Professional Documents

Culture Documents

Chapter 20

Chapter 20

Uploaded by

franciscojavier_garridoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 20

Chapter 20

Uploaded by

franciscojavier_garridoCopyright:

Available Formats

Flying QuaZitiesFlight Test Simulators

Chapter 20 Contents

Flying Qualities Flight Test Simulators

..

20.1 Types of Flying Qualities Simulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-2

20.1 .1 Non Real-Time Flying Qualities Simulators . . . . . . . . . . . . . . . . . . . . . 20-3

20.1.2 Piloted. Ground-based Flying Qualities Simulators . . . . . . . . . . . . . . . . . 20-3

20.1.3 Hardware-in-the-Loop Simulators . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-6

20.1.4 Iron Bird Simulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-7

20.1.5 Piloted Inflight Simulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-8

20.1.6 Flight Control System Test Stand . . . . . . . . . . . . . . . . . . . . . . . . . . 20-10

20.2 Simulator Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-10

20.2.1 Motion Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-10

20.2.2 Visual Display Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-12

20.2.3 Risk Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-13

20.2.4 Cockpit Controls Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-13

.

20.2.5 Aerodynamic and Flight Control System Fidelity . . . . . . . . . . . . . . . . . 20-15

20.2.6 Equations of Motion Fidelity . . . . . . . . . . . . . . . . . . *. . . . . . . . . . . 20-15

20.2.7 Cockpit Fidelity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-15

20.3 Uses and Benefits of a Flight Test Simulator . . . . . . . . . . . . . . . . . . . . . . . . . 20-16

20.3.1 Education . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-16

20.3.2 Handling Qualities Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-16

20.3.3 Developing New Test Maneuvers and Analysis Techniques . . . . . . . . . . 20-17

20.3.4 Creating Programmed Test Input Signals . . . . . . . . . . . . . . . . . . . . . . 20-17

20.3.5 Pilot Proficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-18

20.3.6 Data Reduction Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-18

20.3.7 Test Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-18

20.3.8 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-18

20.3.9 Analyzing and Correcting Deficiencies . . . . . . . . . . . . . . . . . . . . . . . 20-19

20.3.10 Augmenting Test Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-19

20.3.11 Hardware Verification and (Limited) Validation . . . . . . . . . . . . . . . . 20-20

.

20.3.12 Dress Rehearsals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-20

20.4 Justifying a Flight Test Simulator ................................ 20-20

20.5 Building a Flight Test Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

20.5.1 Defming Flight Test Simulator Requirements . . . . . . . . . . . . . . . . . . . 20-24

20.6 Aerodynamic Models for Flight Test Simulators . . . . . . . . . . . . . . . . . . . . . . . 20-26

20.6.1 Wind Tunnel Aerodynamic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-28

20.6.2 Coefficient Aerodynamic Models . . . . . . . . . . . . . . . . . . . . . . . . . . 20-39

20.6.3 Stability Derivative Aerodynamic Models . . . . . . . . . . . . . . . . . . . . . 204

20.6.4 Pseudo Stability Derivative Aerodynamic Models . . . . . . . . . . . . . . . . 20-53

20.6.5 Summary of Advantages and Disadvantages .................... 20-66

Flying Qualities Testing 20-i

Flying Qualities Flight Test Simulators

Chapter 20 Contents

.. . -,

20.7 Flight Control System Models for Flight Test Simulators . . . . . . . . . . . . . . . . . . 20-67

20.8 Configuring a Flight Test Simulator ............................... 20-68

20.9 Waypoint: Fiying Qualities Flight Test Simulators ...................... 20-68

204 Flying Qualities Testing

.. L

Chapter 20

Flying Qualities Flight Test Simulators

The use of simulators was largely pioneered and developed in the world of aviation. During World

War 11, for example, tens of thousands of pilots were introduced to instrument flying procedures in

small simulators called Link trainers (built by a company namd Link). These small simulators had

enclosed cockpits, a pneumatically driven motion system that moved the cockpit in response to the

pilot’s control inputs, and stubby wings and tails that made them look like enlarged copies of a child’s

toy airplane. Today, simulators are still used extensively by airlines, the military, and general

aviation for pilot training and proficiency. But the use of simulators in the world of aviation has

grown to encompass much more than pilot training and proficiency. Simulators are now deeply

embedded in the design and testing of airplanes at every level, including flying qualities, avionics,

propulsion, performance, subsystems, and so on.

In this chapter we will focus exclusively on the use of simulators in flying qualities design and

testing. We will leave other uses of simulation to other areas of your coursework.

Flying qualities simulators are an indispensable tool for designing and testing complex new airplanes

and for designing and testing extensive modifications to existing airplanes. During flying qualities

design, simulators serve as handling qualities testbeds, giving pilots their first opportunity to evaluate

the predicted handling qualities of the airplane. During ground and flight testing, flying qualities

simulators provide a wide range of capabilitieswhich are essential to conducting a safe and productive

test program at the lowest possible cost. They are used to prepare for ground and flight testing, to

conduct certain ground tests, to explore problems encountered during testing, to augment test data,

and so on.

Flying Qualities Testing 20-1

Flying Qualities Flight Test SimuZutors

20.1 Types of Flying Qualities Simulators

..

Because piloted simulators are so heavily used in preparing for and conducting a flying qualities test

program, it is important that they should be available at the test site. This is why the Flight Test

Center has its own flying qualities simulation capability. The Flight Test Center simulators are so

important to flying qualities testing that we commonly refer to them as flight test simulators.

In this chapter we will explore several topics that are directly related to flight test simulators. We

will begin by introducing the kinds of simulator you are likely to encounter during a flying qualities

design and test program. Next, we will discuss the importance and pitfalls of simulater fidelity.

Then we will explore some of the uses of a flight test siinulator and show why it is important that

a test program have an independent flight test simulator. Finally, we will explore the broad topic of

building a simulator, including a discussion of simulator aerodynamic models.

Much of the material presented in this chapter is adapted from Reference 20-1, an excellent seminar

on simulation.

20.1 Types of Flying Qualities Simulators There are many ways to categorize sinhators. At the

most fundamental level, we may divide them into real-time simulators and non real-time simulators.

Real-time simulators produce the simulated airplane response in exactly the amount of time it takes

for the real airplane to produce it. If a 360 degree turn requires one minute in the real airplane, it

will also require one minute in a real-time simulator. To the pilot or observer, there is no

distinguishabledifference between the flow of simulator time and the flow of clock time. Non real-

time simulators, on the other hand, are not constrained by this requirement. A non real-time

simulator might be either faster or slower than clock time, depending on the complexity of the

simulation and the performance of the computer.

Real-time flying qualities simulation is necessary only when the simulator will be flown by pilots or

when it must be connected to flight control computers or other equipment. Otherwise, a non-real-

time simulation will prove adequate.

Real-time flying qualities simulators may be further categorized in several ways. One way is

according to the purpose, or purposes, the simulator serves. In this case, we might speak of handling

qualities evaluation simulators, or flight control system test simulators. Another way to categorize

simulators is according to their physical attributes. In this case, we might speak of large amplitude

motion simulators, or inflight simulators. But because simulators come in so many forms and serve

so many purposes, it is difi'icult to find a single, entirely satisfying way to categorize them.

In the following sections, we will introduce you to six flying qualities simulators you are likely to

encounter during the course of a design and test program. We will refer to them by the labels that

are commonly associated with them. But be wary: often the labels refer to different functions

performed by the same simulator over the course of the program. We will introduce these simulators

in the chronological order in which you are likely to use them. As Test Pilot School students you

will have an opportunityto use or observe examples of these simulators. As working flying qualities

test aircrew and engineers, you will work with them extensively.

