Professional Documents

Culture Documents

Articulo 1 PDF

Articulo 1 PDF

Uploaded by

Jennifer A. PatiñoCopyright:

Available Formats

You might also like

- Industrial Waste Water TreatmentDocument102 pagesIndustrial Waste Water TreatmentSaishiva Sukkala100% (1)

- Guidelines For Potato Farming in Zimbabwe: ©ziminvestors 2015 EditionDocument27 pagesGuidelines For Potato Farming in Zimbabwe: ©ziminvestors 2015 EditionAleck Mutiba100% (3)

- Acido LacticoDocument9 pagesAcido LacticoJuan Victor ChampeNo ratings yet

- Glutamic Acid 2 PDFDocument8 pagesGlutamic Acid 2 PDFneelNo ratings yet

- ScribdDocument9 pagesScribdSrinivas ReddyNo ratings yet

- Batch and Fed-Batch Production of Butyric Acid by Clostridium Butyricum ZJUCBDocument5 pagesBatch and Fed-Batch Production of Butyric Acid by Clostridium Butyricum ZJUCBapi-3743140No ratings yet

- Factors Regulating Production of Glucose Oxidase by Aspergillus NigerDocument5 pagesFactors Regulating Production of Glucose Oxidase by Aspergillus NigerI. Murali KrishnaNo ratings yet

- Aem00154 0187Document8 pagesAem00154 0187HonganhNo ratings yet

- 4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyDocument6 pages4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyOmar KHELILNo ratings yet

- Hanson 1972Document20 pagesHanson 1972Công Thành KiềuNo ratings yet

- Proponoic AcidDocument7 pagesProponoic AcidAnonymous SUbBZzNo ratings yet

- Single Cell ProductionDocument5 pagesSingle Cell Productioncha lieNo ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNo ratings yet

- El Sheekh2012Document8 pagesEl Sheekh2012Hoài Nam PhanNo ratings yet

- Continuous and Batch Cultures of Escherichia Coli KJ134 For Succinic Acid Fermentation: Metabolic Flux Distributions and Production CharacteristicsDocument10 pagesContinuous and Batch Cultures of Escherichia Coli KJ134 For Succinic Acid Fermentation: Metabolic Flux Distributions and Production CharacteristicsSyed ShahNo ratings yet

- Gluconic AcidDocument11 pagesGluconic AcidpalkybdNo ratings yet

- Chen 1996Document4 pagesChen 1996mplatonosNo ratings yet

- Sem Mod Cinet 2Document3 pagesSem Mod Cinet 2Jaza VlogsNo ratings yet

- High-Efficient Production of Citric Acid by Aspergillus Niger From High Concentration of Substrate Based On The Staged-Addition Glucoamylase StrategyDocument9 pagesHigh-Efficient Production of Citric Acid by Aspergillus Niger From High Concentration of Substrate Based On The Staged-Addition Glucoamylase StrategyAndriyani YaniNo ratings yet

- Gluconic Acid: Properties, Applications and Microbial ProductionDocument13 pagesGluconic Acid: Properties, Applications and Microbial ProductionDavid KehindeNo ratings yet

- Pilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourceDocument6 pagesPilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourcekopisusumantapNo ratings yet

- Production of L-Glutamic Acid by Immobilized Cell Reactor of The BacteriumDocument6 pagesProduction of L-Glutamic Acid by Immobilized Cell Reactor of The BacteriumTavo JGNo ratings yet

- Production of Biosurfactant From Torulopsis: BombicolaDocument4 pagesProduction of Biosurfactant From Torulopsis: BombicolaSui GenerisNo ratings yet

- Improvement of Yarrowia Lipolytica Lipase ProductionDocument4 pagesImprovement of Yarrowia Lipolytica Lipase ProductionjuanNo ratings yet

- The Response of Brewing Yeast To Acid WashingDocument9 pagesThe Response of Brewing Yeast To Acid WashingGary SadavageNo ratings yet

- Optimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003Document6 pagesOptimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003jmrozo3No ratings yet

- Repeated PH-stat Fed-Batch Fermentation For RhamnolipidDocument9 pagesRepeated PH-stat Fed-Batch Fermentation For Rhamnolipidsidikmar1425No ratings yet

- Influence of The Nitrogen Source On Saccharomyces Cerevisiae Anaerobic Growth and Product FormationDocument9 pagesInfluence of The Nitrogen Source On Saccharomyces Cerevisiae Anaerobic Growth and Product FormationGeraldiineDuqueSalazarNo ratings yet

- 95428-Article Text-246569-1-10-20131017Document7 pages95428-Article Text-246569-1-10-20131017احمد الدلالNo ratings yet

