Professional Documents

Culture Documents

3 ASSIGN Sem I 2017-18 (QU & ANSWER)

3 ASSIGN Sem I 2017-18 (QU & ANSWER)

Uploaded by

Malik AbedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 ASSIGN Sem I 2017-18 (QU & ANSWER)

3 ASSIGN Sem I 2017-18 (QU & ANSWER)

Uploaded by

Malik AbedCopyright:

Available Formats

EKAB2033/MKAM1033 Assignment Sem I 2017-18 Mac 2017

Group Assignment - Q1: 22 marks; Q2: 21 marks Q3: 19; Q4: 13 marks - Total marks 75 %

Q1 Site investigation (SI) must be planned accordingly so that optimum data can be acquired

at minimal cost and time. Methods used for SI may consist of preliminary and detail

methods, and instrumentation, depending on the stage and types of structure to be

constructed at a site. Answer the following questions.

(a) Document like aerial photos, geological and topographic maps are essential source of

information for planning an effective SI. Describe briefly two (2) types of information of a

site that can be obtained from any of these document? (3 marks)

Accessibility of site for mobilisation of equipment (1.5 marks)

Vegetation and types of geological materials in an area (1.5 marks)

OR topography for mobilisation of equipment

(b) 'For determining the depth of interface between bedrock and soil substrata and the types

of substrata at any depth, geophysical method like seismic survey is often considered as

supplementary method'.

With regard to the above statement, explain the related weaknesses of the seismic method.

(4 marks)

Depth of interface between soil and rock cannot be determine reliably based on seismic

waves as the interface is not a sudden change but a gradual one (2 marks).

Seismic method has no capability of retrieving samples of the sub-strata and as such, the

soil/rock type cannot be identified directly (2 marks)

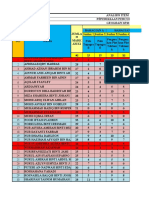

(c) Figure 1 shows the cross-section of a proposed excavation to a depth of 19.0 m. The

boreholes data indicates that the substrata consists of 3 layers of materials; sandy CLAY,

SAND and granite (bedrock); the depth and thickness of the respective layer are in the

figure. How many disturbed (DS/SPT) and undisturbed (UD) samples need to be collected

throughout the depth between 0 and 13 m. Indicate the respective depth and sample

number for the DS/SPT and UD samples collected throughout this depth. (note: assume

sampling starts immediately at 0.00 m depth, and changes from sand to bedrock is

immediate and distinctive). (5

marks)

Layer 1 sandy CLAY from 0 m to 8 m:

Depth Sample number

0.0 m UD 1 (1 mark)

1.5 m UD 2 (1 mark)

3.0 m UD 3 (1 mark)

4.5 m UD 4 (1 mark)

6.0 m UD 5 (1 mark)

7.5 m UD 6 (1 mark)

At 8.0 m Change from sandy CLAY to sand

Layer 2 SAND from 8 m to 13 m:

Depth Sample number

8.0 m DS1/SPT1 (1 mark)

9.5 m DS2/SPT2 (1 mark)

11.0 m DS3/SPT3 (1 mark)

12.5 m DS4/SPT4 (1 mark)

Mohd For Mohd Amin Nov 2017 Page 1

EKAB2033/MKAM1033 Assignment Sem I 2017-18 Mac 2017

13.0 m Change from Sand to granite rock

(d) Typical core sample obtained from drilling in a bedrock is shown in Figure 2. Calculate the

Core Recovery Ratio (CRR) and Rock Quality Designation (RQD) for this core.

