Professional Documents

Culture Documents

Guidelines For Engineering Project

Guidelines For Engineering Project

Uploaded by

Alejandra ValenciaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines For Engineering Project

Guidelines For Engineering Project

Uploaded by

Alejandra ValenciaCopyright:

Available Formats

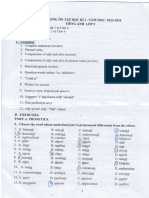

Guidelines for engineering project

Project must describe with details how decisions on process synthesis were made. There

must be documentation of every single analysis that was performed in order to define

process conditions (T, P, Molar ratio, Catalyst, Recycling fraction, etc.).

What does the document must include?:

First Report

1. Brief introduction about the product

2. Determination of production rate and location of plant (very brief – one paragraph).

Support in Annex.

3. Selection of chemical route (Very brief – one paragraph). Support in Annex.

4. Important technical data such as composition, water content, metals contents, or

any other impurity that is required to be considered during process modeling

5. Prices for raw materials, products and catalysts.

6. Validation of thermodynamic properties and models for all phases – comparison of

simulation results against experimental data for density, heat capacity, conductivity,

viscosity, vapor pressure, heat of reaction, heat of vaporization, VLE, LLE, SLE or

any other phase equilibrium required during simulation. Support in Annex.

7. Validation of kinetic models – comparison of simulation results against

experimental data for every kinetics included in the process simulation. Support in

Annex.

8. Input-output structure including design variables determination and economic

potential

9. Reactor design – adiabatic temperature analysis. Cost of reactor

10. Recycle structure including compressors costs. Economic potential update

11. Design of heterogeneous separations if required

12. Design of homogeneous separations. Vapor streams separations design. Liquid

phase separations including (if required) conceptual design of distillation

sequences.

13. Economic potential including separations

14. Process flow diagram using standard formats

15. Heat integration using pinch analysis

16. Process flow diagram after heat integration using standard formats

17. Economic potential including heat integration

18. Environmental and social indicators of the process

Second Report

19. Corrections of first report

20. Definition of design variables for the process

21. Sensitivity analysis: Total costs with respect to change in design variables

22. Identification of optimization variables

23. Formulation of the optimization problem and description of solution method

24. Economic optimization resolution

25. Heat integration of optimized process

26. Conclusions and remarks

27. Recommendations

Main body of document must be no longer that 20 pages, 2.5 cm surrounding margins,

font size 11, 1.2 space width.

Figures and plot must be clear, in the same language of the report, must contain units in

the axes and be readable.

Equations have to be clear and every symbol defined within text

If required, additional information can be included as annexes.

Reports must be printed out on double page, and handed out on time.

You might also like

- CEPE - Printable BDSM Checklist. August 2014Document41 pagesCEPE - Printable BDSM Checklist. August 2014hollywoodbear999990% (10)

- The Environmental Rights Revolution PDFDocument821 pagesThe Environmental Rights Revolution PDFLuz MarinaNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Ballet Arts Young Children: Classwork & Teaching Helps For The Ballet Teacher of Children Ages 4 & 5Document39 pagesBallet Arts Young Children: Classwork & Teaching Helps For The Ballet Teacher of Children Ages 4 & 5L100% (1)

- CH4801 S2AY23-24 - Course InformationDocument7 pagesCH4801 S2AY23-24 - Course InformationAbuBakar SaleemNo ratings yet

- Separations and Reaction Engineering Design Project Production of MTBEDocument10 pagesSeparations and Reaction Engineering Design Project Production of MTBEParaZzzitNo ratings yet

- CHEM+ENG+3030 7054+Design+Project+Brief+2023+Final 075629Document7 pagesCHEM+ENG+3030 7054+Design+Project+Brief+2023+Final 075629noorfatima.okitNo ratings yet

- Ethylene Plus Benzene Design Project Reference (Partial Only)Document11 pagesEthylene Plus Benzene Design Project Reference (Partial Only)YueZhen ChuaNo ratings yet

- CHE4049 Project 3 Handout 2012Document5 pagesCHE4049 Project 3 Handout 2012Tsepo Serakalala100% (1)

- Heat Exchanger MethodolgyDocument12 pagesHeat Exchanger MethodolgyAmr TarekNo ratings yet

- Ammonia D PDFDocument10 pagesAmmonia D PDFrkm_rkmNo ratings yet

- Rigrous Heat Exchanger SimulationDocument6 pagesRigrous Heat Exchanger SimulationJayakumar PararasuramanNo ratings yet

- Review Paper - KhushbooDocument10 pagesReview Paper - Khushboosarin.gaganNo ratings yet