- Wang e Yang 2015Document10 pagesWang e Yang 2015Aline HunoNo ratings yet

- Differences in Rate of Ruminal Hydrogenation of C18 Fatty Acids in Clover and RyegrassDocument7 pagesDifferences in Rate of Ruminal Hydrogenation of C18 Fatty Acids in Clover and RyegrassMiguel Hulfan FoxNo ratings yet

- Hojo 1999Document11 pagesHojo 1999Berk YüzerNo ratings yet

- Bioetanol 1Document9 pagesBioetanol 1Ezequiel QuinterosNo ratings yet

- Alcoholic Fermentation With Different Initial Glucose Concentration Using Immobilized Yeast in Calcium Alginate GelDocument7 pagesAlcoholic Fermentation With Different Initial Glucose Concentration Using Immobilized Yeast in Calcium Alginate GelViệt Euro ĐinhNo ratings yet

- Effect of PH, Agitation and Aeration On Hyaluronic Acid Production Bystreptococcus ZooepidemicusDocument6 pagesEffect of PH, Agitation and Aeration On Hyaluronic Acid Production Bystreptococcus ZooepidemicusJesus C. MendozaNo ratings yet

- Kinetic Simple GoodDocument11 pagesKinetic Simple GoodReza MahoorNo ratings yet

- Ac Citrico 1Document14 pagesAc Citrico 1Maximiliano Rodriguez RiveroNo ratings yet

- Anti Fungal in BreadDocument6 pagesAnti Fungal in BreadRufa Lara MendezNo ratings yet

- Ethanol Production in A Hollow Fiber Bioreactor Using Saccharomyces CerevisiaeDocument5 pagesEthanol Production in A Hollow Fiber Bioreactor Using Saccharomyces CerevisiaeJose CarlosNo ratings yet

- Biotechnology Progress - 2008 - Lenihan - Developing An Industrial Artemisinic Acid Fermentation Process To Support TheDocument7 pagesBiotechnology Progress - 2008 - Lenihan - Developing An Industrial Artemisinic Acid Fermentation Process To Support The774hzz9zd8No ratings yet

- Bioproduction of Hydrogen by Simultaneous SaccharificationDocument8 pagesBioproduction of Hydrogen by Simultaneous SaccharificationProfessor Douglas TorresNo ratings yet

- Aplicacion FermentacionDocument11 pagesAplicacion FermentacionKarenNo ratings yet

- Gluconic Acid Production Under VaryingDocument5 pagesGluconic Acid Production Under VaryingHygor PachecoNo ratings yet

- Improvements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase ProductionDocument16 pagesImprovements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase Productionguime27No ratings yet

- App// D: O., Microbiology BiotechnologyDocument4 pagesApp// D: O., Microbiology BiotechnologyRoger FernandezNo ratings yet

- Succinic Acid 3Document6 pagesSuccinic Acid 3mafechuNo ratings yet

- Optimization of Cell Growth and Poly (Glutamic Acid) Production in Batch Fermentation by Bacillus SubtilisDocument4 pagesOptimization of Cell Growth and Poly (Glutamic Acid) Production in Batch Fermentation by Bacillus Subtilisjona_spNo ratings yet

- Chromocult Coliform PDFDocument4 pagesChromocult Coliform PDFAndres GalárragaNo ratings yet

- Yigitoglu FOKDYRNWCL46033Document7 pagesYigitoglu FOKDYRNWCL46033Fu Shun WongNo ratings yet

- Hiperproduccion de Acido ButiricoDocument27 pagesHiperproduccion de Acido ButiricoCarlos Baca SanchezNo ratings yet

- 10 1007@s002530051232 PDFDocument9 pages10 1007@s002530051232 PDFBarbara Catalina Gomez PerezNo ratings yet

- Fermentation of Glycerol by Clostridium Pasteurianum - Batch and Continuous Culture StudiesDocument9 pagesFermentation of Glycerol by Clostridium Pasteurianum - Batch and Continuous Culture StudiesMauricio AragónNo ratings yet

- Production of Ethanol From MolassesDocument5 pagesProduction of Ethanol From MolassesKrishna PotluriNo ratings yet

- Soriano Perez2011 PDFDocument5 pagesSoriano Perez2011 PDFtienmNo ratings yet

- Rhodototula Glutinis BiodieselDocument5 pagesRhodototula Glutinis BiodieseljrmattarNo ratings yet

- Fermentation 04 00079Document9 pagesFermentation 04 00079CHIRANJEEVINo ratings yet

- Food Chemistry: K. Fujioka, T. ShibamotoDocument5 pagesFood Chemistry: K. Fujioka, T. ShibamotoAjiNo ratings yet

- Qureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodDocument12 pagesQureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodschall0No ratings yet

- Microbial Sensing in FermentationFrom EverandMicrobial Sensing in FermentationSatinder K. BrarNo ratings yet

