Professional Documents

Culture Documents

FlexLock FA VJ DS 0320 P128 129

FlexLock FA VJ DS 0320 P128 129

Uploaded by

9952090083Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FlexLock FA VJ DS 0320 P128 129

FlexLock FA VJ DS 0320 P128 129

Uploaded by

9952090083Copyright:

Available Formats

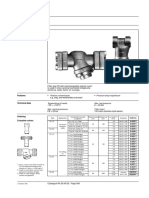

FlexLock Flange Adaptors

Datasheet 1/2

Flange Adaptor

Key

F 1 = Flange Adaptor

2 = End Ring

3 = Gasket

4 = Gasket Gripper Teeth

5 = Stud

A

Setting Gap

2 3 5 1

S

L

FlexLock Flange Adaptors

Pipe Bolt Size Overall Flange Sleeve Working Pressure (bar) Setting Gap FA

Pipe Pipe Flange Flange Nominal Drilling Gasket

OD No.-Dia x Length Thickness Length Weight

Nom Material OD (A) BS EN 1092-1 Water Gas Min Max Mould

(mm) Length (L) (mm) (F) (mm) (S) (kg)

DN50/2" 60.3 Steel 2-M12 x 115 160 123 16 75 50 PN10/16 16 6 10 30 1375 2.3

DN65/2.5" 76.1 Steel 2-M12 x 115 180 123 16 75 60/65 PN10/16 16 6 10 30 1394 2.6

DN80/3" 88.9 Steel 4-M12 x 115 195 123 16 75 80 PN10/16 90 PN6 16 6 10 30 1382 3.4

DN80/3" 98 Ductile Iron 4-M12 x 115 195 123 16 75 80 PN10/16 90 PN6 16 6 10 30 1630 4.0

DN100/4" 114.3 Steel 4-M12 x 115 215 123 16 75 100 PN10/16 110 PN6 16 6 10 30 1367 4.5

DN100/4" 118 Ductile Iron 4-M12 x 115 215 123 16 75 100 PN10/16 16 6 10 30 1618 4.4

DN150/6" 165.1 Steel 8-M12 x 115 285 127 25 75 150 PN10/16 6”E 6”ANSI 150 16 6 10 30 1369 9.3

DN150/6" 168.3 Steel 8-M12 x 115 286 123 19 75 150 PN10/16 16 6 10 30 1369 8.0

DN150/6" 170 Ductile Iron 8-M12 x 115 286 123 19 75 150 PN10/16 16 6 10 30 1369 8.0

DN200/8" 219.1 Steel 8-M12 x 115 341 123 19 75 200 PN10 10 6 10 30 1370 9.7

DN200/8" 219.1 Steel 8-M12 x 115 340 127 25 73 200 PN16 16 6 10 30 1370 15.2

DN200/8" 222 Ductile Iron 6-M16 x 125 341 137 19 75 200 PN16 16 6 10 30 1631 10.6

DN200/8" 222 Ductile Iron 8-M16 x 125 340 137 25 75 200 PN10 8”E 10 6 10 30 1631 13.9

DN250/10" 273.0 Steel 12-M16 x 125 405 137 19 90 250 PN10/16* 10 6 10 30 1737 16.4

DN250/10" 274 Ductile Iron 12-M16 x 125 405 137 19 90 250 PN10/16* 10 6 10 30 1737 16.4

DN300/12" 323.9 Steel 12-M16 x 125 467 137 19 90 300 PN10/16* 10 6 10 30 7667/8 22.7

DN300/12" 326 Ductile Iron 12-M16 x 125 467 137 19 90 300 PN10/16* 10 6 10 30 7667/8 22.7

DR9550_03_2020_ISSUE 6

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors

or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

128 Viking Johnson FlexLock Telephone: +44 (0)1462 443322

FlexLock Flange Adaptors

Datasheet 2/2

Technical Information

Working Pressure Rating General Notes

Water: ➤➤ FlexLock is only suitable for use on Ductile Iron, Steel and

➤➤ DN50

Coated Steel Pipe

to DN200 = 16 bar

➤➤ For coated steel pipe the maximum permitted coating thickness

➤➤ DN250 to DN300 = 10 bar

is 500μ DFT. This is to ensure the stainless steel teeth properly

Gas: grip onto the pipe surface to mobilize the end load capability of

➤➤ DN50 to DN300 = 6 bar the products.

