Professional Documents

Culture Documents

Pagine Estratte Senza Titolo

Pagine Estratte Senza Titolo

Uploaded by

lucaCopyright:

Available Formats

You might also like

- 0005 India Regulation On CoatingDocument33 pages0005 India Regulation On Coatingagustinusset100% (2)

- SAES Q 001 Table ExposureDocument4 pagesSAES Q 001 Table ExposureKhurram ShehzadNo ratings yet

- Annex ZA (Informative) Provisions For The CE Marking of Common Cements Under The EU Construction Products DirectiveDocument1 pageAnnex ZA (Informative) Provisions For The CE Marking of Common Cements Under The EU Construction Products DirectivelucaNo ratings yet

- Tip 13 WDocument1 pageTip 13 WFranky KenNo ratings yet

- TIP 13 - Chloride Limits in Concrete: WHAT Is The Concern With Chlorides?Document1 pageTIP 13 - Chloride Limits in Concrete: WHAT Is The Concern With Chlorides?Restie TeanoNo ratings yet

- Chloride Content of Fresh ConcreteDocument4 pagesChloride Content of Fresh ConcreteAlan KirbyNo ratings yet

- Corrosion of Steel in ConcreteDocument2 pagesCorrosion of Steel in ConcreteaaNo ratings yet

- Hlorides in Oncrete: CTI T N C2Document3 pagesHlorides in Oncrete: CTI T N C2Harley GreavesNo ratings yet

- ADDMIX 55-v3Document2 pagesADDMIX 55-v3Ankita Baban GavadeNo ratings yet

- Chlorides in ConcreteDocument3 pagesChlorides in ConcreteMahmood MuftiNo ratings yet

- Tabla de Maximo Contenido de ClorurosDocument1 pageTabla de Maximo Contenido de ClorurosHumberto MorenoNo ratings yet

- RCPTDocument7 pagesRCPTosama anterNo ratings yet

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala Subramanian0% (1)

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala SubramanianNo ratings yet

- Rrs III UnitDocument119 pagesRrs III UnitBTECH BeautiesNo ratings yet

- Chloride Attack On ConcreteDocument12 pagesChloride Attack On Concretevikram kumarNo ratings yet

- Concrete Behavior (Part 1)Document35 pagesConcrete Behavior (Part 1)Julaine Jimenez BanderasNo ratings yet

- Mechanism of Corrosion in Reinforced Cement ConcreteDocument18 pagesMechanism of Corrosion in Reinforced Cement ConcretejoshjethNo ratings yet

- Cec 225 PDFDocument14 pagesCec 225 PDF8790922772No ratings yet

- A Study of Carbonation in Concrete Structues in Marine EnvironmentDocument57 pagesA Study of Carbonation in Concrete Structues in Marine EnvironmentHaniAminNo ratings yet

- Durability of Concrete StructuresDocument38 pagesDurability of Concrete StructuresSharath WankdothNo ratings yet

- 4 Concrete RepairsDocument3 pages4 Concrete RepairsBenharzallah KrobbaNo ratings yet

- Mechanism of Corrosion in Reinforced Cement ConcreteDocument14 pagesMechanism of Corrosion in Reinforced Cement ConcretejoshjethNo ratings yet

- Chemical AttackDocument35 pagesChemical AttackArjun V CivilNo ratings yet

- Concrete Silica ReactionDocument4 pagesConcrete Silica ReactionHusain Masood ChandharNo ratings yet

- Damage To Concrete Bridges Due To Reinforcement CorrosionDocument7 pagesDamage To Concrete Bridges Due To Reinforcement Corrosionniran_udayangaNo ratings yet

- Determination of Permissible Chloride Levels in Prestressed ConcreteDocument14 pagesDetermination of Permissible Chloride Levels in Prestressed ConcretePranav DevaleNo ratings yet

- Concrete Construction Article PDF - Concrete CoverDocument3 pagesConcrete Construction Article PDF - Concrete CoverTharach JanesuapasaereeNo ratings yet

- CRA Glossery of TermsDocument11 pagesCRA Glossery of TermsDC1234No ratings yet

- Concrete Durability ATC 07.10.05Document38 pagesConcrete Durability ATC 07.10.05Đỗ Văn KhiêmNo ratings yet

- The Effect of Alkalis On The Properties of Portland CementDocument15 pagesThe Effect of Alkalis On The Properties of Portland CementfaheemqcNo ratings yet

- Corrosion of Embedded MetalsDocument6 pagesCorrosion of Embedded MetalsBose CatNo ratings yet