- BP301 (T) Pharmaceutical Organic chemistry-II Unit-Iv: PolynuclearhydrocarbonsDocument27 pagesBP301 (T) Pharmaceutical Organic chemistry-II Unit-Iv: PolynuclearhydrocarbonsSUBHASISH DASHNo ratings yet

- IMDG Class 1-9Document53 pagesIMDG Class 1-9Rheymart FloresNo ratings yet

- Micro Techniques 1Document38 pagesMicro Techniques 1يوسف إبراهيمNo ratings yet

- (NF) (MT6317) Introduction and Generalities of LipidsDocument14 pages(NF) (MT6317) Introduction and Generalities of LipidsJC DomingoNo ratings yet

- JawapanKeseluruhan 2-FlattenedDocument70 pagesJawapanKeseluruhan 2-FlattenedFikri RaisNo ratings yet

- Fphar 12 768268Document25 pagesFphar 12 768268Araceli Anaya AlvaradoNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/23Document20 pagesCambridge International AS & A Level: CHEMISTRY 9701/23nickole.taruc022807No ratings yet

- Module 1: Acid-Base Titration 1. What Is The Difference Between Endpoint and Equivalence Point?Document12 pagesModule 1: Acid-Base Titration 1. What Is The Difference Between Endpoint and Equivalence Point?Angela ReyesNo ratings yet

- REPORTDocument15 pagesREPORTyatharthsharmaschool2009No ratings yet

- Chapter 19 NHDocument89 pagesChapter 19 NH蔡易斈No ratings yet

- Wpt-2 AssingmentDocument21 pagesWpt-2 AssingmentNakib Ibna BasharNo ratings yet

- CoversionDocument12 pagesCoversionSunil KumarNo ratings yet

- Alpha Tocopheron in Red Bell PepperDocument5 pagesAlpha Tocopheron in Red Bell PepperIsabel ElizondoNo ratings yet

- Timbasol WA Phthalo Blue-English (UK ROI)Document9 pagesTimbasol WA Phthalo Blue-English (UK ROI)El bosque del TallacNo ratings yet

- Removal of Benzene From GasolineDocument24 pagesRemoval of Benzene From GasolineNicholas Cecil Munsami100% (1)

- Antimicrobial Properties of Honey: Zafar H. Israili, MS, PHDDocument20 pagesAntimicrobial Properties of Honey: Zafar H. Israili, MS, PHDdhirazhrNo ratings yet

- Formula Number of Equivalents Equivalent Weight Positive IonsDocument3 pagesFormula Number of Equivalents Equivalent Weight Positive IonsAhmed Khalid HussainNo ratings yet

- Intensification of Yam-Starch Based Biodegradable Bioplastic Film With Bentonite For Food Packaging Application (2022)Document12 pagesIntensification of Yam-Starch Based Biodegradable Bioplastic Film With Bentonite For Food Packaging Application (2022)Mahmoud BelabbassiNo ratings yet

- Aiims - Biochemistry Q&ADocument198 pagesAiims - Biochemistry Q&APrahladRao KulkarniNo ratings yet

- Benefits of Betaine in Laying Hen DietsDocument3 pagesBenefits of Betaine in Laying Hen Dietswl cNo ratings yet

- Icient Treatment of Oil Sands PDocument36 pagesIcient Treatment of Oil Sands PLuqmanNo ratings yet

- Ghosh 2023 Eggplant-SFB-GeraniolDocument16 pagesGhosh 2023 Eggplant-SFB-Geraniolkk singhNo ratings yet

- Chimiaadmin,+2009 0327Document4 pagesChimiaadmin,+2009 0327Crystal DaiNo ratings yet

- Linen ImportantDocument24 pagesLinen ImportantabhijitNo ratings yet

- Laboratory Worksheet 2 Buffers and Buffer CapacityDocument3 pagesLaboratory Worksheet 2 Buffers and Buffer CapacityRALPH EDELWEISS GAPASINNo ratings yet

- ANA Hardener 90121 SG6NDocument10 pagesANA Hardener 90121 SG6NAgung Wahyu WidodoNo ratings yet

- Module 10Document22 pagesModule 10Andrew Dela CruzNo ratings yet

- Conduction and Breakdown in Pure & Commercial LiquidsDocument10 pagesConduction and Breakdown in Pure & Commercial LiquidsSumaira SaifNo ratings yet

Articulo 1 PDF

Articulo 1 PDF

Uploaded by

Jennifer A. PatiñoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Articulo 1 PDF

Articulo 1 PDF

Uploaded by

Jennifer A. PatiñoCopyright:

Available Formats

9 1989 by The Humana Press Inc.

All rights of any nature whatsoever reserved.

