Professional Documents

Culture Documents

Carbohydrates Produced Thermal Processing: Chemical by

Carbohydrates Produced Thermal Processing: Chemical by

Uploaded by

Itiel MartínezCopyright:

Available Formats

You might also like

- Ujian 3Document16 pagesUjian 3Resty SimorangkirNo ratings yet

- Unit 3 - CarbohydratesDocument26 pagesUnit 3 - CarbohydratesWinrich Louise M. MontanoNo ratings yet

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat Panchalzaid ansari89% (9)

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat PanchalroceniNo ratings yet

- Alcohol, Phenol and Ethers Digital NotesDocument23 pagesAlcohol, Phenol and Ethers Digital NotesroceniNo ratings yet

- Alcohol Phenol and EthersDocument25 pagesAlcohol Phenol and EthersAyaz100% (2)

- Biomolecules Print PDFDocument5 pagesBiomolecules Print PDFsinghatmesh685No ratings yet

- MonosaccharidesDocument6 pagesMonosaccharidesHello KittyNo ratings yet

- Biomolecules SHORT NotesDocument2 pagesBiomolecules SHORT NotesAstha AgrawalNo ratings yet

- 4 Introductory Organic Chemistry and AlkanesDocument12 pages4 Introductory Organic Chemistry and AlkanesChristina HerculesNo ratings yet

- Topic 2 - Biological MoleculesDocument78 pagesTopic 2 - Biological Moleculesjamalsaeed160No ratings yet

- Hydrocarbons: Section 2Document14 pagesHydrocarbons: Section 2Karam AbdullahNo ratings yet

- Function Groups Crap 2Document1 pageFunction Groups Crap 2sultana.otb2018No ratings yet

- MET180 - Chapter 8Document38 pagesMET180 - Chapter 8saeed khanNo ratings yet

- Pogil Macros-No TitlesDocument4 pagesPogil Macros-No Titleskparsons938512No ratings yet

- BCH 210 CarbohydrateDocument28 pagesBCH 210 CarbohydratedarrielabuaNo ratings yet

- Ch05 MacromoleculesCampbellDocument69 pagesCh05 MacromoleculesCampbellCarl Jasper AquinoNo ratings yet

- Classification of CarbohydratesDocument97 pagesClassification of CarbohydratesALEM, RALPH LAURENCE B.No ratings yet

- Solucionario de Wade-306-323 PDFDocument18 pagesSolucionario de Wade-306-323 PDFCésar PastranoNo ratings yet

- Functional Group Naming TableDocument1 pageFunctional Group Naming Tableinfo.acc231No ratings yet

- 6 Organic Chemistry IDocument27 pages6 Organic Chemistry IAwil AhmedNo ratings yet

- Chemistry of CarbohydratesDocument3 pagesChemistry of CarbohydratesHello KittyNo ratings yet

- Organic Chemistry I EdexcelDocument28 pagesOrganic Chemistry I Edexcelvyb8qpq57yNo ratings yet

- BI115 หลักชีววิทยา (Priciples of biology)Document315 pagesBI115 หลักชีววิทยา (Priciples of biology)สาธิต ปริ นทร์ทองNo ratings yet

- Carboxylic Acid and Their DerivativesDocument5 pagesCarboxylic Acid and Their DerivativesShubham KumarNo ratings yet

- AlcoholsDocument16 pagesAlcoholsLucas “Khumalo” KaunduNo ratings yet

- 1.2.QR - Carbohydrate Structure - UUBiochemDocument2 pages1.2.QR - Carbohydrate Structure - UUBiochemdondavis77No ratings yet

- 6 - Organic ChemistryDocument27 pages6 - Organic ChemistryAlvaro CatalaNo ratings yet

- Structure and Function of CarbohydratesDocument27 pagesStructure and Function of CarbohydratesAli SeenaNo ratings yet

- Carboxylic AcidsDocument23 pagesCarboxylic AcidsSoma Chowdhury RosyNo ratings yet

- 1.chemical - IJCPT - Behaviour of - SamehDocument12 pages1.chemical - IJCPT - Behaviour of - Samehiaset123No ratings yet

- Basic Concepts and Hydrocarbons PDFDocument6 pagesBasic Concepts and Hydrocarbons PDFDr.CharinNo ratings yet

- Carbohydrates ASAS 4104Document53 pagesCarbohydrates ASAS 4104AlbanMugotiNo ratings yet

- 3.1 Revision Guide Introduction Organic AqaDocument9 pages3.1 Revision Guide Introduction Organic AqaIman KhanNo ratings yet

- 3.1 Revision Guide Introduction Organic AqaDocument9 pages3.1 Revision Guide Introduction Organic Aqashafiqur rahmanNo ratings yet

- BiomoleculesDocument32 pagesBiomoleculesanumeha.kinsui23No ratings yet

- Organic Chemistry I EdexcelDocument28 pagesOrganic Chemistry I EdexcelAinara Román MacíasNo ratings yet

- LEC 7 - CarbohydratesDocument5 pagesLEC 7 - Carbohydrateserikapana09No ratings yet

- FC Lect Topic4d AY17-18 StudentDocument29 pagesFC Lect Topic4d AY17-18 StudentRaysonChooNo ratings yet

- Experiment 5 Properties of Carbohydrates: Solubility, Reactivity, and Specific RotationDocument9 pagesExperiment 5 Properties of Carbohydrates: Solubility, Reactivity, and Specific RotationCiara marie BernardoNo ratings yet

- MembraneDocument51 pagesMembraneNinad MunNo ratings yet

- An Aldol Condensation To Synthesize ChalconesDocument6 pagesAn Aldol Condensation To Synthesize ChalconesAssyakurNo ratings yet