Couplings & Flange Adaptors

➤➤ Due to the surface characteristics of stainless steel pipe,

Vacuum Pressure FlexLock grippers are unable to achieve a guaranteed grip

on the pipe surface.

Capable of accommodating a vacuum pressure of -0.7 bar

➤➤ If the product has to be dismantled after installation then for

Site Test Pressure reassembly a new gasket must be used, as there is a risk that

the stainless steel teeth may become dislodged during this

1.5 times working pressure for short duration (2 hours operation. These are available as spares from Viking Johnson

by quoting gasket mould number from the table along with

Flange Drilling gasket compound.

While DN250 to DN300 are supplied with PN1616 drilling

the rated working pressure (water) is only 10 bar as stated Approvals

in the table. The following water contact materials used in FlexLock are

approved for use with potable water:-

Angularity

Rilsan Nylon 11:

Flange Adaptors 3° ➤➤ WRAS, AS/NZS 4020, DVGW, W270, ACS & KIWA

Bolt Torque/Spanner EPDM Gaskets:

➤➤ WRAS, AS/NZS 4020

M12; Torque 55-65Nm on every bolt

M16; Torque 95-120Nm on every bolt In addition to the above, FlexLock range as a finished product has

KIWA certification verifying that the above products comply with

the requirements of the Water Supply (Water Fittings) Regulations

Temperature Rating of Product

for England and Wales 1999, the Water Byelaws 2000, Scotland

Dedicated

EPDM -20°C to +40°C and the Water Regulations Northern Ireland.

Nitrile -20°C to +40°C

Materials & Relevant Standards

End Rings Options: Coatings

➤➤ SG. Iron to BS 1563: Symbol EN-GJS-450-10 Body, Centre Sleeve, & End Rings:

➤➤ Rolled Steel to: BS EN 10025: Grade S275 ➤➤ Rilsan Nylon 11 to WIS 4-52-01 Part 1

Studs & Nuts:

Flange Adaptor Body Options:

➤➤ Sheraplex coated to WIS 4-52-03

➤➤ Ductile Iron to BS EN 1563 EN-GJS-450-10

➤➤ Mild Steel to: BS EN 10025: Grade S275 Studs

Cold Forged Steel Fasteners to: BS EN ISO898-1:

Gasket Property Class 8.8

EPDM compound Grade E to BS EN 681-1

Nuts

Nitrile compound Grade ‘G’ to BS EN 682-1

Steel BS EN 20898-2: Property Class 8

Gasket Gripper Teeth

Washers

Stainless Steel BS 3146: Part 2 Grade ANC2

BS 4320 Form B Stainless Steel BS 1449:PT2: Grade 304 S15

DR9550_03_2020_ISSUE 6

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors

or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

www.vikingjohnson.com Viking Johnson FlexLock 129

You might also like

- Integrated Marketing Communication and Strategies (SURF)Document6 pagesIntegrated Marketing Communication and Strategies (SURF)Ray Alvin Red0% (1)

- Class Annual Survey ChecklistDocument20 pagesClass Annual Survey ChecklistMayank Handa100% (1)

- Power Zone Equipment - NPSH Calculator ResultDocument2 pagesPower Zone Equipment - NPSH Calculator Result9952090083No ratings yet

- 2412 Payslip JunDocument1 page2412 Payslip JunAnonymous 68rvpJvvNo ratings yet

- Strainer CatalogueDocument3 pagesStrainer CatalogueSharun SureshNo ratings yet

- Swing Check DrawDocument1 pageSwing Check DrawPriyanka rajpurohitNo ratings yet

- Dimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesDocument7 pagesDimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesSudhanshu67No ratings yet