20-2 Flying Qualities Testing

Flying Qualities Flight Test Simulators

20.1.2 Piloted, Ground-based Flying Qualities Simulators

.. ,I

20.1.1 Non Real-Tie Flying Qualities Simulators The first simulator a designer is likely to use

is a mn real-time simulator. Non-real-time simulators are software models of the airplane that run

on desktop, mini-, or mainframe computers. Non real-time simulators are sometimes referred to as

butch simulators. (The term "batch" is rooted in years gone by, when digital computer programs

were run by feeding batches of coded cards into the computer.) Non real-time, or batch, simulators

run at the speed of the computer, rather than the speed of the airplane motion.

~

When used for flight control system design and flying qualities testing, non-real-time simulators

include models of the aerodynamics and flight controls, and may also include a model of the

structural dynamics. The complexity of a non real-time simulator depends on the purpose it serves.

If the purpose is to simulate the airplane response to a gust, or to small doublet inputs, a simple

"point" model of the aerodynamics at a single flight condition, together with a simplified model of

the flight control system, might be adequate. If the purpose is to simulate more complex responses

(such ;\s aero-servoelasticallycoupled responses) over a broader expanse of the flight envelope, more

comprehensive models are necessary. *

There are a number of commercially available non real-time simulators, and most of these include

an impressive array of analytical capabilities as well. These analytical capabilities may include

identifying the roots of the characteristic equation, drawing root locus and frequency response plots,

and so on. Often, non real-time simulators are written by airplane designers to serve special

purposes.

Much may be accomplished with a non real-time simulator, but an important drawback is that pilots

cannot fly them and evaluate the simulated handling qualities. For this reason, designers also work

with real-time, pilot-in-the-loop simulators, which are often referred to as piloted simulators. There

are two main categories of piloted simulators: ground-based and inflight. As the names imply, a

ground-based simulator is tied to the ground, whereas an inflight simulator is one that flies. We will

discuss ground-based simulators first.

20.1.2 Piloted, Ground-based Flying Qualities Siulators Piloted, ground-based, flying qualities

simulators are real-time simulators that are used throughout the process of designing and testing an

airplane. During the design phase, they are used primarily to help designers and pilots evaluate and

hone the predicted handling qualities of the airplane. During flight testing, they are put to many

uses, some of which are described in section 20.3. As the name implies, ground-based simulators

are fixed to the ground.

Piloted, ground-based, flying qualities simulators consist of a cockpit, a visual display, an

aerodynamic model, a flight control system model, and perhaps a motion system. In some cases, a

structural dynamics model might also be present. The complexity of these components can span the

gamut from spartan to very elaborate, depending on the purpose the simulator serves.

Flying Qualities Testing 20-3

Flying Qualities Flight Test Simuhtors

20.1.2 Piloted, Ground-based Flying Qualities Simulators

At the spartan end, the cockpit might be nothing more than a folding chair and a simple joystick.

A mid-range level of complexity might include generic, all-purpose, "typical fighter" or "typical

transport" cockpits, such as those used at the Flight Test Center. At the elaborate end of the scale

we might find a complete replica of the test airplane cockpit, including high fidelity control stick and

rudder pedal dynamics.

The level of complexity of visual displays can be equally broad. At the spartan end of the scale, the

visual display might consist of no more than the primary cockpit instruments. Near the middle of

the scale we might find a simple target presented on a monochrome TV screen, or perhaps a narrow

field of view, color, "out-the-window" display of moderate resolution. At the elaborate end, we

might find an all-aspect, high resolution, "out-the-window" view of the world.

The aerodynamic and flight control system models can also span a wide range of complexity. At the

spar& end of the scale, the aerodynamic model might take the form of stability derivatives that are

valid only at a single flight condition, or perhaps over a narrow range of flight conditions. Near the

middle of the scale, the aerodynamic model might be expanded to include larger portions of the flight

envelope. At the elaborate end of the scale, the aerodynamic model might include the entire flight

envelope. A spartan flight control system model might consist of a simplified version of a single

flight control mode together with a simplified, linear actuator model. An elaborate flight control

system model might fully replicate the flight control laws and sensor dynamics, and use high-fidelity,

nonlinear models of the actuators.

Ground-based simulator motion also runs the gamut from the spartan to the very elaborate. At the

spartan end are simulators that do not move at all. At the elaborate end of the scale are motion

systems that produce large amplitude, sixdegree-of-freedom motion. Ground-based simulators that

do not move are calledfied-base simulators. Ground-based simulators that move are called mtion-

based sirnularors.

The level of complexity of the simulator cockpit, visual display, aerodynamic and flight control

models, and motion system is determined by the purpose (or purposes) the simulator serves. It is not

unusual to find a mixture of complexity. For example, a mid-range, generic cockpit might be

coupled with a mid-range visual system, elaborate models of the aerodynamics and flight controls,

and a spartan motion system (that is, no motion at all). Figure 20-1 depicts two fixed-based flying

qualities simulators used at the Flight Test Center. These simulators use a mid-range, generic

cockpit, a mid-range limited field of view display, aerodynamic and flight control system models that

can range from spartan to elaborate, and no motion system. Figure 20-2 depicts a simulator that uses

a mid-range, generic cockpit, an elaborate visual system, aerodynamic and flight control system

models that can range from spartan to elaborate, and a motion system that can range from spartan

(no motion) to elaborate (large amplitude, sixdegree-of-freedom motion). This simulator, called

LAMARS, is located at the Flight Dynamics Laboratory at Wright-Patterson Air Force Base.

LAMARS is an acronym for Large Amplitude Multi-mode Aerospace Research Simulator.

The computers used in piloted, ground-based simulators may be digital, or analog, or a combination

of both. When only digital computers are used, the simulator is called a digital simulator. When

20-4 Flying Quulities Testing

Flying Qualities Flight Test Simulators

2Q.1.2 Piloted, Ground-based Flying Qualities Simulators

c;ji.-Li*- . . -. ,

._a

. ..

Figure 2 6 1 Rioted, ground-based simulators used (2f the Flight Test Center.

Flying Qualities Testing 20-5

Flying Qualities Flight Test Simulators

20.1.3 Hardware-in-the-bpsimulators

only analog computers are used, the simulator is called an analog simukztor. When both digital and . .

analog computers are used, the simulator is called a hybrid simulator. Digital computers offer greater

precision and repeatability than analog computers. But analog computers have a higher bandwidth

than digital computers and do not suffer from computational time delay. The bandwidth of digital

computers is limited by the highest frame rate that can be achieved. Hybrid simulators offer the best

characteristics of both digital and analog computers.

Hybrid simulators are especially useful for simulating airplanes with digital flight control systems.

An analog computer is used to simulate the aerodynamic response and the response of actuators, anti-

aliasing filters, sensors, and other analog components with "life-like" bandwidth, all without

introducing unwanted computational time delay. Simultaneously, a digital computer is used to

simulate the digital part of the flight control system at the frame rate used in the airplane. The digital

computer can also be used to simulate such low bandwidth functions as center of gravity movement

and engine response.

Figure 20-2 A piloted, ground-basedsimulator at the Right LJynarniisLaboratory.