- Lecture 2Document27 pagesLecture 2Behjat BakhtyarNo ratings yet

- Unit II CorrosionDocument3 pagesUnit II CorrosionavishekpatelNo ratings yet

- Corrosion Inhibiting AdmixturesDocument3 pagesCorrosion Inhibiting AdmixturesMalak HindiNo ratings yet

- Final Project ReportDocument40 pagesFinal Project Reportmariam100% (1)

- 108304-9191 Ijcee-IjensDocument6 pages108304-9191 Ijcee-IjensHumamNo ratings yet

- Durability of High Performance Concrete in Relation To 'External' Chemical AttackDocument5 pagesDurability of High Performance Concrete in Relation To 'External' Chemical AttackGeraldNo ratings yet

- Applied SciencesDocument29 pagesApplied Sciencesziko23No ratings yet

- PS 31 Acceptable Use Calcium Chloride ConcreteDocument1 pagePS 31 Acceptable Use Calcium Chloride ConcretekannankrivNo ratings yet

- Chloride Attack of Reinforced ConcreteDocument8 pagesChloride Attack of Reinforced ConcreteBraydon GoyetteNo ratings yet

- 13CR 4v 1210Document8 pages13CR 4v 1210Luis David Concha CastilloNo ratings yet

- Corrosion of Embedded Metal: (Carbonation-Induced and Chloride-Induced Corrosion)Document37 pagesCorrosion of Embedded Metal: (Carbonation-Induced and Chloride-Induced Corrosion)Jagannathan KNo ratings yet

- L2 - MRCS - Embedded Metal Corrosion - 2Document35 pagesL2 - MRCS - Embedded Metal Corrosion - 2Kaushal KumarNo ratings yet

- The Effect of CO2 Injection On Corrosion and Integrity of FacilitiesDocument15 pagesThe Effect of CO2 Injection On Corrosion and Integrity of FacilitiesVlassis SarantinosNo ratings yet

- Influence of Chloride Thresholds in Service Life of RC ConcreteDocument19 pagesInfluence of Chloride Thresholds in Service Life of RC Concreteyyanan1118No ratings yet

- S2 4 3 PDFDocument7 pagesS2 4 3 PDFنورا فوزي عبده CNo ratings yet

- Report On Mix DesignDocument6 pagesReport On Mix DesignForood Torabian IsfahaniNo ratings yet

- Corrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionDocument8 pagesCorrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionanupamrawalNo ratings yet

- Chloride ResistanceDocument37 pagesChloride ResistanceRaghava KumarNo ratings yet

- CTECH10Document22 pagesCTECH10division4 designsNo ratings yet

- Lasting RCC Structures in Coastal AreasDocument2 pagesLasting RCC Structures in Coastal AreassanjeevdasanNo ratings yet

- Durability Design of Segmental Linings For Intended Service LifeDocument11 pagesDurability Design of Segmental Linings For Intended Service LifeJosé Luis Rodríguez SánchezNo ratings yet

- Corrosion of Reinforced Concrete: Handbook of Corrosion Engineering, Third Edition Pierre R. Roberge PH.DDocument28 pagesCorrosion of Reinforced Concrete: Handbook of Corrosion Engineering, Third Edition Pierre R. Roberge PH.DGlaysaa AsiloNo ratings yet

- Using Cathodic Protection To Control Corrosion in Marine EnvironmentsDocument12 pagesUsing Cathodic Protection To Control Corrosion in Marine EnvironmentsMark ByramNo ratings yet

- Mbs-Astm-C1202 06 24 2020Document1 pageMbs-Astm-C1202 06 24 2020DI- CARPNo ratings yet

- Chloride-Induced Corrosion of Steel PDFDocument11 pagesChloride-Induced Corrosion of Steel PDFeid elsayedNo ratings yet

- Effects of Accelerated Carbonation On Physical Properties of MortarDocument6 pagesEffects of Accelerated Carbonation On Physical Properties of MortarБојана ВучићевићNo ratings yet

- Corrosion Basics-1Document57 pagesCorrosion Basics-1qawazkhan311No ratings yet

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- Design 8Document3 pagesDesign 8lucaNo ratings yet

- Tailrace: Water Conveyance System Design Guidelines DoedDocument2 pagesTailrace: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- 2.1.3 Geological and Geotechnical Investigations 2.1.3.1 Investigation ProcedureDocument3 pages2.1.3 Geological and Geotechnical Investigations 2.1.3.1 Investigation ProcedurelucaNo ratings yet

- Water Conveyance System Design Guidelines DoedDocument3 pagesWater Conveyance System Design Guidelines DoedlucaNo ratings yet

