Professional Documents

Culture Documents

Pumps 2

Pumps 2

Uploaded by

Ahmad DeyabCopyright:

Available Formats

You might also like

- Introduction Aspen AdsorptionDocument191 pagesIntroduction Aspen AdsorptionAhmad Deyab100% (2)

- Column Flooding CalculationsDocument6 pagesColumn Flooding CalculationsAhmad DeyabNo ratings yet

- Meaning of Flooding, Weeping, FoamingDocument1 pageMeaning of Flooding, Weeping, FoamingAhmad DeyabNo ratings yet

- NGL Fractionation Using HYSYSDocument30 pagesNGL Fractionation Using HYSYSAhmad Deyab100% (3)

- Hydraulic Schematic 785C PDFDocument13 pagesHydraulic Schematic 785C PDFDany LeaNo ratings yet

- Branch Reinforcement - ASME 31.1Document8 pagesBranch Reinforcement - ASME 31.1zakir84md3639No ratings yet

- Capillary Tubing SizesDocument3 pagesCapillary Tubing Sizesgoodti100% (2)

- Self Priming PumpsDocument4 pagesSelf Priming PumpsMUHAMMAD AWAIS UR REHMANNo ratings yet

- Sir. Linex Fluid MachineryDocument160 pagesSir. Linex Fluid MachineryBrian Montes Bagarinao100% (1)

- Refrigeration Troubleshooting GuideDocument8 pagesRefrigeration Troubleshooting GuideJuan Jose Ramirez CorralesNo ratings yet

- Penberthy EductorDocument16 pagesPenberthy EductorVikk SuriyaNo ratings yet

- Selection of PumpsDocument8 pagesSelection of Pumpssmohsinshah9492100% (9)

- Liquid Ring PumpsDocument3 pagesLiquid Ring PumpsLokesh RavichandranNo ratings yet

- Presentation 2 26 FebDocument27 pagesPresentation 2 26 FebMohamed ElabbasyNo ratings yet

- Pump Theory and CharacteristicsDocument46 pagesPump Theory and Characteristicsandrej.sukoraNo ratings yet

- Flush ValveDocument4 pagesFlush Valveelvacas100% (1)

- Pages From Centrifugal Pumps HandbookDocument4 pagesPages From Centrifugal Pumps HandbookSHINo ratings yet

- Rotary PD Pump Inlet Pressure RequirementsDocument4 pagesRotary PD Pump Inlet Pressure RequirementsRicardo BecNo ratings yet

- Hydraulic Circuit BookDocument52 pagesHydraulic Circuit BookwalkercadillacNo ratings yet

- The Impact of Off BEP Pump Operation (CE)Document1 pageThe Impact of Off BEP Pump Operation (CE)jdgh1986No ratings yet

- Plumbing For Non Mechanical EngineersDocument61 pagesPlumbing For Non Mechanical Engineersmohd farhan ariff zaitonNo ratings yet

- Pump PresentationDocument47 pagesPump Presentationmdzuljpi100% (2)

- 3c CENTRIFUGAL PUMP FAMILIARISATIONDocument5 pages3c CENTRIFUGAL PUMP FAMILIARISATIONДмитро100% (1)

- Pressure Reducing Valves For Steam - TLV - A Steam Specialist Company (Worldwide)Document4 pagesPressure Reducing Valves For Steam - TLV - A Steam Specialist Company (Worldwide)Khurram BasheerNo ratings yet

- Brochure Pneumatic atomizingNEWDocument32 pagesBrochure Pneumatic atomizingNEWGastón CortezNo ratings yet

- Vent Away Condensate Pump Frustrations in A FlashDocument6 pagesVent Away Condensate Pump Frustrations in A FlashBramJanssen76100% (1)

- Avoid Cavitation in Centrifugal PumpsDocument6 pagesAvoid Cavitation in Centrifugal PumpsMatiasefloresNo ratings yet

- Cryomec Supercharger PDFDocument2 pagesCryomec Supercharger PDFDeepak UpadhyayNo ratings yet

- Fire Fighting Course Uploaded by Hady HabibDocument148 pagesFire Fighting Course Uploaded by Hady HabibaxelNo ratings yet

- Nanobubble Generator: Features & BenefitsDocument2 pagesNanobubble Generator: Features & BenefitsLuis BricenhoNo ratings yet

- L1 - Pumps ReviewerDocument3 pagesL1 - Pumps ReviewerJamie RapajonNo ratings yet

- Baker Pressure Relief Sub For Pumping Wells: Remedial Systems Technical UnitDocument2 pagesBaker Pressure Relief Sub For Pumping Wells: Remedial Systems Technical Uniteberthson hernandezNo ratings yet

- Vacuum Pumps and Compressors For The Electric Power IndustryDocument6 pagesVacuum Pumps and Compressors For The Electric Power IndustryPinky BasuNo ratings yet