- Hydrocarbons & Functional GroupsDocument62 pagesHydrocarbons & Functional GroupsNINO DOLINONo ratings yet

- Alchohol ResearchASDocument18 pagesAlchohol ResearchASAhmed SiddiquiNo ratings yet

- NotesDocument44 pagesNotesshrirang chandankhedeNo ratings yet

- Bio Endocrine - 230210 - 002532Document49 pagesBio Endocrine - 230210 - 002532abodeissaalssabagNo ratings yet

- Organic Chemistry For AlevelDocument15 pagesOrganic Chemistry For AlevelNahida HossainNo ratings yet

- Chemistry of Carbohydrates II: ObjectivesDocument22 pagesChemistry of Carbohydrates II: Objectivesahmad671poNo ratings yet

- Oligosaccharides. Polysaccharides. Terpenes.Document182 pagesOligosaccharides. Polysaccharides. Terpenes.Umar M abubakarNo ratings yet

- Chapter 2 Polymerization and Molecular Weight DistributionDocument77 pagesChapter 2 Polymerization and Molecular Weight DistributionEss NatashaNo ratings yet

- Organic Chemistry II: University of Lincoln PresentationDocument20 pagesOrganic Chemistry II: University of Lincoln PresentationkayannaNo ratings yet

- K - Enols and Enolates 11 - F14Document1 pageK - Enols and Enolates 11 - F14shinexblazerNo ratings yet

- Carbohydrates Handout PDFDocument15 pagesCarbohydrates Handout PDFAra AlibasaNo ratings yet

- Introduction To Use of LecithinsDocument11 pagesIntroduction To Use of LecithinsManish MangharamaniNo ratings yet

- Universty: UrdanetaDocument7 pagesUniversty: UrdanetaMello DiaxNo ratings yet

- OCOC 1 Homework 4Document37 pagesOCOC 1 Homework 4TRENDING KNOWLEDGE. INDIANo ratings yet

- Lecture 02Document11 pagesLecture 02CataNo ratings yet

- Lect 4 - Molecules - Cell 2020Document97 pagesLect 4 - Molecules - Cell 2020Sỹ HiệpNo ratings yet

- Department of EducationDocument3 pagesDepartment of EducationMaribel membradoNo ratings yet

- Journal of Polymers - 2014 - Shit - Edible Polymers Challenges and OpportunitiesDocument13 pagesJournal of Polymers - 2014 - Shit - Edible Polymers Challenges and OpportunitiesphmartNo ratings yet

- MetabolomicsDocument12 pagesMetabolomicswatson191No ratings yet

- Module 5: Failure Criteria of Rock and Rock Masses: 5.4.3 Hoek and Brown CriterionDocument8 pagesModule 5: Failure Criteria of Rock and Rock Masses: 5.4.3 Hoek and Brown Criterionفردوس سليمانNo ratings yet

- Lampiran 1: BAHAN AJAR: Report TextDocument3 pagesLampiran 1: BAHAN AJAR: Report TextC R O W N GamingNo ratings yet

- San Matias National High School: Detailed Lesson Plan I. ObjectiveDocument11 pagesSan Matias National High School: Detailed Lesson Plan I. ObjectiveAdrian B. OrtegaNo ratings yet

- APhO Theoretical Problems (2000-2013)Document107 pagesAPhO Theoretical Problems (2000-2013)Science Olympiad Blog100% (7)

- Chapter 7 SolutionDocument26 pagesChapter 7 SolutionNguyễn HùngNo ratings yet

- InTech-Analytical Method ValidationDocument19 pagesInTech-Analytical Method ValidationIordache SorinNo ratings yet

- Textbook An Introduction To Quantum Physics First Edition Anthony P French Ebook All Chapter PDFDocument53 pagesTextbook An Introduction To Quantum Physics First Edition Anthony P French Ebook All Chapter PDFraymond.steiner160100% (26)

- 10 1016@j Cep 2019 107771Document42 pages10 1016@j Cep 2019 107771zjNo ratings yet

- Answers To Revision and Practice Exam QuestionsDocument1 pageAnswers To Revision and Practice Exam QuestionsericaNo ratings yet

- Study of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesDocument10 pagesStudy of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesSyed Kazam RazaNo ratings yet

- A Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional CoresDocument13 pagesA Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional Coresmsmsoft90No ratings yet

- Sample AQA GCSE Chemistry 8462 8464Document40 pagesSample AQA GCSE Chemistry 8462 8464ZuhainaNo ratings yet

- Iron - Cementite Phase DiagramDocument6 pagesIron - Cementite Phase DiagramReverse FlashNo ratings yet

- Simmons ModelDocument14 pagesSimmons Modelsantosh_dengaleNo ratings yet

- 2019-1-1 Test-Report ARB M7 Rev00 enDocument36 pages2019-1-1 Test-Report ARB M7 Rev00 enManjunath AithalNo ratings yet

- GCSE 1b6 RadioactivityDocument48 pagesGCSE 1b6 RadioactivityChahinese FahsiNo ratings yet

- Biodiesel Fuel and How To HandlingDocument35 pagesBiodiesel Fuel and How To Handlingandistwn99No ratings yet

- Recent Advances in Solar-Driven Evaporation SystemsDocument30 pagesRecent Advances in Solar-Driven Evaporation SystemsChristian DennisNo ratings yet

- Subject Orientation Grade 11 Earth and Life Sci, DRRMDocument4 pagesSubject Orientation Grade 11 Earth and Life Sci, DRRMArlance Sandra Marie Medina100% (1)