(5 marks)

Core length = 1430 mm (1 mark)

CRR = 1430/1500 × 100 = 97 % (1 mark)

RQD = [(210+110)+(80+150)+(100+80)+140+190+120)/1430] x 100% (1 mark)

RQD = 1180/1430 x 100% (1 mark)

RQD = 82.5 = 83 % (1 mark)

(e) For slope excavation in rock, state one reason for obtaining core samples of the in situ

bedrock? (2 marks)

To verify the in situ condition of the rock mass particularly regarding its excavatability

(2 marks)

(f) Explain why when drilling through profiles of weathered granite (Zone 4 to Zone 3 with

the presence of rock boulders), it is highly recommended to undertake multiple coring (say

3 to 4 times coring in sequence) to verify the suitability of the granite bedrock for

foundation? (3 marks)

The multiple coring is to verify whether the rock body being cored is actually a

large/small boulder or a massive bedrock (3 marks)

Q2 Drilling and blasting is an important method for surface and underground excavation in

rocks. Although it is a versatile method, it does suffer from several set-backs. As such,

blast design must be carefully considered so the operation can be carried out safely and

effectively. Answer the following questions.

(a) Besides amount of explosive (MIC and powder factor), name another two (2) blast design

parameters that affect maximum travel distance of flyrocks. (2 marks)

Thickness of stemming and diameter of blasthole (2 marks)

(b) In underground excavation, explain why excavation using blasting method can lead to a

thicker yield (disturbed) zone in rock mass around the excavation? (3 marks)

Blasting utilises dynamic/shock waves (vibration) to break rock to smaller pieces. This

wave is difficult to control and may induce further cracks/fractures in the already jointed

rock mass. Consequently, this may weaken the rock further and leads to a thicker yield

zone (3 marks)

(c) Described briefly one advantage of multiple delay multiple round blasting for excavation

of circular shape tunnel. (3 marks)

Mohd For Mohd Amin Nov 2017 Page 2

EKAB2033/MKAM1033 Assignment Sem I 2017-18 Mac 2017

It allows to control sequence of blasting and the amount of charge to be used in each round,

least charges for the final round (at perimeter of tunnel) ensures a good finish profile for

the circular tunnel (3 marks).

OR Controlled blasting can reduce amount of charges used, especially the final round at the

perimeter of the tunnel, and this reduces the vibration and consequently helps to conserve

the inherent strength of the rock around the tunnel.

(d) Blasting work is to be undertaken at a proposed rock slope, which is at a distance (D) 450

m from a sensitive receiver. Related parameters for the blast design and other information

for evaluating the probable impact due to vibration and noise are given in Table 1, and the

predictor equations are given below:

Ground vibration:

V = K(D/Q1/2)B mm/s

Noise level:

A = 165 - [24 log10 (D/Q1/3)] dBL

Verify whether the ground vibration and noise level produced by the blasting work would

be critical to the sensitive receiver? (6 marks)

Ground vibration = 1244(450/79.51/2) 1.45 mm/s (1 mark)

= 4.22 mm/s (1 mark)

Limit for ground vibration is 4.22 < 5mm/s, not critical (1 mark)

Noise level: = 165 [24log10(450/79.51/3)] dBL (1 mark)

= 116.53 dBL (1 mark)

Limit for ground vibration is 116.53 < 124 dBL, not critical (1 mark)

(e) A slope of 8 m height and 20 m length is to be excavated in massive sandstone (a

sedimentary rock). The slope angle is 60 0 from horizontal and without any benching.

Relevant laboratory test results on the rock samples are listed in Table 2.

Using Table 2 and Figure 3, verify the excavatability of the proposed slope material?

(3 marks)

Plotted lines in the figure (1 mark)

Based on the plot the rock material falls within 2 zones; ZONE of RIPPABLE & ZONE of

TRANSITION from ripping to blasting (2 marks)

(f) Based on the excavatability of the slope material in (e) above, recommend a suitable

method to excavate the proposed slope. Justify your answer. (4 marks)

Method for slope excavation is BLASTING (1 mark)

Explanation: Although the rock properties indicate that the rock slope can be excavated

using ripper dozer (RIPPING) however, the shape and massive volume of excavation (8 m

height and 20 m length and sloping at 60 0) make the use of heavy machinery like ripper

dozer will be impossible. (3 marks)

Mohd For Mohd Amin Nov 2017 Page 3

EKAB2033/MKAM1033 Assignment Sem I 2017-18 Mac 2017

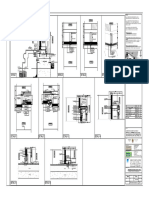

Q3 Multiple-headings/sections is NATM method used for excavating a large underground

cavern. Each heading/section can be excavated in sequence or parallel depending on the

suitability. Excavation can be undertaken using drilling and blasting or mechanical method.