- A Simple Ejector ModificationDocument4 pagesA Simple Ejector ModificationNaiduJagarapuNo ratings yet

- Horizontal Multi-Stage Jet Pumps "HMS-1FL" Series: ModelsDocument8 pagesHorizontal Multi-Stage Jet Pumps "HMS-1FL" Series: ModelsjuliusttNo ratings yet

- 9 - Cavitation in PumpsDocument45 pages9 - Cavitation in Pumpsmedo ElrefaeyNo ratings yet

- Dead Head HeatingDocument6 pagesDead Head HeatingSimon TudorNo ratings yet

- Beowawe Double Flash Cycle Geothermal Power Plant: The First Large-Capacity Module TurbineDocument8 pagesBeowawe Double Flash Cycle Geothermal Power Plant: The First Large-Capacity Module TurbineOmar HammadNo ratings yet

- Pumps, Fans and Blowers and CompressorsDocument80 pagesPumps, Fans and Blowers and CompressorsRomart Barosa100% (2)

- Vaccum Pumps PDFDocument1 pageVaccum Pumps PDFarunperthNo ratings yet

- Flow Initiationswabbing Reverse Circulation Coil TubingDocument17 pagesFlow Initiationswabbing Reverse Circulation Coil TubingMahtab SajnaniNo ratings yet

- Fire Fighting Course Uploaded by Hady HabibDocument148 pagesFire Fighting Course Uploaded by Hady HabibparthivNo ratings yet

- Pump Maintenance: Presented by Naushad Ahmad Department: Mechanical MaintDocument29 pagesPump Maintenance: Presented by Naushad Ahmad Department: Mechanical Maintnaushadmnnit100% (1)

- Hydraulic Dampers: 1. Description 2. ApplicationDocument20 pagesHydraulic Dampers: 1. Description 2. ApplicationJean DuboisNo ratings yet

- Single and Multistage Steam Jet Ejectors: TorinoDocument12 pagesSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiNo ratings yet

- Centrifugal Pumps TRGDocument35 pagesCentrifugal Pumps TRGsudhakarrajam2002No ratings yet

- PUMPSDocument4 pagesPUMPSGrezy MagnoNo ratings yet

- Centrifugal Pump Presentation 1671638565Document51 pagesCentrifugal Pump Presentation 1671638565mohd farhan ariff zaitonNo ratings yet

- PumpDocument4 pagesPumpsaiemNo ratings yet

- Fire Fighting CourseDocument147 pagesFire Fighting Coursejiguparmar20094903No ratings yet

- PUMPSDocument51 pagesPUMPSNikhil DewalkarNo ratings yet

- Ingles DefinitivoDocument1 pageIngles DefinitivoErick VanegasNo ratings yet

- Fluid Oscillation Technical PaperDocument11 pagesFluid Oscillation Technical PaperadrianioantomaNo ratings yet

- Jet Pump CXDocument18 pagesJet Pump CXBramasto MuhammadNo ratings yet

- 354-360 Nirmal BaisDocument7 pages354-360 Nirmal Baisromie NugrahaNo ratings yet

- The Gentle Giant of NiederaussemDocument6 pagesThe Gentle Giant of Niederaussemjayesh gohilNo ratings yet

- NPR250 Diaphragm Valve Pressure Reducing ServiceDocument2 pagesNPR250 Diaphragm Valve Pressure Reducing ServicePedro A Pinzon MNo ratings yet

- Barcenas Auxmach Prelim Lec Assign2Document4 pagesBarcenas Auxmach Prelim Lec Assign2Barcenas Roger Jr.No ratings yet

- Technical Bulletin 1Document8 pagesTechnical Bulletin 1RANAIVOARIMANANANo ratings yet

- General Information: 6.1 Vacuum Pump SystemsDocument6 pagesGeneral Information: 6.1 Vacuum Pump SystemsMaximo Biarrieta RodriguezNo ratings yet

- Pump-Pipe Systems Design-1Document64 pagesPump-Pipe Systems Design-1Neetor TendekayiNo ratings yet

- Pump FullDocument44 pagesPump FullLộc Hoàng VănNo ratings yet

- Cavitation in Centrifugal PumpDocument23 pagesCavitation in Centrifugal PumpmoffatdabNo ratings yet

- Reverse Osmosis Treatment of Drinking WaterFrom EverandReverse Osmosis Treatment of Drinking WaterRating: 3.5 out of 5 stars3.5/5 (4)

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsFrom EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Plate Heat ExchangerDocument1 pagePlate Heat ExchangerMohamed FathyNo ratings yet