- Wireless Module1Document47 pagesWireless Module1vetox31792No ratings yet

- Chapter:-19 Water SafetyDocument5 pagesChapter:-19 Water Safetylolu pandeyNo ratings yet

- Chapter 36Document80 pagesChapter 36law05160% (1)

- Azipine PDFDocument58 pagesAzipine PDFGanesamoorthy Thirunarayanan67% (3)

- GLL63 Fozmula Liquid Level Contents Gauge Data 8 6 5R4Document1 pageGLL63 Fozmula Liquid Level Contents Gauge Data 8 6 5R4energiayservicioNo ratings yet

- ThermodynamicsDocument54 pagesThermodynamicsArbeeChrystelV.AleraNo ratings yet

- All Dimensional Formula List PDF Free Download PDF HunterDocument5 pagesAll Dimensional Formula List PDF Free Download PDF HunterSarthak Kamli100% (1)

- Quantitative Estimation of Amino Acids by NinhydrinDocument4 pagesQuantitative Estimation of Amino Acids by Ninhydrinbhuvana_eee0% (1)

- Me6I Final Year Project ReportDocument18 pagesMe6I Final Year Project ReportShivraj DarekarNo ratings yet

Carbohydrates Produced Thermal Processing: Chemical by

Carbohydrates Produced Thermal Processing: Chemical by

Uploaded by

Itiel MartínezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbohydrates Produced Thermal Processing: Chemical by

Carbohydrates Produced Thermal Processing: Chemical by

Uploaded by

Itiel MartínezCopyright:

Available Formats

Chemical Changes in Carbohydrates

Produced by Thermal Processing

R. Carl Hoseney

Department of Grain Science & Industry, Kansas State University, Manhattan, KS 66506

H-C-0 H-C-OH

Carbohydrates are the predominant chemical species in our H-Cc0

diet. They are the major source of both energy and bulk or 1 II 1

H-C-OH C-OH C-OH

fiber. Chemically, carbohydrates vary from the low-molecu-

lar-weight sugars, such as glucose, fructose, and sucrose, to

1 11

HO-C-H <- HO-C-H H‘°

) -> C-H

some of the largest natural polymers known, amylopectin and f I

See https://pubs.acs.org/sharingguidelines for options on how to legitimately share published articles.

l

cellulose. Some of these high molecular-weight entities are

1

H-C-OH H-C-OH H-C-OH

made up of a single simple sugar; for example, the amylopectin 1

1

1 1

fraction of starch is made up essentially of glucose. With a H-C-OH H-C-OH H-C-OH

molecular weight of 400 X 10®, it thus contains about 3 X 10®

1 1

1 1

Downloaded via 189.235.205.10 on February 20, 2020 at 05:12:12 (UTC).

CH*0H

glucose residues. Other complex carbohydrates consist of

CH,OH CHX OH

numerous sugars and may contain noncarbohydrates, such GLUCOSE

as proteins, lipids, and phenolics.

Most of our foods are thermally treated in bakeries or H—C “

0

canneries before we consume them. In many instances, the I

00

thermal treatment is carried out by processing establishments

HjO

-

and by the purchaser; for example, bread is baked in bakeries

1

C-H

and may be reheated or toasted just before consumption. Al- II

HYDROXYMETHYL FURFURAL

most invariably the thermal treatment changes the food C-H

(bread is different from dough, baked potato is different from

raw potato). Such changes often involve reactions of the car-

bohydrates and can be quite complex. It is those changes that

we will deal with in this discussion.

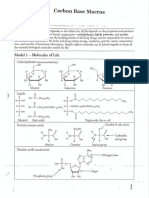

Figure 1. The conversion of glucose to hydroxymethyl furfurat.

Browning Reactions

Given a choice between a raw piece of dough and a baked

loaf of bread most of us would choose the loaf of bread. We

“know” it has a better aroma and taste than does the dough. oration is relatively fast compared to the rate of diffusion.

How does the thermal processing (baking) change the aroma Therefore, as baking proceeds there is a gradient of decreasing

and flavor? If we take a sample from the center of a freshly moisture from the center to the outside of the piece and the

baked loaf of bread, we find it to be doughy in teste and aroma. crust becomes very dry. It is the dry and hot surface that in-

The texture has changed from that of the raw dough, but we duces browning to occur late in the baking cycle.

shall discuss that phenomenon later. This simple demon- The chemistry of the flavor and aroma compounds formed

stration should convince us that the flavor and aroma of during browning is quite complex (1) and clearly outside the

fresh-baked bread comes from changes that occur at the crust scope of this paper. The browning of most baked products is

and not in the interior of the loaf. Another way of reaching the by Maillard-type reactions. The first step of these reactions

same conclusion is to try Chinese steamed bread. Steamed is the condensation of the free amino group, usually from an

bread does not have the brown crust and does not have the amino acid, with the carbonyl of a reducing sugar. Because

flavor and aroma that we associate with freshly baked water is eliminated in the reaction, the reaction is favored by

bread. dehydration conditions. After the condensation there are a

Granting that the flavor and aroma comes from the crust, number of rearrangements that lead to the brown pigments.

what happens during the formation of crust? When bread or Free amino groups are found in most, if not all, baked foods.

other baked foods are placed in a hot oven the moisture at the Since sucrose is a nonreducing sugar and is the one most often

outer surface of the piece evaporates rapidly. Although water used in baked food, we may not always get browning. In

from the moist interior of the piece will diffuse to the surface yeast-leavened products browning does occur because the

and replace the water that has evaporated, the rate of evap- active invertase in yeast rapidly converts sucrose to glucose

308 Journal of Chemical Education

CORN MILO POTATO

Figure 3. Scanning electron photomicrograph of starch isolated from a flour-

water slurry (19).

