Professional Documents

Culture Documents

Damper Datasheet: Stack Damper Multiple Stack Control

Damper Datasheet: Stack Damper Multiple Stack Control

Uploaded by

Ajay BaggaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Damper Datasheet: Stack Damper Multiple Stack Control

Damper Datasheet: Stack Damper Multiple Stack Control

Uploaded by

Ajay BaggaCopyright:

Available Formats

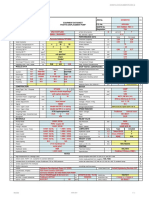

Ref.

EF18001

Doc. No. 7H01-FJ-301

Rev. 0

DAMPER DATASHEET UNIT. Reactor Feed Heater

TAG NO. 70-H-01

PAGES 1 OF 2

NO DAMPER NO. HV-260

1 SERVICE STACK DAMPER

2 TYPE (MULTIPLE / SINGLE LEAF / DIVERTER) MULTIPLE

3 LOCATION STACK

FUNCTION (CONTROL, TIGHT SHUT-OFF, ETC.) CONTROL

4

NORMAL POSITION FOR DAMPER OPEN

5 DUCT POSITION (VERTICAL / HORIZONTAL) VERTICAL

MATERIAL LHV 124

6 LINING DETAILS

THICKNESS 50 MM

7 DAMPER ELEVATION (m) EL. + 15.875

CLOSED FUNCTION

UPSTREAM MEDIUM Not applicable

UPSTREAM CONDITION MIN NOR MAX

OPERATING CASE

8 TEMPERATURE (0C)

PRESSURE (mmWC)

DOWNSTREAM MEDIUM

DOWNSTREAM CONDITION MIN NOR MAX

TEMPERATURE (0C)

PRESSURE (mmWC)

MINIMUM TIGHTNESS AGAINST

9

LEAKAGE (BASED ON FLOW) (%)

OPEN CONDITION

MEDIUM FLUE GAS

MIN NOR MAX

OPERATING CASE DESIGN

10 FLOW RATE (KG/HR) 10202

TEMPERATURE (0C) 288

UPSTREAM PRESSURE (mmWC) (-) 9.6

By damper

PRESSURE DROP (mmWC)

vendor

DENSITY (kg/m3) 0.601

0 06/07/2018 FIRST ISSUE DCa PBo PBo

Rev Date Description BY CHECKED APPROVED

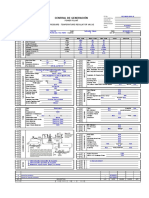

Ref. EF18001

Doc. No. 7H01-FJ-301

Rev. 0

DAMPER DATASHEET UNIT Reactor Feed Heater

TAG NO. 70-H-01

PAGES 2 OF 2

REV

0

DESIGN TEMPERATURE ( C) 338

11

DESIGN PRESSURE (mmWC) + 50

12 DUCT SIZE I/S PLATE (mm) ɸ 1830

13 FLANGE TO FLANGE DIMENSION (mm) 500

14 MAXIMUM TIME TO OPEN / CLOSE (sec) BY DAMPER VENDOR

BLADE SS 304

SUGGESTED MINIMUM MATERIAL OF

15 SHAFT SS 304

CONSTRUCTION

FRAME CS

ACTUATOR NOTE 2 (REFER ACTUATOR DATASHEET 0000-FS-898)

TYPE PNEUMATIC POWER CYLINDER (REFER ACTUATOR DATASHEET 0000-FS-898)

INSTRUMENT AIR SUPPLY PRESSURE

5 / 7 / 12 (Note 4)

(MIN / NOR / MAX) (kg/cm² g)

16

SIGNAL AIR PRESSURE (kg/cm² g)

DAMPER POSITION AT 0.2 kg/cm² g

DAMPER POSITION AT 1 kg/cm² g

ELECTROPNEUMATIC POSITIONER (YES / NO)

17

POSITION TRANSMITTER (YES / NO) / TAG No.