- Foreword: Water Conveyance System Design Guidelines DoedDocument5 pagesForeword: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- 1.1 Background: Chapter - IDocument3 pages1.1 Background: Chapter - IlucaNo ratings yet

- Spiral Case:: Water Conveyance System Design Guidelines DoedDocument3 pagesSpiral Case:: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- Water Conveyance System Design Guidelines DoedDocument2 pagesWater Conveyance System Design Guidelines DoedlucaNo ratings yet

- Definition of Terms Used in The Guidelines: Water Conveyance System Design Guidelines DoedDocument2 pagesDefinition of Terms Used in The Guidelines: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- Table 7 - Values of C Number of Test Results N C For P 10 %Document1 pageTable 7 - Values of C Number of Test Results N C For P 10 %lucaNo ratings yet

- Annex 13 - Case Study On TunnelsDocument31 pagesAnnex 13 - Case Study On TunnelslucaNo ratings yet

- Choice Between Tunnel Boring Machine and Drill & Blast SystemDocument7 pagesChoice Between Tunnel Boring Machine and Drill & Blast SystemlucaNo ratings yet

- Table 8 - Limit Values For Single ResultsDocument1 pageTable 8 - Limit Values For Single ResultslucaNo ratings yet

- 3.3. Exposure To Different Curing Conditions 3.5. Effect of Using AdmixturesDocument1 page3.3. Exposure To Different Curing Conditions 3.5. Effect of Using AdmixtureslucaNo ratings yet

- Table 6 - Acceptability Constant K K For P 5 % For P 10 % Number of Test Results N (Early and Standard Strength, Lower Limit) (Other Properties)Document1 pageTable 6 - Acceptability Constant K K For P 5 % For P 10 % Number of Test Results N (Early and Standard Strength, Lower Limit) (Other Properties)lucaNo ratings yet

- 3.2. Quality of The Recycled Aggregate: Silva Et AlDocument1 page3.2. Quality of The Recycled Aggregate: Silva Et AllucaNo ratings yet

- Table 7 - Values of C Number of Test Results N C For P 10 %Document1 pageTable 7 - Values of C Number of Test Results N C For P 10 %lucaNo ratings yet

- Calvarial 2Document3 pagesCalvarial 2lucaNo ratings yet

- Semilunar Conchal Cartilage Graft in Saddle Nose ReconstructionDocument4 pagesSemilunar Conchal Cartilage Graft in Saddle Nose ReconstructionlucaNo ratings yet

- Martini DataSheet Martini Soffit - 0323Document5 pagesMartini DataSheet Martini Soffit - 0323lac ngoNo ratings yet

- Lecture 4 - Agggregate PropertiesDocument45 pagesLecture 4 - Agggregate Propertiesmuhammad jehangirNo ratings yet

- What Factors Causes Failure of Concrete StructuresDocument4 pagesWhat Factors Causes Failure of Concrete StructuresNick Genese100% (1)

- Sleeves and Sleeve Seals For Hvac PipingDocument4 pagesSleeves and Sleeve Seals For Hvac PipingAhmed OmarNo ratings yet

- Field Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTDocument4 pagesField Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTGerman E.No ratings yet

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForMina RemonNo ratings yet

- PP CC40 - Silon Taboren PC 79 C 40Document1 pagePP CC40 - Silon Taboren PC 79 C 40armandoNo ratings yet

- Rate Analysis SI-PR - DNIT FinalDocument87 pagesRate Analysis SI-PR - DNIT FinalShashikant VermaNo ratings yet

- Filtros HidraulicosDocument45 pagesFiltros Hidraulicosdechamps100% (1)

- Effect of Deposition Time of Sputtering Ag-Cu Thin Film On Mechanical and Antimicrobial PropertiesDocument6 pagesEffect of Deposition Time of Sputtering Ag-Cu Thin Film On Mechanical and Antimicrobial PropertiesmkozinNo ratings yet

- VA42Document4 pagesVA42Ike EvelyneNo ratings yet

- Tec 301 HCS (UAE) : Non Shrink Very High Strength GroutDocument2 pagesTec 301 HCS (UAE) : Non Shrink Very High Strength Groutmanikandan4strlNo ratings yet

- The Power: To EvolveDocument5 pagesThe Power: To EvolveJoshua GobinNo ratings yet

- 1920 F3 Chem First Exam Question PaperDocument6 pages1920 F3 Chem First Exam Question PaperElsaaaNo ratings yet

- Aster Taddele BioplasticDocument119 pagesAster Taddele BioplasticNardos YizengawNo ratings yet