20.1.3 Hardware-in-the-LoopSimulators In hardware-in-the-loop simulators, real flight control

hardware replaces all or selected parts of the simulated flight control system. For example, real flight

20-6 Flying Qualities Testing

Flying Qualities Flight Test Simulators

20.1.4 Iron Bird S imulators

control computers are substituted for modeled control laws, real data busses are substitut& for

simulated connections between computers, and so on. Sometimes, real actuators are substituted for

the modeled actuators. In this way, designers get an early look at how well the real flight control

system hardware works. In Chapter 26, you will learn that hardware-in-the-loop simulators play an

important role in the process of verifying and validating a flight control system.

Hardware-in-the-loop simulators can take on a variety of forms. Sometimes, the piloted, ground-

based simulators we described in section 20.1.2 also serve as hardware-in-the-loop simulators. This

can be accomplished by making it possible to switch between the real flight control hardware and the

flight control system model. A simpler but less flexible approach is to remove the flight control

system model and substitute the real flight control system hardware.

Hardware-in-the-loop simulators are often involved in intensive, round-the-clock testing. This leaves

little, if any, time for other work, such as handling qualities evaluation. As a result, dedicated

simulators are sometimes built for hardware-in-the-loop testing. The aerodynamic model, equations

of motion, atmospheric model, and other software used in these dedicated s@lators might be copied

directly from existing piloted, ground-based simulators. Sometimes, dedicated hardware-in-the-loop

simulators are also used for limited handling qualities evaluations. When this is the case, a cockpit

and a visual display must be provided.

The flying qualities flight test simulators used at the Flight Test Center are occasionally used as

hardware-in-the-loop simulators. This allows them to be used for limited verification and validation

testing and for special purpose trouble-shooting.

20.1.4 Iron Bird Simulators In past chapters, we have often remarked on the importance of

actuator rate limits, control system friction, deadband, and hysteresis, and other characteristics of

mechanical systems. It is usually difficult to model these characteristics reliably. One way to

determine the actual performance of the mechanical components of the control system is to build a

special-purpose, hardware-in-the-loop simulator that is dedicated to testing them. Such a simulator

is called an iron bird simularor.

An iron bird simulator gets its name from the fact that it is built on a large steel framework to which

the mechanical components of the flight control system are attached. The hydraulic system pumps,

accumulators, tubing, and actuators are laid out on the steel framework exactly as they are in the real

airplane. The length of each hydraulic line and the geometry of every bend in the hydraulic lines is

exactly duplicated. The control surface actuators are attached to specially made fittings on the steel

framework that simulate the stiffness of the real airplane structure at the attachment points. And each

control surface is simulated by a specially made block of material that closely matches the mass and

moment of inertia of the real airplane control surface. The same care is taken in laying out the

control stick and rudder pedals and associated cables, pushrods, pulleys, and so on. The electronic

components of the flight control system, such as the flight control computers, are usually hardware,

but might be software simulations in some cases. An aerodynamic model must also be provided.

Flying Qualities Testing 20-7

Flying Qualities Flight Test Sinmlutom

20.1.5 Piloted Innight Simulators

Iron bird simulators are valuable assets for early model validation testing of the flight control system. . .

Because real mechanical hardware is used, and because it is meticulously assembled to duplicate the

real airplane, the performance of the real mechanical components may be tested and compared with

the predicted performance. The fidelity of the iron bird simulator to the real airplane is good enough

that rigid body limit cycle ground testing is sometimes conducted on the simulator rather than on the

airplane.

Because iron bird simulators are typically devoted to flight control system testing rather than handliig

qualities testing, pilots do not normally spend much time flying them. For this reason, if a cockpit

and visual display are included at all, they are usually rudimentary. The aerodynamics, equations

of motion, and so on are usually copied directly from the piloted, ground-based simulator.

................ ....... .

Figure 20-3 The USAFNeridian VISTA/F-I6.

20.1.5 Piloted Intlight Siulators When the flight control system design has been completed and

handling qualities have been evaluated and improved as far as they can be with ground-based

simulators, designers often turn to piloted inflight simulators for one more evaluation. An inflight

simuiator is an airplane that has been specially modified so that the dynamics of other airplanes may

be simulated in flight. Piloted inflight simulators offer better motion and visual fidelity than do their

20-8 Flying Qualities Testing

Flying Qualities Flight Test Simulators

20.1.5 piloted Inflight Simulators

ground-based cousins, so they are commonly regarded as the "top of the line" in handling quditieS'

simulators.

However, piloted inflight simulators are not entirely free of drawbacks. It is usually very expensive

to conduct an inflight simulation program. Also, it is not always possible to exactly simulate the test

airplane response. Sometimes, only relatively low bandwidth responses can be simulated with high

fidelity, although this depends on the dynamics of the airplane bemg simulated.

Over the years, Test Pilot School students have flown a number of inflight simulators, including the

AFFTC variable stability B-25, the Calspan variable stability B-26, the USAF/Calspan NT-33, the

USAFNeridian TIFS (Total InFlight Simulator), the Veridian variable stability LearJets, and the

USAFNeridian VISTA/F-16 (Variable Inflight Stability Training Aircraft). The USAFNeridian

VISTAIF-16 is shown in Figure 20-3.

Figure 20-4 The AFFTC/HPE flight control system test stand and a ~ b age r o d y m ' c sinulkltor. connected to the

VISTA/F-I6for ground testing by Test Pilot School students.

Flying Qualities Testing 20-9

Flying Qualifies Flight Test Simularors

20.2.1 Motion Fidelity

20.1.6 Flight Control System Test Stand One more flight test simulator deserves mention. The

. -,

Flight Test Center uses a special ground test stand that includes an analog aerodynamic simulator.

This test stand and its aerodynamic simulator can be c o ~ e c t e dto a test airplane and used to conduct

rigid body limit cycle testing, structural resonance testing, flight control system functional testing,

and redundancy management system testing. In Figure 20-4 the USAF/HPE flight control system

test stand is shown connected to the USAFNeridian VISTA/F-16 for verification and validation

ground testing, conducted by Test Pilot School

students and Veridian, of a studenf project.

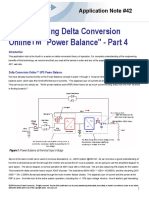

r In Figure 20-5 we present a schematic diagram

that shows how control surface deflections are

transmitted to the test stand and simulated

airplane responses are transmitted back to the

flight control system in the airplane. This

arrangement is similar to the hardware-in-the-

loop and iron bird simulators,we described in

sections 20.1.3 and 20.1.4. The only

difference is that, instead of laying out

hardware in a laboratory, the real airplane is

connected to an aerodynamic simulator.

Despite its small size and somewhat innocuous

appearance, this test stand, with its

aerodynamic simulator, is a powerful piece of

Figure 20-5 Schemoric showing connection ofAFnCflisht ground testing equipment.

control system test stand to a test airplane.

20.2 Simulator Fidelity When we speak of simulator9delity we are referring to how closely a

simulator matches the airplane it is simulating. For handling qualities evaluation, our interest in

fidelity is directed mainly at dynamic response fidelity, or how well the simulator matches the

dynamics of the real airplane. Aspects of dynamic response fidelity that are of particular interest

include visual display response, motion response, the equations of motion, the control stick force-feel

characteristics, the aerodynamic model, and the flight control system model. Of course, we are

interested in other aspects of fidelity as well. For example, the placement of controls, switches,

instruments, and displays in the simulator cockpit may affect the usefulness of the simulator in some

ways.

In the following sections we will discuss several important aspects of simulator fidelity, including

motion fidelity, visual display fidelity, risk fidelity, cockpit controls fidelity, aerodynamic and flight

control system fidelity, equations of motion fidelity, and cockpit fidelity.