LIMIT SWITCHES (YES / NO)

18 TYPE

QUANTITY / TAG No. (REFER ACTUATOR DATASHEET 0000-FS-898 FOR ACTUATOR TYPE AND INSTRUMENT

ACCESSORIES)

SUPPLY VOLTAGE

SOLENOID VALVES

19

LIMIT SWITCHES

POSITION TRANSMITTER

20 SOLENOID VALVE (YES / NO) / TAG No.

21 ELECTRICAL AREA CLASSIFICATION

22 FAIL SAFE POSITION

23 INTERLOCK ACTUATION POSITION

NOTES :-

1 Dampers shall be provided with external position indicator which shall be visible while operating winch & cable arrangement located at grade.

2 Arrangement shall be provided to delink the pneumatic actuator / power cylinder and operate the damper manually with winch & cable arrangement from grade.

Damper shall attain fail safe position, as specified, in the event of failure of instrument air or signal. Positioner to be selected so that fail safe position is reached

3

on loss of signal. If required, counter weight arrangement shall be provided.

Instrument air pressure specified is at battery limit. Adequate pressure loss across FR, tubing, etc., where ever applicable, to be considered for designing power

4

cylinder. As a minimum, actuator shall be sized for 4.2 kg/cm2g instrument air pressure as per API 560.

4 Flue gas to be considered:

1) Rich Natural gas composition %vol: O2: 3.19 / CO2: 8.85 / H2O:15.95 / N2: 71.12 / Ar: 0.88 2) Lean

5

Natural gas composition %vol: O2: 3.18 / CO2: 8.62 / H2O:16.33 / N2: 70.99 / Ar: 0.88 3) LPG %vol: O2:

3.25 / CO2: 8.62 / H2O:13.48 / N2: 72.41 / Ar: 0.90 4) H2 Rich gas %vol: O2: 3.02 /

CO2: 2.09 / H2O: 26.83 / N2: 67.23 / Ar: 0.84

6 Position Transmitter shall be 4-20 mA "Smart" type with HART protocol

Vendor shall prepare and submit a suitable damper control scheme taking care of all operating / fail safe requirements. All instrumentation required for safe

7

damper operation shall be included by the vendor.

8 Vendor shall furnish damper characteristic curves showing % angle of opening vs flowrate for regulating dampers.

9 Solenoid valves and limit switches with flying leads are not acceptable.

10

12

13

14

You might also like

- Iso 3746 - 1996Document37 pagesIso 3746 - 1996Ajay BaggaNo ratings yet

- Ginaf Systeemboek Hpvs EvsDocument157 pagesGinaf Systeemboek Hpvs Evsfish11173100% (3)

- Spring Support Data Sheet-Process AreaDocument1 pageSpring Support Data Sheet-Process AreaArash AghagolNo ratings yet

- EW160Document13 pagesEW160Nihad volvo50% (2)

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 pageMagnetrol TD2-8D00-032 + Tma-A210-007BRUNONo ratings yet

- Shell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupDocument3 pagesShell & Tube Gas HEATER EXCHANGER (P-1233002) : Srge/EsupRobles DreschNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument4 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- (cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationDocument2 pages(cm3) (MM) (MM) (KG) (°C) : Compressor Applicationأبو زينب المهندسNo ratings yet

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselDocument4 pages45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalNo ratings yet

- T4638 DatasheetDocument12 pagesT4638 DatasheetMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

- MixerDocument4 pagesMixerMarcelo PerettiNo ratings yet

- Feuilles de Donnees Transmetteur de NiveauDocument5 pagesFeuilles de Donnees Transmetteur de NiveauAHMED AMIRA100% (1)

- AGITATORDATA HWPDocument1 pageAGITATORDATA HWPbrat.jose2023No ratings yet

- Ebara ManualDocument114 pagesEbara Manualantz12345100% (5)

- SP0793 3110 71 2602 0Document1 pageSP0793 3110 71 2602 0JULIO INQUILLAYNo ratings yet

- Differential Pressure SwitchDocument3 pagesDifferential Pressure SwitchJKKNo ratings yet

