Professional Documents

Culture Documents

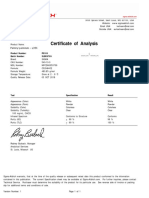

Certificate of Analysis - Certified Reference Material: Cetyl Palmitate

Certificate of Analysis - Certified Reference Material: Cetyl Palmitate

Uploaded by

Rachel McArdleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate of Analysis - Certified Reference Material: Cetyl Palmitate

Certificate of Analysis - Certified Reference Material: Cetyl Palmitate

Uploaded by

Rachel McArdleCopyright:

Available Formats

Certificate of Analysis – Certified Reference Material

CETYL PALMITATE

Product no.: PHR1166-1G

Lot no.: LRAB3616

Description of CRM: White Powder

Expiry date: 31 December 2021

Storage: Room Temperature/Protect from Light

Certificate version: LRAB3616.3 (Note: Certificates may be updated due to

Pharmacopeial Lot Changes or the availability of new data.

Check our website at: www.sigma-aldrich.com for the most

current version.)

Chemical formula: C32H64O2

Molecular mass: 480.85

CAS No.: 540-10-3

Certified Purity ± associated uncertainty U, U=k . u (k=) (Mass Balance/

Analyte

basis)

CETYL PALMITATE 98.4 % Ucrm = ± 0.2 %, k = 2 (Mass Balance/as is basis)

Metrological traceability: Traceable to the SI and higher order standards from NIST through an unbroken

chain of comparisons. Additional traceability to Primary Standards is established

through comparative assay determinations. See “Details on metrological

traceability” on page 2.

Measurement method: Where applicable, the certified value is based on a purity determination by mass

balance. See “Certification process details” on page 3.

Intended use: Intended for R&D and Analytical Use only. Not for drug, household or other uses.

Minimum sample size: 50 mg

Instructions for handling Do not dry, use on the as is basis. The internal pressure of the container may be

and correct use: slightly different from the atmospheric pressure at the user’s location. Open

slowly and carefully to avoid dispersion of the material. Attachment of a 20 mm

aluminum crimp seal recommended for unused portions.

Health and safety All chemical reference materials should be considered potentially hazardous and

information: should be used only by qualified laboratory personnel. Please refer to the Safety

Data Sheet for detailed information about the nature of any hazard and appropriate

precautions to be taken.

Accreditation: Sigma-Aldrich RTC is accredited by the US accreditation authority ANAB as a

registered reference material producer AR-1470 in accordance with ISO 17034.

Certificate issue date: 31 May 2020

ISO 17034

AR-1470 [Andy Ommen; Quality Control] [Mark Pooler; Quality Assurance]

Sigma-Aldrich RTC, 2931 Soldier Springs Rd. Laramie, WY 82070, USA;

Tel. 1 307-742-5452; Fax 1 307-855-831-9211; www.sigmaaldrich.com

Sigma-Aldrich RTC is a subsidiary of Merck KGaA, Darmstadt, Germany.

Certificate Page 1 of 6 Certificate version 03

Packaging: 1 g in amber vial

Details on metrological This standard has been gravimetrically prepared using balances that have been

traceability: fully qualified and calibrated to ISO 17025 requirements. All calibrations utilize

NIST traceable weights which are calibrated externally by a qualified ISO 17025

accredited calibration laboratory to NIST standards. Qualification of each balance

includes the assignment of a minimum weighing by a qualified and ISO 17025

accredited calibration vendor taking into consideration the balance and installed

environmental conditions to ensure compliance with USP tolerances of NMT

0.10% relative error. Fill volume to predetermined specifications is

gravimetrically verified throughout the dispensing process using qualified and

calibrated balances. Further traceability to a corresponding Primary Standard

may be achieved through a direct comparison assay. Where a Primary Standard

is available, the assay value will be included in the specified section of the COA.