Figure 2. Light photomicrographs of an isolated small-granule wheat starch

(SGW) and prime starches isolated from wheat, barley, rye, rice, oat, corn, grain

sorghum (mile), and potato (W).

and fructose, both reducing sugars. However, in cake the su-

crose isquite stable and our cakes do not brown unless we add

another source of reducing sugar. The most common other

source is milk, which contains the reducing sugar lactose, or

eggs which contain small amounts of glucose.

Sugars also can brown in the absence of free amino groups.

This process is also a dehydration followed by various rear-

rangements and is called caramelization (2). The reactions Figure 4. Bright field and polarizing micrographs of wheat starch heated in the

occur at moderate pH values. The steps thought to lead to DSC to 57°C (a,b) and 64°C (c,d) at a water-to-starch ratio of 0.5 (5).

hydroxymethyl furfural are given in Figure 1. Hydroxymethyl

furfural polymerizes into brown pigments. Caramelization is

commonly used in candy and icing preparation, where sugar

and small amounts of water are heated to relatively high and partially crystalline. The crystallinity can be seen by

temperature to give caramel flavor. If butter is used in place X-ray diffraction (Fig. 5).

of water, a butterscotch flavor is produced. When starch is heated with excess water it undergoes a

transition from ordered to disordered that we call gelatini-

Starch in Food Systems zation. As shown in Figure 6, the transition can be followed

Starch is the predominant chemical entity in our foods. It conveniently with a differential scanning calorimeter. The

makes up 70% or so of the cereals and tubers (dry weight) that thermogram is a plot of heat flow versus temperature and the

are such a large part of our diets. In addition, starch is found area under the curve gives an estimate of the energy used in

in much lower quantities in many fruits and in beans and other the transition. As shown in the figure, the area under the curve

legumes. decreases as the water content is decreased. Also as water is

Starch in our uncooked food occurs as small packets or decreased the thermogram becomes biphasic and the tem-

granules. The size and shape of the granules vary with the perature range over which the transition occurs is much

source (Fig. 2). In many cases they vary even within a single broader.

source. For example, wheat starch varies both in size and The term gelatinization is often used to describe all changes

shape (Fig. 3). The large starch granules in wheat are about that occur when we heat starch and water, however, it should

35 pm across and are lenticular. The small granules are only be restricted to the loss of birefringence. Once the starch has

2 to 5 pm in diameter and are spherical. lost its birefringence, continued heating to higher temperature

The molecules in starch granules are ordered. Because of with water brings about a continuum of changes. These

this order the granule detracts plane-polarized light in the changes can be described best as solubilization. With wheat

characteristic maltese cross pattern (Fig. 4). This property is starch, complete solubilization occurs at about I2CTC. As most

called birefringence. The birefringence is often confused with food systems are heated to less than 100°C and with limited

crystallinity. However, material can be birefringent (ordered) water, our cooked foods are a mixture of solubilized and in-

but not crystalline. Starch, it turns out, is both birefringent soluble starch.

Volume 61 Number 4 April 1984 309

TEMPERATURE (°C)

Figure 7. Effect of 2% monoglyceride (MG) or sodium steoryl lactylate (SSL)

on the Brabender viscosity of wheat starch (3).

Figure 5. X-ray diffraction patterns of the insoluble residue of wheat starch heated

wi1h sodium stearoyl lactylate to: a, 60°C; b, 70°C; c, SfFC; and d, 95°C

(20).

Figure 8. Water activity of sugar solutions versus gelatinization temperature;

F =

fructose, G = glucose, M = maltose, S = sucrose, T = maltotriose (7).

the viscosity becomes very large, and the cake or bread

sets.

Figure 6. Differential scanning thermograms of wheat starch heated with The temperature at which starch gelatinization occurs de-

water-to-starch ratios of: a, 2.0; b, 1.0; c, 0.75; d, 0.5; e, 0.44; f. 0.35 (5). pends first on the source of starch. For example, potato starch

gelatinizes at a lower temperature than does corn starch.

Generally, we must speak of a gelatinization temperature

Raw (uncooked) starch does not absorb much water (about range rather than a specific temperature. With most starches,

30% of its dry weight). Evidently, the crystallinity of the starch the temperature range over which gelatinization occurs in

limits its swelling and thus limits the amount of water it can excess water is 7-10°C. As water becomes more limiting (Fig.

absorb. With gelatinization, the crystallinity is lost and the 6) the temperature range becomes much broader (5). The

granules are free to swell. With swelling the granule is free to temperature at which starch starts to gelatinize does not

take up much more water. Also with gelatinization the starch change as water is limited (6, 7). The second major factor that

loses its raw starch taste and becomes smooth or cooked. affects starch gelatinization temperature is which and how

Cooking starch or starchy foods in water leads to an increase many molecules are dissolved in the available water. Small

in the viscosity of the cooked product, gravies and sauces being molecules dissolved in water will decrease the water activity.

good examples. The rather large increases in viscosity (Fig. As water activity is decreased gelatinization temperature is

7) can be followed conveniently with an amylograph. In the increased. Sugars, of course, will affect water activity. In ad-

amylograph a dilute starch:buffer (4% starch) solution is dition to their effect on water activity, sugars (Fig. 8), will

heated at a constant lV2°C/min and the relative viscosity re- cause starch gelatinization to occur at higher temperatures

corded. The rapid increase in viscosity appears to be the result apparently by an additional mechanism (7,8). In many of our

of two factors {3,4). The uptake of water by the starch gran- food systems this is used to control the temperature at which

ules decreases the amount of water remaining in the system. the product sets.

