Professional Documents

Culture Documents

IECEE Retesting Guidleine PDF

IECEE Retesting Guidleine PDF

Uploaded by

Aashish Moyal0 ratings0% found this document useful (0 votes)

44 views5 pagesOriginal Title

IECEE Retesting Guidleine.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

44 views5 pagesIECEE Retesting Guidleine PDF

IECEE Retesting Guidleine PDF

Uploaded by

Aashish MoyalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

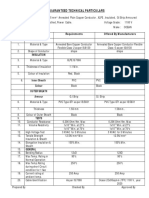

IEC 61215:1993 Ed. 1.0 and IEC 61215:2008 Ed. 20

[Crystalline silicon terrestrial photovoltaic (PV) modules - Design qualification and type

approval.

IEC 61646:1996 Ed. 1.0 Thin-film terrestrial photovoltaic (PV) modules - Design

3 qualification and type approval

BRetesting Guideline

Product or Process Modifications Requiring Limited CBTL Retesting to

Maintain Certification

This document sets forth a uniform approach to maintain the certification of products that have,

or will, undergo modification from the articles originally certified. It should not be used as 2

guideline to certify new product submittals.

‘Changes in material selection, components and manufacturing process can impact electrical

performance and reliability of the modified product. The recommended test sequences given

below have been selected to identify adverse changes to the modified product.

Those products meeting the requirements of the relevant standard after retesting are

considered to be compliant and will be issued an amended CB Conformity Assessment

Certificate and an Amended Technical Report Form.

‘The number of samples to be included in the retesting program and the pass/fail criteria is to be

taken from the standard originally used to certify the product (either IEC 61215 or IEC 61646).

The document is organized by major modification headings and spegific supporting examples.

Following this is the recommended retesting sequence with parenthetical reference to the

specific clauses of the relevant IEC standard.

For the modifications listed below, the Qualification Approval tests in IEC 61215 and IEC 61646,

shall be used as a guideline by the National Certification Body (NCB) and Certification Body

Testing Laboratory (CBTL)

For the modifications listed below, the Qualification Approval tests in IEC 61215 and IEC 61646,

shall be used as a guideline by the assessor:

a) Change in cell technology

For modifications such as:

— metallization materials and/or process,

— anti-reflective coating material,

—__ type of diffusion process

— semiconductor layer materials,

— order of cell process if the change involves the metallization system,

— change of manufacturing site of the solar cells not under the same QA system,

— use of cells from a different manufacturer and

— major reduction in cell thickness (greater than 25%).

2006-04-30 us © IECEE 2006

- L

, IEC 61215:1993 Ed. 1.0 and IEC 61215:2005 Ed. 2.0

/ Crystalline silicon terrestrial photovoltaic (PV) madules - Design qualification and type

‘ approval.

FS IEC 61646:1996 Ed. 1.0 Thin-film terrestrial photovotta

| : qualification and type approval iH fe eeeoeet

a

Retesting Guideline

Repeat:

— Thermal cycling, 200 cycles (10.11),

— Damp heat (10.13),

— Outdoor exposure (10.8), and

— Hot spot endurance (10.9).

b) Modification to encapsulation system

For modifications such as: 7

°)

For modifications such

2006-04-30 215

different materials,

different additives and

Different encapsulation process e.g. curing rate

UV (10.10) / thermal cycling, 50 cycles (10.11) / humidity freeze sequence (10.12),

Damp heat (10.13),

Wet leakage current (10.15 Ed. 2.0 only), NS i

Outdoor exposure (10.8), :

Hail impact (10.17) if not tempered glass, and

Hot spot (10.9) if material composition changes.

Modification to superstrate

different material,

different thickness, reduced by more than 10%

ifglass, retest if there is a reduction in the heat strengthening process (for example retest

if change is from tempered glass to heat strengthened or annealed), and

different surface treatments, adhesives or primers if they are in direct contact with

‘encapsulate material

Ifthe change is from glass to non-glass or vice-versa, it should be considered a new

product altogether.

UV (10.10) / thermal cycling, 50 cycles (10.11) / humidity freeze (10.12) sequence,

Mechanical load test (10.16),

Hail test (10.17),

‘amp heat (10.13) (if non-glass)

Wet leakage current test (10.15 Ed. 2.0 only for non-glass constructions)

Hot spot (10.9) for non-glass if material changes or thickness is reduced and

Outdoor exposure (10.8) if change in material.