- Polyurethane Types, Synthesis and Applications - A ReviewDocument30 pagesPolyurethane Types, Synthesis and Applications - A ReviewCarlotta C.No ratings yet

- Thermal CeramicsDocument2 pagesThermal CeramicsJulius ValenciaNo ratings yet

- Investigation of Causes of Severe Perforation of Supply Gas Pipeline After Just Four Years of InstallationDocument13 pagesInvestigation of Causes of Severe Perforation of Supply Gas Pipeline After Just Four Years of InstallationIstiak MahmoodNo ratings yet

- Infino NE-1030: Lotte Chemical CorporationDocument3 pagesInfino NE-1030: Lotte Chemical CorporationVu TranNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationRavi JainNo ratings yet

- EN380 Homework #7 SolutionDocument6 pagesEN380 Homework #7 SolutionMafer ReyesNo ratings yet

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaNo ratings yet

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- What Is White Portland CementDocument3 pagesWhat Is White Portland CementOliver Raymundo100% (1)

- Lijadora de Palma DW412 DewaltDocument35 pagesLijadora de Palma DW412 DewaltMARIA FERNo ratings yet

- 300M - E4340 Mod Alloy SteelDocument2 pages300M - E4340 Mod Alloy SteelCristiano BeckNo ratings yet

- 250 KVA Genset Wiring PDFDocument1 page250 KVA Genset Wiring PDFSZANo ratings yet

- Applicable Pec Standard For Eim NC IiDocument89 pagesApplicable Pec Standard For Eim NC IiJunrey Eguna100% (2)

- RFE-HF (I) : Armoured and Pair Screened Instrumentation and Communication Cable 250VDocument2 pagesRFE-HF (I) : Armoured and Pair Screened Instrumentation and Communication Cable 250VDaniel GarciaNo ratings yet

- Mill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateDocument1 pageMill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateNurzamain AdiNo ratings yet

Pagine Estratte Senza Titolo

Pagine Estratte Senza Titolo

Uploaded by

lucaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pagine Estratte Senza Titolo

Pagine Estratte Senza Titolo

Uploaded by

lucaCopyright:

Available Formats

2 Silva et al.

Materials Research

aggregate (RCA), a given aggregate must comprise a minimum from mixing water. Chlorides may also come from external

of 90%, by mass, of Portland cement-based paste and NA. sources, e.g. de-icing salts, pools and marine environment22.

RA sourced from crushed masonry, or recycled masonry Corrosion of steel occurs because of electrochemical

aggregates (RMA), may include: aerated and lightweight action, which usually occurs when two dissimilar metals are

concrete blocks; ceramic bricks; blast-furnace slag bricks in electrical contact in the presence of moisture and oxygen.

and blocks; ceramic roofing tiles and shingles; and sand‑lime Chloride ions surrounding the reinforcement react at anodic

bricks21. RMA are composed of a minimum of 90%, by sites to form hydrochloric acid, which destroys the passive

mass, of the summation of the aforementioned materials. layer. The steel’s surface then becomes activated locally to

Aggregates acquired from mixed demolition debris, or form the anode, with the passive surface forming the cathode.

mixed recycled aggregates (MRA), are a mixture of the two The ensuing corrosion is in the form of localized pitting22.

main components obtained from the beneficiation process According to EN 20626, the maximum chloride content

of CDW: crushed and graded concrete and masonry rubble. allowed is 1.0% by mass of cement for concrete not containing

Some specifications7,15 state that they are composed of less any embedded steel except for corrosion-resisting lifting

than 90%, by mass, of Portland cement-based fragments devices (Table 1). For steel reinforcement or other embedded

and NA. In other words, they may contain several other metal, two limits are given: 0.2% and 0.4%. Similarly, for

common CDW materials such as masonry-based materials. prestressed concrete, two limits, lower than the previous

ones, are given: 0.1% and 0.2%.

3. Factors Affecting the Chloride Ion EN 19727 specifies a limit of 0.1% of chloride content in

cement. In cases where the cement is type CEM III, it may

Penetration of Recycled Aggregate

contain more than 0.1%, but the value must be declared.

