Professional Documents

Culture Documents

Experiment No.6 Compressive Strength of Cylindrical Concrete Specimens

Experiment No.6 Compressive Strength of Cylindrical Concrete Specimens

Uploaded by

Seungcheol ChoiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment No.6 Compressive Strength of Cylindrical Concrete Specimens

Experiment No.6 Compressive Strength of Cylindrical Concrete Specimens

Uploaded by

Seungcheol ChoiCopyright:

Available Formats

ADC

UNIVERSITY OF THE EAST

COLLEGE OF ENGINEERING

CIVIL ENGINEERING DEPARTMENT

CALOOCAN

CONSTRUCTION MATERIALS AND TESTING

EXPERIMENT No. 6

Compressive Strength of Cylindrical Concrete Specimens

ASTM Designation

ASTM C39

Purpose

To determine the compressive strength of cylindrical PCC specimens, such as molded cylinders

and drilled cores.

Significance and Use

This test provides the compressive strength of concrete, which is used universally as a measure

of concrete quality.

Apparatus

Loading machine (Universal Testing Machine).

Test Specimens

The standard specimen size used to determine the compressive strength of concrete is

152 mm diameter by 304 mm high for a maximum aggregate size up to 50 mm

Conduct the compression test on the moist-cured specimens directly after removing

them from the curing room. Test specimens must be moist when tested.

Specimen age, at time of testing, should be 24 hours ± 0.5 hours, 3 days ± 2 hours, 7days

± 6 hours, 28 days ± 20 hours, or 90 days ± 2 days

Test Procedure

1. Measure the diameter of the test specimen to the nearest 0.25mm by averaging two

diameters measured at right angles to each other at the middle height of the specimen.

2. Adjust the bearing block into position.

3. Clean the faces of the bearing blocks and the specimen.

4. Carefully align the axis of the specimen with the center of the thrust of the spherically-

seated block.

5. Apply the load continuously and without shock. For hydraulically operated machines,

apply the load at a constant rate within the range of 20 psi/sec to 50 psi/sec.

6. Continue applying the load until the specimen fails.

7. Record the maximum load carried by the specimen during the test.

8. Note the type of failure and the appearance of concrete.

Analysis and Results

Calculate the compressive strength as

P max

f ' c=

A

Experiment No. 7 Page 1

ADC

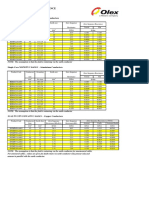

Report

Specimen identification number

Diameter and length in mm

Cross-sectional area

Maximum load

Compressive strength, calculated to the nearest 0.07 MPa

Types of failure

Age of specimen

Figure 7.1 Typical fracture patterns of concrete cylinders

Experiment No. 7 Page 2

You might also like

- Amendment No. 4 July 2019 TO Is 1786: 2008 High Strength Deformed Steel Bars and Wires For Concrete Reinforcement - SpecificationDocument2 pagesAmendment No. 4 July 2019 TO Is 1786: 2008 High Strength Deformed Steel Bars and Wires For Concrete Reinforcement - SpecificationThetarun76% (17)

- Unconfined Compressive Strength TestDocument5 pagesUnconfined Compressive Strength TestManish Arya50% (2)

- Zero Sequence1 - SummaryDocument4 pagesZero Sequence1 - SummaryTosikur Rahman100% (1)

- PG&E Parkway Moraga Hanger Plate ReportDocument29 pagesPG&E Parkway Moraga Hanger Plate ReportABC10100% (1)

- Compressive Strength of Lightweight Insulating Concrete': Standard Test Method ForDocument3 pagesCompressive Strength of Lightweight Insulating Concrete': Standard Test Method Forayan3176No ratings yet

- Mapetherm Tile System PDFDocument52 pagesMapetherm Tile System PDFMilovan MitrovićNo ratings yet

- Modulus of RaptureDocument18 pagesModulus of RaptureHitesh PatilNo ratings yet

- Determine Splitting Tensile Strength of Cylindrical Concrete SpecimensDocument5 pagesDetermine Splitting Tensile Strength of Cylindrical Concrete SpecimenssuryakantameNo ratings yet

- CEMB 111 Civil Engineering Materials: Laboratory Experiment 9Document7 pagesCEMB 111 Civil Engineering Materials: Laboratory Experiment 9hamedNo ratings yet

- CIP35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNo ratings yet

- Compressive Strength of Concrete: 1. ObjectiveDocument6 pagesCompressive Strength of Concrete: 1. ObjectivedavyordersNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument7 pagesCIP 35 - Testing Compressive Strength of ConcretesudhakarmnNo ratings yet

- Manual Concrete PDFDocument48 pagesManual Concrete PDFHamza HussainNo ratings yet