- Ficha Técnica GEDocument10 pagesFicha Técnica GEMaria Hernandez RNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"DIESEL MOTORSNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- SHT Size: - A - : Certificate of Compliance RequiredDocument1 pageSHT Size: - A - : Certificate of Compliance RequiredMike TuccioNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- SPP SP2021 ON PR 112 P 0101, Process+equipment+data+sheet+for+112 P 101, R4Document3 pagesSPP SP2021 ON PR 112 P 0101, Process+equipment+data+sheet+for+112 P 101, R4ali khosravinarNo ratings yet

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Ash 13.8 em 411B - AsbuiltDocument25 pagesAsh 13.8 em 411B - AsbuiltMr IlchamNo ratings yet

- VP-PP4-MP-255-PK-1401-0431 - Rev.0 - Vendor Document For H2so4 Dosing PumpDocument10 pagesVP-PP4-MP-255-PK-1401-0431 - Rev.0 - Vendor Document For H2so4 Dosing PumpMinh PhamNo ratings yet

- 10J01762 Ict DS 000 012 D0Document14 pages10J01762 Ict DS 000 012 D0Sardar PerdawoodNo ratings yet

- PRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpDocument3 pagesPRAI-M0-YT01-LA-7500 - As-Built - Data Sheet For Feed Water PumpSuman GhoshNo ratings yet

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNo ratings yet

- 0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2Document6 pages0P16-I-IN-DTS-01-007 Datasheet For Temperature Gauge - Rev2fathan fathullahNo ratings yet

- GVAR360 HTFF354AS Service ManualDocument21 pagesGVAR360 HTFF354AS Service ManualUEENo ratings yet

- A3080 6040 Dat MC 142 eDocument11 pagesA3080 6040 Dat MC 142 erameshqcNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEnokarajuNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Reactor Design Calculation 06062123Document2 pagesReactor Design Calculation 06062123projectliterature767835No ratings yet

- Page 5Document1 pagePage 5Anuj VermaNo ratings yet

- Drawing PDFDocument18 pagesDrawing PDFJeremiah LangoeyNo ratings yet

- Bosch Rexroth - Datasheet - Counterbalance ValvesDocument2 pagesBosch Rexroth - Datasheet - Counterbalance ValvesDiogo LuisNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- VP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPDocument10 pagesVP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPMinh PhamNo ratings yet

- Data Sheet For Temperature Gauges and ThermowellsDocument29 pagesData Sheet For Temperature Gauges and ThermowellsSardar PerdawoodNo ratings yet

- 5500 I.D. 1400 I.D. 1000: Vessel SpecificationDocument2 pages5500 I.D. 1400 I.D. 1000: Vessel SpecificationMustafa AhsanNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument7 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- DS Pressure Transmitter PDFDocument3 pagesDS Pressure Transmitter PDFadrian bargasNo ratings yet

- Nuclear Fuel Complex: Tata Projects LimitedDocument4 pagesNuclear Fuel Complex: Tata Projects LimitedAniket GaikwadNo ratings yet

- Espicificaciones Mecanicos de Bombas de Impulsion Datasheet 54-P01A/B/CDocument3 pagesEspicificaciones Mecanicos de Bombas de Impulsion Datasheet 54-P01A/B/Cmauro.vergaraNo ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- StanadyneDocument1 pageStanadyneJunior IungNo ratings yet

- Parametros SopladoraDocument7 pagesParametros SopladoraOswaldo LinaresNo ratings yet

- Sp0793 - Pueblo Viejo PH 1: Pull Wire SwitchDocument1 pageSp0793 - Pueblo Viejo PH 1: Pull Wire SwitchJULIO INQUILLAYNo ratings yet

- Daftar Kontrol 53711.2Document15 pagesDaftar Kontrol 53711.2Medy MdNo ratings yet

- Cone Strainer - DTS - JTB-RJJ000-L0-DTS-900-10901 Rev DDocument1 pageCone Strainer - DTS - JTB-RJJ000-L0-DTS-900-10901 Rev Ddanielph15No ratings yet