Figure 4 shows a large cavern, width = 18 m and height = 24 m, which has been proposed

for installation of turbine system for a hydro-electric project. The following conditions are

known:

Maximum time required to clear the shot-pile (mucking) and to install temporary

support system on the wall and roof, per 2 m advance is 4 hours. Time required for

drilling & blasting for each 2 m advance is 2 hours. Based on the RMR ratings, the

stand-up time for unsupported roof and walls, per 2 m advance, are listed in Table 3. If

the excavation is not supported within the specified time, failure of rock mass will

occur.

To excavate the cavern, 3 excavation designs have been proposed; as shown in Figure

5(a), (b) and (c). The dimensions and sequence of excavation for each heading and section

are explained in Table 4.

(a) For the excavation design in Figure 5(a), explain the problem that would be faced by

the working crew during installation of temporary support system on the roof of the

cavern? (3 marks)

Excavation as Figure 5(a) will lead to free span of 18 m on the roof (1 mark)

18 m free span gives a stand-up of the roof less than 0.5 hours (1 mark)

0.5 hours is too short a time to install temporary support system as it requires at

least 4 hours (1 mark)

(b) Explain why, for excavating the top-heading of the cavern (with large free span on

the roof), it is recommended to adopt either excavation design shown in Figure 5(b)

or Figure 3(c)? (3 marks)

Excavation as Figure 5(b) and 5(c) adopts multiple sections method in excavating

the top-heading (1 mark)

This leads to a shorter roof span for each section and subsequently, a longer stand-

up time for installing temporary support system (2 marks).

(c) Explain the min advantages for adopting excavation design shown in Figure 5(c)

(2 marks)

Excavation as Fig 5(c) allows section 1 and section 1 to be excavated in parallel and

this enables for the working crew to be fully utilised (2 marks)

(d) By simple calculation, show that the excavation design in Figure 5(c) will take a

longer time than Figure 5(b) (4 marks)

Per 2 m advancement:

To excavate the 2 sections in Figure 5(b) will require 2 (2 + 4) = 12 hours to

complete the top heading. (2 marks)

To excavate the 3 sections in Figure 5(c) will require 3(2 + 4) = 18 hours to

complete the top-heading. (2 marks)

Mohd For Mohd Amin Nov 2017 Page 4

EKAB2033/MKAM1033 Assignment Sem I 2017-18 Mac 2017

Thus excavation design Figure 5(c) takes a longer time than 5(b)

(e) If Section 1 and Section 1 in the top-heading in Figure 5(c) are to be excavated in

parallel, explain why Section 2 must be the last portion to be excavated? (3 marks)

The rock column in Section 2 acts as buffer/protection zone for the working crew

during blasting operation (3 marks)

(f) For underground excavation, explain why instrumentation system is an important

scope to be included in design of the underground cavern. (3 marks)

Design of underground cavern is associated with a lot of uncertainties and higher

FOS. So the instrumentation is used to monitor and to check the reliability of the

design approach adopted (3 marks)

Q4 Underground structures like tunnel and cavern require careful consideration on their design

and excavation. Even the basic design parameters like shape and size must be given due

consideration for their stability. Figure 6 shows 3 different shape of tunnel [(a), (b) and (c)]

excavated in same rock type. The in situ rock displays 2 inclined joint sets (discontinuous)

which are intersecting. All the excavations have similar cross-sectional area.

(a) Which tunnel will display the shortest stand-up and state one appropriate reason for

your answer. (3 marks)

Tunnel [a] (1 mark)

Tunnel [a] displays the longest roof span and flat roof. Since the rock displays 2

inclined and intersecting joint sets therefore, it will be the weakest and exhibits the

shortest stand-up time (2 marks).