- Valves: 1 - Gate 2 - Plug 3 - Globe 4 - Ball 5 - Butterfly 6 - Diaphragm 7 - Pinch 8 - Relief 9 - CheckDocument1 pageValves: 1 - Gate 2 - Plug 3 - Globe 4 - Ball 5 - Butterfly 6 - Diaphragm 7 - Pinch 8 - Relief 9 - CheckAhmad DeyabNo ratings yet

- Combined Heat and PowerDocument19 pagesCombined Heat and PowerAhmad DeyabNo ratings yet

- Compressors CLASSIFICATIONDocument1 pageCompressors CLASSIFICATIONAhmad DeyabNo ratings yet

- Area Tolerance & NFP Diam FactorDocument1 pageArea Tolerance & NFP Diam FactorAhmad DeyabNo ratings yet

- Sherwood/Leva/Eckert GPDC Pressure Drop Correlation For PackingDocument3 pagesSherwood/Leva/Eckert GPDC Pressure Drop Correlation For PackingAhmad Deyab100% (1)

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 pagesBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNo ratings yet

- Steam Velocity Chart ExampleDocument2 pagesSteam Velocity Chart ExampleAhmad Deyab100% (1)

- LinkedIn-Pump Vendor Data Sheet and Curve PDFDocument9 pagesLinkedIn-Pump Vendor Data Sheet and Curve PDFBehnaz Motamed100% (1)

- Advanced Process Control-HYSYSDocument27 pagesAdvanced Process Control-HYSYSAhmad DeyabNo ratings yet

- Active Energy Efficiency Using Speed ControlDocument25 pagesActive Energy Efficiency Using Speed ControlAhmad DeyabNo ratings yet

- Performance of Centrifugal PumpsDocument52 pagesPerformance of Centrifugal Pumpsvisitabhinav100% (4)

- TEG With HysysDocument2 pagesTEG With HysysAhmad DeyabNo ratings yet

- ATM CDU Distillation in Aspen HYSYS V10Document27 pagesATM CDU Distillation in Aspen HYSYS V10Ahmad Deyab100% (2)

- Reports in HysysDocument6 pagesReports in HysysAhmad DeyabNo ratings yet

- Lecture1 2Document31 pagesLecture1 2Ahmad DeyabNo ratings yet

- Best Practice Guide For EE ProjectsDocument45 pagesBest Practice Guide For EE ProjectsAhmad DeyabNo ratings yet

- Grasses As EnergyDocument134 pagesGrasses As EnergyAhmad DeyabNo ratings yet

- PVC Vs HDPEDocument8 pagesPVC Vs HDPELuisPajueloNo ratings yet

- Saf NetDocument6 pagesSaf NetLokoNo ratings yet

- Francis Turbine Formulas - enDocument10 pagesFrancis Turbine Formulas - ensivakumar subramanianNo ratings yet

- Lab Manual Sem 1 2020-2021 PDFDocument24 pagesLab Manual Sem 1 2020-2021 PDFDinesh RaviNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsinnovativekarthiNo ratings yet

- Ssi LC 12 2021Document23 pagesSsi LC 12 2021Validaciones VicarNo ratings yet

- Air Conditioner - FBDocument79 pagesAir Conditioner - FBMuhammad Purwa PrasetyaNo ratings yet

- Chemical Engineering MSC PDFDocument24 pagesChemical Engineering MSC PDFJoão Gabriel GarciaNo ratings yet

- w2p All Product CatalogueDocument10 pagesw2p All Product CatalogueAngirishNo ratings yet

- Complete Details of Our Requirements by GFDocument6 pagesComplete Details of Our Requirements by GFabhijitNo ratings yet

- Catologue Mang MBR LG-KOReD 03.2021Document16 pagesCatologue Mang MBR LG-KOReD 03.2021shjnbe18No ratings yet

- Chemical Dosing GuideDocument4 pagesChemical Dosing GuideBaskar KannaiahNo ratings yet

- Jones EngineeringDocument5 pagesJones EngineeringPreciousNo ratings yet

- Report M&e Function Ventilation SystemDocument8 pagesReport M&e Function Ventilation SystemAquw ArishaNo ratings yet

- Instrumentation Design BasicsDocument28 pagesInstrumentation Design BasicsCharles ChettiarNo ratings yet

- A33a PMS PDFDocument5 pagesA33a PMS PDFS.selvakumarNo ratings yet

- ERTWF - Screw Chiller Shockwave Product Report (Sao-Tam Giac)Document2 pagesERTWF - Screw Chiller Shockwave Product Report (Sao-Tam Giac)Vu Thieu TuanNo ratings yet

- Reguladores de PresionDocument7 pagesReguladores de PresiondanielNo ratings yet

- Lecture 1 Surface and Interfacial PhenomenaDocument26 pagesLecture 1 Surface and Interfacial Phenomenabattal eduNo ratings yet

