonitoringPavan VNo ratings yet

- Importance of Flower Arrangements in Hotel1Document4 pagesImportance of Flower Arrangements in Hotel1Jatti GrewalNo ratings yet

- Biodegradable PolymerDocument33 pagesBiodegradable PolymerMohamed Abu-BakrNo ratings yet

- New PPT 12062021Document15 pagesNew PPT 12062021SSãï Pãvãñ KümãrNo ratings yet

- Project On Cost Analysis of Setting Up A Waste Paper Recycling UnitDocument15 pagesProject On Cost Analysis of Setting Up A Waste Paper Recycling UnitPrakhar KulshreshthaNo ratings yet

- Development of Reverse Vending Machine RVM Framewo PDFDocument6 pagesDevelopment of Reverse Vending Machine RVM Framewo PDFEbrahim Abd El HadyNo ratings yet

- Hazaka Plant:: Solving Waste Problems in IndonesiaDocument10 pagesHazaka Plant:: Solving Waste Problems in Indonesianugroho arbeeNo ratings yet

- Guide To The Three Bin System - 2020 Update PDFDocument20 pagesGuide To The Three Bin System - 2020 Update PDFElspeth KerneboneNo ratings yet

- Smart CityDocument13 pagesSmart CityatharNo ratings yet

- Banan Fiber PDFDocument19 pagesBanan Fiber PDFtulasi saladiNo ratings yet

- Plastic Waste Management RulesDocument22 pagesPlastic Waste Management RulesBedatrayee05No ratings yet

- Recycled Polyamides, A Literature Review and Research OpportunitiesDocument15 pagesRecycled Polyamides, A Literature Review and Research OpportunitiesTomGaliciaNo ratings yet

- Ornamental PlantsDocument7 pagesOrnamental PlantsMalbruaNo ratings yet

- FDR PresentationDocument16 pagesFDR Presentationjeicg21No ratings yet

- Chemical Recycling Insight June 2022Document23 pagesChemical Recycling Insight June 2022Ponglert ChantornNo ratings yet

- Scrappy ManagementDocument14 pagesScrappy ManagementSaurabh JunejaNo ratings yet

- Câu 3Document6 pagesCâu 3Yến VyNo ratings yet

- Preparation of Electrospun Affinity Membrane and Cross Flow System For Dynamic Removal of Anionic Dye From Colored WastewaterDocument13 pagesPreparation of Electrospun Affinity Membrane and Cross Flow System For Dynamic Removal of Anionic Dye From Colored WastewaterManu SharmaNo ratings yet

- Catalytic Transformation or Waste Polymers To Fuel OilDocument8 pagesCatalytic Transformation or Waste Polymers To Fuel Oilsanty cuervoNo ratings yet

- pb13530 Waste Hierarchy Guidance PDFDocument14 pagespb13530 Waste Hierarchy Guidance PDFyusyus 241No ratings yet

- 0049 0060 PDFDocument12 pages0049 0060 PDFManush MaranNo ratings yet

- SustentabilidadeDocument1 pageSustentabilidadeJoaoNo ratings yet

- Effects of Peroxide and Gamma Radiation PDFDocument10 pagesEffects of Peroxide and Gamma Radiation PDFFocuNo ratings yet

- Allied Filter Bag BrochureDocument9 pagesAllied Filter Bag BrochureRICARDOALEXBORGESNo ratings yet

- Thermal TreatmentDocument23 pagesThermal TreatmentANILNo ratings yet

- ACS 2019 - Sorbent KapokDocument8 pagesACS 2019 - Sorbent KapoklavrovjurijNo ratings yet

- Saba2016 DMADocument6 pagesSaba2016 DMAGustavoNo ratings yet

- Plastic Waste Age 12-18Document20 pagesPlastic Waste Age 12-18Wilhelmina MurrayNo ratings yet

- Circular Plastics in AsiaDocument1 pageCircular Plastics in AsiaKelvin Tai Wei LimNo ratings yet

- 2022 Chen - Superabsorbent PolymersDocument35 pages2022 Chen - Superabsorbent PolymersSabbir RahmanNo ratings yet

- A Recyclability Study of Bagasse Fiber Reinforced Polypropylene - 2018Document8 pagesA Recyclability Study of Bagasse Fiber Reinforced Polypropylene - 2018bakhrul ilmiNo ratings yet

- Polycarboxylate Environmental Stewardship Program For Polymers Used in Cleaning ProductsDocument1 pagePolycarboxylate Environmental Stewardship Program For Polymers Used in Cleaning ProductsZahid MahmoodNo ratings yet

- 19PEE02Document30 pages19PEE02Martin GómezNo ratings yet

- Mater BiDocument10 pagesMater BihanjunyieeNo ratings yet

- RECYFIX Material EN 2014Document24 pagesRECYFIX Material EN 2014ThierryNo ratings yet

- 1 s2.0 S2214785322011294 MainDocument7 pages1 s2.0 S2214785322011294 MainANAND KUMARNo ratings yet

- Identification of Recalcitrant Stickies and Their Sources in Newsprint ProductionDocument12 pagesIdentification of Recalcitrant Stickies and Their Sources in Newsprint ProductionRanveersingh SuryawanshiNo ratings yet