- Date:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0Document10 pagesDate:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0alifbaharunNo ratings yet

- Flange Drilling StandardDocument4 pagesFlange Drilling StandardNitin Aggarwal100% (2)

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- Item Description Remarks QTY UOM Total Delivered Qty/ Tank: Done Done Done Done Done Done Done Done Done Done DoneDocument5 pagesItem Description Remarks QTY UOM Total Delivered Qty/ Tank: Done Done Done Done Done Done Done Done Done Done DoneJerick VillonesNo ratings yet

- Ifield Products Hoses, Fittings & AccessoriesDocument27 pagesIfield Products Hoses, Fittings & Accessoriesfixture DeptNo ratings yet

- 21-50-007 AVK Resilient Seated Gate Valve DN50-400Document2 pages21-50-007 AVK Resilient Seated Gate Valve DN50-400Ferdi SagalaNo ratings yet

- Tabel Material RBDocument268 pagesTabel Material RBRanda SadorNo ratings yet

- Osy 300fDocument4 pagesOsy 300fmaxgomotorNo ratings yet

- Flange Drilling Standard PDFDocument4 pagesFlange Drilling Standard PDFguslohNo ratings yet

- Transaxle Shifter MechanismDocument2 pagesTransaxle Shifter MechanismNeftali FuentesNo ratings yet

- Data Sheet For Metal Seated Gate Valves: ManufacturerDocument11 pagesData Sheet For Metal Seated Gate Valves: ManufacturerAHSAN GGCNo ratings yet

- Valve and SupportsDocument3 pagesValve and SupportsMohamed ArafaNo ratings yet

- OSFDocument2 pagesOSFUyab100% (1)

- AP014Document1 pageAP014Bibene MakitaNo ratings yet

- BLM 3 Nisan 2010 KTLDocument14 pagesBLM 3 Nisan 2010 KTLsertackcdgNo ratings yet

- OS&Y Viking Copy 4Document42 pagesOS&Y Viking Copy 4ayaNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- OS&Y VikingDocument42 pagesOS&Y VikingayaNo ratings yet

- k1 06 pb1c eDocument113 pagesk1 06 pb1c enursultanNo ratings yet

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Document2 pages621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1John Mendoza PachecoNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Brochure en MK4Document6 pagesBrochure en MK4AttallaEANo ratings yet

- Equipment UpdateDocument100 pagesEquipment Updatejc casordNo ratings yet

- Ball Valve - VIRDocument1 pageBall Valve - VIRMF CHOONGNo ratings yet

- Strutfast Clamps, Fasteners & Anchors LRDocument7 pagesStrutfast Clamps, Fasteners & Anchors LRzimtonyNo ratings yet

- 2023 12 10 TümDocument32 pages2023 12 10 Tümercan inceNo ratings yet

- Cushcraft: Assembly and Installation InstructionsDocument16 pagesCushcraft: Assembly and Installation InstructionsedualoviNo ratings yet

- Webster Engine - Bill of MaterialsDocument2 pagesWebster Engine - Bill of MaterialsDefri TrayNo ratings yet

- Foot Valves Stainless Steel 304 Strainer & Cast Iron Body - F320Document2 pagesFoot Valves Stainless Steel 304 Strainer & Cast Iron Body - F320immanuel izaniNo ratings yet

- KZ 2017 Bro Ka 2001XDocument1 pageKZ 2017 Bro Ka 2001XmarusahaNo ratings yet

- Flush Bottom Valve 9100Document4 pagesFlush Bottom Valve 9100BASKARNo ratings yet

- TR XX FLNG Tables v1 1Document6 pagesTR XX FLNG Tables v1 1TaweelarpMekaNo ratings yet

- Nut, Bolt, Screw, Ring, Washer EtcDocument96 pagesNut, Bolt, Screw, Ring, Washer EtcRendy Adam FarhanNo ratings yet