- Olga For Wells PapersDocument7 pagesOlga For Wells PapersĐức TrầnNo ratings yet

- Design and Operation of High-Rate Filters-Part 1Document11 pagesDesign and Operation of High-Rate Filters-Part 1305773253No ratings yet

- 3 - WSP-02-WS-OGO - Rev0Document37 pages3 - WSP-02-WS-OGO - Rev0ThalesSouzaNo ratings yet

- SPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesDocument9 pagesSPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesSofiaNo ratings yet

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocument24 pagesTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsmarsulexNo ratings yet

- A Look at Hot Gas Defrost: Figure 1 Is A Diagram of An Ammonia Air Unit Designed ForDocument1 pageA Look at Hot Gas Defrost: Figure 1 Is A Diagram of An Ammonia Air Unit Designed ForBen MusimaneNo ratings yet

- Flowmeter Selection MatrixDocument1 pageFlowmeter Selection Matrixmilton1987No ratings yet

- Solar - Collectors - and - ApplicationsDocument121 pagesSolar - Collectors - and - Applicationsladybuzz89No ratings yet

Pumps 2

Pumps 2

Uploaded by

Ahmad DeyabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pumps 2

Pumps 2

Uploaded by

Ahmad DeyabCopyright:

Available Formats

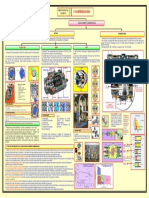

MODULE # 1

MECHANICAL

BASICS PUMPS

DISPLACEMENT PUMPS

FIRST SLIDE (1 OF 2)

DYNAMIC PUMPS

1- CAVITATION

1- cavitation is the formation of vapor bubbles in any flow that is subjected SPECIAL CENTRIFUGAL

to an ambient pressure equal to or less than the vapor pressure of the liquid 1- A Centrifugal Pump Use A Rotating Impeller To Add Velocity To The Liquid Being Pumped.

being pumped. 2- Within The Pump, The Velocity Of The Liquid Is Generated By The Centrifugal Force.

2- cavitation damage is the loss of material produced JET EJECTOR HYDRAULIC RAM 3- The Velocity Of The Solution Is Converted Within Internal Restrictions Within The Pump To

COLLAPSE OF

by the collapse of the vapor bubbles against the VAPOUR BUBBLES

Into Pressure.

surfaces of the impeller or casing. Formation of these 1- A Surface Mounted Centrifugal Pump That 1- Use The Energy Of A Large Amount Of 4- Used For Liquids That Are Water Like Viscosity And When Quantities Of Flow Are Large

bubbles cannot occur if the net positive suction head Uses An “Ejector” Device To Augment Its Water Falling A Small Height To Lift A Small Compared To The Pressure Requirements.

supplied, or NPSHA, exceeds the NPSH required for Suction Capacity. The Ejector May Be Down In Amount Of That Water To A Much Greater

cavitation inception. The Well , To Assist The Pump In Overcoming Height.

The Limitations Of Suction AXIAL FLOW RADIAL FLOW MIXED FLOW

3- life cycle of a bubble to be on the order of 0.003 s.

CRYOGENIC

4- The bubbles rebounded following the initial collapse

and caused pitting of the boundary. Pressures on the order of 104 atm have been estimated during 1- The Regime Of Cryogenic Technology Has Been Generally Taken To Indicate

collapse of a bubble. All known materials can be damaged by exposure to bubble collapse for a sufficiently Temperatures Colder Than 100°F (73°C). Fluids Such As Liquid Oxygen,

long time. Nitrogen, Hydrogen, Helium, Argon, Methane, And Ethane, With Normal

Boiling Points Below 100°F (73°C) Are Called Cryogenic Fluids.

2- NET POSITIVE SUCTION HEAD (NPSH) Axial-flow Radial-flow Mixed-flow

2- For The Pump Designer, The Cryogenic Regime Requires Consideration Of

1- NPSH is the pressure at the suction, above the liquid vapor pressure, which will allow the The Effect Of Low Temperatures On The Properties Of Construction

pump to operate without, cavitations or vapor lock problems. Materials And The Effect Of Varying Shrinkage Rates On Critical Fits And

Clearances. The Problem Is Further Complicated By The Fact That Cryogenic

2- NPSH = SUCTION HEAD MINUS LIQUID VAPOUR PRESSURE. There fore, NPSH must Fluids Are Stored At Near Atmospheric Pressure And Must Be Pumped At Or

always be a positive figure. Near Their Normal Boiling Point, So The Only NPSH Available Is That Due To

The Liquid Level Above The Pump Suction.

3- BEARING HOUSING LUBRICATION (CONSTANT LEVEL OILER)

1- The Oil Stays In The Bottle As Long As The Oil Level In The LIQUEFIED HYDROCARBON GASES

Bearing Housing Is Level With The Mouth Of The Bottle.