Associated uncertainty: Uncertainty values in this document are expressed as Expanded Uncertainty (UCRM)

corresponding to the 95% confidence interval. UCRM is derived from the combined

standard uncertainty multiplied by the coverage factor k, which is obtained from

a t-distribution and degrees of freedom. The components of combined standard

uncertainty include the uncertainties due to characterization, homogeneity, long

term stability, and short term stability (transport). The components due to stability

are generally considered to be negligible unless otherwise indicated by stability

studies.

Traceability Assay:

Comparative assay demonstrates direct traceability to Pharmacopeial Standards

ASSAY vs. USP REFERENCE STANDARD (as is basis)

ASSAY VALUE vs. USP LOT

99.7 % G1H314

Labeled Content = None, Assume 100 %

METHOD: GC (ref.: Cetyl Palmitate, Current Compendial Monographs)

Column: SPB-1, 30 m x 0.25 mm x 0.25 µm

Carrier Gas: H2

Flow: 1 mL/min

Split Ratio: 1:10

Temperature Program: 300 °C, hold 30 min

Injection: 1 µL/310 °C

Detector: FID/310 °C

Internal Standard: Alpha-Tocopherol

Representative Chromatogram from Lot: LRAB3616 vs USP Analysis

ASSAY vs. EP CRS (as is basis)

ASSAY VALUE vs. EP BATCH

98.8 % 2.0 Cetyl Palmitate 95

Labeled Content = None

Assigned Content = 91.4 % *

*The assigned content of the EP CRS was determined by assay against the USP Reference Standard

Certificate Page 2 of 6 Certificate version 03

METHOD: GC (ref.: Cetyl Palmitate, Current Compendial Monographs)

Column: Equity-1, 30 M x 0.25 mm x 1 µm

Carrier Gas: H2

Flow: 1 mL/min

Split Ratio: 1:10

Temperature Program: 300 °C, hold 30 min

Injection: 1 µL/310 °C

Detector: FID/310 °C

Internal Standard: Alpha-Tocopherol

Representative Chromatogram from Lot: LRAB3616 vs EP Analysis

Certification process details:

The certified purity is determined by mass balance and calculated as

(100 − 𝑇𝐶𝐼) (100 − 𝐿𝑂𝐷) (100 − 𝐻2𝑂) (100 − 𝑅𝑂𝐼) (100 − 𝑅𝑆)

% 𝑃𝑢𝑟𝑖𝑡𝑦 = ( ∗ ∗ ∗ ∗ ) ∗ 100%

100 100 100 100 100

• TCI = Total Chromatographic Impurities

• LOD = Loss on Drying

• H2O = Water content determined by Karl Fischer analysis

• ROI = Residue on Ignition

• RS = Residual Solvents

Methods for impurity determination may be added or deleted as required. The following techniques are applied:

CHROMATOGRAPHIC IMPURITY ANALYSIS

METHOD: GC (ref.: Cetyl Palmitate, Current Compendial Monographs)

Column: Equity-1, 15 M x 0.53 mm x 1.5 µm

Carrier Gas: H2

Flow: 3.95 mL/min

Split Ratio: 1:10

Temperature Program: 40 °C for 1 min, 20 °C/min to 300 °C, hold 25 min

Injection: 1 µL/310 °C

Detector: FID/310 °C

Impurities Detected:

Impurity 1: 0.1 %

Impurity 2: 0.3 %

Impurity 3: 1.1 %

Total Impurities: 1.5 %

Certificate Page 3 of 6 Certificate version 03

Representative Chromatogram from Lot: LRAB3616 Impurity Analysis

RESIDUAL SOLVENTS

Method: GC-MS Headspace (ref.: Adapted from Residual Solvents USP <467>)

Column: DB-1301

Carrier gas: He

Flow: 1.2 mL/min

Split Ratio: 1:5

Injection/Temperature: 1 µL/250 °C

Temperature Program: 40 °C for 20 min, 10 °C/min to 240 °C, hold 20 min

Solvents Detected: None

LOSS ON DRYING/VOLATILES

Method: Oven at 105 ºC (ref.: Current Compendial Monographs)