- LAB REPORT 13 - For PrintingDocument5 pagesLAB REPORT 13 - For PrintingBeatrex June LademoraNo ratings yet

- 09-Cylinder Test - 1Document6 pages09-Cylinder Test - 1armaan.dinajpurNo ratings yet

- PARTIALLY DESTRUCTIVE TESTS and NON DESTRUCTIVE TESTINGDocument4 pagesPARTIALLY DESTRUCTIVE TESTS and NON DESTRUCTIVE TESTINGAfzal Waseem100% (1)

- Institute of Engineering Department CivilDocument27 pagesInstitute of Engineering Department CivilSabbir HossainNo ratings yet

- Compressive Strength of Concrete: 1. ObjectiveDocument3 pagesCompressive Strength of Concrete: 1. ObjectiveShahrukhNo ratings yet

- TRE ManualDocument21 pagesTRE ManualPrathamesh PatilNo ratings yet

- C495 M - 12Document3 pagesC495 M - 12Lila Ester Ashook VillarrealNo ratings yet

- Core TestDocument15 pagesCore Testsumitbelsare28No ratings yet

- Compressive Strength of Lightweight Insulating Concrete: Standard Test Method ForDocument3 pagesCompressive Strength of Lightweight Insulating Concrete: Standard Test Method ForVikas SharmaNo ratings yet

- SOM Lab Manual PDFDocument31 pagesSOM Lab Manual PDFchetbkNo ratings yet

- Compressive Strength of Lightweight Insulating Concrete: Standard Test Method ForDocument3 pagesCompressive Strength of Lightweight Insulating Concrete: Standard Test Method ForibrahimNo ratings yet

- Strength Test On ConcreteDocument23 pagesStrength Test On ConcreteMukesh Kumar SamotaNo ratings yet

- Conducting A Compressive Strength TestDocument8 pagesConducting A Compressive Strength TestCeleste Amor FactorNo ratings yet

- Refresher Module 30 (S21) - Construction Materials Testing and CodesDocument2 pagesRefresher Module 30 (S21) - Construction Materials Testing and CodesJohnMichaelPeraltaNo ratings yet

- BRCM College of Engineering & Technology Bahal, Bhiwani: Practical Experiment Instructions SheetDocument31 pagesBRCM College of Engineering & Technology Bahal, Bhiwani: Practical Experiment Instructions SheetAnonymous vvO0nZWflrNo ratings yet

- Testing The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixDocument2 pagesTesting The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixPritha DasNo ratings yet

- Testing The Compressive Strength of Concrete - What, Why, & How - Nevada Ready MixDocument4 pagesTesting The Compressive Strength of Concrete - What, Why, & How - Nevada Ready Mixdhan singhNo ratings yet

- FEWEFDocument3 pagesFEWEFHeril JainNo ratings yet

- Report On: Tribhuvan UniversityDocument48 pagesReport On: Tribhuvan UniversityNiroj MaharjanNo ratings yet

- Ce6411 Strength of Materials Laboratory (Civil)Document32 pagesCe6411 Strength of Materials Laboratory (Civil)Koleshwar Mahto KoleshwarNo ratings yet

- Method For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Document4 pagesMethod For Determining The Unconfined Compressive Strength of Intact Rock Core Specimens SCT39Deepak Kumar MallickNo ratings yet

- Astm C 364Document3 pagesAstm C 364Amar JabarNo ratings yet

- BMT LAB NEW Final111111 PDFDocument85 pagesBMT LAB NEW Final111111 PDFmohanNo ratings yet

- Flexural Strength TestDocument23 pagesFlexural Strength TestJommel GonzalesNo ratings yet

- Advanced SOM. LAB. Manual-2Document15 pagesAdvanced SOM. LAB. Manual-2Sudip LouhaNo ratings yet

- Is 5816 Splitting Tesile Strength of Concrete-Method of Test.182112830Document11 pagesIs 5816 Splitting Tesile Strength of Concrete-Method of Test.182112830shinjinkuroNo ratings yet

- Class 10 Module 2 Cocrete ExtendedDocument18 pagesClass 10 Module 2 Cocrete ExtendedAnanyaNo ratings yet

- Determination of The Compressive Strength of Concrete Hollow BlocksDocument54 pagesDetermination of The Compressive Strength of Concrete Hollow BlocksChrissaNo ratings yet

- C.T. Lab Manual 2019-20 New1Document52 pagesC.T. Lab Manual 2019-20 New1James DNo ratings yet

- Testing of Material-Lab-Report-7Document6 pagesTesting of Material-Lab-Report-7Mariefel Therese AlsaNo ratings yet

- Hardness TestDocument25 pagesHardness TestDeniThomasBoban100% (1)

- C 1245 - 93 - QzeyndutotmDocument7 pagesC 1245 - 93 - QzeyndutotmgadNo ratings yet