0273-2289/89/2021--0491503.80

Continuous Fermentation

for the Production of Citric Acid

from Glucose

T. K. KLASSON, E. C. CLAUSEN,* AND J. L. GADDY

University of Arkansas, Department of Chemical Engineering,

Fayetteville, AR 72 701

ABSTRACT

Citric acid is finding new areas of use each year and the demand

for the acid is constantly increasing. Being a bulk chemical, the con-

tinuous production of citric acid would be advantageous. The paper

presents the results from ammonia limited batch and continuous fer-

mentations using the yeast strain Saccharomycopsis (Candida) lipolytica

(NRRL Y-7576). Mathematical models were developed for growth and

glucose utilization in batch and continuous culture. Cell and acid

yields appeared to be almost the same in batch and continuous culture.

The specific production rates were found to be constant, equal to 0.053

g/g h, in the batch fermentations but varied in the continuous experi-

ments from 0 to 0.11 gig h depending on the fermentation conditions.

Continuous production in a single stage CSTR was studied for over

1,000 hours without shutdown.

Index Entries: Citric acid; Saccharomycopsis Iipolytica; Candida Iipo-

lytica; continuous production; stirred-tank reactor.

NOMENCLATURE

[CIT] Citric acid concentration (anhydrous) g/L

D Dilution rate h- 1

[GLU] Glucose concentration g/L

[ISO] Isocitric acid concentration g/L

K Constant in growth equations h-1

[NH3] Ammonia concentration g/L

t Time h

*Author to whom all correspondence and reprint requests should be addressed.

Applied Biochemistry and Biotechnology 491 Vol. 20/21, 1989

492 Klasson, Clausen, and Gaddy

X Dry weight cell concentration g/L

lYE] Yeast extract concentration g/L

YA/G Actual acid yield on glucose g/g

YN/Y Ammonia equivalent of yeast extract g/g

YX/G Actual cell yield on glucose g/g

YX/N Overall cell yield on ammonia g/g

Yk/N Cell yield on ammonia at beginning of batch g/g

# Specific growth rate of cells h-1

P Specific production rate of acids g/g h

Subscripts

o Initial concentration in batch

f Feed concentration in continuous

Superscripts

c Continuous

INTRODUCTION

Citric acid is one of the most commonly used acids in the food, bever-

age, and pharmaceutical industries, mainly because of its low toxicity and

ease of assimilation. It has also found a niche in the detergent industry,

where its salt, trisodium citrate, is replacing tetrapotassium pyrophosphate

as a surfactant (1). The world production of citric acid and its salts was

about 300-350 thousand tons in 1982 (2).

The classic method for the production of citric acid is by batch fermen-

tation using strains of the fungus Aspergillus niger. The two main producers

of citric acid in the US are Charles Pfizer, Inc. and Miles Laboratories, Inc.

Pfizer, the first US commercial producer, has developed a batch surface

culture process (2), and Miles Laboratories has adapted a submerged cul-

ture fermentation process (3).

Batch fermentation processes have several advantages over continuous

processes, such as easy control of microbial contaminants and increased

product quality per batch. However, for large scale production, batch re-

actors require high capital investments since the volumetric efficiency of

the reactor is low, based on total processing time. The batch process also

requires extensive labor. A continuous system (CSTR) does not have these

disadvantages, can give a more consistent product, and provides a steady

rate of crude product to be processed in the recovery system.

In employing a continuous fermentation process, the microorganism

used must be rigid enough to withstand shear while still being easily

pumped. The fungus A. niger generally yields multicellular growth and

develops mycelia that can easily cause clogging problems in a continuous

system. The yeast Saccharomycopsis (Candida) lipolyticia does not form

mycelia, has shown good stability, and gives high citric acid yields on

glucose (4). However, one disadvantage in using yeasts is that isocitric

acid is also produced in parallel with citric acid.

Applied Biochernistry and Biotechnology Vol. 20/21, 1989

Production of Citric Acid 493

Several continuous processes using yeast have been reported in the

literature. Pfizer (3,5) patented a single-stage continuous process with

Candida lipolytica grown on an n-paraffin mixture for a total period of 304

hours. After an initial batch stage, continuous feed was started and efflu-

ent withdrawn. A multistage process using three fermentors has also been

patented (3, 6) using C. oleophila with yields up to 148% by weight reported.

A German patent (7) claimed a continuous process using molasses as a

substrate with strains of C. guilliermondii as the organism. This continuous

fermentation consisted of a batch startup period followed by continuous

feed after nearly complete conversion of sugars in the batch stage. The

overall productivity for a fermentation lasting 189 h (including 47 h at the

batch stage) was 0.35 g/L h. One of the few reported results (8,9) in the

open literature of a successful continuous fermentation used C. lipolytica in

a single-stage CSTR in order to study the metabolic pathway for growth on

different substrates. The highest volumetric productivity reported was 0.2

g/L h (8).