1- The Cryogenic Fluids Encountered In This Service Are Primarily LNG (A Mixture That Is Normally More Than 90%

2- When The Oil Level Drops, Air Enters The Bottle Allowing Oil To

Methane), Ethylene, And Ethane, Along With The Liquefied Petroleum Gases (LPG) Propane And Butane.

Flow Out Until The Oil Level In The Bearing Housing Is Again Up To

The Mouth Of The Bottle.

2- A Novel Approach To Pumping These Fluids Was Introduced In 1959 With The Application Of The Submerged

Electric-motor-driven Pump. Because These Fluids Are Excellent Dielectrics, Part Of The Pumped Fluid Stream Can

3- The Oil Level In The Bearing Housing Therefore Stays Constant.

Be Directed Through The Motor To Cool It And Lubricate The Bearings.

The Oiler Is Usually Set So That The Oil Either:

There Is No Need To Can Or Treat The Windings With Anything Other Than Specially Selected Varnishes. Many

1. Covers Half Of The Lowest Ball In A Flood Oil Lubricated Ball Bearing, Or

2. Is ¼” Above The Bottom Of The Oil Ring In A Ring Oiled Bearing. Advantages Accrue To This Design, Such As

NOTE • No Cool-down Requirement On Pumps Installed In Tanks SINGLE STAGE CENTRIFUGAL PUMP

• High Inherent Reliability Due To Protection From Corrosion And Humidity And Elimination Of Shaft Seal

• Low Hazard Due To 100% Rich Environment

1- OIL LEVEL IN THE

• Minimal Differential Shrinkage Problems

OILER DOESN’T

• Capability Of Directing Rejected Heat In Accordance With Designer’s Wishes

INDICATE THE OIL SUBMERGED

LEVEL IN THE CRYOGENIC PUMP

BEARING HOUSING. PUMP SEALING DEVICES

2- THE CORRECT OIL

1-PACKING

LEVEL IN THE

BEARING HOUSING Packing Is Used In The Stuffing Box Of A Centrifugal

APPEARS IN THE Pump To Control The Leakage Of The Pumped

SIGHT GLASS. Liquid Out, Or The Leakage Of Air In. The Three

Major Virtues Of A Packed Stuffing Box Are: Stuffing Box With Lantern Ring Stuffing Box and Packing

1- It Is Relatively Inexpensive In Initial Cost.

4-WEARING RINGS Shaft Sleeve

2- It Rarely Is The Cause Of An Unscheduled Shutdown Of The Pump Since Its

1- For A Pump To Operate Correctly There Must Be A Physical Separation Sealing Efficiency Usually Deteriorates Slowly.

Between The High And Low-pressure Sides. Other Wise, Fluid Would Simply

Circulate From The High-pressure Side To The Low Pressure Are Side And Be 3- To Compensate For Wear, The Packing Can Be Adjusted Or Completely Replaced

Re-pumped. Without Disassembly Of The Pump.

2- When This Fluid Passes From High To Low Pressure Side Some Solids Pass

As Well. These Solids Can Cause The Impeller And Casing To Wear. 2-MECHanical SEALS

A mechanical seal is a sealing device that provides a seal

3- Wearing Ring Prevent Damage To Impeller And Casing. They Are Usually between rotating and stationary parts, thus keeping the liquid

Made Of The Same Material As The Impeller And Casing. being pumped inside the pump. Today, the design of liquid

handling equipment with rotating parts usually include the

features necessary for the use of a mechanical seal.

Some of the advantages mechanical seals offer over

conventional packing include:

Rotating Seal Stationary Seal

1. Reduced friction and power losses because of lower drag in the stuffing box.

Flat type rings L-Type Rings 2. Reduced leakage from the stuffing box. 3. Reduced shaft or sleeve wear. 4. Reduced maintenance.

You might also like

- Introduction Aspen AdsorptionDocument191 pagesIntroduction Aspen AdsorptionAhmad Deyab100% (2)

- Column Flooding CalculationsDocument6 pagesColumn Flooding CalculationsAhmad DeyabNo ratings yet

- Meaning of Flooding, Weeping, FoamingDocument1 pageMeaning of Flooding, Weeping, FoamingAhmad DeyabNo ratings yet

- NGL Fractionation Using HYSYSDocument30 pagesNGL Fractionation Using HYSYSAhmad Deyab100% (3)

- Hydraulic Schematic 785C PDFDocument13 pagesHydraulic Schematic 785C PDFDany LeaNo ratings yet

- Branch Reinforcement - ASME 31.1Document8 pagesBranch Reinforcement - ASME 31.1zakir84md3639No ratings yet

- Capillary Tubing SizesDocument3 pagesCapillary Tubing Sizesgoodti100% (2)