© IECEE 2006

4

|

3

{

HEC 61215:1993 Ed. 1.0 and IEC 61215:2006 Ed. 2.0

[Crystalline silicon terrestrial photovoltaic (PV) module

‘approvel.

Design qualification and type

TEC 61646:1996 Ed. 1.0 Thin-fim terrestrial photovoltai :

WS qualification and type approval e itaic (PV) modules - Design

‘i Retesting Guideline

d) Increase in module size

— _ For increase by more than 20% of length or width.

Repeat:

-- Thermal cycling, 200 cycles (10.11),

— Mechanical load (10.16), and

— Hail impact (10.17) (for size increases of more than 50%),

e) Modification to backsheet/substrate

For modifications such as:

— Different material

— _ Different thickness, and

— _ Different additives, surface treatments, adhesives and primers.

— UV (10.10) / thermal cycling, 50 cycles (10.11) / humidity freeze 110.12) sequence,

— _ Robustness of terminations (10.14),

‘Damp heat (10.13) (if non-glass),

— Wet leakage current test (10.15 Ed. 2.0 only),

~ Hail impact (10.17) if rigidity depends on the backsheet,

— Mechanical load (10.16) if mounting depends on the backsheet/substrate.

If there is a change from superstrate to substrate design or from substrate to superstrate design,

the entire qualification test sequence in IEC 61215 shall be conducted.

n Modification to frame and/or mounting structure

For modifications such as:

— cross section of frame

— different framing material

— different mounting technique

— Mechanical load test (10.16),

— Outdoor exposure (10.18) if plastic material is used,

— UV (10.10) / thermal cycling (10.11), 50 cycles / humidity freeze (10.12) sequence, if

plastic material is used,

— Damp heat (10.13) if an adhesive system is

— Thermal cycling (10.11), 200 cycles, if an adhesive syster

and

— Wet leakage current (10.15 Ed.

changes).

2006-04-30

used fo mount the module,

used to mount the module,

2.0 only if the area or location of contact to the laminate

35

© IECEE 2008

IEC 61215:1993 Ed. 1.0 and IEC 61215:2005 Ed. 2.0

‘Crystalline silicon terrestrial photovoltaic (PV) modules - Design qualification and type

approval.

Twill IEC 61646:1996 Ed. 1.0 Thin-fim terrestrial photovoltaic (PV) modules - Design

3 qualification and type approval

‘BRetesting Guideline

9) Modification to junction box/electrical termination

For modifications such as:

different material,

different design.

different potting material, and

different method of attachment.

Repeat:

— — Robustness of terminations (10.14),

— TC 50 (10.11), 10 HF (10.12),

— Damp heat (10.13),

— Wet leakage current test (10.15 Ed. 2.0 only), and

— _ By-pass diode thermal test (10.18 Ed. 2.0 only, if bypass diode is in the box).

h) Change in cell interconnect materials or technique ~~

For modifications such as:

—__ Different interconnect material,

— different thickness of interconnect material

— different bonding technique

— different number of interconnects

— different number of solder bonds

— different solder material or flux.

Repeat:

— Temperature cycling, 200 cycles (10.11),

— Damp heat (10.13) for changes in materials, and

— Hot spot for changes in bonding technique or solder material (10.9).

i) Change in electrical circuit of an identical package

For modifications such as:

— Modifications to the interconnection circuitry (for example more cells per bypass diode or

re-routing of output leads) and

— _ Reconfiguration of voltage (ie. 12 to 24)

2006-04-30 45 © IECEE 2006,

IEC 61215:1993 Ed. 1.0 and IEC 61216:2005 Ed. 2.0

Crystalline silicon terrestrial photovoltaic (PV) modules - Design qualification and type

approval.

IEC 61646:1996 Ed. 1.0 Thin-fim terrestrial photovoltaic (PV) modules - Design

WF qualification and type approval

‘

\

BRetesting Guideline |

|

|

Repeat:

— Hot spot (10.9),

— _ By-pass diode thermal test if the current in each diode increases (10.18 Ed. 2.0 only), and

— Temperature cycling, 200 cycles (10.11) if there are internal conductors behind the cells.