Concrete For prestressed concrete, cements may be produced with

The durability of concrete is an essential subject as it a lower value, which will replace the aforementioned and

allows understanding the performance of concrete throughout must be reported by the manufacturer.

the service life of a structure. The reduced durability of EN 1262028 states that aggregates may contain chlorides

concrete may be prompted by external agents arising from in the form of salts, the limit amount of which mainly depends

the environment or by internal agents within concrete22. One on the aggregates’ origin. To minimize the risk of corrosion

of the degradation phenomena that deserve most attention of embedded metals, it is normal to limit the total amount

is reinforcement corrosion, which is one of the pathological of chloride ions for all constituents of concrete. Following

manifestations most important and difficult to intervene that standard EN 1744-1: “Tests for chemical properties of

affect reinforced concrete structures23,24. aggregates - Part 1: Chemical analysis”29, it is possible to

The alkalinity resulting from the cement’s hydration determine the chloride content, which if lower than 0.01% then

process protects the reinforcement from corrosion until this value may be used in the calculation of the total chloride

chemical or physical changes occur, which enable external ion content of all constituents.

aggressive agents to act. The two main phenomena that A study30 on the comparison of several specifications for

initiate reinforcement corrosion by destroying its passive the use of RA in concrete shows that the maximum allowed

coating are carbonation and chloride ingress25. chloride content is, in most cases9,11,16,18, between 0.03% and

The strongly alkaline nature of calcium hydroxide 0.15%. NBR-15.11615 has a less demanding limit for chloride

(Ca(OH)2) prevents the corrosion of steel reinforcements by content (1%) of water soluble chlorides. It is normal to find

the formation of a thin protective film of iron oxide on their RA with higher levels of chloride than those of NA31 because

surface. However, if water and oxygen are present, there they may either contain old adhered mortar with relatively

may come a time when carbonation or soluble chlorides high chloride content, or the original material may have

reach the steel and then corrosion of reinforcement may been in contact with a chloride-enriched environment10,32.

take place. The deleterious action of chloride ions may come Nevertheless, chlorides contaminating the RA may leach if

from internal agents, such as aggregates with high chloride they are soaked in water. Washing with water is one way

content or from calcium chloride used as an accelerator of reducing the concentration of these constituents because

when concrete is placed at very low temperatures or even they are not bonded to the cementitious microstructure and

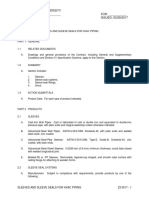

Table 1. Maximum chloride content of concrete according to EN 20626.

Chloride Maximum Cl- content

Concrete use

content classa by mass of cementb

Not containing any steel reinforcement or other embedded metal Cl 1.0 1.0%

with the exception of corrosion-resisting lifting devices

Containing steel reinforcement or other embedded metal Cl 0.2 0.2%

Cl 0.4 0.4%

Containing prestressing steel reinforcement Cl 0.1 0.1%

Cl 0.2 0.2%

a - For a specific concrete use, the class to be applied depends upon the provisions valid in the environment where concrete is used. b - Where type II

additions are used and are taken into account for the cement content, the chloride content is expressed as the percentage of chloride ions by mass of cement

plus total mass of additions that are taken into account.

You might also like

- 0005 India Regulation On CoatingDocument33 pages0005 India Regulation On Coatingagustinusset100% (2)

- SAES Q 001 Table ExposureDocument4 pagesSAES Q 001 Table ExposureKhurram ShehzadNo ratings yet

- Annex ZA (Informative) Provisions For The CE Marking of Common Cements Under The EU Construction Products DirectiveDocument1 pageAnnex ZA (Informative) Provisions For The CE Marking of Common Cements Under The EU Construction Products DirectivelucaNo ratings yet

- Tip 13 WDocument1 pageTip 13 WFranky KenNo ratings yet

- TIP 13 - Chloride Limits in Concrete: WHAT Is The Concern With Chlorides?Document1 pageTIP 13 - Chloride Limits in Concrete: WHAT Is The Concern With Chlorides?Restie TeanoNo ratings yet

- Chloride Content of Fresh ConcreteDocument4 pagesChloride Content of Fresh ConcreteAlan KirbyNo ratings yet

- Corrosion of Steel in ConcreteDocument2 pagesCorrosion of Steel in ConcreteaaNo ratings yet

- Hlorides in Oncrete: CTI T N C2Document3 pagesHlorides in Oncrete: CTI T N C2Harley GreavesNo ratings yet

- ADDMIX 55-v3Document2 pagesADDMIX 55-v3Ankita Baban GavadeNo ratings yet

- Chlorides in ConcreteDocument3 pagesChlorides in ConcreteMahmood MuftiNo ratings yet

- Tabla de Maximo Contenido de ClorurosDocument1 pageTabla de Maximo Contenido de ClorurosHumberto MorenoNo ratings yet

- RCPTDocument7 pagesRCPTosama anterNo ratings yet

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala Subramanian0% (1)

- Repair and RehabilitationDocument115 pagesRepair and RehabilitationBala SubramanianNo ratings yet

