Professional Documents

Culture Documents

Van Gogh PDF

Van Gogh PDF

Uploaded by

js100%(1)100% found this document useful (1 vote)

557 views2 pagesOriginal Title

Van Gogh.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

557 views2 pagesVan Gogh PDF

Van Gogh PDF

Uploaded by

jsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

VAN GOGH

“ The Art of the Ocean”

Multipurpose Diving Support Construction Vessel

The DP2 DSCV VAN GOGH is advanced designed and FEATURES:

built to Ultra Deep Solutions specification for deepwater

deployment worldwide. The Van Gogh is a state of art 111.58m length x 23m Breadth

DP2 Multipurpose Diving Support Vessel / SPS Code

DP2 Multipurpose Diving

2008, with an 18 men single bell saturation system for

Support Vessels

depth down to 300 meter. The Van Gogh has its own

moonpool, an air diving system, and fitted with 2 Work

Class with LARS. 150 T AHC Crane with single

fall up to 3,000m water depth

The vessel is equipped with diesel electric frequency

controlled propulsion, highly efficient azimuth thrusters, Built-in 18 Man Saturation

dynamic positioning system and 150t offshore cranes Diving System capable of

(3,000m water depth). A large platform deck 1,000 m2 operating at 300m depth

deck space suitable for wellhead servicing, inspection

and construction diving and ROV support. Clear deck area 1,000m2

The vessel accommodates up to 120 personnel. Van

Accommodates up to 120

Gogh is an optimized hull design with excellent

characteristic for deployment worldwide. personnel

Delivery – Q4 2017 Green design by Marin Teknikk

AS with reduced fuel

consumption and reduced

exhaust emission

Excellent speed, high safety

level, low sound and vibration

level.

Ultra Deep Charter Ltd / Ultra Deep Subsea Pte Ltd

7 Tuas South Street 11, Singapore 637091. II +65 6702 6771 II joey.teo@ultradeepsolutions.com II www.ultradeepsolutions.com

VAN GOGH

“Technical Specification”

The vessel is designed according to the class notation “Clean Design”

and SPS Code and high focus is given to low fuel consumption, which

reduces emission to the environment. FO tank arrangement according

to “Clean Design” and MARPOL - oil fuel tank protection.

The vessel is designed to fulfil following duties:

Diving operations with a 18 men (single bell) SAT dive system rated at

300 msw, ROV and seabed construction work.

In addition to diving, and construction work the vessel is arranged with

2 WROV`s with LARS in the hangar. The vessel can also perform

normal field support duties. Subsea Construction Vessel available for

deployment worldwide.

MAIN DIMENSIONS WORKING DECK AREA: HELICOPTER DECK

Length o.a.: ........................................................................ 111.58 m Main work deck (aft of hangar):......................................... ~1000 m2 Helicopter deck of aluminium for Sikorsky S92 acc. to HELIDK

Length b.p.p.: ..................................................................... 103.70 m Cargo deck max width:.............................................................. 23 m class notation, IMO regulation and UK Aviation Authorities UK 437

Breadth mld.: ........................................................................ 23.00 m M. deck load: Stern—fr.74 : .................................................. 10 t/m2 regulation. Sky lobby allocated for in/out going passengers.

Depth Main deck: ................................................................. 10.00 m M. deck load: fr.74—fr.113....................................................... 5 t/m2

Depth Shelter deck: .............................................................. 12.80 m Removable bulwark according to GA FLOW METERS

Max draft midship (SWL): ...................................................... 7.00 m Flow meter for fuel oil with printer.

Corresponding Freeboard: ..................................................... 3.00 m MAIN ENGINES / GENERATORS

2x MAN 8L32/40........................................................each 3840 ekW DP CONTROL AND NAVIGATION EQUIPM.

CLASS / AUTHORITIES 2x MAN 7L32/40.......................................................each 3380 ekW DP System: Kongsberg K-Master

DNVGL + 1A1 - SPS - E0 - Dynpos AUTR - DK(+) - HELDK-SH, Total:.................................................................................14440 ekW -Kongsberg independ. joystic sys.