The starch that is solubilized during the heating then is dis- Starch heated beyond its gelatinization temperature forms

solved in less total water resulting in a more viscous system. a paste, which, when cooled, becomes a gel. The gel results

In limited water systems, such as cake batters or bread doughs, from the hydrogen bonding between water and the soluble

310 Journal of Chemical Education

TEMPERATURE -

°C

Figure 10. Effect of reheating temperature on freshness of a five-day-old bread

sample (10).

TEMPERATURE -

°C

Figure 9. DSC thermograms of bread samples stored for 1, 3, 5, and 7 days

(10).

starch molecules. With time, and particularly with freezing

CH.OH CH.OH CH.OH

and thawing, water is expressed from the gel (syneresis). This

is caused by the hydrogen-bonding of starch with starch,

which eliminates water. Modified starches (primary cross-

linked starches) are fixed in space and thus cannot get close

enough together to hydrogen bond. Thus, such starches pro- OH OH OH

duce gels that have good freeze-thaw stability.

Starch gels when stored, particularily at low temperature, Figure 11. Hydrolysis of an ct-1,4-glycosidic bond in a segment of a starch

chain.

often become cloudy. This is caused by a recrystallization of

the starch, a process called retrogradation. The recrystalli-

zation does not give the same crystal structure (X-ray dif-

fraction pattern) as found in ungelatinized starch granules.

Von Eberstein et al. (9) have shown differential scanning energy will result in the formation of dextrins. One type of

calorimetry (DSC) data for both amylose and amylopectin starch modification still used is a dry roasting process that

retrogradation. In dilute systems the amylose fraction of the produces dextrins (11).

starch will retrograde very rapidly. However, in food systems At less extreme temperatures carbohydrates, and particu-

where water is quite limiting, the amylopectin appears to be larly starch, can be hydrolyzed in aqueous systems (12). The

the fraction that slowly retrogrades. Bread crumb that had amount of thermal energy required is greatly dependent on

retrograded for different periods of time gave, in general, a the pH of the media. At low pH, the amorphous regions of

larger DSC peak with longer storage time (Fig. 9). starch will hydrolyze at a reasonable rate at room temperature

This retrogradation phenomenon generally is considered (Fig. 11). Near neutral pH, the hydrolysis is slow even at ele-

to be a major factor in bread staling and, indeed, the firming vated temperatures (see table).

that is found in many starchy foods. It appears that staling

Extrusion Cooking

probably involves more than just retrogradation, but retro-

gradation undoubtedly is one of the factors. It is interesting The cooker-extruder has become popular for thermal pro-

that bread can be refreshened simply by heating (toasting). cessing of both food and feed products (13). The cooker-ex-

This is clearly shown in Figure 10, in which bread staled for truder is actually an inefficient pump. Most of the heat used

5 days was heated in “browning bags” to various temperatures for the thermal processing is generated from friction. In a

and the firmness determined. The use of the browning bags cooker-extruder, both temperature and pressure increase as

allows the bread to be heated without a significant moisture the feed material progresses down the barrel. Thus, thermal

loss. With this reheating, the crystal structure of the retro- processing is rather severe. The fact that the system is closed

graded starch disappears. The relationship between crystal and thus excludes oxygen undoubtedly limits the amount of

structure and firmness, however, does not appear to be strictly chemical change that we see in the carbohydrates during ex-

causative (10). trusion.

Much of the effectiveness of the cooker-extruder is because

Hydrolysis of Carbohydrates of factors other than the thermal processing, such as the shear

Carbohydrates by their very nature as hydrates of carbon imparted by the rotating screw and the effect of the rapid

are not stable under extremes of thermal processing. High heat change in pressure as the feed material exits the extruder die.

will bring about dehydration, as discussed previously. With Both of those factors are important in the changes brought

large molecules, such as starch, large increases in thermal about in the extrudates.

Volume 61 Number 4 April 1984 311

Effect of Microwave Heating of Starch in Sealed Tubes a

to emulsify, and to alter the texture of the products. Appli-

Duration

cations would include stabilization of icings and glazes, in-

Reducing

Cone, of of Heal Sugar/ creasing the viscosity of salad dressings, and many others.

Starch Treatment Starch Perhaps the most common effect of gums with thermally

<%) (min.) pH <%) processed food is the modification of crystal growth in ice

cream manufacture. The physical alteration of crystal growth

10 16 4.5 3.1

20 16 3.8 1.9

give rise to smooth ice cream. Without such modification ice

30 16 3.8 19.3 crystals will grow large giving a gritty or icy product.

30 18 3.2 41.7

30 20 3.1 53.4

Summary

Carbohydrates are a major part of our diets and vary widely

a

Adapted trom ret. I (2). in their chemical make-up. Most of our food is thermally

processed before consumption. The changes occurring as a

Cookies and Candies result of that thermal processing are also quite varied. The

carbohydrates are involved in the browning that occurs during

Although they may not seem so, many cookies and candies thermal processing. That browning is responsible for much

are very similar. Of course, the wide variations in both cookies of the color and aroma of foods.

and candies make generalizations difficult. The most pro- Starch is our most predominant chemical entity in our

nounced changes that occur during thermal processing of ei- foods. The changes that starch undergoes as it is heated with

ther cookies or candies is the browning reaction that affects water has a great influence on texture and taste (raw versus

flavor and aroma. cooked) of many of our foods. In foods, starch acts as a heat-

As a result of thermal processing of sugar in these very

triggered water sink. The binding of the water by the starch

limited water systems, practically no change in the chemical leads to a rapid increase in the viscosity of the media. Thus,

structure of the carbohydrates is found. In fact, with the

gravies or sauces thicken and bread doughs or cake batters set.