- Rrs III UnitDocument119 pagesRrs III UnitBTECH BeautiesNo ratings yet

- Chloride Attack On ConcreteDocument12 pagesChloride Attack On Concretevikram kumarNo ratings yet

- Concrete Behavior (Part 1)Document35 pagesConcrete Behavior (Part 1)Julaine Jimenez BanderasNo ratings yet

- Mechanism of Corrosion in Reinforced Cement ConcreteDocument18 pagesMechanism of Corrosion in Reinforced Cement ConcretejoshjethNo ratings yet

- Cec 225 PDFDocument14 pagesCec 225 PDF8790922772No ratings yet

- A Study of Carbonation in Concrete Structues in Marine EnvironmentDocument57 pagesA Study of Carbonation in Concrete Structues in Marine EnvironmentHaniAminNo ratings yet

- Durability of Concrete StructuresDocument38 pagesDurability of Concrete StructuresSharath WankdothNo ratings yet

- 4 Concrete RepairsDocument3 pages4 Concrete RepairsBenharzallah KrobbaNo ratings yet

- Mechanism of Corrosion in Reinforced Cement ConcreteDocument14 pagesMechanism of Corrosion in Reinforced Cement ConcretejoshjethNo ratings yet

- Chemical AttackDocument35 pagesChemical AttackArjun V CivilNo ratings yet

- Concrete Silica ReactionDocument4 pagesConcrete Silica ReactionHusain Masood ChandharNo ratings yet

- Damage To Concrete Bridges Due To Reinforcement CorrosionDocument7 pagesDamage To Concrete Bridges Due To Reinforcement Corrosionniran_udayangaNo ratings yet

- Determination of Permissible Chloride Levels in Prestressed ConcreteDocument14 pagesDetermination of Permissible Chloride Levels in Prestressed ConcretePranav DevaleNo ratings yet

- Concrete Construction Article PDF - Concrete CoverDocument3 pagesConcrete Construction Article PDF - Concrete CoverTharach JanesuapasaereeNo ratings yet

- CRA Glossery of TermsDocument11 pagesCRA Glossery of TermsDC1234No ratings yet

- Concrete Durability ATC 07.10.05Document38 pagesConcrete Durability ATC 07.10.05Đỗ Văn KhiêmNo ratings yet

- The Effect of Alkalis On The Properties of Portland CementDocument15 pagesThe Effect of Alkalis On The Properties of Portland CementfaheemqcNo ratings yet

- Corrosion of Embedded MetalsDocument6 pagesCorrosion of Embedded MetalsBose CatNo ratings yet

- Lecture 2Document27 pagesLecture 2Behjat BakhtyarNo ratings yet

- Unit II CorrosionDocument3 pagesUnit II CorrosionavishekpatelNo ratings yet

- Corrosion Inhibiting AdmixturesDocument3 pagesCorrosion Inhibiting AdmixturesMalak HindiNo ratings yet

- Final Project ReportDocument40 pagesFinal Project Reportmariam100% (1)

- 108304-9191 Ijcee-IjensDocument6 pages108304-9191 Ijcee-IjensHumamNo ratings yet

- Durability of High Performance Concrete in Relation To 'External' Chemical AttackDocument5 pagesDurability of High Performance Concrete in Relation To 'External' Chemical AttackGeraldNo ratings yet

- Applied SciencesDocument29 pagesApplied Sciencesziko23No ratings yet

- PS 31 Acceptable Use Calcium Chloride ConcreteDocument1 pagePS 31 Acceptable Use Calcium Chloride ConcretekannankrivNo ratings yet

- Chloride Attack of Reinforced ConcreteDocument8 pagesChloride Attack of Reinforced ConcreteBraydon GoyetteNo ratings yet

- 13CR 4v 1210Document8 pages13CR 4v 1210Luis David Concha CastilloNo ratings yet

- Corrosion of Embedded Metal: (Carbonation-Induced and Chloride-Induced Corrosion)Document37 pagesCorrosion of Embedded Metal: (Carbonation-Induced and Chloride-Induced Corrosion)Jagannathan KNo ratings yet

- L2 - MRCS - Embedded Metal Corrosion - 2Document35 pagesL2 - MRCS - Embedded Metal Corrosion - 2Kaushal KumarNo ratings yet

- The Effect of CO2 Injection On Corrosion and Integrity of FacilitiesDocument15 pagesThe Effect of CO2 Injection On Corrosion and Integrity of FacilitiesVlassis SarantinosNo ratings yet

- Influence of Chloride Thresholds in Service Life of RC ConcreteDocument19 pagesInfluence of Chloride Thresholds in Service Life of RC Concreteyyanan1118No ratings yet