COMF-V(3) – CLEAN DE- SIGN – DSV-SAT– DSV SURFACE – -Kongsberg dynamic pos. system (Dynpos AUTR) Dynamic

CRANE – ICE C – NAUT OSV(A) - BWM-T - RECYCLABLE EMERGENCY. GEN. SET DIVE Positioning Syst. DnV AUTR, IMO Class II. Position reference

Flag: TBA. 1 of CAT C32 910 ekW at 1800 rpm. systems: DPS132, DPS232, laser reference system, two hydro

acoustic reference units Hipap 500 mounted in steel trunks with

SPEED HARBOUR/EMERGENCY. GEN. SET SHIP remote operated gate valves

Speed at d=5 m: ..............................................................~12.5 knots of CAT C32 910 ekW at 1800 rpm.

The Vessel systems is designed for service with the following -Kongsberg I.A.S.

environmental conditions: DISTILLED AND MAKE-UP WATER SYSTEMS Radar Equipm, Satellite Navigator, Chart System, Conning,

Ambient air temperature between down to -20 °C to +40 °C and sea off FW reverse osmosis plant, capacity approx. 20 m3/24h to be Compass System, Autopilot, Echo Sounder Speed log, Sat log AIS,

temperature up to 32 °C. arranged. VDR, Ra- dio Equipment, TV Parabol, Helicopter beacon,

monitoring syst. Acc. to rules and high class standard requirements.

TONNAGE 2 off LO separator for each main generator set. 2 off DO separators

Gross Tonnage (GRT): . .......................................................~9200 T Navigation equipment according to NAUT OSV Radio installation

Net Tonnage (NRT): . ...........................................................~2760 T PROPELLERS acc. to GMDSS – area A3 Satcom C, Fleet-77

of Azimut FP, each 3000 kW, frequency con- trolled. Two V-Sat communication antennas Internal Communication

ACCOMMODATION ULSTEIN COM®

Accommodation for 120 persons, THRUSTERS FORE common distribution of automatic telephone, data network and

28 x 1 man cabins, 46 x 2 men cabins of tunnel thrusters, FP, 1800 kW, el. driven, satellite TV antenna signal to all offices and cabins.

1 off retractable thruster, FP, 1200 kW, el. driven, Thrusters are Batteryless telephone system, separate PA, DECT TV satellite

Tween Deck: Sat Control Room, Dive System Switchboard room, freq. controlled. antenna

Pantry store, Dive pantry, Diver suit dry, Diver suit wash,

Switchboard room, Workshop store, Toilet ELECTRICAL MAIN SWITCHBOARDS LOADING COMPUTER

Hareid Elektriske / Siemens/ ABB. Marin Teknikk:...............................................................MT-ShipLoad

Main Deck: Locker room, Wardrobe, Toilet x6, Laundry work cloth., The ships electrical power is generated by the main generator sets.

Engine contr. room, Store x3, Linen, Laundry, Tech. Library, The power levels are divided into 4 different voltage ranges 6600 V- DIVE SYSTEM

Incinerator, Tech. workshop, Dive tech. store, Techs. office, Project 60Hz, 690V- 60Hz, 440V-60Hz, 230V-60Hz and Dive system:............................................................................18 men

office, Client office, Air dive chamber, Dive control, Dive 24VDC. single bell saturation system, for depth down to 300 m.

store/workshop, ROV Workshop, ROV Trafo room, Dive Hangar Chambers 3x6 men.

Area, Paint store, Rigging store, Deck workshop DECK EQUIPMENT/CRANES Air dive system 1x2 men.

Integrated Automation System (IAS) 2x independent Launch and Recovery Systems. Design criteria sea

Shelter Deck: Reception, Dry provision x3, Cool, Freeze, Galley, The system consists of the following functionality and sub systems: state 5.5 m sign. wave height (to be clarified with dive supplier).

Bakery, Scullery, Mess room, Dayroom, Day room smokers, ROV Alarm and Monitoring System.

control room, Waste trunk, Broom closet, Toilet x3 Power Management System (PMS) interface. CONSUMPTION

Econ. transit ~13 kn.................................................................~ t/day

Forecastle Deck: Client and Crew cabins, Laundry, Linen x2, Wind/Mooring: Econ. transit ~10 kn.................................................................~ t/day

Instrument room 2 of Rauma or similar, min........................................................... 15 t DP operations.....................................................................~5-7 t/day

2 of Capstan/mooring winch aft.................................................... 15 t Port.........................................................................................~1 t/day

Boat Deck: Client and Crew cabins, Instrument room, Store, Toilet,

Broom closet, Hospital, Gymnasium Deck cranes: Consumption at D=4.5m, propulsion only

1 of main AHC offshore crane: Details are believed to be correct but not guaranteed.