20.2.1 Motion Fidelity Let's begin hy acknowledging the importance of motion to handling

qualities. A pilot's control inputs produce airplane rotational and translational accelerations, rates,

20-10 Flying Qualities Testing

Flying Qualities Flight Test Sirnuho&

20.2.1 Motion Fidelity

and displacements. These motion responses determine how easy it is for a pilot to land an air&&:

track a target, perform aerial refueling, maintain formation, and so on. Because a pilot's assessment

of handling qualities is closely tied to motion, we must approach motion fidelity carefully.

Motion is detected both visually and "physically." By "physically," we mean detection by the inner

ear and by the "seat of the pants," or proprioceptively. For example, pitching and rolling motion

can be detected visually by looking out of the cockpit or by looking at cockpit instruments. The same

motion can also be detected by the inner ear and the seat of the pants. Wherwe refer to motion

fidelity we are usually referring to motion that can be "physically" detected by the inner ear and the

seat of the pants. In other words, motion fidelity refers to how closely the physical motion of the

simulator cockpit matches the physical motion of the real airplane cockpit. This is to be distinguished

from the appearance,or impression of motion produced by cockpit instruments or visual displays.

Inflight simulators provide the best opportunity for achieving a high level of motion fidelity, but even

inflight simulators have limits. Special control surfaces are needed to produce the forces and

moments required for high fidelity motion at the pilot station. These specid control surfaces are not

available on all inflight simulators. Even when they are, they might not be sufficiently fast or

effective to produce the desired motion.

For ground-based simulators, motion fidelity is a problematical issue. In fixed-base simulators there

is no motion fidelity at all. Yet fixed-base simulators have proved to be very useful flight test tools.

In motion-based simulators, hydraulic or electric motion systems attached to a simulator cockpit can

produce impressive rotational and translational accelerations and rates. But the available range of

displacement is necessarily limited. As a result, accelerations and rates can be maintained for only

a short length of time before the motion drive system exceeds the allowable range of displacement.

To prevent the motion drive system from crashing into its limits, washout (or high-pass) filters are

added to the motion system. Washout filters cause the motion system to attenuate low frequency

motion (such as a turn or a loop) while responding more faithfully to higher frequency dynamics,

such as the short period and dutch roll modes. This works well in preventing the motion system from

exceeding its physical limits, but it has the unhappy sideeffect of changing the handling qualities of

the simulated airplane. You may recall from section 12.2.4 in Chapter 12 that washout filters add

low frequency phase lead. As a result, there may be less phase lag in the simulator motion than there

is in the real airplane motion. According to the RSmith criteria, which we introduced in Chapter 16,

if the simulator has less phase lag than the real airplane, the simulator handling qualities will be better

than the airplane handing qualities.

The problem of restricted range of motion (and the necessity for washout filters) is one that cannot

be avoided in ground-based simulators. This problem stimulates much discussion and disagreement

within the flying qualities community. Is washed-out motion better or worse than no motion at all?

Consider this question in terms of a simulator evaluation of pilot-in-the-loop oscillation (or PIO)

susceptibility. It is widely accepted that some PIOs cannot occur without motion feedback to the

pilot. Consequently, they cannot occur in a fixed-base simulator (unless they are artificially

stimulated). But experience shows that they might not occur in a motion-base simulator either,

Flying Qualities Testing 20-11

Flying Qualities Flight Test Sinurlators

20.2.2 Visual Display Fidelity

. -,

because the motion system washout filters artificially improve handling qualities enough to hide the

tendency to PIO.

Another interesting aspect of motion fidelity is sometimes encountered in motion-based simulators.

When the motion system is not carefully synchronized with the visual system, the resulting mismatch

of motion and visual responses can be very disconcerting to the evaluation pilot, sometimes to the

point of inducing nausea.

20.2.2 Visual Display Fidelity While much can be accomplished with a simulator that does not

move, a piloted flying qualities simulator without a visual display of some kind would be worthless.

Visual displays come in a variety of forms. Successful simulation programs have been conducted

with visual displays as simple as the primary flight instnunents, and as sophisticated as a high

resolution, all-aspect, "out-the-window'' visual scene. Out-the-window displays attempt to present

the view a pilot sees when looking outside the cockpit. These displays are improving in quality as

increasingly powerful computers make it possible to significantly improve resolution, clarity, and

texture while reducing time delay.

Despite the importance of visual displays and the presumed importance of visual display fidelity, there

is no definitive research and little agreement on how much and what kind of visual fidelity is

necessary for a flying qualities simulator. Are primary flight instruments alone an adequate visual

display? Is a television screen with a simple horizon bar, or a simple target, or a simple line drawing

of a runway sufficient? Is a detailed, high resolution, high clarity, highly textured, "out-the-window"

scene required? While we do not have definitive answers to these questions, experience suggests that

the answers depend on the task the pilot is performing and on the objectives of the test. For

example, there is little doubt that resolution, clarity, and texture are more important when performing

handling qualities tasks that involve close proximity to the ground or to another airplane. Such tasks

include approach and landing, terrain following, and aerial refueling.

Nor is there a consensus on how much visual system time delay is permissable. Time delay in the

visual system adds phase lag to the simulator dynamics, which can result in degraded simulator

handling qualities. According to the RSmith criteria, the degrading effect of visual system time delay

depends on the phase lag of the modeled airplane dynamics. Suppose the RSmith criterion frequency

for a test airplane were o,=4 radians/second and the predicted Cooper-Harper rating were 5. If the

visual system time delay were 100 milliseconds, approximately 23 degrees of phase lag would be

added to the augmented airplane transfer functions at the criterion frequency. This additional phase

lag would degrade the predicted handling qualities from a Cooper-Harper rating of 5 to a Cooper-

Harper rating of about 7.7. Clearly, it is important to strive for small visual system time delays.

Nor is there a consensus on how large the field of view must be. The role of peripheral vision in

landing flare and touchdown, for example, is not completely understood.

Complete visual display fidelity is as difficult to achieve as complete motion fidelity. Inflight

simulators offer the best opportunityto achieve high visual fidelity, because the pilot can look outside

20-12 Flying Qualities Testing

Flying QuaIMes Flight Test Sinurlators

20.2.4 Cockpit Controls Fidelity

and see the same clear, textured, undelayed real world that would be visible in the real airplane.. But c-

visual fidelity in an inflight simulator can be degraded by the same constraints that affect motion

fidelity. When accurate motion cannot be produced at the pilot's location, visually sensed motion will

be affected also.

20.2.3 Risk Fidelity An elusive but important (some might say critical) component of simulator

fidelity is something we will call "risk fidelity." Riskfidelily refers to our ability to make pilots

flying a simulator respond to hazards or surprisesjust as they would in a real airplane. Risk fidelity

may be more important than you suppose. Flying qualities experience is replete with incidents and

accidents that were triggered by a pilot's response to an imminent hazard. Unfortunately, risk fidelity

is difficult to achieve for the simple reason that there is no penalty for "crashing" a simulator. The

pilot simply presses the "Reset" button and starts over. Even in an inflight simulator, the evaluation

pilot knows that if things get out of hand, the safety pilot will assume comrnand and return the

simulator to a safe, baseline configuration. It has been sportingly proposed that risk fidelity might

be impkved by administering memorable electrical shocks to evaluation pilots when they "crash."

Or by poking them with needles driven by a special apparatus mounted in the simulator seat.