Mean of three measurements, Loss = 0.07 %

RESIDUE ANALYSIS

Method: Sulfated Ash (ref.: Current Compendial Monographs)

Sample Size: ~ 100 mg

Mean of three measurements, Residue = 0.02 %

CERTIFIED PURITY BY MASS BALANCE

98.4 % Ucrm = ± 0.2 %, k = 2

(as is basis)

Homogeneity Homogeneity was assessed in accordance with ISO Guide 35. Completed units

assessment: were sampled using a random stratified sampling protocol. The results of

chemical analysis were then compared by Single Factor Analysis of Variance

(ANOVA). The uncertainty due to homogeneity was derived from the ANOVA.

Heterogeneity was not detected under the conditions of the ANOVA.

Analytical method: GC

Sample size: 50 mg

Stability assessment: Significance of the stability assessment will be demonstrated if the analytical

result of the study and the range of values represented by the Expanded

Uncertainty do not overlap the result of the original assay and the range of its

values represented by the Expanded Uncertainty. The method employed will

usually be the same method used to characterize the assay value in the initial

evaluation.

Long Term Stability Evaluation - An assessment, or re-test, versus a Compendial

Reference Standard may be scheduled, within the 3 year anniversary date of a

release of a Secondary Standard. The re-test interval will be determined on a

case-by-case basis. Short Term Stability Study - It is useful to assess stability

under reasonably anticipated, short term transport conditions by simulating

exposure of the product to humidity and temperature stress. This type of study

is conducted under controlled conditions of elevated temperature and humidity.

Certificate Page 4 of 6 Certificate version 03

Identification Test:

INFRARED SPECTROPHOTOMETRY (Comparative identification analysis demonstrates direct traceability to

Pharmacopeial standards)

Cetyl Palmitate PHR1166 LRAB3616 vs USP Lot G1H314

Cetyl Palmitate PHR1166 LRAB3616 vs EP Batch 2.0

Certificate Page 5 of 6 Certificate version 03

Indicative Values:

1H NMR (Data provided by an external laboratory; not in scope of accreditation)

LRAB3616 Cetyl Palmitate

Consistent with structure

MELTING RANGE

Mettler Toledo FP900 Thermosystem with FP81 Measuring Cell

Mean of three measurements = 53.2-54.0 °C

Certificate of analysis revision history:

Certificate version Date Reason for version

LRAB3616.1 13 March 2017 Original Release

LRAB3616.2 21 March 2018 Stability & Requalification Test

LRAB3616.3 31 May 2020 Requalification Test

Disclaimer:

The purchaser is required to determine the suitability of this product for any particular

application. Sigma-Aldrich RTC makes no warranty of any kind, express or implied, other than

its products meet all quality control standards set by Sigma-Aldrich RTC. We do not guarantee

that the product can be used for any particular application.

The vibrant M, Supelco, TraceCERT and Sigma-Aldrich are trademarks of Merck KGaA, Darmstadt, Germany or its affiliates.

All other trademarks are the property of their respective owners.

Detailed information on trademarks is available via publicly accessible resources.

© 2018 Merck KGaA, Darmstadt, Germany and/or its affiliates. All Rights Reserved.

Certificate Page 6 of 6 Certificate version 03

You might also like

- Malaysia Local and StandardsDocument569 pagesMalaysia Local and Standardsswati0% (4)

- Certificate of Analysis: Retinyl Palmitate (Vitamin A Palmitate)Document6 pagesCertificate of Analysis: Retinyl Palmitate (Vitamin A Palmitate)Anonymous pCIauPOGNo ratings yet

- Certificate of Analysis: 4-AminophenolDocument6 pagesCertificate of Analysis: 4-AminophenolLaurențiu Mihai BălanNo ratings yet

- 2015 EPA Certificate of Conformity - Totyota CorollaDocument1 page2015 EPA Certificate of Conformity - Totyota Corollajoynern7No ratings yet