limited water and high amounts of sugar found in many The temperature at which those changes occur depends upon

cookies, the starch does not gelatinize during baking (14). primarily the sugar content of the water in the food. It is also

Instead, the water-to-carbohydrate ratio is changed, and thus, thought that starch is responsible for the staling of foods such

upon cooling, the sugar is found in a much different physical as bread, primarily by a recrystallization process called re-

form. An example would be the heating of sugar, water, and

trogradation.

minor flavor components to a certain boiling temperature Thermal processing also can cause other changes in car-

(determined by the sugar/water ratio) and then rapidly cooling bohydrates. These can be hydrolysis of starch to form dextrins

the mixture to give a glass that we know as hard candy. Im- or sugars or simply a change in physical form as found with

proper temperature control will yield a system in which the candies and cookies.

sugar will recrystallize and thus change the texture of the

candy. Literature Cited

In cookies the system is much more complicated because, (1) Hodge, J. E., and Osman, Elizabeth M., “Carbohydrates,” in “Food Chemistry” (Editor:

in addition to sugar and water, the formula contains flour, Fenenema, Owen R.)t Marcel Dekker, New York, 1976.

(2) Eichenberger, W. R., "Caramel Colors: Manufacture, Properties, and Food Applica-

baking soda, leavening acids, milk, and many other ingredi- tions,” in “Encyclopedia of Food Science" (Edited by: Peterson, M. S., and Johnson,

ents. During baking, water is driven off, and the sugar/water A. H,), AVI Publishing, Westport, CT, 1978.

ratio is changed. Generally, a glass is not formed because of (3) Ghiasi, K., Varriano-Marston, E., and Hoseney, R. C., Cereal Chem., 59, 262 (1982).

(4) Miller, B. S., Derby, R. 1., and Trimbo, H. B., Cereal Chem., 50 271 (1973).

all the impurities. However, after cooling, a crystallization of (5) Ghiasi, K., Hoseney, R. C., and Varriano-Martson, E., Cereal Chem., 59, 258 (1982).

the sugar may occur that changes the cookie from a soft, (6) Donovan, J. W., Biopolymers, 18, 263 (1979).

(7) Spies, R. D., and Hoseney, R. C., Cereal Chem., 59, 128 (1982).

pliable type to one that breaks with a snap (15). (8) Ghiasi, K., Hoseney, R. C., and Varriano-Marston, E., Cereal Chem., 60,58 (1983).

(9) Von Eberstein, K., Hopcke, R., Konieczny-Jacda, G., and Stute, R., Starke, 23, 397

Gums (1980).

(10) Ghiasi, K., Hoseney, R. C., Zeleznak, K., and Rogers, D. E., Cereal Chem., in press.

The naturally occurring gums or hydrocolloids are chemi- (11) Acton, W.,“The Manufacture of Dextrins and British Gums,” in “Starch Production

cally quite diverse (16,17). Most of the important gums are Technology” (Editor: Radley, J. A.), Applied Science Publishers Ltd., London,

1976.

primarily carbohydrate, but their diversity of composition (12) Rasheed Khan, A., Johnson, J. A., and Robinson, R. J., Cereal Chem., 56, 303

makes changes due to thermal processing difficult to sum- (1979).

(13) Faubion, J. M,, Hoseney, R. C., and Seib, P. A., Cereal Foods World, 27, 212 (1982).

marize. Most gums are useful because they alter the viscosity (14) Abboud, A. M-, and Hoseney, R. C., Cereal Chem., 61,34 (1984).

of solutions. Unlike starch, which is heat triggered, most gums (15) Curley, Lynn, and Hoseney, R. C., Cereal Chem., in press.

are not greatly affected by heat. The gums are usually classi- (16) Glicksman, M., “Gum Technology in the Food Industry,” Academic Press, New York,

1969.

fied according to their source for the naturally occurring one, (17) Meer, W. A., and Meer G.} “Hydrocolloids (Natural Plant),” in “Encyclopedia of Food

for example, agar alginates, arabic, carrageenan, guar, karaya, Science” (Editor: Peterson, M. S., and Johnson, A. H.), AVI Publishing Company,

Westport, CT, 1978, p. 391.

locust bean. The synthetic gums are more often classified by (18) Hoseney, R. C,, Atwell, W. A., and Lineback. D. R., Cereal Foods World, 22, 56,

the chemical type, carboxymethyl cellulose or xanthan, for (1977).

(19) Hoseney, R. C., Finney, K. F., Pomeranz, Y., and Shogren, M., Starch. Cereal Chem.,

example. 48, 191 (1971).

Gums are used in foods to increase viscosity, to stabilize, (20) Ghiasi, K., Varriano-Marston, E. and Hoseney, R. C., Cereal Chem., 59, 86 (1982).

312 Journal of Chemical Education

You might also like

- Ujian 3Document16 pagesUjian 3Resty SimorangkirNo ratings yet

- Unit 3 - CarbohydratesDocument26 pagesUnit 3 - CarbohydratesWinrich Louise M. MontanoNo ratings yet

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat Panchalzaid ansari89% (9)

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat PanchalroceniNo ratings yet

- Alcohol, Phenol and Ethers Digital NotesDocument23 pagesAlcohol, Phenol and Ethers Digital NotesroceniNo ratings yet

- Alcohol Phenol and EthersDocument25 pagesAlcohol Phenol and EthersAyaz100% (2)

- Biomolecules Print PDFDocument5 pagesBiomolecules Print PDFsinghatmesh685No ratings yet

- MonosaccharidesDocument6 pagesMonosaccharidesHello KittyNo ratings yet

- Biomolecules SHORT NotesDocument2 pagesBiomolecules SHORT NotesAstha AgrawalNo ratings yet