Another facet of risk fidelity is related to a high level of pilot excitement. Experience indicates that

handling qualities deficiencies may be exposed not only by imminent danger, but also when a pilot's

level of excitement is unusually high. Evidence of this has been observed during combat, when a

pilot is tracking and shooting at a jinking target. The desire for a kill may increase the pilot's

excitement to a very high level indeed. When the pilot's level of excitement exceeds a certain

threshold, the pilot may begin to fly the airplane differently, exposing handling qualities which make

it more difficult to score a hit. We discussed this phenomenon in section 23.1 in Chapter 21.

20.2.4 Cockpit Controls Fidelity Control stick, rudder pedal, and throttle fidelity are additional

facets of simulator fidelity. Control stick fidelity is widely recognized as an important element of

simulator fidelity. The rudder pedals and throttle are sometimes given shorter shrift. Let's discuss

control stick fidelity first.

The control stick is the pilot's primary means of controlling the airplane. If the force-feel

characteristicsof the stick are not accurately modeled, the pilot's perception of handling qualities may

be significantly affected. You may appreciate this by imagining that, in an airplane you fly regularly,

the stick forces were suddenly halved or doubled, or the deadband or hysteresis were doubled. These

changes would almost certainly affect your opinion of the airplane handling qualities. They might

also make it more difficult, or perhaps easier, to land the airplane, or perform aerial refueling, or

track a target, or maintain tight formation, and so on.

It is not always easy to model control stick force-feel characteristics accurately. This is particularly

true when the force-feel characteristics include a nonlinear forcedeflection curve plus a deadband,

complex hysteresis characteristics, and so on. Commercially available hardware, such as the widely

Flpng Qualities Testing 20-13

Flying Qualities Flight Test Simulators

20.2.4 Cockpit Controls Fidelity

known McFadden control stick simulators, offers impressive capability. Unfortunately, these control

-. x

stick simulators tend to be complex and expensive.

Yet even when the measured simulator stick characteristicsclosely match the airplane, a frequent pilot

comment is that the simulator stick doesn’t feel like the airplane stick. These comments may be

traceable in part to evidence that a pilot’s perception of control stick fidelity is related to motion

fidelity. One hypothesis is that when pilots do not feel the expected motion response to their stick

inputs, they are naturally inclined to question the fidelity of the stick dynamics. ~

Control stick geometry, including location and pivot point, can also influence a pilot’s perception of

control stick fidelity. For example, when the stick is further away in the simulator, pilots are likely

to report that the stick forces are higher than in the airplane.

Rudder pedal fidelity is often regarded as being secondary in importance to control stick fidelity.

There are two principal reasons for this. First, modem flight control systems often make it

unnecessary (oiless necessary) for the pilot to use the rudder pedals to maneuver the airplane. This

means that the rudder pedals are used less extensively than the control stick. Second: hands and arms

are more sensitive than legs and feet, especially booted feet. Pilots are less likely to notice minor

discrepancies between the simulated rudder pedals and the real airplane rudder pedals. So long as

a reasonable level of rudder pedal fidelity is present, it is unlikely that pilots will complain.

The importance of throttle fidelity is sometimes underestimated. The force-feel characteristics of the

throttle lever and the response of the engine model may significantly influence a pilot’s perception

of handling qualities for certain tasks, such as close formation, aerial refueling, and approach and

landing. Engine response characteristics are often modeled rather simply in flying qualities

simulators. For example, a simple first order filter is often used to simulate engine spool-up and

spool-down. In many cases this might be a perfectly satisfactory model. In others it might not.

When a simulator will be used to evaluate aerial refueling, or close formation maneuvering, or

powered lift landings, it may be important to model throttle characteristics and engine response with

greater fidelity.

As in the case of the control stick, however, a pilot’s perception of throttle response fidelity might

be affected by motion fidelity. Evidence suggests that when pilots do not feel the expected motion

response to their throttle inputs, they are naturally inclined to question the fidelity of the throttle

response.

We conclude by noting that the physical fidelity of the control stick and throttle may be important

in a flying qualities simulator. In military airplanes, the stick and throttle grips have become

important interfaces, or centers of activity, between the pilot and the airplane. Careful thought

should be given to the consequences of mismodeling these interfaces. If the grips are different from

the real airplane, or if switches are missing, or are in a different location, or work differently, the

usefulness of the simulator may be compromised.

20-14 Flying Qualities Testing

Flying m e s Flighf Test Sirnuhorn

20.2.7 Cockpit Fidelity

’

20.2.5 Aerodynamic and Flight Control System Fidelity Time and again we have remark& on

the importance to handling qualities of high fidelity aerodynamic and flight control system models.

If either the aerodynamic or flight control system models are in error, the airplane response to a pilot

input or a gust disturbance will be in error. In Chapter 7 we showed that an incorrect stability

derivative value can have an important effect on the airplane response, and in Chapters 10 and 11

we showed that simplified actuator models can make an airplane appear to be more stable than it

really is. Modeling errors such as these can affect the airplane response and hence the pilot’s

perception of handling qualities. ~

Before ground testing and flight testing begin, the simulator aerodynamic and flight control system

models are necessarily predicted models, with attendant levels of uncertainty. These levels of

uncertainty may be significant. If these models are not validated and corrected during ground and

flight testing, the lack of simulator dynamic response fidelity will quickly become apparent to the

pilots. As a result, the usefulness of the simulator will decline steadily as the test program

progresses. This would prove costly indeed, as you will learn in section 20.3.

.

20.2.6 Equations of Motion Fidelity We have said nothing about the importance of high fidelity

equations of motion since Chapter 4 in Part 11. Yet we devoted most of that chapter to developing

a set of equations that would accurately describe the airplane motion you are most likely to

experience. You may recall that we tailored these equations of motion to rigid body airplanes of

constant or slowly changing mass, flying at speeds below 3000 to 5000 feet per second, during

maneuvers lasting less than a minute or so. These equations of motion, which we presented as

Equations (4-71) and (4-72) in section 4.6.9 in Chapter 4, are widely used in flying qualities

simulators, including the simulators we use at the Flight Test Center.

But it is possible that you may one day test an airplane that violates the assumptions we made: a

rocket powered hypersonic airplane perhaps. Equations (4-71) and (4-72) are unsuitable for such an

airplane: they would produce airplane motion that is quite different from the real airplane motion.

To simulate a rocket powered hypersonic airplane, it would be necessary to use higher fidelity

equations of motion that accommodate rapid changes of mass, very high speeds, and perhaps lohger

test maneuvers. A set of equations that satisfies these more exotic conditions is also available for use

in Flight Test Center flying qualities simulators.

20.2.7 Cockpit Fidelity When we speak of cockpit fidelity we are referring to how closely the

simulator cockpit duplicates the real airplane cockpit: the geometry; the seat; whether or not all

cockpit instruments, control panels, warning lights, and circuit breakers are present and functional;

and so on. Cockpit fidelity can be important. Imagine that a certain flying qualities test maneuver

requires moving certain switches and using certain cockpit displays. If the switches and displays are

missing, or in the wrong position, or don’t work, the usefulness of the simulator could be called into

question. In cases such as this, cockpit fidelity is important.

Hying Qualities Testing 20-15

Flying eucJities Flight Test Simulators

20.3.2 Handling Qualities Evaluation

The level of cockpit fidelity you need depends on how you plan to use your simulator. For flying

..

qualities testing, experience at the Flight Test Center indicates that cockpit fidelity is generally not

as critical as aerodynamic, flight control system, or control stick fidelity. Much of the best simulator

work done at the Flight Test Center involved relatively simple, general purpose cockpits. A rule of

thumb is that primary flight instruments or multi-function displays should be present, functioning,

and positioned as they are in the real airplane. Secondary instruments may not be necessary, and

avionics control panels, warning light panels, and circuit breaker panels usually aren’t necessary.