Capt. Deck: Client and Officers cabin, Instrument room, Broom 150 ton @ 10.5 m Wire cap. for AHC cranes 3000 m., arr. with Last updated 15 April 2015.

closet, Laundry, Linen, Ship’s office, Lounge, Conference room pers. lifting/remote access

1 of crane..................................................................... 10 t @ 12.5 m

Bridge Deck: Bridge/manouvre consols fore/ aft, Survey area’s in 2 of foldable crane............................................................ 2 t @ 15 m

bridge wings, Office area in lowered level, Radio station, Toilet,

Kitchen, Store ROLL REDUCTION SYSTEM

A passive anti-roll system. 1 of roll reduction tank.

Top of wheelhouse: Sky lounge, Sky lobby, Reception/TV-room,

Heli Suites, Battery room, Store, Toilet LIFE SAVING EQUIPMENT

Life rafts:.................................................................acc. to rules. SPS

ROV HANGAR Survival Suits for ..................................................................120 men

2 WROV LARS over SB side and P side Safety Equipment:...acc. to SOLAS for 120 pers.

1 of Rescue Mob Boat (Lifeboat PS)

MOON POOL 2 of Life Boats: ..................................................................2x 60 pers.

1 of Moon Pool for dive bell 3.9 m x 3.9 m 2 of Hyperbaric Life Boat: .................................................1x 18 pers.

CARGO CAPACITIES FIRE DETECTION SYSTEM

Deadweight at max d.:. ........................................................ ~ 5500 t Stand-alone addressable fire detection central for all compartments

and cabins

CARGO TANK CAPACITIES

Fuel Oil: . ............................................................... approx ~1350 m3 ANTI HEEL SYSTEM

Fresh Water: . ...................................................... approx ~1200 m3 Pump:............................................................ 2x 1200 m3/h -10 mwh

Water Ballast:. ....................................................... approx ~6000 m3 Anti Heeling tk. cap.:.............................................................1050 m3

Anti Heeling:. ......................................................... approx ~1050 m3

Lubricating Oil: .......................................................... approx ~50 m3

Misc.tanks: (inkl. bildge). ....................................... approx ~250 m3

Potable water .......................................................... approx ~300 m3

Ultra Deep Charter Ltd / Ultra Deep Subsea Pte Ltd

7 Tuas South Street 11, Singapore 637091. II +65 6702 6771 II joey.teo@ultradeepsolutions.com II www.ultradeepsolutions.com

You might also like

- NOAA Diving ManualDocument520 pagesNOAA Diving Manualdasalomon100% (5)

- VP - PSV SEA VEGA REV.0 (New Logo) r2Document4 pagesVP - PSV SEA VEGA REV.0 (New Logo) r2Sugiman LayantoNo ratings yet

- Recomm Manifolds 2017Document68 pagesRecomm Manifolds 2017Dong NguyenNo ratings yet

- Rules and Regulations For The Construction and Classification of Submersibles and DDocument185 pagesRules and Regulations For The Construction and Classification of Submersibles and Dvijuindia1111No ratings yet

- SPHL Emergency Evacuation and Rescue ProceduresDocument30 pagesSPHL Emergency Evacuation and Rescue ProceduresPraise Sam Abraham100% (3)

- Barecon 2001 PDFDocument12 pagesBarecon 2001 PDFKhoai Sai GonNo ratings yet

- Explaintory NotesDocument8 pagesExplaintory Notespgupta71No ratings yet

- Msds EngDocument7 pagesMsds EngHakim YahiaouiNo ratings yet

- Oriental Dragon (DSV) - Main SpecificationDocument2 pagesOriental Dragon (DSV) - Main Specificationjs100% (1)

- Diving Operations StandardDocument18 pagesDiving Operations StandardRidha FalehNo ratings yet

- Qf-Fsc-Le-002 - Ship Repair AgreementDocument2 pagesQf-Fsc-Le-002 - Ship Repair AgreementAaron PerezNo ratings yet

- Explanatory Notes To GENTIMEDocument17 pagesExplanatory Notes To GENTIMETrufea TeodoraNo ratings yet