- Self Priming PumpsDocument4 pagesSelf Priming PumpsMUHAMMAD AWAIS UR REHMANNo ratings yet

- Sir. Linex Fluid MachineryDocument160 pagesSir. Linex Fluid MachineryBrian Montes Bagarinao100% (1)

- Refrigeration Troubleshooting GuideDocument8 pagesRefrigeration Troubleshooting GuideJuan Jose Ramirez CorralesNo ratings yet

- Penberthy EductorDocument16 pagesPenberthy EductorVikk SuriyaNo ratings yet

- Selection of PumpsDocument8 pagesSelection of Pumpssmohsinshah9492100% (9)

- Liquid Ring PumpsDocument3 pagesLiquid Ring PumpsLokesh RavichandranNo ratings yet

- Presentation 2 26 FebDocument27 pagesPresentation 2 26 FebMohamed ElabbasyNo ratings yet

- Pump Theory and CharacteristicsDocument46 pagesPump Theory and Characteristicsandrej.sukoraNo ratings yet

- Flush ValveDocument4 pagesFlush Valveelvacas100% (1)

- Pages From Centrifugal Pumps HandbookDocument4 pagesPages From Centrifugal Pumps HandbookSHINo ratings yet

- Rotary PD Pump Inlet Pressure RequirementsDocument4 pagesRotary PD Pump Inlet Pressure RequirementsRicardo BecNo ratings yet

- Hydraulic Circuit BookDocument52 pagesHydraulic Circuit BookwalkercadillacNo ratings yet

- The Impact of Off BEP Pump Operation (CE)Document1 pageThe Impact of Off BEP Pump Operation (CE)jdgh1986No ratings yet

- Plumbing For Non Mechanical EngineersDocument61 pagesPlumbing For Non Mechanical Engineersmohd farhan ariff zaitonNo ratings yet

- Pump PresentationDocument47 pagesPump Presentationmdzuljpi100% (2)

- 3c CENTRIFUGAL PUMP FAMILIARISATIONDocument5 pages3c CENTRIFUGAL PUMP FAMILIARISATIONДмитро100% (1)

- Pressure Reducing Valves For Steam - TLV - A Steam Specialist Company (Worldwide)Document4 pagesPressure Reducing Valves For Steam - TLV - A Steam Specialist Company (Worldwide)Khurram BasheerNo ratings yet

- Brochure Pneumatic atomizingNEWDocument32 pagesBrochure Pneumatic atomizingNEWGastón CortezNo ratings yet

- Vent Away Condensate Pump Frustrations in A FlashDocument6 pagesVent Away Condensate Pump Frustrations in A FlashBramJanssen76100% (1)

- Avoid Cavitation in Centrifugal PumpsDocument6 pagesAvoid Cavitation in Centrifugal PumpsMatiasefloresNo ratings yet

- Cryomec Supercharger PDFDocument2 pagesCryomec Supercharger PDFDeepak UpadhyayNo ratings yet

- Fire Fighting Course Uploaded by Hady HabibDocument148 pagesFire Fighting Course Uploaded by Hady HabibaxelNo ratings yet

- Nanobubble Generator: Features & BenefitsDocument2 pagesNanobubble Generator: Features & BenefitsLuis BricenhoNo ratings yet

- L1 - Pumps ReviewerDocument3 pagesL1 - Pumps ReviewerJamie RapajonNo ratings yet

- Baker Pressure Relief Sub For Pumping Wells: Remedial Systems Technical UnitDocument2 pagesBaker Pressure Relief Sub For Pumping Wells: Remedial Systems Technical Uniteberthson hernandezNo ratings yet

- Vacuum Pumps and Compressors For The Electric Power IndustryDocument6 pagesVacuum Pumps and Compressors For The Electric Power IndustryPinky BasuNo ratings yet

- A Simple Ejector ModificationDocument4 pagesA Simple Ejector ModificationNaiduJagarapuNo ratings yet

- Horizontal Multi-Stage Jet Pumps "HMS-1FL" Series: ModelsDocument8 pagesHorizontal Multi-Stage Jet Pumps "HMS-1FL" Series: ModelsjuliusttNo ratings yet

- 9 - Cavitation in PumpsDocument45 pages9 - Cavitation in Pumpsmedo ElrefaeyNo ratings yet

- Dead Head HeatingDocument6 pagesDead Head HeatingSimon TudorNo ratings yet

- Beowawe Double Flash Cycle Geothermal Power Plant: The First Large-Capacity Module TurbineDocument8 pagesBeowawe Double Flash Cycle Geothermal Power Plant: The First Large-Capacity Module TurbineOmar HammadNo ratings yet

- Pumps, Fans and Blowers and CompressorsDocument80 pagesPumps, Fans and Blowers and CompressorsRomart Barosa100% (2)