However, this may vary from test program to test program. -

20.3 Uses and Benefits of a Flight Test Sinlator Experience at the Flight Test Center shows that

much may be accomplished with relatively simple, piloted, ground-based simulators. which we often

refer to as flight test simulators. In this section we will enumerate some important uses and benefits

of flight test simulators. These include education, handling qualities evaluation, development of new

test maneuvers and analysis techniques, developing programmed test input signals, pilot proficiency,

data reduction &heckout,test planning, safety, analyzing and exploring deficiencies, augmenting test

data, hardware verification and (limited) validation, and dress rehearsals for specialhight tests. The

list of uses and benefits we outline here is by no means complete. Simulators are so versatile that

new uses and benefits are continually arising.

20.3.1 Education Chronologically, education is the first benefit provided by a flight test simulator.

To build a simulator (or more accurately, to build the models that make up a simulator), test

engineers must become intimately familiar with the details of the airplane aerodynamics and flight

control system. As a result, there is no better way to prepare for a flight test program than to build

a simulator. You will learn the details of the various flight control modes; where handling qualities

are predicted to be satisfactory or less than satisfactory; at what test conditions the airplane is

predicted to become directionally unstable; what the actuator rate limits are; which feedback

parameters are most important; and so on.

20.3.2 Handling Qualities Evaluation Handling qualities evaluation using a simulator is probably

most closely associated with the design process, but it is equally useful throughout the test program.

During the design process, the primary use of a piloted ground-based simulator is to assist the

designer in tailoring the flight control system to achieve good handling qualities. When the pilot is

dissatisfied with the handling qualities, the designer adjusts the flight control system architecture or

compensation until the problem is corrected.

During the flight test program, handling qualities evaluation using a simulator serves several

purposes. One is to familiarize the pilots with the predicted handling qualities of the test airplane.

This is important when the flight envelope is being expanded, when new test maneuvers are

performed, or when new pilots are introduced to the airplane.

20-16 Flying Qualities Testing

Flying Qualities HigM Test Simuhtors

20.3.4 Creating Programmed Test Input Signals

Handling qualities evaluation using a simulator is also an important part of validating a simulator:'

As test data become available, the simulator aerodynamic and flight control system models must be

incrementally corrected and validated. An important step in this process is the evaluation of simulator

handling qualities. Before a simulator can be regarded as validated, the pilots must judge that the

simulator handling qualities are sufficiently similar to the real airplane. If the pilots judge that there

are significant differences between the simulator and the airplane handling qualities, the source of the

differences must be found and corrected.

~

Handling qualities evaluation using a simulator is also important when evaluating and correcting

airplane deficiencies discovered during flight testing. The first step in this process is to validate the

simulator aerodynamic and flight control system models, so the airplane deficiency can be duplicated

in the simulator. Successive steps in the process are to identify and understand the cause of the

deficiency (mispredicted aerodynamics, mismodeled flight control system, unreliable design guidance,

and so on); to propose a solution, or perhaps several candidate solutions, for the deficiency; to

evaluate the candidate solutions in the simulator and select the one that appears most promising; and

to evaluate the selected solution in flight. .

203.3 Developing New Test Maneuvers and Analysis Techniques While building and using a

flight test simulator, you may discover that certain features of the test airplane cannot be properly

evaluated using conventional test or analysis methods. This may occur when the test airplane uses

unusual control effectors (such as vortex control jets or thrust vectoring), or an unusual control

function (such as inflight thrust reversing), or redundant control surfaces, or for other reasons.

Similarly, an airplane designed to perform an unusual mission, or a mission performed to unusually

exacting standards, may also require new or modified test or analysis methods. Simulators have

proved to be an excellent tool for developing new test maneuvers and for obtaining data to validate

new analysis techniques. And when unusual features of a new airplane require that the airplane be

configured in a special way for testing, a simulator is almost indispensable to working out the details

of implementation.

20.3.4 Creating Programmed Test Input Signals Simulators are an excellent tool for developing

programmed test input signals for aerodynamic and flight control system model validation testing.

At the Flight Test Center, many hours of simulator time have been devoted to creating test input

signals that will produce satisfactoryestimates of stability derivatives or frequency response functions.

This is done by trying proposed test input signals on the simulator, collecting and analyzing simulator

test results, and comparing the results with the model in the simulator. This procedure is repeated

until satisfactory shapes and amplitudes have been developed for the test input signal. Many hours

of expensive flight test time can be saved in this way, without risk to the airplane. In some cases this

approach allows us to successfully conduct model validation testing that would otherwise prove

impossible.

Flying Qualities Testing 20-17

Flying Qualities Flight Test Sinwlators

20.3.8 Safety

20.3.5 Pilot Proficiency Pilots find that practicing test maneuvers in a simulator is an effective way - . I .

to improve or recover their proficiency. It is cheaper, safer, and more efficient to learn new test

maneuvers and techniques, or polish familiar ones, in a simulator than in the real airplane. Increased

pilot proficiency yields two important dividends: higher quality test data and more test maneuvers

per flight hour.

20.3.6 Data Reduction Checkout At the Flight Test Center we find it helpful to use "test data"

from a simulator to check out data reduction and analysis software. This is more important than it

might sound. Data reduction and analysis software is complex, and must be tailored to each new test

program. Experienced testers know that without a rigorous pre-first-flight checkout, several flights

may be needed to expunge the bugs from sophisticated data reduction and analysis software. Using

simulator "test data" to perform a pre-first-flight checkout can dramatically reduce lost flight time and

test maneuvers.

20.3.7 Test Planning Using a simulator, we can learn before flight testing $hat kind of test

maneuvers are needed to satisfy the test objectives, how many maneuvers must be flown, and how

much time will be needed to fly them. We can also learn how much the test conditions are likely to

change during the maneuver: for example, how much airspeed or altitude might be. lost. When flight

test time is critical, a simulator can be used to work out the most efficient sequence of maneuvers.

20.3.8 Safety A flight test simulator enhances safety in at least three ways. First, it can be used

to prepare pilots for a range of possible responses when they fly a new or modified airplane. Second,

it can prepare the pilots for both planned and unplanned flight control system failures. And third,

it can reduce the hazards associated with envelope expansion testing.

The first way a simulator can be used to enhance safety is by preparing pilots for a range of possible

responses. As you know by now, the uncertainties in predicted aerodynamic and flight control

system models can affect handling qualities in important ways. Using a procedure we call sensiriviry

resting, a simulator can prepare pilots for the effects of these uncertainties. For example, varying

the values of predicted stability derivatives (or combinations of stability derivatives) allows the pilot

to develop a feel for how sensitive the handling qualities might be to errors in the aerodynamic

model. Similarly, the effect of lower than expected actuator rate limits (induced, perhaps, by higher

than anticipated hydraulic system demands) may be investigated. Sensitivitytesting prepares the pilot

to recognize some of the handing qualities surprises that are likely to be encountered during testing.

Equally important, sensitivity testing prepares the pilot to respond correctly to those surprises.