(b) If the width of tunnel [b] and [c] is similar, explain why tunnel [c] is more stable

than tunnel [b] (2 marks)

For a give roof span, a curve shape roof will display a higher capability to sustain

vertical loading (overburden pressure), and this leads to a more stable excavation. (2

marks).

(c) Among the 3 shape of tunnels shown, which tunnel is likely to induce the highest

level of disturbance into the surrounding rock mass after its excavation. Explain

your answer (4 marks)

Tunnel [a] (1 mark)

With regard to shape, disturbance induced into the rock mass is associated with the

most unstable shape. Tunnel [a] is the most unstable, hence it will induce the highest

level of disturbance (3 marks)

(d) Ground Reaction Curve (GRC) for a given rock condition is an important element in

NATM. With reference to installation of support system, explain the main purpose

of GRC? (3 marks)

Upon excavation, the rock mass around the excavation (i.e. the yield zone), will

move towards the excavation. This rock movement must be stop as soon as possible

by installing support system as continuous deformation will eventually lead to

failure. So, GRC is a means to determine the best time and amount of deformation to

install the support system (3 marks).

Mohd For Mohd Amin Nov 2017 Page 5

You might also like

- 31-TMSS-06 (Rev 00)Document8 pages31-TMSS-06 (Rev 00)GardellNo ratings yet

- Script BI 2014 PDFDocument37 pagesScript BI 2014 PDFskbtblogNo ratings yet

- Rancangan Pengajaran Tahunan 2020: Physics Form 4Document9 pagesRancangan Pengajaran Tahunan 2020: Physics Form 4Liz GhazaleNo ratings yet

- Jadual Tadarus Al Quran GuruDocument2 pagesJadual Tadarus Al Quran GuruAzuhan OthmanNo ratings yet

- CQI 9 Heat Treatment Rev 01Document64 pagesCQI 9 Heat Treatment Rev 01ukavathekar50% (2)

- Project On Eicher MotorsDocument72 pagesProject On Eicher MotorsManjunath Leo38% (8)

- Vturn-NP16 NP20Document12 pagesVturn-NP16 NP20José Adalberto Caraballo Lorenzo0% (1)

- Bengkel Skema Pemarkahan Fizik Kertas'3Document39 pagesBengkel Skema Pemarkahan Fizik Kertas'3Salmizam IzamNo ratings yet

- Borang Pemarkahan Syarahan Bahasa Inggeris FarinaDocument1 pageBorang Pemarkahan Syarahan Bahasa Inggeris FarinaZamhidatul NabilaNo ratings yet

- Scrabble Competition Concept Paper 2023Document10 pagesScrabble Competition Concept Paper 2023KARTHIGAYAN A/L PASUPATHY MoeNo ratings yet

- Choral Speaking Competition Primary and Secondary Schools 2024Document18 pagesChoral Speaking Competition Primary and Secondary Schools 2024Johan SafriNo ratings yet

- Bio F4 PPT KSSM 2021Document18 pagesBio F4 PPT KSSM 2021Haslinda Sheikh100% (1)

- Program Tentatif Mukhayyam 'ArabiyDocument2 pagesProgram Tentatif Mukhayyam 'ArabiyWan Ahmad NaufalNo ratings yet

- HC Autogenerate Menengah RendahDocument1 pageHC Autogenerate Menengah RendahEmmaNo ratings yet

- Choral Speaking Nuri Madani Competition 2023 Concept PaperDocument15 pagesChoral Speaking Nuri Madani Competition 2023 Concept PapersyuhadaNo ratings yet

- RPT KSSMPK English For Communication T1Document34 pagesRPT KSSMPK English For Communication T1Noraliza Che Idris100% (1)

- Poetry Recitation Primary Schools 2024 2Document13 pagesPoetry Recitation Primary Schools 2024 2nur hayy qayyumNo ratings yet