- Radiator - MountingDocument3 pagesRadiator - MountingJESUSNo ratings yet

- Type C: Hopper Shape Knife Gate ValveDocument13 pagesType C: Hopper Shape Knife Gate ValveAbdur Rohman Al BaabNo ratings yet

- VACOM CF DNacuumcomponentsDocument22 pagesVACOM CF DNacuumcomponentsllmm_088No ratings yet

- Glass Machinery Burners and Tools Sales List 2019Document2 pagesGlass Machinery Burners and Tools Sales List 2019Dan George IonescuNo ratings yet

- Sight Glass Inline Type Flanged En558Document2 pagesSight Glass Inline Type Flanged En558Jorge FerrerNo ratings yet

- View Looking S View Looking E: Primary Support Material ListDocument1 pageView Looking S View Looking E: Primary Support Material ListJeremy GutiérrezNo ratings yet

- Pending Reservation As On 19.01.2024Document1 pagePending Reservation As On 19.01.2024Sagar PatilNo ratings yet

- Ds-Ser.14 XC en r6Document2 pagesDs-Ser.14 XC en r6fajringocar1No ratings yet

- S-3 M#aterial Su#pply Wu - Comp@ressedDocument2 pagesS-3 M#aterial Su#pply Wu - Comp@ressedTari IslamNo ratings yet

- UL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510Document1 pageUL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510alanNo ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsRonaldNo ratings yet

- RSERV21GTW400-Gateway J Valves S14 S15 ISODocument11 pagesRSERV21GTW400-Gateway J Valves S14 S15 ISOgfdgdfgdfNo ratings yet

- Dismantling Joint - AVKDocument2 pagesDismantling Joint - AVKtecnoturbines ttNo ratings yet

- Semi-Lugged Lever Operated Butterfly Valves PN16: Features & BenefitsDocument1 pageSemi-Lugged Lever Operated Butterfly Valves PN16: Features & Benefitsimtz2013No ratings yet

- CX210 Excavadora Case 4Document3 pagesCX210 Excavadora Case 4JESUSNo ratings yet

- Gala 333FF-300Document1 pageGala 333FF-300Adriano BispoNo ratings yet

- Model: Wafer Style Knife Gate ValveDocument16 pagesModel: Wafer Style Knife Gate ValveMohamed RaafatNo ratings yet

- Elbow Union Coupling Plate Pipe: No. Description Brand QTY UOM Harga Remarks Unit Rate TotalDocument1 pageElbow Union Coupling Plate Pipe: No. Description Brand QTY UOM Harga Remarks Unit Rate TotalAsima Jaya TamaNo ratings yet

- Valvula de Retencion A Clapeta Oscilante Din pn16 dn50 300Document2 pagesValvula de Retencion A Clapeta Oscilante Din pn16 dn50 300JOHNNY CALERONo ratings yet

- HFO & LFO Fuel Level Indicator Indent: SL - No Description Size (MM) Qty Unit RemarksDocument1 pageHFO & LFO Fuel Level Indicator Indent: SL - No Description Size (MM) Qty Unit RemarksJahidul IslamNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Maxifit & Maxifitxtra: Couplings & End CapsDocument2 pagesMaxifit & Maxifitxtra: Couplings & End Caps9952090083No ratings yet

- Wide Tolerance Range: Includes MaxifitDocument34 pagesWide Tolerance Range: Includes Maxifit9952090083No ratings yet

- Laththur Arasu Trading Company: Nifty Option Day Trading Plan Nifty TrendDocument1 pageLaththur Arasu Trading Company: Nifty Option Day Trading Plan Nifty Trend9952090083100% (1)

- Flexlock: Couplings & Flange AdaptorsDocument8 pagesFlexlock: Couplings & Flange Adaptors9952090083No ratings yet

- Carel PDFDocument2 pagesCarel PDF9952090083No ratings yet

- Getting Started With PDMS: Version 11.6SP1Document92 pagesGetting Started With PDMS: Version 11.6SP1995209008367% (3)

- Vostro1015 Spec Sheet Final EnapDocument2 pagesVostro1015 Spec Sheet Final Enap9952090083No ratings yet