Citric acid is generally considered to be a secondary metabolite, pro-

duced only in nutrient-limited cultures where growth has ceased. However,

some of the examples shown above indicate that growth and production

are somewhat coupled. Yeasts such as S. lipolytica have a well-developed

TCA-cycle and are known to overproduce citric acid when subjected to

ammonia limitation (8,10,11). The phenomena is easily seen in a batch

fermentation, where the ammonia concentration is closely followed.

After ammonia exhaustion the citric and isocitric acids accumulate in the

broth.

Being a bulk-chemical, citric acid production in a continuous opera-

tion, if possible, would prove advantageous. However, the lack of reliable

data for true continuous fermentations makes it hard to evaluate and com-

pare batch and continuous systems. Kinetic parameters for growth and

production are vital information for any process design and scaleup. This

type of data for yeast growing on glucose is not readily available in the

literature, mainly because it was long thought that citric acid could not be

produced in a continuous fermentation.

The purpose of this paper is to compare citric acid production and

growth for the yeast S. lipolytica in batch and single-stage CSTR culture.

Models are developed and compared for predicting the specific growth

rate and product yields for the strain in batch and continuous culture.

MATERIALS AND METHODS

Organism and Media

Saccharomycopsis lipolytica, NRRL Y-7576, was obtained from Northern

Regional Research Center, Peoria, IL. Stock cultures were kept on slants

(YM-broth, 1.5% agar) at 4~ and transferred every 6 too.

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

494 Klasson, Clausen, and Gaddy

Table 1

Media Composition for the Fermentations, in g/L

Glucose 30-150

Yeast extract (Difco) 0.05 (batch), 2.0 (CSTR)

NH4C1 0.3-1.3

KH2PO4 0.3 (0.45 in one CSTR exp.)

MgSO4 97 H20 0.2 (0.30 in one CSTR exp.)

Thiamine-HC1 0.0001 (0.00015 in one CSTR exp.)

The fermentation media for batch and continuous fermentation studies

is shown in Table 1. When the time for autoclaving was greater than 30 rain

and the NH4CI concentration was over 1.0 g/L, the NH4C1 was sterilized

separately from the rest of the media. The pH was adjusted to 5.5 before

autoclaving using H2SO4 and/or NaOH. The dissolved oxygen was kept

above 50% air saturation by mixing oxygen and air in the sparger. NaOH

was used to control the pH at 5.5 in all fermentations.

Equipment

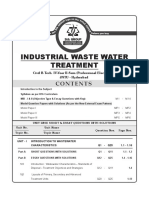

A Braun Instruments Company Biostat-M, with a working volume of

750-1500 mL, was used in carrying out both batch and continuous fer-

mentations. The fermentor was equipped with electrodes for measuring

pH and dissolved oxygen. The Biostat-M also had controls for pH, tem-

perature, agitation, and foam. The pH was controlled using 5 N NaOH

and DF 10P MOD 11 antifoam (Mazer Chemicals, Inc.) was used to control

foam at a tolerable level. For the continuous fermentations a Masterflex

pump (Cole Palmer) with two pump-heads for different size tubing diam-

eters was used for controlling feed and effluent. A schematic of the fer-

mentor can be seen in Fig. 1.

Analytical Methods

The following analytical methods were used on a routine basis for

substrate, product, and cell concentration measurements.

Glucose Assay

Glucose concentrations were determined using a DNS reducing sugar

procedure, based upon the work of Summers (12). A Spectronic 21

(Milton Roy Co.), set at 540 nm, was used for measuring light absorption.

Cell Concentration

Cell concentrations were determined by turbidity measurement at

660 nm using the Spectronic 21. A standard curve for dry (48 h, 105~

cell weight was prepared.

Ammonia Assay

Ammonia analyses were performed with a gas-sensing ammonia

electrode, obtained from Orion Research, Inc.

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

Production of Citric Acid 495

1. Liquid Feed

2. Alkali/Antifoam Addition

3. Dissolved Oxygen Probe

4. Level Control

5. Ring Sparger

6. pH Probe

7. Foam Sensor

8. Liquid Sample Port

9. Exit-gas Cooler

10. Air/Oxygen (Gas Feed)

Fig. 1. Schematic of reaction system.

Citric and lsocitric Acid

Product concentrations were determined according to the methods of

Marier and Boulet (13) and Stern (14). The specific enzymatic conversion

of isocitrate to o~-ketogluturate was measured with the Spectronic 21 at 340

nm. The colorimetric method for tricarboxylic acids served as a basis for

the citric acid assay, using the Spectronic 21 at 420 nm. Citric acid concen-

trations were calculated by difference from the results of the two assays.

RESULTS AND DISCUSSION

Batch Results

The results from batch experiments with S. lipolytica showed the same

type of behavior as reported by Briffaud et al. (10) and Behrens et al. (11).