- Conceptual Desgn For Chemical Processes - pdf.2Document3 pagesConceptual Desgn For Chemical Processes - pdf.2Audrey Patrick KallaNo ratings yet

- DME Synthesis Via Catalytic Distillation: Experiments and SimulationDocument6 pagesDME Synthesis Via Catalytic Distillation: Experiments and SimulationediabcNo ratings yet

- Subject 3. - Overview of Process Synthesis OCWDocument19 pagesSubject 3. - Overview of Process Synthesis OCWxhche7No ratings yet

- Separations and Reaction Engineering Design Project Production of AmmoniaDocument10 pagesSeparations and Reaction Engineering Design Project Production of AmmoniaRyan WahyudiNo ratings yet

- CBB3024 Flowsheeting 1Document93 pagesCBB3024 Flowsheeting 1Yunaida YusoffNo ratings yet

- Ethanol DDocument13 pagesEthanol DAndrea LeonNo ratings yet

- 6 Int Journal LyYtQrP5PTCA090PJWv0Document15 pages6 Int Journal LyYtQrP5PTCA090PJWv0Siddhartha SharmaNo ratings yet

- HYSYS Tutorial PDFDocument607 pagesHYSYS Tutorial PDFsalman hussainNo ratings yet

- Chemcad Features2Document18 pagesChemcad Features2Aditi PhalakNo ratings yet

- Application of CFD in Thermal Power PlantsDocument4 pagesApplication of CFD in Thermal Power PlantsAnonymous 4R6sDK8eNo ratings yet

- Integrate Process Simulation and Process SynthesisDocument6 pagesIntegrate Process Simulation and Process Synthesisjanota24No ratings yet

- Project - Description - S1 - 2024 - CHEN3010Document5 pagesProject - Description - S1 - 2024 - CHEN3010KHÁNH VÂN DIỆPNo ratings yet

- Kern Method Heat ExchangerDocument30 pagesKern Method Heat ExchangerCS100% (3)

- Integrate Process Simulation and Process Synthesis - DesbloqueadoDocument5 pagesIntegrate Process Simulation and Process Synthesis - DesbloqueadoVictor Heredia MattaNo ratings yet

- 1 Process Integration Lecture 1Document32 pages1 Process Integration Lecture 1yonas simur100% (1)

- Che C332 32Document3 pagesChe C332 32Manvendra SinghNo ratings yet

- Process Integration Through Pinch AnalysisDocument7 pagesProcess Integration Through Pinch AnalysisCORNELIUS CHIRUMENo ratings yet

- Acetone 3Document5 pagesAcetone 3Juan Medina CollanaNo ratings yet

- Chapter 2Document25 pagesChapter 2Siya YadavNo ratings yet

- FYDP 2 Students Briefing PDFDocument15 pagesFYDP 2 Students Briefing PDFCai ZiminNo ratings yet

- Project Standards and Specifications Plant Operating Manuals Rev01Document10 pagesProject Standards and Specifications Plant Operating Manuals Rev01hiyeonNo ratings yet

- An Approach For TopologyDocument32 pagesAn Approach For Topologyemma.fumaratiNo ratings yet

- The Design of A Chemical Plant For The Production of Methanol From Synthesis GasDocument4 pagesThe Design of A Chemical Plant For The Production of Methanol From Synthesis GasHenry NwidoNo ratings yet

- Pinch TechDocument32 pagesPinch TechDaniel Puello Rodelo100% (1)

- CH4801 Final Year Design Project (FYDP) Semester 2, AY 2017-2018Document4 pagesCH4801 Final Year Design Project (FYDP) Semester 2, AY 2017-2018Daryl ChianNo ratings yet

- Open ElectiveDocument7 pagesOpen ElectivevibhaNo ratings yet

- Integrated Fischer Tropsch Modular Process ModelDocument13 pagesIntegrated Fischer Tropsch Modular Process ModelAnwar AliNo ratings yet

- PP 2Document311 pagesPP 2Dinesh MechNo ratings yet

- Energy Management and Efficiency for the Process IndustriesFrom EverandEnergy Management and Efficiency for the Process IndustriesNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsFrom EverandMultiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureFrom EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisNo ratings yet

- Thermal Design: Heat Sinks, Thermoelectrics, Heat Pipes, Compact Heat Exchangers, and Solar CellsFrom EverandThermal Design: Heat Sinks, Thermoelectrics, Heat Pipes, Compact Heat Exchangers, and Solar CellsRating: 5 out of 5 stars5/5 (1)