- S2 4 3 PDFDocument7 pagesS2 4 3 PDFنورا فوزي عبده CNo ratings yet

- Report On Mix DesignDocument6 pagesReport On Mix DesignForood Torabian IsfahaniNo ratings yet

- Corrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionDocument8 pagesCorrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionanupamrawalNo ratings yet

- Chloride ResistanceDocument37 pagesChloride ResistanceRaghava KumarNo ratings yet

- CTECH10Document22 pagesCTECH10division4 designsNo ratings yet

- Lasting RCC Structures in Coastal AreasDocument2 pagesLasting RCC Structures in Coastal AreassanjeevdasanNo ratings yet

- Durability Design of Segmental Linings For Intended Service LifeDocument11 pagesDurability Design of Segmental Linings For Intended Service LifeJosé Luis Rodríguez SánchezNo ratings yet

- Corrosion of Reinforced Concrete: Handbook of Corrosion Engineering, Third Edition Pierre R. Roberge PH.DDocument28 pagesCorrosion of Reinforced Concrete: Handbook of Corrosion Engineering, Third Edition Pierre R. Roberge PH.DGlaysaa AsiloNo ratings yet

- Using Cathodic Protection To Control Corrosion in Marine EnvironmentsDocument12 pagesUsing Cathodic Protection To Control Corrosion in Marine EnvironmentsMark ByramNo ratings yet

- Mbs-Astm-C1202 06 24 2020Document1 pageMbs-Astm-C1202 06 24 2020DI- CARPNo ratings yet

- Chloride-Induced Corrosion of Steel PDFDocument11 pagesChloride-Induced Corrosion of Steel PDFeid elsayedNo ratings yet

- Effects of Accelerated Carbonation On Physical Properties of MortarDocument6 pagesEffects of Accelerated Carbonation On Physical Properties of MortarБојана ВучићевићNo ratings yet

- Corrosion Basics-1Document57 pagesCorrosion Basics-1qawazkhan311No ratings yet

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- Design 8Document3 pagesDesign 8lucaNo ratings yet

- Tailrace: Water Conveyance System Design Guidelines DoedDocument2 pagesTailrace: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- 2.1.3 Geological and Geotechnical Investigations 2.1.3.1 Investigation ProcedureDocument3 pages2.1.3 Geological and Geotechnical Investigations 2.1.3.1 Investigation ProcedurelucaNo ratings yet

- Water Conveyance System Design Guidelines DoedDocument3 pagesWater Conveyance System Design Guidelines DoedlucaNo ratings yet

- Foreword: Water Conveyance System Design Guidelines DoedDocument5 pagesForeword: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- 1.1 Background: Chapter - IDocument3 pages1.1 Background: Chapter - IlucaNo ratings yet

- Spiral Case:: Water Conveyance System Design Guidelines DoedDocument3 pagesSpiral Case:: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- Water Conveyance System Design Guidelines DoedDocument2 pagesWater Conveyance System Design Guidelines DoedlucaNo ratings yet

- Definition of Terms Used in The Guidelines: Water Conveyance System Design Guidelines DoedDocument2 pagesDefinition of Terms Used in The Guidelines: Water Conveyance System Design Guidelines DoedlucaNo ratings yet

- Table 7 - Values of C Number of Test Results N C For P 10 %Document1 pageTable 7 - Values of C Number of Test Results N C For P 10 %lucaNo ratings yet

- Annex 13 - Case Study On TunnelsDocument31 pagesAnnex 13 - Case Study On TunnelslucaNo ratings yet

- Choice Between Tunnel Boring Machine and Drill & Blast SystemDocument7 pagesChoice Between Tunnel Boring Machine and Drill & Blast SystemlucaNo ratings yet

- Table 8 - Limit Values For Single ResultsDocument1 pageTable 8 - Limit Values For Single ResultslucaNo ratings yet

- 3.3. Exposure To Different Curing Conditions 3.5. Effect of Using AdmixturesDocument1 page3.3. Exposure To Different Curing Conditions 3.5. Effect of Using AdmixtureslucaNo ratings yet

- Table 6 - Acceptability Constant K K For P 5 % For P 10 % Number of Test Results N (Early and Standard Strength, Lower Limit) (Other Properties)Document1 pageTable 6 - Acceptability Constant K K For P 5 % For P 10 % Number of Test Results N (Early and Standard Strength, Lower Limit) (Other Properties)lucaNo ratings yet

- 3.2. Quality of The Recycled Aggregate: Silva Et AlDocument1 page3.2. Quality of The Recycled Aggregate: Silva Et AllucaNo ratings yet