- M/V "Transco Sky": Main Engine Damage en Route From Japan To Philippine On 4 June 2012Document17 pagesM/V "Transco Sky": Main Engine Damage en Route From Japan To Philippine On 4 June 2012frankharriskNo ratings yet

- Brochure Mermaid Commander 4-8-15Document1 pageBrochure Mermaid Commander 4-8-15Khaw Seek ChuanNo ratings yet

- Minisat 120-00 - 1407410602Document25 pagesMinisat 120-00 - 1407410602RicardoNo ratings yet

- Instruction Manual For The CITIZEN Promaster Eco-Drive AQUALAND Titanium Divers Watch JV0055-51EDocument50 pagesInstruction Manual For The CITIZEN Promaster Eco-Drive AQUALAND Titanium Divers Watch JV0055-51EMeor Amri100% (2)

- UltradeepMatisse VesselDocument2 pagesUltradeepMatisse VesselBedon Esem100% (1)

- Where To Build Where To Repair 2014 TrialsDocument52 pagesWhere To Build Where To Repair 2014 TrialsHarisNo ratings yet

- Opex The Ship Management View: V.ShipsDocument19 pagesOpex The Ship Management View: V.Shipsricardo nais100% (1)

- Off - Hire Statement: Magnus Carriers CorporationDocument1 pageOff - Hire Statement: Magnus Carriers CorporationIhwan AsrulNo ratings yet

- KV Resources SDN BHD: 3 × 350HP Outboard Engines Magnetic Compass. Multi Directional SearchlightDocument2 pagesKV Resources SDN BHD: 3 × 350HP Outboard Engines Magnetic Compass. Multi Directional SearchlightIzza NasirNo ratings yet

- BIMCO Membership BenefitsDocument2 pagesBIMCO Membership BenefitsodinshippingNo ratings yet

- Brochure Tge GasDocument13 pagesBrochure Tge GasCemGülerNo ratings yet

- LPG Tanker 1Document2 pagesLPG Tanker 1Somayajula SuryaramNo ratings yet

- Green Ship Technologies - Brochure PDFDocument13 pagesGreen Ship Technologies - Brochure PDFGowtham Rajagopal100% (2)

- StandardAero - Company ProfileDocument2 pagesStandardAero - Company ProfileYuvraj KumarNo ratings yet

- All Vessels General RequirementsDocument10 pagesAll Vessels General RequirementsAamir Sirohi100% (2)

- Rs Impa CodesDocument220 pagesRs Impa CodesInnov8 OilNo ratings yet

- Diamond 53 BrochureDocument3 pagesDiamond 53 Brochuregipanaul100% (1)

- Camarc SAR 2015Document2 pagesCamarc SAR 2015Syaiful Anam100% (1)

- An Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsDocument50 pagesAn Estimate of Operating Costs For Bulk, Ro-Ro and Container ShipsJoseo100% (1)

- Aderco L1050 Introduction Brochure + Instructution SheetDocument7 pagesAderco L1050 Introduction Brochure + Instructution SheetSaw WinNo ratings yet

- Container Vessel: Reefers/ContainersDocument5 pagesContainer Vessel: Reefers/ContainersErmanda Mesquita SoaresNo ratings yet

- BIMCODocument22 pagesBIMCOfletchNo ratings yet

- Arneson Surface Drives CatalogueDocument12 pagesArneson Surface Drives CatalogueWoodsy12No ratings yet

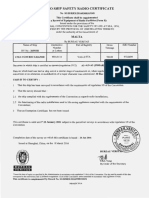

- Safety Radio Cert PDFDocument4 pagesSafety Radio Cert PDFdavid espositoNo ratings yet

- Institute Cargo ClausesDocument20 pagesInstitute Cargo ClausesSathish Kumar JNo ratings yet

- Multiple Vessel Dry Docking PDFDocument5 pagesMultiple Vessel Dry Docking PDFGermán AguirrezabalaNo ratings yet

- Owner's Management of Ship Construction ContractsDocument21 pagesOwner's Management of Ship Construction ContractsgopalptkssNo ratings yet

- Ship Station Licence and The Maritime Mobile Service Identity (Mmsi) NumberDocument2 pagesShip Station Licence and The Maritime Mobile Service Identity (Mmsi) NumberSkipperNo ratings yet