- PipeSpec 20CDocument2 pagesPipeSpec 20C9952090083No ratings yet

- H05V-U (Yse) / H05V-K (Ysf)Document21 pagesH05V-U (Yse) / H05V-K (Ysf)Ademir DzanicNo ratings yet

- Philippine Buildings + ArchitectsDocument12 pagesPhilippine Buildings + ArchitectsKristineNo ratings yet

- Rules of ThumbDocument88 pagesRules of ThumbSaravanan Muthuraman100% (3)

- Training PODFA: Overview of The Pyroprocessing ComponentsDocument50 pagesTraining PODFA: Overview of The Pyroprocessing ComponentsДен СтаднікNo ratings yet

- Data Keamanan Reagen Xpert Mtb-RifDocument139 pagesData Keamanan Reagen Xpert Mtb-RifSagir AlvaNo ratings yet

- Testing Directional Overcurrent Relays From ValenceDocument8 pagesTesting Directional Overcurrent Relays From ValenceM Kumar MarimuthuNo ratings yet

- Seminar ReportDocument29 pagesSeminar ReportUrja DhabardeNo ratings yet

- EFL IS User ManualDocument26 pagesEFL IS User Manualarupamguria05No ratings yet

- Case Study Grading Rubric Presenter Name: Judges Initials:: Case Presentation/ Uniqueness of CaseDocument1 pageCase Study Grading Rubric Presenter Name: Judges Initials:: Case Presentation/ Uniqueness of CaseKevin DR Sumba100% (2)

- Scheduling Practice ProblemsDocument2 pagesScheduling Practice ProblemsM ThuNo ratings yet

- SS-Lab Manual PDFDocument57 pagesSS-Lab Manual PDFAbhishek SukumarNo ratings yet

- G. Ra 9003 RevisedDocument93 pagesG. Ra 9003 Revisedjohne jossef medranoNo ratings yet

- ECSS E ST 10 03 Rev.1 (31may2022) - Annex - A - (AIT Plan)Document3 pagesECSS E ST 10 03 Rev.1 (31may2022) - Annex - A - (AIT Plan)LNo ratings yet

- Robotic Aid For Commando OperationDocument23 pagesRobotic Aid For Commando OperationShafi PulikkalNo ratings yet

- Allwinner H3 Datasheet V1.1Document616 pagesAllwinner H3 Datasheet V1.1Daniel Trejo0% (1)

- TOP500 - 201906 ListDocument37 pagesTOP500 - 201906 ListLado KranjcevicNo ratings yet

- After Cooler InspectionAE3Document1 pageAfter Cooler InspectionAE3boy qsiNo ratings yet

- Moglix PPE Kit PDFDocument9 pagesMoglix PPE Kit PDFAnkur SahuNo ratings yet

- A Spam Transformer Model For SMS Spam DetectionDocument11 pagesA Spam Transformer Model For SMS Spam Detectionsireesha payyavulaNo ratings yet

- Application For ParoleDocument2 pagesApplication For ParoleChristian Rivera100% (3)

- Eng Cressi Manu 03842Document7 pagesEng Cressi Manu 03842Marin PintarNo ratings yet

- An Investigation Into The Shear Strength of Rock DiscontinuityDocument6 pagesAn Investigation Into The Shear Strength of Rock DiscontinuityAzeNo ratings yet

- Quiz 20 Past QuizzesDocument23 pagesQuiz 20 Past QuizzesSarah Joy Corpuz-Cabasag100% (1)

- Third Party Registration - Real Time CommunicationDocument14 pagesThird Party Registration - Real Time CommunicationSpy CameraNo ratings yet

- DSKH Ngan Hang Vietcombank Gui TienDocument32 pagesDSKH Ngan Hang Vietcombank Gui TienTi TanNo ratings yet

- Butterfly HouseDocument5 pagesButterfly HouseViral PatelNo ratings yet

- Drdo 1Document28 pagesDrdo 1Basavaraj PatilNo ratings yet