- Table 7 - Values of C Number of Test Results N C For P 10 %Document1 pageTable 7 - Values of C Number of Test Results N C For P 10 %lucaNo ratings yet

- Calvarial 2Document3 pagesCalvarial 2lucaNo ratings yet

- Semilunar Conchal Cartilage Graft in Saddle Nose ReconstructionDocument4 pagesSemilunar Conchal Cartilage Graft in Saddle Nose ReconstructionlucaNo ratings yet

- Martini DataSheet Martini Soffit - 0323Document5 pagesMartini DataSheet Martini Soffit - 0323lac ngoNo ratings yet

- Lecture 4 - Agggregate PropertiesDocument45 pagesLecture 4 - Agggregate Propertiesmuhammad jehangirNo ratings yet

- What Factors Causes Failure of Concrete StructuresDocument4 pagesWhat Factors Causes Failure of Concrete StructuresNick Genese100% (1)

- Sleeves and Sleeve Seals For Hvac PipingDocument4 pagesSleeves and Sleeve Seals For Hvac PipingAhmed OmarNo ratings yet

- Field Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTDocument4 pagesField Coil Assembly or Pole Shoe Package Replacement Instructions 37MT, 41MT 42MTGerman E.No ratings yet

- Calcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForDocument4 pagesCalcium Silicate Block and Pipe Thermal Insulation: Standard Specification ForMina RemonNo ratings yet

- PP CC40 - Silon Taboren PC 79 C 40Document1 pagePP CC40 - Silon Taboren PC 79 C 40armandoNo ratings yet

- Rate Analysis SI-PR - DNIT FinalDocument87 pagesRate Analysis SI-PR - DNIT FinalShashikant VermaNo ratings yet

- Filtros HidraulicosDocument45 pagesFiltros Hidraulicosdechamps100% (1)

- Effect of Deposition Time of Sputtering Ag-Cu Thin Film On Mechanical and Antimicrobial PropertiesDocument6 pagesEffect of Deposition Time of Sputtering Ag-Cu Thin Film On Mechanical and Antimicrobial PropertiesmkozinNo ratings yet

- VA42Document4 pagesVA42Ike EvelyneNo ratings yet

- Tec 301 HCS (UAE) : Non Shrink Very High Strength GroutDocument2 pagesTec 301 HCS (UAE) : Non Shrink Very High Strength Groutmanikandan4strlNo ratings yet

- The Power: To EvolveDocument5 pagesThe Power: To EvolveJoshua GobinNo ratings yet

- 1920 F3 Chem First Exam Question PaperDocument6 pages1920 F3 Chem First Exam Question PaperElsaaaNo ratings yet

- Aster Taddele BioplasticDocument119 pagesAster Taddele BioplasticNardos YizengawNo ratings yet

- Polyurethane Types, Synthesis and Applications - A ReviewDocument30 pagesPolyurethane Types, Synthesis and Applications - A ReviewCarlotta C.No ratings yet

- Thermal CeramicsDocument2 pagesThermal CeramicsJulius ValenciaNo ratings yet

- Investigation of Causes of Severe Perforation of Supply Gas Pipeline After Just Four Years of InstallationDocument13 pagesInvestigation of Causes of Severe Perforation of Supply Gas Pipeline After Just Four Years of InstallationIstiak MahmoodNo ratings yet

- Infino NE-1030: Lotte Chemical CorporationDocument3 pagesInfino NE-1030: Lotte Chemical CorporationVu TranNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationRavi JainNo ratings yet

- EN380 Homework #7 SolutionDocument6 pagesEN380 Homework #7 SolutionMafer ReyesNo ratings yet

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaNo ratings yet

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- What Is White Portland CementDocument3 pagesWhat Is White Portland CementOliver Raymundo100% (1)

- Lijadora de Palma DW412 DewaltDocument35 pagesLijadora de Palma DW412 DewaltMARIA FERNo ratings yet

- 300M - E4340 Mod Alloy SteelDocument2 pages300M - E4340 Mod Alloy SteelCristiano BeckNo ratings yet

- 250 KVA Genset Wiring PDFDocument1 page250 KVA Genset Wiring PDFSZANo ratings yet

- Applicable Pec Standard For Eim NC IiDocument89 pagesApplicable Pec Standard For Eim NC IiJunrey Eguna100% (2)

- RFE-HF (I) : Armoured and Pair Screened Instrumentation and Communication Cable 250VDocument2 pagesRFE-HF (I) : Armoured and Pair Screened Instrumentation and Communication Cable 250VDaniel GarciaNo ratings yet

- Mill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateDocument1 pageMill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateNurzamain AdiNo ratings yet