1. Rapid growth, decreasing as the ammonia concentration

dropped to low values;

2. Citric and isocitric acid accumulation initiated by ammonia ex-

haustion, followed by a period of acids production and increase

in cell mass; and,

3. A stationary phase with continued acid production.

The results from a typical batch fermentation are shown in Figs. 2 and

3. The solid curves represent the results from the mathematical models

developed for substrate, cell, and product concentrations in batch culture.

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

496 Klasson, Clausen, and Oaddy

(-liB) uo!~.e.tl.ueouoo egoonlE)

o ~o. o o. q q

LO Or) "- 0 0 0

"- "- "- (3"I I'-- LO0

! ' I ' I ' ! 'RI"

I--'

(~

c)

0

<~ o o

o

~ 0 0 t~

0

0 0 o

0 o

~0 2

o ~

C

<1 0

o ~- ~

{.J

C

o

r,j

C~

[-,

0

L'N c,i

! I I I I I I

0

0 0 o o o q o q q

N 0:i ~o ~: oJ 0

~ r

(-I/B) uo!~.~aJ.1.ueouoz) lleC:)

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

Production of Citric Acid 497

(7/6) uo!.l.eJ~ueouo:D sP!OV

o o o q o

d d d o d o

~- m oJ ,-- d 0

I ' I ' I ~ I '

0

0

~> ~-- 0

~>

>, t> 0

o

0

0 o

E

"0

o

[] 1> 9

0

C~

I I I ,,,! I I I

0

q q q o o

o o o d d

0 0 0 0

~" ~ 04 ',-

(-Ill, UJ) uop, eJJ,ueouo:z) e!uou~.uv

Applied Biochemistry and Biotechnology Vol. 2 0 / 2 I, 1989

498 Klasson, Clausen, and Gaddy

15.0

d

v

r 10.0

0i _

(3

.E_ 5.0 ~x. Yx~ = 28.2 (g/g)

X

0.0 V . , , , ,

0.0 0.2 0.4 0.6

Initial Ammonia, as Nit 3 (g/L)

Fig. 4. Cell yield on ammonia.

As noted in Fig. 2, the glucose concentration decreased steadily with time

over the entire fermentation. The cell concentration, on the other hand,

reached a maximum cell concentration level after 40 h of fermentation.

Figure 3 shows that citric acid was produced only after the ammonia was

depleted from the medium. A maximum citric acid concentration of 30 g/L

was obtained at the end of this experiment. Higher levels of citric acid can

be obtained by allowing the fermentation to proceed further.

In measuring the effect of ammonia concentration on growth, the

maximum cell concentration was found to be linearly dependent on the

initial ammonia concentration in the medium. The overall cell yield, YX/N,

was found to be 28.2 g of cells (dry wt)/g of ammonia (as NH3), as noted

in Fig. 4. During non-ammonia limited growth, an average yield, Y k/N of

9.2 g cells/g NH3 was found. It is important to realize the difference be-

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

Production of Citric Acid 499

tween the two yields. The overall yield, YX/N, refers to the maximum cell

concentration obtained from a known amount of ammonia. Y~/N, on

the other hand, is equal to dX/d[NH3] during the initial phase of the batch

fermentation when ammonia is still present in the medium. YX/N was

found to be approximately three times higher than Y kiN, indicating a cell

increase of about 200% after ammonia was depleted from the medium.

The growth of S. lipolytica in batch culture was modeled using a logistic

curve, shown in Eq. (1) below. The simplicity of this equation is also one

of its drawbacks (15,16), since no term is included for substrate concen-

tration. However, since the limiting substrate, ammonia, was not present

in the medium during the most part of the cell growth, other empirical

equations which relate growth to a limiting substrate were impossible to

use, unless intracellular measurements are made.

dX ! dt = K X (1 - X / Xmax) (1)

Equation (1) implies that growth is proportional to the product of cell con-

centration and an inhibition term, which is the fraction remaining in

reaching the maximum cell concentration. With ammonia limited growth,

the maximum cell concentration depends upon the initial concentration

of ammonia and the number of cells present at startup. Equation (1) fits

the data well in all of the experiments where the limiting nutrient was

ammonia. Figure 5 shows a plot of specific growth rate, I/X dX/dt, as a

function of 1-X/Xma• where Xmax w a s estimated as:

Xmax = YX/N([NH3]o + Xo/YkiN) (2)

The correlation coefficient for the data was 0.92, indicating that the model

of Eq. (1) fits the data very well.

The specific production rate in batch culture was found to be constant

and equal to 0.053 g!g h. Figure 6 shows a plot of the total acids produced

as a function of the time integrated cell concentration at various ammonia

concentrations. As noted, a single straight line was obtained, yielding the

specific production rate. A specific production rate of 0.05 g/g h was also

found by Briffaud and Engasser (10) as the maximum specific production

rate, when studying the effect of oxygen on production. The ratio between

citric acid and isocitric acid varied during the production phase from 3 to

6.5 g citric acid/g isocitric acid. The ratio increased steadily, favoring citric

acid as production proceeded.