- TXTL-De-F1!07!032 - A - Gas Electric Heater For Auxiliary Power UnitDocument4 pagesTXTL-De-F1!07!032 - A - Gas Electric Heater For Auxiliary Power UnitMiguel Jiménez FloresNo ratings yet

- 3827-E10-062 - Two Position Valve - DDocument4 pages3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- Strength Calculation Sheet For Item No. C-053-12Document297 pagesStrength Calculation Sheet For Item No. C-053-12Urdian Syah100% (1)

- 2598 8410 DS P2232 33 1 - A2Document7 pages2598 8410 DS P2232 33 1 - A2Ronald VillalongaNo ratings yet

- Central de Generación: Power Plant Pressure - Temperature Regulator ValveDocument1 pageCentral de Generación: Power Plant Pressure - Temperature Regulator Valvejuan carlos suaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- GS RC The 001 en 01Document10 pagesGS RC The 001 en 01Ajay BaggaNo ratings yet

- GS RC Ins 200 en 01 PDFDocument41 pagesGS RC Ins 200 en 01 PDFAjay Bagga100% (2)

- GS RC Ecp 100 en 01Document85 pagesGS RC Ecp 100 en 01Ajay BaggaNo ratings yet

- General Specification: Welding - MaterialsDocument18 pagesGeneral Specification: Welding - MaterialsAjay Bagga100% (1)

- E1696-Ctse1000 RDDocument41 pagesE1696-Ctse1000 RDAjay BaggaNo ratings yet

- General Specification: Steel StructuresDocument12 pagesGeneral Specification: Steel StructuresAjay Bagga100% (2)

- E1696-Ctce1000 RDDocument11 pagesE1696-Ctce1000 RDAjay BaggaNo ratings yet

- Preferred Manufacturer and Fabricator List Overview: PSX - Steel - Mills - PMFL-SHP2 Page1of 3Document3 pagesPreferred Manufacturer and Fabricator List Overview: PSX - Steel - Mills - PMFL-SHP2 Page1of 3Ajay BaggaNo ratings yet

- Pip-Elemt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetDocument9 pagesPip-Elemt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetAjay BaggaNo ratings yet

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- 071973C G00 PP 908 0BDocument13 pages071973C G00 PP 908 0BAjay BaggaNo ratings yet

- Procedure For Positive Material Identification at Vendor'S WorksDocument7 pagesProcedure For Positive Material Identification at Vendor'S WorksAjay BaggaNo ratings yet

- Is 432 Part I-1982 PDFDocument11 pagesIs 432 Part I-1982 PDFAjay BaggaNo ratings yet

- 81H0-FC-350 Damper FSDocument2 pages81H0-FC-350 Damper FSAjay BaggaNo ratings yet

- D792Document6 pagesD792Pankaj KushwahaNo ratings yet

- Is.1367.14.1.2002 - ISO 3506-1 1997Document25 pagesIs.1367.14.1.2002 - ISO 3506-1 1997Ajay BaggaNo ratings yet

- Is 1893 2002 Part1 Design of Structures EarthquakesDocument41 pagesIs 1893 2002 Part1 Design of Structures EarthquakesPriyanka100% (4)

- IS 1367-PART - 14-Sec1-2002Document25 pagesIS 1367-PART - 14-Sec1-2002Ajay BaggaNo ratings yet

- Trane Model CRHR-400 Physical and Electrical SpecificationsNEWDocument1 pageTrane Model CRHR-400 Physical and Electrical SpecificationsNEWalfredjajNo ratings yet

- Kamco AE SyllubusDocument3 pagesKamco AE SyllubusAmalTSathyan100% (1)

- Nissan D22 ZD30 Turbo SpecsDocument4 pagesNissan D22 ZD30 Turbo SpecsDesron SamuelNo ratings yet

- Tensiometro InstructionsDocument2 pagesTensiometro InstructionsKike DavilaNo ratings yet