- Cal Cert FormatDocument6 pagesCal Cert FormatINSTRUCAL CALIBRATION SERVICESNo ratings yet

- PHR1001 Lrab7720Document6 pagesPHR1001 Lrab7720labanacabreraNo ratings yet

- Measurement Uncertainty and Analytical Decision in AASDocument33 pagesMeasurement Uncertainty and Analytical Decision in AASmilossmileNo ratings yet

- Certificate of Analysis - Certified Reference Material: GlycineDocument7 pagesCertificate of Analysis - Certified Reference Material: GlycineVishal JhelumNo ratings yet

- Guideline: Saudi Standards, Metrology and Quality OrgDocument9 pagesGuideline: Saudi Standards, Metrology and Quality OrgacecNo ratings yet

- Certificate of Calibration: CustomerDocument1 pageCertificate of Calibration: Customergaconvt92No ratings yet

- COA Meat and Bone Meal BVAQDocument1 pageCOA Meat and Bone Meal BVAQbagor.tea9926No ratings yet

- COA of MelatoninDocument1 pageCOA of MelatoninPan EmmaNo ratings yet

- Thiamine Hydrochloride COA - 07Document2 pagesThiamine Hydrochloride COA - 07ASHOK KUMAR LENKANo ratings yet

- USP Certificate: Caffeine Melting Point StandardDocument2 pagesUSP Certificate: Caffeine Melting Point StandardKimia AsikNo ratings yet

- Certificate of Calibration: HTLS/DPG/04Document2 pagesCertificate of Calibration: HTLS/DPG/04Umang SOdhiNo ratings yet

- Soya Lecithim PowderDocument1 pageSoya Lecithim PowderASHOK KUMAR LENKANo ratings yet

- Analytical Balance SOPDocument2 pagesAnalytical Balance SOPdivine productionNo ratings yet

- BelzDocument24 pagesBelzrohanmanimaniNo ratings yet

- CoA Demin WaterDocument1 pageCoA Demin WaterBambang Yan ArdiantoNo ratings yet

- RDS - TTR 1887Document1 pageRDS - TTR 1887emc roorkee59100% (1)

- G&B Calibration BrochureDocument45 pagesG&B Calibration Brochureanon_521111922No ratings yet

- Coa 20040202 PDFDocument1 pageCoa 20040202 PDFRisen ChemicalsNo ratings yet

- Certificate of Calibration: A. ArámburoDocument2 pagesCertificate of Calibration: A. ArámburoEmily Hernandez CincoNo ratings yet

- Certificado TermohigrometroDocument1 pageCertificado Termohigrometroconsuelo alarcon ramosNo ratings yet

- COA Nitric Acid 68Document1 pageCOA Nitric Acid 68Noviyanti Violita Hamisi100% (1)

- Ethanol 96Document1 pageEthanol 96Brilian WidiantoNo ratings yet

- Certificate of Calibration: Customer InformationDocument2 pagesCertificate of Calibration: Customer InformationSazzath HossainNo ratings yet

- 1 COA of Carbopol 940 PDFDocument1 page1 COA of Carbopol 940 PDFHayk HayrapetyanNo ratings yet

- Laporan Kalibrasi Calliper LatihanDocument24 pagesLaporan Kalibrasi Calliper LatihanMuhammad BurhanuddinNo ratings yet

- Calibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Document4 pagesCalibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Sherwin John Navarro100% (1)

- Certificate of AnalysisDocument1 pageCertificate of AnalysisMiracle CafeNo ratings yet

- Chlorine Test: SpectroquantDocument1 pageChlorine Test: Spectroquantanica moldovanNo ratings yet

- COA OF Benzalkonium Chloride 80 Solution PDFDocument1 pageCOA OF Benzalkonium Chloride 80 Solution PDFViniciusNo ratings yet

- CC Calibration FileDocument6 pagesCC Calibration FilesheikmoinNo ratings yet

- 6 135Document6 pages6 135Ashok LenkaNo ratings yet

- CALIBRATION OF Piston Pipette and Buritte PDFDocument98 pagesCALIBRATION OF Piston Pipette and Buritte PDFBan ZanganaNo ratings yet