- 4 Introductory Organic Chemistry and AlkanesDocument12 pages4 Introductory Organic Chemistry and AlkanesChristina HerculesNo ratings yet

- Topic 2 - Biological MoleculesDocument78 pagesTopic 2 - Biological Moleculesjamalsaeed160No ratings yet

- Hydrocarbons: Section 2Document14 pagesHydrocarbons: Section 2Karam AbdullahNo ratings yet

- Function Groups Crap 2Document1 pageFunction Groups Crap 2sultana.otb2018No ratings yet

- MET180 - Chapter 8Document38 pagesMET180 - Chapter 8saeed khanNo ratings yet

- Pogil Macros-No TitlesDocument4 pagesPogil Macros-No Titleskparsons938512No ratings yet

- BCH 210 CarbohydrateDocument28 pagesBCH 210 CarbohydratedarrielabuaNo ratings yet

- Ch05 MacromoleculesCampbellDocument69 pagesCh05 MacromoleculesCampbellCarl Jasper AquinoNo ratings yet

- Classification of CarbohydratesDocument97 pagesClassification of CarbohydratesALEM, RALPH LAURENCE B.No ratings yet

- Solucionario de Wade-306-323 PDFDocument18 pagesSolucionario de Wade-306-323 PDFCésar PastranoNo ratings yet

- Functional Group Naming TableDocument1 pageFunctional Group Naming Tableinfo.acc231No ratings yet

- 6 Organic Chemistry IDocument27 pages6 Organic Chemistry IAwil AhmedNo ratings yet

- Chemistry of CarbohydratesDocument3 pagesChemistry of CarbohydratesHello KittyNo ratings yet

- Organic Chemistry I EdexcelDocument28 pagesOrganic Chemistry I Edexcelvyb8qpq57yNo ratings yet

- BI115 หลักชีววิทยา (Priciples of biology)Document315 pagesBI115 หลักชีววิทยา (Priciples of biology)สาธิต ปริ นทร์ทองNo ratings yet

- Carboxylic Acid and Their DerivativesDocument5 pagesCarboxylic Acid and Their DerivativesShubham KumarNo ratings yet

- AlcoholsDocument16 pagesAlcoholsLucas “Khumalo” KaunduNo ratings yet

- 1.2.QR - Carbohydrate Structure - UUBiochemDocument2 pages1.2.QR - Carbohydrate Structure - UUBiochemdondavis77No ratings yet

- 6 - Organic ChemistryDocument27 pages6 - Organic ChemistryAlvaro CatalaNo ratings yet

- Structure and Function of CarbohydratesDocument27 pagesStructure and Function of CarbohydratesAli SeenaNo ratings yet

- Carboxylic AcidsDocument23 pagesCarboxylic AcidsSoma Chowdhury RosyNo ratings yet

- 1.chemical - IJCPT - Behaviour of - SamehDocument12 pages1.chemical - IJCPT - Behaviour of - Samehiaset123No ratings yet

- Basic Concepts and Hydrocarbons PDFDocument6 pagesBasic Concepts and Hydrocarbons PDFDr.CharinNo ratings yet

- Carbohydrates ASAS 4104Document53 pagesCarbohydrates ASAS 4104AlbanMugotiNo ratings yet

- 3.1 Revision Guide Introduction Organic AqaDocument9 pages3.1 Revision Guide Introduction Organic AqaIman KhanNo ratings yet

- 3.1 Revision Guide Introduction Organic AqaDocument9 pages3.1 Revision Guide Introduction Organic Aqashafiqur rahmanNo ratings yet

- BiomoleculesDocument32 pagesBiomoleculesanumeha.kinsui23No ratings yet

- Organic Chemistry I EdexcelDocument28 pagesOrganic Chemistry I EdexcelAinara Román MacíasNo ratings yet

- LEC 7 - CarbohydratesDocument5 pagesLEC 7 - Carbohydrateserikapana09No ratings yet

- FC Lect Topic4d AY17-18 StudentDocument29 pagesFC Lect Topic4d AY17-18 StudentRaysonChooNo ratings yet

- Experiment 5 Properties of Carbohydrates: Solubility, Reactivity, and Specific RotationDocument9 pagesExperiment 5 Properties of Carbohydrates: Solubility, Reactivity, and Specific RotationCiara marie BernardoNo ratings yet

- MembraneDocument51 pagesMembraneNinad MunNo ratings yet

- An Aldol Condensation To Synthesize ChalconesDocument6 pagesAn Aldol Condensation To Synthesize ChalconesAssyakurNo ratings yet

- Hydrocarbons & Functional GroupsDocument62 pagesHydrocarbons & Functional GroupsNINO DOLINONo ratings yet

- Alchohol ResearchASDocument18 pagesAlchohol ResearchASAhmed SiddiquiNo ratings yet

- NotesDocument44 pagesNotesshrirang chandankhedeNo ratings yet

- Bio Endocrine - 230210 - 002532Document49 pagesBio Endocrine - 230210 - 002532abodeissaalssabagNo ratings yet

- Organic Chemistry For AlevelDocument15 pagesOrganic Chemistry For AlevelNahida HossainNo ratings yet

- Chemistry of Carbohydrates II: ObjectivesDocument22 pagesChemistry of Carbohydrates II: Objectivesahmad671poNo ratings yet

- Oligosaccharides. Polysaccharides. Terpenes.Document182 pagesOligosaccharides. Polysaccharides. Terpenes.Umar M abubakarNo ratings yet

- Chapter 2 Polymerization and Molecular Weight DistributionDocument77 pagesChapter 2 Polymerization and Molecular Weight DistributionEss NatashaNo ratings yet