The glucose consumption rate decreased from a maximum during the

early part of the fermentation to a constant specific consumption rate dur-

ing acid production. The consumption rate can thus be described by the

equation

- d[GLU] ! dt = 1 / Yx/c dX ! dt + 1 ! YA/Gd([CIT] + [ISO]) / dt (3)

Equation (3) may be integrated to yield the following expression.

[GLU]o - [GLU] = 1/YxzG (X - Xo) + 1/YA/G ([CIT] + [ISO]) (4)

Applied Biochernistry and Biotechnology Vol. 20/21, 1989

500 Klasson, Clausen, and Oaddy

0.5

Inltlal ~ l a

Conoentratlon

0.4 A 0,11 g/L

v

0 0,28 g/L

(D 0

m I"3 0.31 Q/L

rr 0.3 0 0.44 g& uy

o

(3 0.2 *

a

0

\ K = 0.31 (h-')

r 0.1

0

0.0 0

0.0 0.2 0.4 0.6 0.8 1.0 1.2

1 - X/X,~

Fig. 5. Testing the batch model of Eq. (1) for growth.

The two yields on glucose, Yx/c and YA/C, were found through multiple

regression analysis to be equal to 0.67 and 0.87, respectively. Figure 7

demonstrates the validity of Eq. (4), showing that a slope of essentially

unity was obtained when plotting glucose uptake as a function of esti-

mated consumption. In Fig. 7, the points correspond to smoothed data

for different initial ammonia concentrations. Any decrease in cell mass

during the final part of the fermentation was neglected. Eqs. (1), (2), and

(3) together with the two following equations for ammonia uptake and

total acid production constitute a differential equation system that de-

scribes the time events in a batch citric acid fermentation.

- d [NH3] / dt = 1 / Yk/N dX ! dt Yk/N = 9.2 gig (5)

and

d[CIT + I S O ] ! d t -- ~,X i, = 0.053 g/g h (6)

Applied Biochemistry and Biotechnology Vol. 20/2 I, 1989

Production of Citric Acid 501

60.0

Initial Ammonia

Concentration

_.1

A 0.11 g/L

v

t- 0 O.28 g/L

O 0

[] 031 g/L

L.

4~

t-

40.0

0 0.44 o/L

o/

r

O

t-

O

0 <)

-0

, m

0 20.0

<

m

= 0.053 (g/gh)

4-1

O

O0 9 ! * f I I * i t

0 200 400 600 800 1000

fXdt (gh/L)

Fig. 6. Determination of specific production rate in batch culture.

As a final check the differential equation system was solved numeri-

cally and curves were generated predicting cell, ammonia, glucose, and

total acid concentrations. The solid curves in Figs. 2 and 3 correspond to

the numerical solutions. A short lag phase for Eq. 6, between ammonia

exhaustion and citric acid production was also accounted for when solv-

ing the equations. A similar time period after ammonia exhaustion and

before citric acid production was found by Behrens et al. (11).

CONTINUOUS FERMENTATION RESULTS

Prior to this work, continuous fermentations for citric acid pro-

duction using yeast had only been run for short time periods. Continuous

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

502 Klasson, C/ausen, and Gaddy

60.0

Initial Ammonia

0

Cmoml~tlon

Zl 0.11 g/L.

0

A o ~..

_.!

[] 0.31 g/L

V

40.0

<> o,44 ~ _

D 13

....J

(9

L ~

slope = 0 . 9 9

0

0 13

D 20.0

..J

r3

11 |

,Z ~

13

0.0

0.0 20.0 40.0 60.0

(X-Xo)/.67 + ([CIT]+[ISO])/.87 (g/L)

Fig. 7. Testing the batch model of Eq. (4) for glucose uptake.

runs for over 1000 h were carried out in this experimental study. Since the

batch fermentation results clearly s h o w e d that growth and production

were d e p e n d e n t upon the ammonia concentration, continuous fermenta-

tions were planned and conducted with different concentrations of am-

monia in the feed and variable dilution rates. The batch model predicts

that citric acid should be produced w h e n the dilution rate is less than a

dilution rate where the rate of ammonia input from the feed exceeds the

consumption rate by the cells. Equation (1) may be rearranged'noting that

/~= D at steady-state in a continuous stirred-tank fermentor:

D = Kc (1 - X / Xmax) (7)

where Xmaxis a function of the ammonia and yeast extract concentrations

in the feed. Solving for X, Eq. 7 becomes

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

Production of Citric Acid 503

X = Xma• (1 -- D / Kc) (8)

which predicts a linear relationship between cell concentration and dilu-

tion rate.