- Tapak Pengiraan OTI Secara OutoDocument22 pagesTapak Pengiraan OTI Secara OutoHajar MansorNo ratings yet

- Pecutan Akhir Science 2021Document29 pagesPecutan Akhir Science 2021Azween SabtuNo ratings yet

- Rca English 2019Document9 pagesRca English 2019SYAZMIZA100% (1)

- Action Song Competition For Primary Schools Rules and GuidelinesDocument8 pagesAction Song Competition For Primary Schools Rules and GuidelinesazmiNo ratings yet

- Analisis Item Geo SPM 2023 - MineDocument11 pagesAnalisis Item Geo SPM 2023 - MineCekgu ZalihaNo ratings yet

- Badminton Round RobinDocument2 pagesBadminton Round RobinMohd Faizal WahabNo ratings yet

- Contoh Headcount PT3Document63 pagesContoh Headcount PT3Nieta Bulhani AmansanitaNo ratings yet

- Checklist Pembinaan Rumah PDFDocument2 pagesChecklist Pembinaan Rumah PDFBarryRonaldGabrielNo ratings yet

- Jadual FutsalDocument2 pagesJadual FutsalKyrul NizamNo ratings yet

- Print Jadual PerlawananDocument16 pagesPrint Jadual PerlawananZul Aizat HamdanNo ratings yet

- 7 - SKEMA MODUL CEMERLANG FIZIK 2015 - T5 - ms146 - 165Document20 pages7 - SKEMA MODUL CEMERLANG FIZIK 2015 - T5 - ms146 - 165murni100% (4)

- Jarak Meja CalonDocument2 pagesJarak Meja Calonas100% (2)

- Analisis Item Sejarah Form 123 Format PT3Document1 pageAnalisis Item Sejarah Form 123 Format PT3Afifah RivaiNo ratings yet

- Action Song Concept Paper 2023Document11 pagesAction Song Concept Paper 2023Liau JacquelineNo ratings yet

- The Rules in Playing Teng TengDocument1 pageThe Rules in Playing Teng TengKoay Han HuiNo ratings yet

- RPT Science FRM 2Document12 pagesRPT Science FRM 2Jalil MonNo ratings yet

- Borang Transit Sains Ting 2 PrintDocument3 pagesBorang Transit Sains Ting 2 PrintZaidah MYNo ratings yet

- Checklist Peralatan Perkhemahan 2018Document2 pagesChecklist Peralatan Perkhemahan 2018Astrica PoshieNo ratings yet

- Kertas 3Document13 pagesKertas 3cekminNo ratings yet

- Latihan Pengiraan Gred PurataDocument16 pagesLatihan Pengiraan Gred Puratappdmg100% (8)

- WTP 5043 Retaining Wall Works NilaiDocument4 pagesWTP 5043 Retaining Wall Works NilaiFamilypizza PerlisNo ratings yet

- Online Poetry Recitation For Secondary SchoolsDocument15 pagesOnline Poetry Recitation For Secondary SchoolsMUHAMMAD HAZWAN BIN KAYUN MoeNo ratings yet

- Jadual Kelas Tambahan 2022 SPM 2021Document1 pageJadual Kelas Tambahan 2022 SPM 2021SitiAsmahParlanNo ratings yet

- Plant NutritionDocument37 pagesPlant NutritionWen Shan ChuaNo ratings yet

- Ajk Kenduri KahwinDocument2 pagesAjk Kenduri KahwinTashuta HamsulaiNo ratings yet

- Logo SK Taman Bukit DahliaDocument1 pageLogo SK Taman Bukit DahliaRidhaudin MahmoodNo ratings yet

- Answer Ulangkaji Berfokus 1 Understanding SkillDocument10 pagesAnswer Ulangkaji Berfokus 1 Understanding SkillCart KartikaNo ratings yet

- Format Headcount 4 ExamDocument3 pagesFormat Headcount 4 ExamkayathridevanathanNo ratings yet