- Certificate of Analysis ListDocument3 pagesCertificate of Analysis ListJorge Luis ParraNo ratings yet

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- Adobe Scan 03 Aug 2022Document1 pageAdobe Scan 03 Aug 2022Subasini Biswajit Narayan NayakNo ratings yet

- Methylene Chloride COA - ChinaDocument1 pageMethylene Chloride COA - ChinaHuỳnh Thanh HảiNo ratings yet

- Sanas TR 79-03Document9 pagesSanas TR 79-03Hi Tech Calibration ServicesNo ratings yet

- Thermography Report 125Document3 pagesThermography Report 125madhavanNo ratings yet

- 9620,9621 Abbemat HP, MCP300Document8 pages9620,9621 Abbemat HP, MCP300Ali RizviNo ratings yet

- OQ Muffle FurnaceDocument8 pagesOQ Muffle FurnaceMohsin AliNo ratings yet

- Calb 4Document1 pageCalb 4ranjt53No ratings yet

- Standard Calibration Procedure Vernier Caliper Doc. No. Call/SCP/008 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Vernier Caliper Doc. No. Call/SCP/008 Rev. 00 May 01, 2015Ajlan Khan100% (1)

- 022-Temperature CalibratorDocument4 pages022-Temperature CalibratorAjlan Khan100% (1)

- Kalibratiecertificaat Trescal Koffernr BF1-004Document2 pagesKalibratiecertificaat Trescal Koffernr BF1-004mega dorreNo ratings yet

- COA of Ginkgo Biloba ExtractDocument1 pageCOA of Ginkgo Biloba ExtractPan EmmaNo ratings yet

- A New Calibration Method For Ultrasonic Clamp-On Flowmeters IFMC Coventry 2015Document18 pagesA New Calibration Method For Ultrasonic Clamp-On Flowmeters IFMC Coventry 2015MARIANNo ratings yet

- Termometro Extech HY-CAL-002Document2 pagesTermometro Extech HY-CAL-002luisa perezNo ratings yet

- Pt. Smart-Lab Indonesia: Manufacturer of Analytical ReagentsDocument1 pagePt. Smart-Lab Indonesia: Manufacturer of Analytical Reagentspckantor unoNo ratings yet

- Calibration Certificate - Gas Coriolis - Unit#1Document2 pagesCalibration Certificate - Gas Coriolis - Unit#1Said100% (1)

- As 2360 6 2 1993 Measurement of Fluid Flow in Closed Conduits Volumetric Methods by Volume PDFDocument8 pagesAs 2360 6 2 1993 Measurement of Fluid Flow in Closed Conduits Volumetric Methods by Volume PDFLalo MejiaNo ratings yet

- COA FOR Vanillyl Butyl Ether (Oil Soluble) PDFDocument1 pageCOA FOR Vanillyl Butyl Ether (Oil Soluble) PDFMajorNo ratings yet

- CRSR507F1Document1 pageCRSR507F1armando fuentesNo ratings yet

- 1.0 Customer's Details: Calibration Certificate NDocument2 pages1.0 Customer's Details: Calibration Certificate NCyriaque KagororaNo ratings yet

- Standard Calibration Procedure Hydrometer Doc. No. Call/SCP/033 Rev. 00 May 01, 2015Document4 pagesStandard Calibration Procedure Hydrometer Doc. No. Call/SCP/033 Rev. 00 May 01, 2015Ajlan Khan100% (1)

- Calibration Certificate M1Document1 pageCalibration Certificate M1AHmed YaSsenNo ratings yet

- Certificate of Analysis - Certified Reference Material: Ciprofloxacin HydrochlorideDocument7 pagesCertificate of Analysis - Certified Reference Material: Ciprofloxacin HydrochlorideSheraz AkhterNo ratings yet