- Organic Chemistry II: University of Lincoln PresentationDocument20 pagesOrganic Chemistry II: University of Lincoln PresentationkayannaNo ratings yet

- K - Enols and Enolates 11 - F14Document1 pageK - Enols and Enolates 11 - F14shinexblazerNo ratings yet

- Carbohydrates Handout PDFDocument15 pagesCarbohydrates Handout PDFAra AlibasaNo ratings yet

- Introduction To Use of LecithinsDocument11 pagesIntroduction To Use of LecithinsManish MangharamaniNo ratings yet

- Universty: UrdanetaDocument7 pagesUniversty: UrdanetaMello DiaxNo ratings yet

- OCOC 1 Homework 4Document37 pagesOCOC 1 Homework 4TRENDING KNOWLEDGE. INDIANo ratings yet

- Lecture 02Document11 pagesLecture 02CataNo ratings yet

- Lect 4 - Molecules - Cell 2020Document97 pagesLect 4 - Molecules - Cell 2020Sỹ HiệpNo ratings yet

- Department of EducationDocument3 pagesDepartment of EducationMaribel membradoNo ratings yet

- Journal of Polymers - 2014 - Shit - Edible Polymers Challenges and OpportunitiesDocument13 pagesJournal of Polymers - 2014 - Shit - Edible Polymers Challenges and OpportunitiesphmartNo ratings yet

- MetabolomicsDocument12 pagesMetabolomicswatson191No ratings yet

- Module 5: Failure Criteria of Rock and Rock Masses: 5.4.3 Hoek and Brown CriterionDocument8 pagesModule 5: Failure Criteria of Rock and Rock Masses: 5.4.3 Hoek and Brown Criterionفردوس سليمانNo ratings yet

- Lampiran 1: BAHAN AJAR: Report TextDocument3 pagesLampiran 1: BAHAN AJAR: Report TextC R O W N GamingNo ratings yet

- San Matias National High School: Detailed Lesson Plan I. ObjectiveDocument11 pagesSan Matias National High School: Detailed Lesson Plan I. ObjectiveAdrian B. OrtegaNo ratings yet

- APhO Theoretical Problems (2000-2013)Document107 pagesAPhO Theoretical Problems (2000-2013)Science Olympiad Blog100% (7)

- Chapter 7 SolutionDocument26 pagesChapter 7 SolutionNguyễn HùngNo ratings yet

- InTech-Analytical Method ValidationDocument19 pagesInTech-Analytical Method ValidationIordache SorinNo ratings yet

- Textbook An Introduction To Quantum Physics First Edition Anthony P French Ebook All Chapter PDFDocument53 pagesTextbook An Introduction To Quantum Physics First Edition Anthony P French Ebook All Chapter PDFraymond.steiner160100% (26)

- 10 1016@j Cep 2019 107771Document42 pages10 1016@j Cep 2019 107771zjNo ratings yet

- Answers To Revision and Practice Exam QuestionsDocument1 pageAnswers To Revision and Practice Exam QuestionsericaNo ratings yet

- Study of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesDocument10 pagesStudy of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesSyed Kazam RazaNo ratings yet

- A Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional CoresDocument13 pagesA Laboratory Study of Hot Carbon Dioxide Injection Into Fractured and Conventional Coresmsmsoft90No ratings yet

- Sample AQA GCSE Chemistry 8462 8464Document40 pagesSample AQA GCSE Chemistry 8462 8464ZuhainaNo ratings yet

- Iron - Cementite Phase DiagramDocument6 pagesIron - Cementite Phase DiagramReverse FlashNo ratings yet

- Simmons ModelDocument14 pagesSimmons Modelsantosh_dengaleNo ratings yet

- 2019-1-1 Test-Report ARB M7 Rev00 enDocument36 pages2019-1-1 Test-Report ARB M7 Rev00 enManjunath AithalNo ratings yet

- GCSE 1b6 RadioactivityDocument48 pagesGCSE 1b6 RadioactivityChahinese FahsiNo ratings yet

- Biodiesel Fuel and How To HandlingDocument35 pagesBiodiesel Fuel and How To Handlingandistwn99No ratings yet

- Recent Advances in Solar-Driven Evaporation SystemsDocument30 pagesRecent Advances in Solar-Driven Evaporation SystemsChristian DennisNo ratings yet

- Subject Orientation Grade 11 Earth and Life Sci, DRRMDocument4 pagesSubject Orientation Grade 11 Earth and Life Sci, DRRMArlance Sandra Marie Medina100% (1)

- Wireless Module1Document47 pagesWireless Module1vetox31792No ratings yet

- Chapter:-19 Water SafetyDocument5 pagesChapter:-19 Water Safetylolu pandeyNo ratings yet

- Chapter 36Document80 pagesChapter 36law05160% (1)

- Azipine PDFDocument58 pagesAzipine PDFGanesamoorthy Thirunarayanan67% (3)

- GLL63 Fozmula Liquid Level Contents Gauge Data 8 6 5R4Document1 pageGLL63 Fozmula Liquid Level Contents Gauge Data 8 6 5R4energiayservicioNo ratings yet

- ThermodynamicsDocument54 pagesThermodynamicsArbeeChrystelV.AleraNo ratings yet

- All Dimensional Formula List PDF Free Download PDF HunterDocument5 pagesAll Dimensional Formula List PDF Free Download PDF HunterSarthak Kamli100% (1)

- Quantitative Estimation of Amino Acids by NinhydrinDocument4 pagesQuantitative Estimation of Amino Acids by Ninhydrinbhuvana_eee0% (1)

- Me6I Final Year Project ReportDocument18 pagesMe6I Final Year Project ReportShivraj DarekarNo ratings yet