- Tanker SizeThere Are Different Tanker Sizes Used For The International Transportation of OilDocument4 pagesTanker SizeThere Are Different Tanker Sizes Used For The International Transportation of OilAnonymous UCveMQNo ratings yet

- Sub: Maintenance of The NO Record Book of Engine ParametersDocument6 pagesSub: Maintenance of The NO Record Book of Engine ParametersSatyabrat GaanNo ratings yet

- DNV Unveils LNG-Fueled VLCC..Document3 pagesDNV Unveils LNG-Fueled VLCC..VelmohanaNo ratings yet

- Incoterms 2010: EXW (Ex Works)Document2 pagesIncoterms 2010: EXW (Ex Works)Sergio O. Chong Lugo100% (1)

- Code On Alerts and Indicators 2009Document61 pagesCode On Alerts and Indicators 2009Hasancan YavaşNo ratings yet

- Bearing Failure Service LetterDocument7 pagesBearing Failure Service LetterAurvin SinghNo ratings yet

- Tema 5 PDFDocument133 pagesTema 5 PDFAndreiGeorgescuNo ratings yet

- 27snii15 Week27 2015Document151 pages27snii15 Week27 2015Kunal SinghNo ratings yet

- Myanmar Oil Gas Trends Market Opportunities andDocument8 pagesMyanmar Oil Gas Trends Market Opportunities andKhin Maung KyuNo ratings yet

- Seals Amp Bearings PDFDocument16 pagesSeals Amp Bearings PDFLingu LsNo ratings yet

- TOJan Mar23Document28 pagesTOJan Mar23buzbonNo ratings yet

- Deviation StatementDocument2 pagesDeviation StatementnikoskarandinosNo ratings yet

- MSF HHH Req12 8 Builders CertificateDocument2 pagesMSF HHH Req12 8 Builders Certificatebehzad parsiNo ratings yet

- Ultra Dynamics of ShipDocument17 pagesUltra Dynamics of ShipSaiTeja BandaruNo ratings yet

- Assignment - Ship Sale and PurchaseDocument4 pagesAssignment - Ship Sale and PurchaseCapt.Deepak Karan100% (1)

- 0000 General: LPG 5000 - Technical Specification Page - 1Document114 pages0000 General: LPG 5000 - Technical Specification Page - 1crnica006No ratings yet

- Ropax and Cruise-Ferry ServicesDocument12 pagesRopax and Cruise-Ferry ServicessilidiriNo ratings yet

- 2020 Daily Running CostsDocument39 pages2020 Daily Running CostsVladimir Letavin100% (1)

- 87.90m Platform Supply Vessel: Intan Offshore Pte LTD 19, Pandan Road Singapore 609271Document4 pages87.90m Platform Supply Vessel: Intan Offshore Pte LTD 19, Pandan Road Singapore 609271Wahyu KyozukeNo ratings yet

- P - Cargo Handling Equipment Productivity Analysis, WmuDocument126 pagesP - Cargo Handling Equipment Productivity Analysis, WmuTrifescu Radu ConstantinNo ratings yet

- Vopak Durban Terminal Capacity Storage Allocation MechanismDocument21 pagesVopak Durban Terminal Capacity Storage Allocation MechanismbiondimiNo ratings yet

- ContractDocument9 pagesContractwerliefeNo ratings yet

- New Company Profile PRO MARITIM INVESTINDODocument7 pagesNew Company Profile PRO MARITIM INVESTINDOBona Raja DamanikNo ratings yet

- Charter PartiesDocument7 pagesCharter PartiesJana KegaljNo ratings yet

- Annual RPT 09-10 PDFDocument105 pagesAnnual RPT 09-10 PDFBrilly EffendyNo ratings yet

- DSV RoyalIHCSeven Atlantic HSBDocument6 pagesDSV RoyalIHCSeven Atlantic HSBJorge Ricardo AlcivarNo ratings yet

- Calmar - Dive Support Daughter Craft (WEB - R4 (1) )Document2 pagesCalmar - Dive Support Daughter Craft (WEB - R4 (1) )Yashini SathiaselanNo ratings yet

- Soil Machine Dynamics LTD: SCALE: 1: 15Document1 pageSoil Machine Dynamics LTD: SCALE: 1: 15jsNo ratings yet

- DSV Shen Qian Hao: ROV Saturation Diving SystemDocument2 pagesDSV Shen Qian Hao: ROV Saturation Diving SystemjsNo ratings yet