- Vaccum Pumps PDFDocument1 pageVaccum Pumps PDFarunperthNo ratings yet

- Flow Initiationswabbing Reverse Circulation Coil TubingDocument17 pagesFlow Initiationswabbing Reverse Circulation Coil TubingMahtab SajnaniNo ratings yet

- Fire Fighting Course Uploaded by Hady HabibDocument148 pagesFire Fighting Course Uploaded by Hady HabibparthivNo ratings yet

- Pump Maintenance: Presented by Naushad Ahmad Department: Mechanical MaintDocument29 pagesPump Maintenance: Presented by Naushad Ahmad Department: Mechanical Maintnaushadmnnit100% (1)

- Hydraulic Dampers: 1. Description 2. ApplicationDocument20 pagesHydraulic Dampers: 1. Description 2. ApplicationJean DuboisNo ratings yet

- Single and Multistage Steam Jet Ejectors: TorinoDocument12 pagesSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiNo ratings yet

- Centrifugal Pumps TRGDocument35 pagesCentrifugal Pumps TRGsudhakarrajam2002No ratings yet

- PUMPSDocument4 pagesPUMPSGrezy MagnoNo ratings yet

- Centrifugal Pump Presentation 1671638565Document51 pagesCentrifugal Pump Presentation 1671638565mohd farhan ariff zaitonNo ratings yet

- PumpDocument4 pagesPumpsaiemNo ratings yet

- Fire Fighting CourseDocument147 pagesFire Fighting Coursejiguparmar20094903No ratings yet

- PUMPSDocument51 pagesPUMPSNikhil DewalkarNo ratings yet

- Ingles DefinitivoDocument1 pageIngles DefinitivoErick VanegasNo ratings yet

- Fluid Oscillation Technical PaperDocument11 pagesFluid Oscillation Technical PaperadrianioantomaNo ratings yet

- Jet Pump CXDocument18 pagesJet Pump CXBramasto MuhammadNo ratings yet

- 354-360 Nirmal BaisDocument7 pages354-360 Nirmal Baisromie NugrahaNo ratings yet

- The Gentle Giant of NiederaussemDocument6 pagesThe Gentle Giant of Niederaussemjayesh gohilNo ratings yet

- NPR250 Diaphragm Valve Pressure Reducing ServiceDocument2 pagesNPR250 Diaphragm Valve Pressure Reducing ServicePedro A Pinzon MNo ratings yet

- Barcenas Auxmach Prelim Lec Assign2Document4 pagesBarcenas Auxmach Prelim Lec Assign2Barcenas Roger Jr.No ratings yet

- Technical Bulletin 1Document8 pagesTechnical Bulletin 1RANAIVOARIMANANANo ratings yet

- General Information: 6.1 Vacuum Pump SystemsDocument6 pagesGeneral Information: 6.1 Vacuum Pump SystemsMaximo Biarrieta RodriguezNo ratings yet

- Pump-Pipe Systems Design-1Document64 pagesPump-Pipe Systems Design-1Neetor TendekayiNo ratings yet

- Pump FullDocument44 pagesPump FullLộc Hoàng VănNo ratings yet

- Cavitation in Centrifugal PumpDocument23 pagesCavitation in Centrifugal PumpmoffatdabNo ratings yet

- Reverse Osmosis Treatment of Drinking WaterFrom EverandReverse Osmosis Treatment of Drinking WaterRating: 3.5 out of 5 stars3.5/5 (4)

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsFrom EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Plate Heat ExchangerDocument1 pagePlate Heat ExchangerMohamed FathyNo ratings yet

- Valves: 1 - Gate 2 - Plug 3 - Globe 4 - Ball 5 - Butterfly 6 - Diaphragm 7 - Pinch 8 - Relief 9 - CheckDocument1 pageValves: 1 - Gate 2 - Plug 3 - Globe 4 - Ball 5 - Butterfly 6 - Diaphragm 7 - Pinch 8 - Relief 9 - CheckAhmad DeyabNo ratings yet

- Combined Heat and PowerDocument19 pagesCombined Heat and PowerAhmad DeyabNo ratings yet

- Compressors CLASSIFICATIONDocument1 pageCompressors CLASSIFICATIONAhmad DeyabNo ratings yet

- Area Tolerance & NFP Diam FactorDocument1 pageArea Tolerance & NFP Diam FactorAhmad DeyabNo ratings yet

- Sherwood/Leva/Eckert GPDC Pressure Drop Correlation For PackingDocument3 pagesSherwood/Leva/Eckert GPDC Pressure Drop Correlation For PackingAhmad Deyab100% (1)

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 pagesBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiNo ratings yet

- Steam Velocity Chart ExampleDocument2 pagesSteam Velocity Chart ExampleAhmad Deyab100% (1)