- SDLG Wheel Loader LG968 - E6811213A36 ENGINE DongFeng SC11CB C6121Document330 pagesSDLG Wheel Loader LG968 - E6811213A36 ENGINE DongFeng SC11CB C6121Emmanuel Garcia Ozan100% (2)

- 2015-08-17 ZPMC1080 JYHG170 Final DrawingsDocument50 pages2015-08-17 ZPMC1080 JYHG170 Final Drawingssep650cengrNo ratings yet

- Electronic Throttle Body Datasheet 51 en 10726070795Document5 pagesElectronic Throttle Body Datasheet 51 en 10726070795DxArmyMember001No ratings yet

- 3900 - Trane Ccud 104Document6 pages3900 - Trane Ccud 104HoàngViệtAnhNo ratings yet

- Analysis of Block Vibrations Induced by Combustion Chamber Pressure in A Diesel EngineDocument10 pagesAnalysis of Block Vibrations Induced by Combustion Chamber Pressure in A Diesel Engineganesh naniNo ratings yet

- 3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Connecting RodDocument5 pages3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Connecting RodPhamLeDanNo ratings yet

- Catalogo KSB SPBlocDocument8 pagesCatalogo KSB SPBlocRuddy Fabrizio Galvez Justiniano0% (1)

- Assignment 3Document7 pagesAssignment 3Surenderan LoganNo ratings yet

- The Hybrid Stepper Motor Modeling in Simulink: 978-1-4799-7306-4/15/$3l.00 Ieee 282Document4 pagesThe Hybrid Stepper Motor Modeling in Simulink: 978-1-4799-7306-4/15/$3l.00 Ieee 282Iyyappan VNo ratings yet

- Data-Sheet 2D View - Page 1/2Document2 pagesData-Sheet 2D View - Page 1/2RizkiWiraPratamaNo ratings yet

- 34 Avanza (Cont. Next Page) : Engine Control (From Aug. 2015 Production)Document5 pages34 Avanza (Cont. Next Page) : Engine Control (From Aug. 2015 Production)Wiro Anom100% (1)

- Order MaterialsDocument4 pagesOrder MaterialsAndri AjaNo ratings yet

- Parts List: RV-123/IRV403-90Document126 pagesParts List: RV-123/IRV403-90Ming Wey LimNo ratings yet

- Hydraulic Sheet Bending MachineDocument15 pagesHydraulic Sheet Bending MachineNitinNo ratings yet

- Control de Trasm 410g. 3 PDFDocument2 pagesControl de Trasm 410g. 3 PDFdavidNo ratings yet

- Ice PlantDocument14 pagesIce PlantJan GarciaNo ratings yet

- Compact Wheel LoadersDocument12 pagesCompact Wheel LoadersВолодимир КривкоNo ratings yet

- Synchronous Servo Motors: AutomationDocument32 pagesSynchronous Servo Motors: AutomationAllison GallowayNo ratings yet

- 1) The Bottle Opener Is An Example Of: Force, Work and EnergyDocument4 pages1) The Bottle Opener Is An Example Of: Force, Work and EnergyVinothini SreedharNo ratings yet

- 1150 Air Cat Impact Wrench SchematicsDocument1 page1150 Air Cat Impact Wrench Schematicssanop37428No ratings yet

- Komatsu Cp340nlc 7k Parts CatalogueDocument20 pagesKomatsu Cp340nlc 7k Parts CatalogueBlanch98% (63)

- TM044 TG - : CLARK TC C8602-146 REV.1 Assesment SheetDocument5 pagesTM044 TG - : CLARK TC C8602-146 REV.1 Assesment SheetXG WNo ratings yet

- Piaggio Liberty 125 - 150 4T I.E. Vietnam MY 2010 (EN)Document275 pagesPiaggio Liberty 125 - 150 4T I.E. Vietnam MY 2010 (EN)Manualles80% (10)

- WX 185Document324 pagesWX 185Александр Панкратов100% (1)