- Engineering Materials Exp. - 3Document7 pagesEngineering Materials Exp. - 3Nahid SultanNo ratings yet

- Determination of Tensile Strength of Concrete Cylinder (Split Tension or Equivalent)Document4 pagesDetermination of Tensile Strength of Concrete Cylinder (Split Tension or Equivalent)Ceddie PamintuanNo ratings yet

- Compressive Strength of Concrete & Concrete Cubes - What - How - CivilDigitalDocument13 pagesCompressive Strength of Concrete & Concrete Cubes - What - How - CivilDigitalArdhi TaNo ratings yet

- Tests On Concrete (Viva Voce)Document4 pagesTests On Concrete (Viva Voce)Mani KandanNo ratings yet

- C695-15 Standard Test Method For Compressive Strength of Carbon and GraphiteDocument3 pagesC695-15 Standard Test Method For Compressive Strength of Carbon and GraphiteDuc Nguyen VanNo ratings yet

- Astm C39 C39M-16Document7 pagesAstm C39 C39M-16Yao Leslie Armande MélissaNo ratings yet

- Concrete TestingDocument1 pageConcrete TestingNadia IzzatiNo ratings yet

- Lab Manual: International Islamic University Malaysia Department of Mechanical EngineeringDocument36 pagesLab Manual: International Islamic University Malaysia Department of Mechanical EngineeringMuhamad HilmiNo ratings yet

- Compression Strength and Rebound Hammer TestDocument20 pagesCompression Strength and Rebound Hammer TestAmir AkmalNo ratings yet

- Compressi Test of Concrete CylindersDocument10 pagesCompressi Test of Concrete CylindersMark Anthony DimenNo ratings yet

- Strength of Materials Lab-Ahmed AlsharaDocument24 pagesStrength of Materials Lab-Ahmed AlsharaMṜ ΛßßΛSNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- Testing Compressive Strength of Concrete PDFDocument2 pagesTesting Compressive Strength of Concrete PDFaaNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- Atm1112 Engineering Materials Module 6Document14 pagesAtm1112 Engineering Materials Module 6Nelly DavedNo ratings yet

- MIE2241 - Mechanics Lab Manual - PART1 - FINALDocument57 pagesMIE2241 - Mechanics Lab Manual - PART1 - FINALrahulprakashjiNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Allowable Loads On One Bolt in Seasoned Wood Loaded at Both Ends in Normal Duration - Timber Design ReviewDocument7 pagesAllowable Loads On One Bolt in Seasoned Wood Loaded at Both Ends in Normal Duration - Timber Design ReviewSeungcheol ChoiNo ratings yet

- Timber Design - ReviewDocument7 pagesTimber Design - ReviewSeungcheol ChoiNo ratings yet

- Types of Annuities - Engineering EconomyDocument9 pagesTypes of Annuities - Engineering EconomySeungcheol ChoiNo ratings yet

- Concrete Foundation - Three Types of Concrete FoundationsDocument5 pagesConcrete Foundation - Three Types of Concrete FoundationsSeungcheol ChoiNo ratings yet

- Annuities and Capitalized Cost - Engineering EconomyDocument4 pagesAnnuities and Capitalized Cost - Engineering EconomySeungcheol ChoiNo ratings yet

- Foundation Drainage - Using Drain Pipe & Dimple BoardsDocument12 pagesFoundation Drainage - Using Drain Pipe & Dimple BoardsSeungcheol ChoiNo ratings yet

- 05 Simple InterestDocument16 pages05 Simple InterestSeungcheol ChoiNo ratings yet

- Frost Heave - How Frost Heaving WorksDocument3 pagesFrost Heave - How Frost Heaving WorksSeungcheol ChoiNo ratings yet

- Bearing Capacity of Soil - Bearing Pressure ChartDocument4 pagesBearing Capacity of Soil - Bearing Pressure ChartSeungcheol ChoiNo ratings yet

- Concrete Properties Archives - The ConstructorDocument10 pagesConcrete Properties Archives - The ConstructorSeungcheol ChoiNo ratings yet

- Bearing CapacityDocument47 pagesBearing CapacitySeungcheol ChoiNo ratings yet

- Application of Lasers in Highway Engineering (PDF) - The ConstructorDocument7 pagesApplication of Lasers in Highway Engineering (PDF) - The ConstructorSeungcheol ChoiNo ratings yet

- UBC 1997 Seismic Design Example - Structural GuideDocument7 pagesUBC 1997 Seismic Design Example - Structural GuideSeungcheol ChoiNo ratings yet

- Experiment No.5 Slump of Freshly Mixed Portland CementDocument2 pagesExperiment No.5 Slump of Freshly Mixed Portland CementSeungcheol ChoiNo ratings yet