- Potassium Cyanide-COADocument4 pagesPotassium Cyanide-COADeepthi RNo ratings yet

- Coa Propylene GlycolDocument8 pagesCoa Propylene GlycolNadaNursetiyantiNo ratings yet

- Certificate of Analysis: Product Number: 114545 Batch Number: MKBX8904VDocument2 pagesCertificate of Analysis: Product Number: 114545 Batch Number: MKBX8904VRachel McArdleNo ratings yet

- Certificate of Analysis: Product Number: P0169 Batch Number: SLBX9799Document1 pageCertificate of Analysis: Product Number: P0169 Batch Number: SLBX9799Rachel McArdleNo ratings yet

- Viscosity Standard s8000 5171109031Document1 pageViscosity Standard s8000 5171109031Rachel McArdleNo ratings yet

- Certificate of Analysis: Benzyl BenzoateDocument6 pagesCertificate of Analysis: Benzyl BenzoateRachel McArdleNo ratings yet

- Viscosity Standard n4000 5181005110Document1 pageViscosity Standard n4000 5181005110Rachel McArdleNo ratings yet

- Thioacetamide 172502 bcbv6290Document1 pageThioacetamide 172502 bcbv6290Rachel McArdleNo ratings yet

- Thioacetamide 163678 bcbt5023Document1 pageThioacetamide 163678 bcbt5023Rachel McArdleNo ratings yet

- Certificate of Analysis: Product Number: T0501 Batch Number: SLBT5627Document1 pageCertificate of Analysis: Product Number: T0501 Batch Number: SLBT5627Rachel McArdleNo ratings yet

- 2,2,4-TRIMETHYLPENTANE 360066 stbh6281Document1 page2,2,4-TRIMETHYLPENTANE 360066 stbh6281Rachel McArdleNo ratings yet

- Certificate of Analysis: Product Number: 242845 Batch Number: MKCJ5422Document1 pageCertificate of Analysis: Product Number: 242845 Batch Number: MKCJ5422Rachel McArdleNo ratings yet

- Trifluoroacetic Acid 302031-STBJ1904 01.10.2020Document1 pageTrifluoroacetic Acid 302031-STBJ1904 01.10.2020Rachel McArdleNo ratings yet

- Ammonium Acetate A1542 SLCD8173 01.10.2020Document1 pageAmmonium Acetate A1542 SLCD8173 01.10.2020Rachel McArdleNo ratings yet

- Certificate of Analysis: Product Number: 221473 Batch Number: MKCL8595Document2 pagesCertificate of Analysis: Product Number: 221473 Batch Number: MKCL8595Rachel McArdleNo ratings yet

- XYLENOL ORANGE TETRASODIUM SALT 33825 bcbn7544vDocument1 pageXYLENOL ORANGE TETRASODIUM SALT 33825 bcbn7544vRachel McArdleNo ratings yet

- Astm C114 18Document12 pagesAstm C114 18maniharimeenaNo ratings yet

- ASTM 4444 - Standard Practice For Field Calibration and Application of Hand-Held MoistureDocument10 pagesASTM 4444 - Standard Practice For Field Calibration and Application of Hand-Held Moisturerafael1989chemicalNo ratings yet

- Rata - Cga EpaDocument10 pagesRata - Cga EpaayudyaNo ratings yet

- UV-Vis Spectrophotometers For Pharmaceutical Analysis: Supporting USP 38 Chapter Compliance With Evolution SpectrophotometersDocument8 pagesUV-Vis Spectrophotometers For Pharmaceutical Analysis: Supporting USP 38 Chapter Compliance With Evolution SpectrophotometersEhsan BadarNo ratings yet

- E1329-Withdrawn 4257Document12 pagesE1329-Withdrawn 4257delta lab sangliNo ratings yet

- Validation in Clinical Chemistry: Elvar TheodorssonDocument26 pagesValidation in Clinical Chemistry: Elvar TheodorssonDanica AgojoNo ratings yet