The second way a flight test simulator can be used to enhance test safety is by preparing pilots for

both planned and unplanned flight control system failures. Planned failures are intentionally induced

(perhaps using an inflight fault simulation and clearing capability) so that failure state handling

qualities may be evaluated. It is prudent to use a simulator to prepare for these tests so that the pilot

knows what to expect in flight. Preparation should include an exploration of the effects of

20-18 Flying Qualities Testing

Flying QuaWes Flight Test Simulcrtors

20.3.10 Augmenting Test Data

~ -,

aerodynamic uncertainty. Unplanned failures are, of course,unexpected. Pilots should spendtime

in a simulator learning how to recognize and respond to unexpected failures and the handling qualities

they produce.

Occasionally, flight control system failure states produce handling qualities that are judged to be too

hazardous for inflight evaluation. In these cases the only way to explore the failure. state handling

qualities is to use a validated simulator.

~

The third way a flight test simulator can be used to enhance test safety is by reducing the hazards

associated with envelope expansion testing. Envelope expansion is an incremental process of

correcting and validating the predicted models of the airplane aerodynamics, flight control system,

structure, and handling qualities. A cardinal principle of envelope expansion testing is that it begins

in the least hazardous region of the flight envelope and progresses to the most hazardous regions.

As envelope expansion progresses and flight test results become available, the simulator models can

be coqected and validated. The validated simulator can in turn be used to predict the airplane

response at succeeding (and more hazardous) test points, where the m$el validation process is

repeated. This procedure can reduce the number of unpleasant surprises you encounter. By the time

the envelope has been expanded to the most hazardous regions, the airplane models are reasonably

well understood. As a result, the hazardous regions of the envelope may prove to be less hazardous

than supposed when testing began.

20.3.9 Analyzing and Correcting Deficiencies When deficiencies are discovered during testing,

flight test simulators are an important tool for understanding and correcting them. The first step is

to validate the simulator in that part of the flight envelope where the deficiency exists. Once the

response of the simulator matches the response of the airplane, the deficiency may be explored in the

simulator rapidly, inexpensively, and safely. The flight conditions at which the deficiency occurred

can be easily controlled in a simulator, and the test maneuver may be repeated as often as desired

without risk to the aircrew or airplane. When the problem is understood, candidate solutions can be

proposed. These solutions may be evaluated in the simulator at length to determine which one, or

more, should be evaluated in flight.

2Q3.10 Augmenting Test Data As a test program progresses and the simulator is incrementally

validated, it can be used to augment flight test data. We can, for example, use the simulator to

determine frequency, damping ratio, roll mode time constant, stability margins, and so on at selected

flight conditions. This means that valuable flight test time may be devoted to more critical testing

that can be accomplished only in the real airplane, such as handling qualities evaluation. Using a

validated simulator to augment flight test data helps keep test programs on schedule and withii

budget. Also, "Speccompliance" testing (demonstrating compliance with contractual flying qualities

requirements) is more easily, more accurately, and less expensively accomplished using a validated

simulator than a real airplane.

Flying Qualities Testing 20-19

Flying Qualities Flight Test Simulators

20.4 Justifying a Flight Test Simulator

20.3.11 Hardware Verification and ( L i m i t e d ) Validation At the Flight Test Center, flying

qualities flight test Simulators have sometimes been used for hardware-in-the-loop testing. This has

proved valuable for verifying that control law changes have been correctly implemented in the flight

control computers before the computers are replaced in the airplane for flight testing. Limited

validation testing may also be performed. For example, the predicted handling qualities may be

evaluated on the simulator to determine whether the control law changes are likely to produce the

desired improvement. Full validation testing can only be conducted in flight.

20.3.12 Dress Rehearsals A flight test simulator may be used to conduct full dress rehearsals of

an entire flight, or of portions of a flight. This can be very important for test programs that involve

only a few short, high intensity flights, or unusual or especially hazardous test maneuvers. The X-15

test program, the lifting body test programs, and the space shuttle Enterprise approach and landing

test program are examples of test programs made up of short, high intensity flights. High angle of

attack testing includes examples of test maneuvers that are unusual and especially hazardous.

For test programs or test maneuvers such as these, pre-flight rehearsals offer segeral advantages.

One is pilot proficiency. Timing and proficiency take on added importance when the duration of a

flight may be no more than a few minutes, during which time many test maneuvers must be

performed. Flight conditions may be changing rapidly, so each test maneuver must be flown at

exactly the right moment, and correctly, because there are no second chances. Because these flights

must go like clockwork, rehearsals are essential. In the past, pilots have reported that even with the

help of rehearsals the flights seemed to go much faster than in the simulator. Success was achieved

only because the rehearsals made it possible to step through the test maneuvers in an almost

mechanical fashion. Otherwise, relatively little would have been accomplished.

Experience at the Flight Test Center indicates that, to be helpful, at least three rehearsals must be

conducted. When fast-paced, high intensity flights are being rehearsed it may prove beneficial to run

the simulator at a faster pace. For example, during the lifting body test programs, the pilots felt that

running the simulator about 30 percent faster than real time made the rehearsal seem more realistic.

We should note that dress rehearsals are equally important to test engineers, who monitor the test data

during the flight and who must be prepared to quickly interpret the data, diagnose anomalies, and if

need be, recommend a course of action to the pilot. Rehearsals prepare the engineers to recognize

and interpret test maneuver responses on the control room displays. Responses that differ

significantly from simulator predictions should arouse a sense of caution. Rehearsals may also be

used to validate minimum and maximum values for stripchart parameters, and "knock it off," or

maneuver termination limits for key parameters.

20.4 Justifying a Flight Test Simulator Two of the most important components of a successful

flying qualities test program are a properly configured test airplane and a flight test simulator. It is

unlikely that a new or significantly modified airplane can be successfully tested without these two

components. In Chapter 19 we discussed the importance of a properly configured test airplane and

20-20 Flying Qualities Testing

Flying Qualities Flight Test Simulators

20.4 Justifying a Flight Test Simulator

in section 20.3 we outlined a few of the uses and benefits of a flight test simulator. In this &tion,

you will learn why an independent flight test simulator is necessary at the flight test site, which in

most cases is the Flight Test Center.

Air Force procuring agencies and contractors sometimes oppose building a simulator at the Flight

Test Center. This is partly because they want to save money, partly because they believe one

simulator (the contractor’s) is enough, and partly because they are unfamiliar with the uses of a flight

test simulator. For these reasons they are inclined to regard a flight test simulator at the test site as

an unnecessary expense.

It is understandable that the cost of building and supporting a simulator at the Flight Test Center is

a matter of concern. Money doesn’t grow on trees, and to the inexperienced it may appear that a

flight test simulator is a redundant expense. But return on investment must also be considered. Each

of the uses of a simulator we outlined in the precediig section represents a return on investment:

flight hours saved, improved test results, increased safety, new test maneuvers and analysis

techni&es, increased efficiency, and so on. These add up to money the tegt program does not have

to spend, and airplanes it might not have to repair or replace. To illustrate this point, consider the

AFTVF-16 test program, which documented the return on investment in its flight test simulator

during the first few years of testing. To the astonishment of everyone outside the test program, the

cost of the sirnulaor w m repaid 120 times over. This return on investment represented the

accumulated savings from all of the various uses we outlined in the preCeaig section. It did not

include the potential savings of a damaged or lost test airplane.

A simulator pays for itself in another way, too. For a number of reasons, ranging from politics to

operational requirements, it is important that a test program stay on schedule and withii budget.

Nevertheless, schedules and budgets are routinely exceeded. But experience at the Flight Test Center

indicates that test programs that have a flight test simulator and a properly configured test airplane

fare better than those that don’t.