- LinkedIn-Pump Vendor Data Sheet and Curve PDFDocument9 pagesLinkedIn-Pump Vendor Data Sheet and Curve PDFBehnaz Motamed100% (1)

- Advanced Process Control-HYSYSDocument27 pagesAdvanced Process Control-HYSYSAhmad DeyabNo ratings yet

- Active Energy Efficiency Using Speed ControlDocument25 pagesActive Energy Efficiency Using Speed ControlAhmad DeyabNo ratings yet

- Performance of Centrifugal PumpsDocument52 pagesPerformance of Centrifugal Pumpsvisitabhinav100% (4)

- TEG With HysysDocument2 pagesTEG With HysysAhmad DeyabNo ratings yet

- ATM CDU Distillation in Aspen HYSYS V10Document27 pagesATM CDU Distillation in Aspen HYSYS V10Ahmad Deyab100% (2)

- Reports in HysysDocument6 pagesReports in HysysAhmad DeyabNo ratings yet

- Lecture1 2Document31 pagesLecture1 2Ahmad DeyabNo ratings yet

- Best Practice Guide For EE ProjectsDocument45 pagesBest Practice Guide For EE ProjectsAhmad DeyabNo ratings yet

- Grasses As EnergyDocument134 pagesGrasses As EnergyAhmad DeyabNo ratings yet

- PVC Vs HDPEDocument8 pagesPVC Vs HDPELuisPajueloNo ratings yet

- Saf NetDocument6 pagesSaf NetLokoNo ratings yet

- Francis Turbine Formulas - enDocument10 pagesFrancis Turbine Formulas - ensivakumar subramanianNo ratings yet

- Lab Manual Sem 1 2020-2021 PDFDocument24 pagesLab Manual Sem 1 2020-2021 PDFDinesh RaviNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsinnovativekarthiNo ratings yet

- Ssi LC 12 2021Document23 pagesSsi LC 12 2021Validaciones VicarNo ratings yet

- Air Conditioner - FBDocument79 pagesAir Conditioner - FBMuhammad Purwa PrasetyaNo ratings yet

- Chemical Engineering MSC PDFDocument24 pagesChemical Engineering MSC PDFJoão Gabriel GarciaNo ratings yet

- w2p All Product CatalogueDocument10 pagesw2p All Product CatalogueAngirishNo ratings yet

- Complete Details of Our Requirements by GFDocument6 pagesComplete Details of Our Requirements by GFabhijitNo ratings yet

- Catologue Mang MBR LG-KOReD 03.2021Document16 pagesCatologue Mang MBR LG-KOReD 03.2021shjnbe18No ratings yet

- Chemical Dosing GuideDocument4 pagesChemical Dosing GuideBaskar KannaiahNo ratings yet

- Jones EngineeringDocument5 pagesJones EngineeringPreciousNo ratings yet

- Report M&e Function Ventilation SystemDocument8 pagesReport M&e Function Ventilation SystemAquw ArishaNo ratings yet

- Instrumentation Design BasicsDocument28 pagesInstrumentation Design BasicsCharles ChettiarNo ratings yet

- A33a PMS PDFDocument5 pagesA33a PMS PDFS.selvakumarNo ratings yet

- ERTWF - Screw Chiller Shockwave Product Report (Sao-Tam Giac)Document2 pagesERTWF - Screw Chiller Shockwave Product Report (Sao-Tam Giac)Vu Thieu TuanNo ratings yet

- Reguladores de PresionDocument7 pagesReguladores de PresiondanielNo ratings yet

- Lecture 1 Surface and Interfacial PhenomenaDocument26 pagesLecture 1 Surface and Interfacial Phenomenabattal eduNo ratings yet

- Olga For Wells PapersDocument7 pagesOlga For Wells PapersĐức TrầnNo ratings yet

- Design and Operation of High-Rate Filters-Part 1Document11 pagesDesign and Operation of High-Rate Filters-Part 1305773253No ratings yet

- 3 - WSP-02-WS-OGO - Rev0Document37 pages3 - WSP-02-WS-OGO - Rev0ThalesSouzaNo ratings yet

- SPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesDocument9 pagesSPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesSofiaNo ratings yet

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocument24 pagesTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsmarsulexNo ratings yet

- A Look at Hot Gas Defrost: Figure 1 Is A Diagram of An Ammonia Air Unit Designed ForDocument1 pageA Look at Hot Gas Defrost: Figure 1 Is A Diagram of An Ammonia Air Unit Designed ForBen MusimaneNo ratings yet

- Flowmeter Selection MatrixDocument1 pageFlowmeter Selection Matrixmilton1987No ratings yet

- Solar - Collectors - and - ApplicationsDocument121 pagesSolar - Collectors - and - Applicationsladybuzz89No ratings yet