- The Way I See The WorldDocument2 pagesThe Way I See The WorldLIM SIEW BUCK KPM-GuruNo ratings yet

- Jadual Penggunaan Bilik TayanganDocument1 pageJadual Penggunaan Bilik TayanganRichard WongNo ratings yet

- Borang Keputusan Pencapaian Penilaian Prestasi Ncs-Core AbilitiesDocument4 pagesBorang Keputusan Pencapaian Penilaian Prestasi Ncs-Core AbilitiesbailiniNo ratings yet

- Kadar Sewaan DewanDocument5 pagesKadar Sewaan DewanIzzati AtiqahNo ratings yet

- Dewan KG Perwira Jaya 1Document1 pageDewan KG Perwira Jaya 1Fahmie SuhaimiNo ratings yet

- Data Headcount Form 5 2014Document74 pagesData Headcount Form 5 2014Mohd ErizuanNo ratings yet

- Soalan Kuiz Sains KarnivalDocument1 pageSoalan Kuiz Sains KarnivalNurFadzilah ZanilZainalNo ratings yet

- Soalan SPM Sebenar Bahasa Inggeris 2011 PDFDocument22 pagesSoalan SPM Sebenar Bahasa Inggeris 2011 PDFAdhaJamalulail0% (1)

- Au Ku Insan Da GumaabDocument3 pagesAu Ku Insan Da GumaabValerie Claire EdwardNo ratings yet

- Graf Prestasi Diri Murid (Headcount) SPMDocument3 pagesGraf Prestasi Diri Murid (Headcount) SPMNorlly Mohd IsaNo ratings yet

- Takwim Kafa 2021Document1 pageTakwim Kafa 2021Roslan Ahmad FuadNo ratings yet

- Latihan OsiloskopDocument10 pagesLatihan OsiloskopFairos ZakariahNo ratings yet

- Jadual Guru Bertugas Spot CheckDocument3 pagesJadual Guru Bertugas Spot CheckAnonymous 0gBzy7uMNo ratings yet

- The Determination of Optimal Parameters of The Geometry of Contour and Production DrillingsDocument9 pagesThe Determination of Optimal Parameters of The Geometry of Contour and Production DrillingsFrasher BrahimajNo ratings yet

- HW No4 Solution CPT CrelationssoilDocument4 pagesHW No4 Solution CPT CrelationssoilHanafiahHamzahNo ratings yet

- Paper - Contour Blasting - F. Brahimaj R. Dambov - Varna1Document8 pagesPaper - Contour Blasting - F. Brahimaj R. Dambov - Varna1Frasher BrahimajNo ratings yet

- Topic 2Document88 pagesTopic 2HCNo ratings yet

- UNITEC-Geotechnical Engineering C 7045 2013 s2Document9 pagesUNITEC-Geotechnical Engineering C 7045 2013 s2DonNo ratings yet

- P 1Document3 pagesP 1vishalguptastudy01No ratings yet

- Slope Engineering Concept: Associate Professor DR Nazri AliDocument30 pagesSlope Engineering Concept: Associate Professor DR Nazri AliMalik AbedNo ratings yet

- Faculty of Civil Engineering: Department of Geotechnics & TransportationDocument1 pageFaculty of Civil Engineering: Department of Geotechnics & TransportationMalik AbedNo ratings yet

- R Epi KB: Solution: Part 1: Checking Pile BehaviourDocument3 pagesR Epi KB: Solution: Part 1: Checking Pile BehaviourMalik AbedNo ratings yet

- Faculty of Civil Engineering: Department of Geotechnics & TransportationDocument1 pageFaculty of Civil Engineering: Department of Geotechnics & TransportationMalik AbedNo ratings yet

- Test 1 MKAJ 1033Document4 pagesTest 1 MKAJ 1033Malik Abed100% (1)

- SAND DRAIN EXAMPLE Utm Geo PDFDocument3 pagesSAND DRAIN EXAMPLE Utm Geo PDFMalik AbedNo ratings yet