The procurement agency and the contractor sometimes argue that the contractor’s simulator is

adequate to support flight testing. There are several reasons why this is not so. First, and perhaps

surprisingly, contractors sometimes shut down their simulators soon after first flight. This is because

their primary use for the simulator is flight control system design. After first flight they may feel

that the simulator has served its purpose. When the contractor does maintain a simulator beyond first

flight, it is often devoted to on-going design work, such as avionics integration, instead of flight test

support.

Sometimes, the test team is required to use the contractor’s simulator for flight test support. In these

cases, the test team might be given a few one or two week blocks of simulator time, arbitrarily

sprinkled over the course of the program. This is completely inadequate. The uses we outlined in

the previous section require almost daily access from months before first flight until the last flight

is completed and the test reports are written. Envelope expansion alone requires daily use of a

simulator for extended periods of time. Analysis of flight control system or handling qualities

deficiencies requires that the simulator be available soon after the flight.

Flying Qualities Testing 20-21

Flying Qualities Flight Test Simulators

20.4 Justifying a Flight Test Simulator

. I

. -,

Using the contractor’s simulator is inadequate for other reasons, too. The test team might not be

allowed to modify the contractor’s simulator to serve flight test purposes. Without such modifications

it may prove impractical to use the simulator productively. For example, it may prove difficult to

conduct aerodynamic and flight control system sensitivity testing, or to develop test input signals, and

so on. Moreover, data from the contractor’s simulator is rarely in a suitable format for flight test

purposes.

Contractors do not always validate their simulators. This makes it difficult to use the s<mulator for

envelope expansion, or to explore and correct deficiencies, or to augment flight test data.

Also, contractors may model the aerodynamics or the flight control system differently than would test

team engineers. Here is an interesting, but not unique, example. Perhaps you have heard of the

inadvertant first flight of the YF-16. This occurred when a high speed taxi test turned into a lateral

pilot-in-the-loop oscillation and the pilot wisely elected to take off rather than run the airplane off the

.

This PI0 occurred because the lateral flight control system gain

was based on mismodeled aileron control effectiveness. This is

illustrated in Figure 20-6, which shows the predicted curve of C,

versus 6, together with the model of this curve used in the

contractor’s simulator. The contractor’s model was a straight

line connecting the two end points of the predicted curve. (The

contractor chose this model for the sake of simplicity and to

preserve the endpoints of the curve, so that full deflection roll

rates could be reliably simulated.) Using this model, small

Figure 2 0 4 Predicted and modekd aileron deflections were about half as effective in the simulator

aikron conuol t$eciiveness.

as they were in the real airplane. As a result, the contractor’s

simulator was operating at about half the open-loop . gain

. of the

real airplane. Consequently, the contractor’s simulator provided no indication of the roll sensitivity

and PI0 experienced during the high speed taxi test.

In contrast to the contractor, the test team modeled the aileron effectiveness with greater fidelity in

the Flight Test Center simulator. As a result, this simulator accurately predicted the behavior

demonstrated during the high speed taxi test. Unfortunately, the contractor chose to be guided by

the results from the contractor simulator.

Here is another example of a contractor modeling the aerodynamics differently than the test team

might have. F-lll wind tunnel data indicated that the directional stability derivative, C”,, went to

zero between 13 and 14 degrees angle of attack. The contractor regarded these results as suspect,

and so discarded them. Consequently, the contractor’s aerodynamic model did not extend beyond

12 degrees angle of attack. During flight testing, two F-111s were lost when they exceeded 12

degrees angle of attack, departed, and entered unrecoverable spins.

20-22 Flying Qualities Testing

F l y i g Qualities Flight Test Simulators

20.5 Building a Flight Test Simulator

..

Another reason why Air Force procurement agencies and contractors resist building simulators at the

Flight Test Center is their sense of optimism. Because they are "success-oriented" they do not

anticipate problems. They believe everything will go smoothly, from design through flight testing.

Consequently, they see no reason to spend money on a flight test simulator. At the Flight Test

Center, however, we have learned through experience that problems are the norm.

20.5 Building a Flight Test Simulator Building a flight test simulator is a trig job. It would be

dishonest to understate the time it takes, or the money. But, as we pointed out in the two prewediig

sections, the uses and benefits of a flight test simulator outweigh the time and money required to

build one.

It is important that the requirement for a flight test simulator at the AFFTC be acknowledged right

from the start, before the contract for a new airplane is signed. Money must be allocated to the

contraqtor to provide data on the aerodynamics, flight control system, cockpit layout, and so on.

These data must be made available to the test engineers in a suitable format and as early as possible.

Work on the flight test simulator should begin early. Adequate lead time must be provided to

purchase special computers (if needed), to fabricate hardware for the cockpit (if needed), and to build

aerodynamic and flight control system models. The goal should be to have the simulator ready for

use six months to a year before first flight.

Flight test simulators are built by simulation engineers and technicians working with flying qualities

test engineers. Roughly speaking, the task is divided in the following way. Simulation engineers and

technicians are responsible for writing and debugging software,fabricating hardware, and integrating

the two. Test engineers are responsible for assembling aerodynamic data, flight control system

diagrams, weight and balance data, propulsion system data, and so on. Test engineers are also

responsible for outlining how the simulator will be used. Confirming that the simulator models,

hardware, and software have been correctly implemented is the responsibility of both simulation and

test engineers.

The availability of powerful desktop computers, together with generic cockpits and relatively simple

but fast displays, makes it possible today to build reliable and useful simulators for a small fraction

of the cost ordinarily associated with flight test simulators. The USAFMPE simulator depicted in

Figure 20-1 in section 20.1.2 is an example of such a simulator, which could profitably be stationed

next to the desks of flying qualities test engineers.

k

The first task in building a simulator is to decide how it will be used. The cost of a flight test

simulator is determined primarily by the capabilities it must have. These capabilities are in turn

dictated by the ways in which the simulator will be used. We discussed a number of important uses

in section 20.3. Your test program may have others as well. Because the cost of a flight test

simulator is related to the ways in which it will be used, you should not require capabilities that will

not be used. For example, a medium fidelity, general purpose simulator cockpit is usually adequate

for flight test purposes. Unless your test program has an unusual requirement for a high fidelity

Flying Qualities Testing 20-23

Flying Qualifies Flight Test Simulators

20.5.1 Defining Flight Test Simulator Requirements

-. . -,

cockpit, there is no good reason to spen6 extra money to exactly match the geometry, switches,

lights, instruments, and displays in the real cockpit. That money can be spent more productively,

or saved. In the next section we will show you how flight test simulator requirements are defmed.

20.5.1 Defining Flight Test Simulator Requirements Defining simulator requirements is a two

step process. First, you must decide how the simulator will be used to support your test program.

Second, you must decide how much fidelity is required to serve those uses.

The catalogue of uses we examined in section 20.3 and the discussion of fidelity we presented in

section 20.2 are starting points for you to consider when you are determining simulator requirements.

In Table 20-1 we have mapped fidelity requirements versus simulator use for a typical flight test

simulator. Using this map, and tailoring it to your test program, may help you determine a set of

cost effective simulator requirements. Consider, for example, that a high level of cockpit fidelity is

not required for any of the uses listed in Table 20-1, whereas a medium level of fidelity is desired

for a number of uses. Hence, money can be saved by specifying a medium level otcockpit fidelity,

with no negative effect on usefulness. Or consider that a high level of motion fidelity is desirable

for three of the flight test simulator uses listed in Table 20-1, whereas the remaining uses require a