- LA 201-7 MS ISO IEC 17025 ChecklistDocument14 pagesLA 201-7 MS ISO IEC 17025 ChecklistmimmaNo ratings yet

- Standard Human Plasma - Thrombin ReagentDocument2 pagesStandard Human Plasma - Thrombin ReagentTRITEST TRITEST0% (1)

- E1086-14 Standard Test Method For Analysis of Austenitic Stainless Steel by Spark Atomic Emission SpectrometryDocument5 pagesE1086-14 Standard Test Method For Analysis of Austenitic Stainless Steel by Spark Atomic Emission SpectrometryCarlos Guillermo Somoza Alvarenga100% (2)

- CRM Opc BlainesDocument2 pagesCRM Opc BlainesVara Prasad PaluriNo ratings yet

- Certificate of Analysis: (Batch G) Certified Reference Material InformationDocument4 pagesCertificate of Analysis: (Batch G) Certified Reference Material InformationrahulNo ratings yet

- Full Download Book Modern Sample Preparation For Chromatography 2Nd Edition PDFDocument41 pagesFull Download Book Modern Sample Preparation For Chromatography 2Nd Edition PDFthomas.allard610100% (27)

- Conostan StandardsDocument36 pagesConostan StandardsPriya RanjithNo ratings yet

- Sys Master - Pdfs - h47 - h97 - 10137304694814 - COA - RTC PHR 1003 - ST WB CERT 2140232 1 1 1Document7 pagesSys Master - Pdfs - h47 - h97 - 10137304694814 - COA - RTC PHR 1003 - ST WB CERT 2140232 1 1 1Rayan Ayyesha AuliaNo ratings yet

- Certificate of Analysis - Certified Reference Material: Certipur Iron Standard Solution 1000 MG/L FeDocument2 pagesCertificate of Analysis - Certified Reference Material: Certipur Iron Standard Solution 1000 MG/L FeAndresOchoaNo ratings yet

- Certificate of Analysis - Certified Reference Material: Certipur Silver Standard Solution 1000 MG/L AgDocument2 pagesCertificate of Analysis - Certified Reference Material: Certipur Silver Standard Solution 1000 MG/L AgfarilarakhmanikaNo ratings yet

- Aavld Auditor Checklist Version 4 3 06-01-12Document14 pagesAavld Auditor Checklist Version 4 3 06-01-12MIRIAN CATARINo ratings yet

- The Traceability of Analytical MeasuremeDocument7 pagesThe Traceability of Analytical MeasuremeChong Chiew LetNo ratings yet

- C-Therm TCi Operator ManualDocument138 pagesC-Therm TCi Operator ManualrubenssanNo ratings yet

- LIPOMDDocument288 pagesLIPOMDKarlaMoránNo ratings yet

- TOTL-SP04 Metrological Traceability ProcedureDocument15 pagesTOTL-SP04 Metrological Traceability ProcedurefaikNo ratings yet

- KAN U-06 Policy On Tracebility (Rev.1)Document9 pagesKAN U-06 Policy On Tracebility (Rev.1)Syamil ajaNo ratings yet

- Cama Faqs: Asset Management Council LTDDocument6 pagesCama Faqs: Asset Management Council LTDHelio Hermes100% (1)

- FNRI Proficiency Testing Scheme: 3rd EditionDocument35 pagesFNRI Proficiency Testing Scheme: 3rd Editionsarah abreaNo ratings yet

- Mindray CLIA Calibrator Traceability Report-20231123Document6 pagesMindray CLIA Calibrator Traceability Report-20231123aymanepocketNo ratings yet

- Estimates of Uncertainty in Optical Emission Spectrometric Method With Arc and Sparks Excitement (SEOASE)Document5 pagesEstimates of Uncertainty in Optical Emission Spectrometric Method With Arc and Sparks Excitement (SEOASE)mirelamanteamirelaNo ratings yet

- Iron in Water: Standard Test Methods ForDocument12 pagesIron in Water: Standard Test Methods ForEnrique Alejandro OvandoNo ratings yet