- Arunagiri2020 - Raman en EmulsionesDocument11 pagesArunagiri2020 - Raman en EmulsionesAlbaMariaLotoNo ratings yet

- Chemical Recycling and The Plastics IndustryDocument6 pagesChemical Recycling and The Plastics IndustryAA GGNo ratings yet

- Review On Membranes For The Filtration of Aqueous Based Solution - Oil in Water Emulsion - 2018Document16 pagesReview On Membranes For The Filtration of Aqueous Based Solution - Oil in Water Emulsion - 2018Carmen StefanescuNo ratings yet

- 7 Solid Waste ManagementDocument41 pages7 Solid Waste ManagementEmrico Luiz PerezNo ratings yet

- CFA18 Waste To Value Part 1 and Part 2Document76 pagesCFA18 Waste To Value Part 1 and Part 2Ahmad SafrizalNo ratings yet

- Selecting The Most Appropriate Products For The Forest BiorefineryDocument8 pagesSelecting The Most Appropriate Products For The Forest BiorefineryBalaKumar KarthikeyanNo ratings yet

- Chemical Upcycling of Polymers - 1115 - Britt - BESAC - Chemical - Upcycling - of - Polymers - Update - 201907Document20 pagesChemical Upcycling of Polymers - 1115 - Britt - BESAC - Chemical - Upcycling - of - Polymers - Update - 201907Eddy SoenNo ratings yet

- Environmental, Health, and Safety Guidelines For Food and Beverage ProcessingDocument17 pagesEnvironmental, Health, and Safety Guidelines For Food and Beverage Processingmohamed sabryNo ratings yet

- Project Making of High Durability Plates With Rice HuskDocument78 pagesProject Making of High Durability Plates With Rice Huskarnab SarkarNo ratings yet

- Green Consumer DayDocument14 pagesGreen Consumer Dayashish250195No ratings yet

- University of The West of ScotlandDocument6 pagesUniversity of The West of ScotlandAnonymous PL4XsFgrNo ratings yet

- Sds-Flor KlenDocument3 pagesSds-Flor KlenConnie SoonNo ratings yet

- Ra 9003 51723 C.evaDocument83 pagesRa 9003 51723 C.evahannamaebonnitNo ratings yet

- SintexDocument2 pagesSintexMLastTryNo ratings yet

- Racumin Tracking Powder MSDSDocument9 pagesRacumin Tracking Powder MSDSprincess ferrerNo ratings yet

- Laboratory Waste Disposal 1705592042Document1 pageLaboratory Waste Disposal 1705592042Edwin leo ArockiadassNo ratings yet

- Textile SludgeDocument11 pagesTextile Sludgejakir_envNo ratings yet

- Proposed Manufacturing Unit of Apis & Api Intermediates: Pre Feasibility ReportDocument29 pagesProposed Manufacturing Unit of Apis & Api Intermediates: Pre Feasibility ReportWQDNo ratings yet

- 01 Green Audit SukDocument144 pages01 Green Audit SukMuthu Praveen SarwanNo ratings yet

- On The Effectiveness in Implementing A Waste-Management-Plan Method in ConstructionDocument9 pagesOn The Effectiveness in Implementing A Waste-Management-Plan Method in ConstructionRashidul IslamNo ratings yet

- Starostka-Patyk, M. 2012. The Meaning and Properties of Closed-Loop in Supply Chain Management (SCM) - 3 (3), 105-113.Document9 pagesStarostka-Patyk, M. 2012. The Meaning and Properties of Closed-Loop in Supply Chain Management (SCM) - 3 (3), 105-113.TasyaNo ratings yet

- 114Document11 pages114Kclyn Clemente0% (1)

- TDC OliveDocument31 pagesTDC OliveFrancesco La Cara100% (1)

- Garbage Collection Fee 1Document5 pagesGarbage Collection Fee 1Liza Mae Cagampang100% (1)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument9 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingrizwanNo ratings yet

- Resarch Paper 2eqv5z5Document10 pagesResarch Paper 2eqv5z5Anchal jainNo ratings yet

- Principles of Green Chemistry With ApplicationsDocument20 pagesPrinciples of Green Chemistry With ApplicationsKiran BhoirNo ratings yet

- SemenDocument8 pagesSemenLuraselly Arda ApriliaNo ratings yet

- Apes Review Packet Answers 2016 HongDocument116 pagesApes Review Packet Answers 2016 Hongapi-306763520No ratings yet

- Bloomberg Sustainability SurveyDocument8 pagesBloomberg Sustainability SurveyJager ChenNo ratings yet

- PT English Math Science MAPEHDocument23 pagesPT English Math Science MAPEHMariya Aren KashirihanNo ratings yet

- COVID-19 Waste Management Self-Assessment - Compliance Audit Checklist - Combined - UP Drive - Google Forms - Rev2Document24 pagesCOVID-19 Waste Management Self-Assessment - Compliance Audit Checklist - Combined - UP Drive - Google Forms - Rev2Arlene AngelesNo ratings yet

- Ec 0709 PaintsDocument18 pagesEc 0709 PaintsWanessa SuárezNo ratings yet