- Geothermal Heat Pump and Heat Engine Systems: Theory And PracticeFrom EverandGeothermal Heat Pump and Heat Engine Systems: Theory And PracticeNo ratings yet

- Membrane Reactor Engineering: Applications for a Greener Process IndustryFrom EverandMembrane Reactor Engineering: Applications for a Greener Process IndustryNo ratings yet

- Sustainable Retail RefrigerationFrom EverandSustainable Retail RefrigerationJudith A. EvansRating: 5 out of 5 stars5/5 (1)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- Constructed Wetlands for Industrial Wastewater TreatmentFrom EverandConstructed Wetlands for Industrial Wastewater TreatmentAlexandros I. StefanakisNo ratings yet

- Knowledge Management & Specialized Information SystemsDocument21 pagesKnowledge Management & Specialized Information SystemsAntonyNo ratings yet

- 32 Osmeña III V SSSDocument10 pages32 Osmeña III V SSSAisa CastilloNo ratings yet

- Chapter 3 - The Subject and Content of ArtDocument5 pagesChapter 3 - The Subject and Content of ArtJo Grace PazNo ratings yet

- The Right of Privacy in The Digital AgeDocument16 pagesThe Right of Privacy in The Digital AgeGrace KPATINVONo ratings yet

- 06380492Document18 pages06380492Imam Adhita ViryaNo ratings yet

- Math9 q1 m4 FinalDocument16 pagesMath9 q1 m4 FinalRachelleNo ratings yet

- SCHOOL YEAR 2017 - 2018: 1. Informational DataDocument8 pagesSCHOOL YEAR 2017 - 2018: 1. Informational Datadamyan_salazarNo ratings yet

- Service Training Seriese 02 Product Know-How SL300 Drive Technology - HPV-02 Control M1Document20 pagesService Training Seriese 02 Product Know-How SL300 Drive Technology - HPV-02 Control M1xxsh100% (1)

- CESPL - Profile1Document93 pagesCESPL - Profile1Satvinder Deep SinghNo ratings yet

- Aafp2016mcq 170208194322Document78 pagesAafp2016mcq 170208194322Amanda KayNo ratings yet

- Radar Radome and Its Design Considerations: December 2009Document6 pagesRadar Radome and Its Design Considerations: December 2009Suresh MadhevanNo ratings yet

- D Claves - Examen A2Document1 pageD Claves - Examen A2Anyelin JaimesNo ratings yet

- Simple Past Full ExercisesDocument6 pagesSimple Past Full Exercisespablo1130No ratings yet

- What Is DiarrheaDocument4 pagesWhat Is Diarrheasanozuke02No ratings yet

- Statements of Financial Position As at 31 December 2009 and 2010Document3 pagesStatements of Financial Position As at 31 December 2009 and 2010mohitgaba19No ratings yet

- 15 Win1 Midas-Xr New Brand enDocument18 pages15 Win1 Midas-Xr New Brand encristiNo ratings yet

- NutriSmart - Food Products Recommendation SystemDocument3 pagesNutriSmart - Food Products Recommendation SystemAnonymous izrFWiQNo ratings yet

- JCDecaux Gen Z IRL Opportunity ReportDocument28 pagesJCDecaux Gen Z IRL Opportunity ReportBlake Samson-ReißkyNo ratings yet

- 1.socio Economic Determinants of HealthDocument64 pages1.socio Economic Determinants of HealthdenekeNo ratings yet

- Islamic Economics and The Islamic Sub EconomyDocument18 pagesIslamic Economics and The Islamic Sub EconomyNoerma Madjid Riyadi100% (1)

- Mendelssohn Op. 19 Nr. 1 Analyse ENDocument2 pagesMendelssohn Op. 19 Nr. 1 Analyse ENLianed SofiaNo ratings yet

- Pengembangan Prosedur Dan Penataan Dinas JagaDocument11 pagesPengembangan Prosedur Dan Penataan Dinas JaganoviNo ratings yet

- Coupling - Machine DesignDocument73 pagesCoupling - Machine DesignAk GamingNo ratings yet

- B. SC Nursing: Medical Surgical Nursing Unit V - Disorders of The Cardio Vascular SystemDocument31 pagesB. SC Nursing: Medical Surgical Nursing Unit V - Disorders of The Cardio Vascular SystemPoova Ragavan100% (1)

- SENEPOL1Document36 pagesSENEPOL1JuanNo ratings yet

- Carter Procession Closure MapDocument1 pageCarter Procession Closure Mapcookiespiffey21No ratings yet

- G9 Nghĩa ĐiềnDocument10 pagesG9 Nghĩa ĐiềnNguyệt Võ Thị MinhNo ratings yet