Ut Higher or lower power output (by 10%) in the identical package including size and |

using the identical cell process

Repeat 24-6 -+-1=/,2 ZY

— Hot spot (10.9), and Vets 263 ne

— Bypass diode thermal test (10.18 Ed. 2.0 only) if greater than 10% higher. teohg

k) Qualification of a frameless module after the design has received certification as a

framed module

Repeat the following tests with the laminate mounted using the manufacturers mounting

instructions, ~s 7 4

— Damp heat (10.13) (Ifframe is part of the package seal), \

— Mechanical load (10.16),

— Hail impact (untess superstrate is tempered glass) (10.17), and

— Wet leakage current (10.15 Ed. 2.0 only).

Modifications that do not require re-testing

Provided that all structural components, materials used and processes (including cell process)

remain the same, the following modifications shall not require re-testing:

— fewer cells in module;

— smaller cells in module, as long as each cell has the same number or area of

interconnects and equivalent numbers of solder bonds per unit area.

2006-04-30 515 © IECEE 2006

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CIT Procedure - 14.02.2020 - Rev.01 PDFDocument9 pagesCIT Procedure - 14.02.2020 - Rev.01 PDFAashish MoyalNo ratings yet

- TS - 016A - Temporary - Cathodic - Protection - 24.07.2020 - R-1Document24 pagesTS - 016A - Temporary - Cathodic - Protection - 24.07.2020 - R-1Aashish Moyal100% (1)

- Qap - TCP-PCP-HPCLDocument2 pagesQap - TCP-PCP-HPCLAashish MoyalNo ratings yet

- IC#9 HBL Inspection Waiver ProfomaDocument2 pagesIC#9 HBL Inspection Waiver ProfomaAashish MoyalNo ratings yet

- TS - 016C - Corrosion Survey-Edt-1 09.05Document7 pagesTS - 016C - Corrosion Survey-Edt-1 09.05Aashish MoyalNo ratings yet

- Datasheet & QAP of TCP - BSDocument8 pagesDatasheet & QAP of TCP - BSAashish MoyalNo ratings yet

- Schematic Diagram For Bppl-Rev D-30.07.2020Document1 pageSchematic Diagram For Bppl-Rev D-30.07.2020Aashish MoyalNo ratings yet

- Data - Sheet - Ac - DC - 82a R-1Document6 pagesData - Sheet - Ac - DC - 82a R-1Aashish MoyalNo ratings yet

- 016B - PCP - Rev-4 04.07.2020 R-4Document36 pages016B - PCP - Rev-4 04.07.2020 R-4Aashish MoyalNo ratings yet

- Aan Bapl SRP - Ace 24.03.2020 PDFDocument16 pagesAan Bapl SRP - Ace 24.03.2020 PDFAashish MoyalNo ratings yet

- Aashis: Approved As NotedDocument16 pagesAashis: Approved As NotedAashish MoyalNo ratings yet

- AAN - SRP Procedure - TCP - BPCL - RUPNAGAR1 18.08.2020Document15 pagesAAN - SRP Procedure - TCP - BPCL - RUPNAGAR1 18.08.2020Aashish MoyalNo ratings yet

- Aarcs Projects - Company Profile PDFDocument105 pagesAarcs Projects - Company Profile PDFAashish MoyalNo ratings yet

- AAN - 2C X 95CU POWER - Revised Datasheet Solar Cable 15.09.2020Document1 pageAAN - 2C X 95CU POWER - Revised Datasheet Solar Cable 15.09.2020Aashish MoyalNo ratings yet

- UPS Load Requirement of Metering Skid PDFDocument5 pagesUPS Load Requirement of Metering Skid PDFAashish MoyalNo ratings yet

- 2C X 95CU POWER - Revised Datasheet Solar CableDocument1 page2C X 95CU POWER - Revised Datasheet Solar CableAashish MoyalNo ratings yet

- 8062Document27 pages8062Aashish Moyal100% (1)

- SSD DataSheetDocument1 pageSSD DataSheetAashish MoyalNo ratings yet

- 3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFDocument6 pages3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFAashish MoyalNo ratings yet