- 13FC016 - SQH Emergency Notification Flowchart (ENF) PDFDocument1 page13FC016 - SQH Emergency Notification Flowchart (ENF) PDFjsNo ratings yet

- Untitled Attachment 07022 PDFDocument17 pagesUntitled Attachment 07022 PDFjsNo ratings yet

- DPDSV TOISA PALADIN - Ships ParticularsDocument1 pageDPDSV TOISA PALADIN - Ships ParticularsjsNo ratings yet

- External Function Examples OflexDocument14 pagesExternal Function Examples OflexjsNo ratings yet

- The Influence of Pipe Soil InteractionDocument16 pagesThe Influence of Pipe Soil InteractionjsNo ratings yet

- Iso 6425 2018Document11 pagesIso 6425 2018alexeigeNo ratings yet

- The Diving Medical Advisory Committee: Aide Mémoire For Recording and Transmission of Medical Data To ShoreDocument21 pagesThe Diving Medical Advisory Committee: Aide Mémoire For Recording and Transmission of Medical Data To ShoreFernando Cadena DuqueNo ratings yet

- Solarzilla ManualDocument45 pagesSolarzilla Manualmeor3705No ratings yet

- DMAC01Document17 pagesDMAC01AlexisRoyENo ratings yet

- Epic Divers Marine BrochureDocument12 pagesEpic Divers Marine Brochureren kaiNo ratings yet

- كل القطع من يوم 30-10-2017 حتى 13-11-2017Document41 pagesكل القطع من يوم 30-10-2017 حتى 13-11-2017nada abdelrahmanNo ratings yet

- OVPQ Master FullDocument40 pagesOVPQ Master FullFaidzy RahmanNo ratings yet

- OSG Rev3Document39 pagesOSG Rev3y6d6pct9fyNo ratings yet

- Deepwater ArchaeologyDocument193 pagesDeepwater Archaeologyzrinka_vekic100% (2)

- Vessel Specs - OLV VENTURE 1 PDFDocument7 pagesVessel Specs - OLV VENTURE 1 PDFgo michibataNo ratings yet

- Bibby Topaz 10oct14Document6 pagesBibby Topaz 10oct14tjsprangNo ratings yet

- Aviation, Space Physio and Deep Sea DivingDocument104 pagesAviation, Space Physio and Deep Sea DivingPrashant Singh RajputNo ratings yet

- Picture 1. Chamber Saturation Control PanelDocument2 pagesPicture 1. Chamber Saturation Control PanelHHNo ratings yet

- Significant Small Ships 2009Document68 pagesSignificant Small Ships 2009Salvatore BuonoNo ratings yet

- Sat Iii: Saturation Diving SystemDocument2 pagesSat Iii: Saturation Diving SystemJahel LootiNo ratings yet

- Diving SpreadDocument41 pagesDiving SpreadSyed Abdul RahmanNo ratings yet

- 46afe7d1fa0f4965bac5acb439f46028Document29 pages46afe7d1fa0f4965bac5acb439f46028Lucian GrecNo ratings yet

- Deep Explorer: Purpose-Designed Diving Support and Heavy Construction VesselDocument2 pagesDeep Explorer: Purpose-Designed Diving Support and Heavy Construction Vesselkyle krugerNo ratings yet

- Commercial Diving Doc-Bro-4 r0 Screen Version 3Document22 pagesCommercial Diving Doc-Bro-4 r0 Screen Version 3OswaldNo ratings yet

- 95.4M / 300 Men Subsea Installation and Dive Support Barge: PW NatunaDocument1 page95.4M / 300 Men Subsea Installation and Dive Support Barge: PW NatunaIgorNo ratings yet

- Sat System RaffaellaDocument6 pagesSat System RaffaellaMarco VacchieriNo ratings yet

- Yaya Komunikasi Bisnis 1Document8 pagesYaya Komunikasi Bisnis 1Risal RahmanNo ratings yet

- UntitledDocument176 pagesUntitledldigasNo ratings yet

- READING-2 - BAHASA INGGRIS 3 - St. Nur Rofiah Chaerunnisa Kadir - 200204622029Document8 pagesREADING-2 - BAHASA INGGRIS 3 - St. Nur Rofiah Chaerunnisa Kadir - 200204622029Nurrofiah ChennelNo ratings yet