- Settlements Calculations Revised For Tabuk Zone 5Document4 pagesSettlements Calculations Revised For Tabuk Zone 5Malik AbedNo ratings yet

- Unsaturated Shmit MechanicsDocument1 pageUnsaturated Shmit MechanicsMalik AbedNo ratings yet

- Sand Drain Example PDFDocument3 pagesSand Drain Example PDFMalik AbedNo ratings yet

- Muhammadhafizi 2022765415 Art&CraftDocument10 pagesMuhammadhafizi 2022765415 Art&Craftwan saiyidah nafisahNo ratings yet

- Antisubmarine Weapons State ArtDocument14 pagesAntisubmarine Weapons State Artoldseas2ppf100% (2)

- Reducto Res SewDocument216 pagesReducto Res SewLG Milton LuisNo ratings yet

- Mitsubishi AcDocument28 pagesMitsubishi AcZeeshanNo ratings yet

- HP Openview Integration: User'S GuideDocument9 pagesHP Openview Integration: User'S Guideparacho20No ratings yet

- Traffic Control in Iloilo CityDocument2 pagesTraffic Control in Iloilo CitySabrina Dorado VinsonNo ratings yet

- MIFAB Control Flo Roof DrainsDocument5 pagesMIFAB Control Flo Roof DrainsjavedwestNo ratings yet

- Kuliah 15 Peralatan Komplesi AHDocument29 pagesKuliah 15 Peralatan Komplesi AHLast WinterNo ratings yet

- Ground Floor GW 07Document1 pageGround Floor GW 07MiteshSuneriyaNo ratings yet

- Dzekad% Izf'k (K.K) LQJ (KK, Oa I kZ@93@1346@2019 FnukadDocument2 pagesDzekad% Izf'k (K.K) LQJ (KK, Oa I kZ@93@1346@2019 FnukadPavan VaggiNo ratings yet

- Getting Started With IFIXDocument138 pagesGetting Started With IFIXchris75726No ratings yet

- G O BaldocerDocument93 pagesG O Baldocerruba herbawiNo ratings yet

- History With AnswerDocument8 pagesHistory With AnswerDaryl JohnNo ratings yet

- Accounting VoucherDocument6 pagesAccounting VoucherSATYA NARAYAN BAGARIANo ratings yet

- Shubham (2221) PDFDocument1 pageShubham (2221) PDFStatus whatsapp statusNo ratings yet

- Material Safety Data Sheet: HealthDocument7 pagesMaterial Safety Data Sheet: HealthAulia AnnaNo ratings yet

- Nitroeyhane 121Document19 pagesNitroeyhane 121dogandodog100% (1)

- Hyster H05 BrochureDocument8 pagesHyster H05 BrochureAziz DarwishNo ratings yet

- Excell - 30keys Memory Service Eng (21263)Document35 pagesExcell - 30keys Memory Service Eng (21263)Javier Zegarra100% (1)

- A New Energy Saving Twin Rudder System - Gate Rudder: November 2016Document17 pagesA New Energy Saving Twin Rudder System - Gate Rudder: November 2016Ignacio DavilaNo ratings yet

- ASTM B241 ASTM B241 PDF: US$67.00 - in StockDocument4 pagesASTM B241 ASTM B241 PDF: US$67.00 - in StockSanjay MehtaNo ratings yet

- CHS 114.3x4.5, CHS 114.3x5Document2 pagesCHS 114.3x4.5, CHS 114.3x5MoustafaNo ratings yet

- Geometric ModellingDocument37 pagesGeometric Modellingphanirao1No ratings yet

- ELWE Separation Sleeve Technical DatasheetDocument3 pagesELWE Separation Sleeve Technical DatasheetEvolution Oil ToolsNo ratings yet

- Product Data Sheet: Dehnguard Modular DG M TT 275 FM (952 315)Document1 pageProduct Data Sheet: Dehnguard Modular DG M TT 275 FM (952 315)dfghjNo ratings yet