- Experiment No.4 Sieve Analysis of AggregateDocument2 pagesExperiment No.4 Sieve Analysis of AggregateSeungcheol ChoiNo ratings yet

- Fds Series: Fiber Dosing-Feeding SystemDocument15 pagesFds Series: Fiber Dosing-Feeding SystemPaul Ticla PuenteNo ratings yet

- Site Mix k125Document2 pagesSite Mix k125WindiDwiPerkasaNo ratings yet

- Auer Stekla Borosilicate PDFDocument8 pagesAuer Stekla Borosilicate PDFrisbo12No ratings yet

- Anlage - D PL 19033 01 00a EnglischDocument99 pagesAnlage - D PL 19033 01 00a EnglischDanZel DanNo ratings yet

- Revitex VSC25 SleevingDocument2 pagesRevitex VSC25 Sleevingmichele muccioliNo ratings yet

- 75 75 75 75 75 75 500 500 500 500 500 500 M40 M40 M40 M40 M40 M40 0.30 0.30 0.30 0.30 0.30 0.30 33 33 33 33 33 33 1.60 1.60 1.60 1.60 1.60 1.60 3 3 3 3 3 3Document1 page75 75 75 75 75 75 500 500 500 500 500 500 M40 M40 M40 M40 M40 M40 0.30 0.30 0.30 0.30 0.30 0.30 33 33 33 33 33 33 1.60 1.60 1.60 1.60 1.60 1.60 3 3 3 3 3 3Manupriya KapleshNo ratings yet

- Design of Tension MembersDocument70 pagesDesign of Tension MembersAbdallahNo ratings yet

- Impact Test Behavior of Aluminum Alloys Welded Joints: Experimental and Numerical AnalysisDocument16 pagesImpact Test Behavior of Aluminum Alloys Welded Joints: Experimental and Numerical AnalysisMKM OfficialNo ratings yet

- Microstructure and Durability of Ground Granulated Blast FurnaceDocument10 pagesMicrostructure and Durability of Ground Granulated Blast FurnaceAbd El-nour RamdNo ratings yet

- Aam Materials 2 Alloy Constitution PDFDocument40 pagesAam Materials 2 Alloy Constitution PDFHigam ArbatimNo ratings yet

- Transformation-Induced Plasticity (TRIP) in Advanced Steels - A ReviewDocument14 pagesTransformation-Induced Plasticity (TRIP) in Advanced Steels - A ReviewFernandoNo ratings yet

- Tube Forming Processes A Comprehensive Guide (Greg G. Miller)Document378 pagesTube Forming Processes A Comprehensive Guide (Greg G. Miller)An NguyenNo ratings yet

- Is 2062 - 92 StandardDocument10 pagesIs 2062 - 92 StandardRohit BansalNo ratings yet

- Standard Series: Leaded VaristorsDocument16 pagesStandard Series: Leaded Varistorsأياام زمانNo ratings yet

- Ultramid: PA6-GF20 FRDocument2 pagesUltramid: PA6-GF20 FRLjubivoje MićićNo ratings yet

- Damp Proof CourseDocument11 pagesDamp Proof CourseSenthil YoungsterNo ratings yet

- Company Profile Piling PipeDocument52 pagesCompany Profile Piling PipeMargaretta WijayantiNo ratings yet

- Imperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Document17 pagesImperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Phan Đào Hoàng HiệpNo ratings yet

- Properties of Reinforced Concrete BeamDocument22 pagesProperties of Reinforced Concrete BeamDenise CastilloNo ratings yet

- Bar ChartDocument33 pagesBar ChartRico EdureseNo ratings yet

- Column Splices - Code of Practice - IHBDocument13 pagesColumn Splices - Code of Practice - IHBAnonymous ARMtmNKLNo ratings yet

- Yoshikazu Kanematsu, Naotaka Uehigashi, Motohide Matsui, Shoji NoguchiDocument13 pagesYoshikazu Kanematsu, Naotaka Uehigashi, Motohide Matsui, Shoji NoguchiPedro JuarezNo ratings yet

- Cosmopost / Ips Empress® Cosmo IngotDocument24 pagesCosmopost / Ips Empress® Cosmo IngotJuliana Iório CabritaNo ratings yet

- Unit 2 PolymerDocument61 pagesUnit 2 PolymerAayush ChikhalkarNo ratings yet

- Multiple Uses of Universal Testing Machine: Iraq University College Department of Civil EngineeringDocument31 pagesMultiple Uses of Universal Testing Machine: Iraq University College Department of Civil EngineeringAhmed NasratNo ratings yet

- Furniture CoatingsDocument34 pagesFurniture CoatingsMOEEN KHAN ASLAM KHAN RISALDARNo ratings yet