Experiments were conducted in a single-stage continuous vessel, with

the results shown in Figs. 8 and 9. Figure 8 shows typical cell concen-

tration profiles for different ammonia concentrations in the feed. Figure 9

shows the corresponding acid profiles. As noted in Fig. 8, a linear rela-

tionship was indeed obtained in the region studied. However, since yeast

extract was added to the continuous feed in concentrations up to 2.0 g/L,

this contribution to cell mass must be accounted for when evaluating

Xmax. Therefore, the following expression was used for Xma•

Xmax = Y~(/N([NH3]f + [YE]f Y~/y) (9)

where Y~/Y corresponds to the ammonia equivalent (as NH3) of yeast ex-

tract. The solids lines in Fig. 8 were determined using Eqs. (8) and (9).

The values for Kc and Y~/Ywere obtained using nonlinear regression anal-

ysis as demonstrated in Fig. 10. Y~(/Nwas given a value of 28.2 gig as was

found in batch experiments. The latter value of Kc (0.23 h -~) was much

lower than in batch culture. This can be explained by considering that the

collected data for continuous fermentation only compares to the action

during the batch fermentation where growth and production occurred

simultaneously. Data for the batch culture in this region would indicate a

K value of 0.24 h -1, which is close to the one found in continuous fer-

mentation.

As noted in Fig. 9, the production of acids in continuous culture was

not directly comparable to batch culture results. The specific production

rate was found to be constant during the batch fermentations, but it

changed in continuous culture. It is possible that the nitrogen content per

cell was one of the factors affecting the production. For most of the pro-

duction phase in batch culture (stationary growth phase), the nitrogen

content per cell remained constant. In the continuous fermentation this

value changed, since for a fixed nutrient composition in the feed, different

cell concentrations can be obtained at various dilution rates. The ammonia

to cell ratio was therefore different at each steady-state and may have

caused the cells to work under different environments.

The glucose consumption rates in continuous culture were studied,

comparing well with batch fermentation results. Figure 11 shows the actual

glucose uptake rate as a function of the predicted consumption rate cal-

culated using cell and acid yields found in batch studies. The line in the

figure corresponds to expected values from batch culture (see Eq. (4)). A

rigorous multiple regression analysis of the continuous fermentation

data gave a cell yield of 0.67 g cell/g glucose and a product yield of 0.61 g

acids/g glucose. These results are close to the yields predicted in batch

culture.

Applied Biochemistry and Biotechnology Vol. 2 0 / 2 I, 1989

504 Klasson, Clausen, and Gad@

0

0

i /11 r-]

o

"11 II

o

~ o ~ o o ,",,'; :"

/ I I I

/ / I I I

! I I I

/ I I I

I I

/ o a o

q o q q

d ~ o

f-l/B) uop,~4uaouo:D IlaO ~qO!aM ~G

Applied Biochemistry and Biotechnology Vol. 2 0 / 2 I, 1989

Production of Citric Acid 505

0

0

Boqoo

~++++~

0

I o

r .=

i ~

v

III ~ I> ~ 0 Q

o o

[] 09

I> ~J

~

0 c/3

[] D o

0 ~

n

[] D 0

0 o <J

[] [] .2

0

0 F~

0

D[] I>01> o<

I> <]

0 [] b=

o

q o o q

I--

d

"t--

~i o

(q/B) uo!~laJ~,ueouo:D s P ! o V

Applied Biochemistry and Biotechnology Vol. 20/2 I, 1989

.506 Klasson, Clausen, and Gadd.q

20,0 Ammonia end Yeeet

Extract Concentratlone

A 0.096 g/L + 0.05 g/L

V O.Og6 g/1.. + 2.0 g/l_

El 0.1gl g/L + 2.0 g/L /

/

0 0.318 g/L + 2.0 g/L /

/

+ extra ~lte //

10.0

f-

,0

/ 9 • 9 m I I I | I,

0,0 10.0 20.0

28.2([NH3] , + 0.066[YE]~(1 - D/0.23) (g/L)

Fig. 10. Testing the continuous model of Eqs. (8) and (9) for growth.

Table 2 shows a summary of the results for the batch and continuous

fermentations. The table also lists results for citric acid production by S.

lipolytica from the literature. Specific production rates from the literature

agree well with the results obtained in batch culture in the present work.

Continuous specific production rates in the present work were as much

as twice the values obtained in batch cultures.

The cell yields on ammonia were essentially the same in all studies re-

ported. Cell yields on glucose in the present study, however, were nearly

double the values presented in the literature. The yields of acids on glu-

cose were comparable to the higher values presented in the literature.

Applied Biochemistry and Biotechnology VoL 20/21, 1989

Production of Citric Acid 507

70.0 Ammonia end Y eaet

Extract Concenlratione

60.0 A O.O96 g/L + 0.05 g/L

V 0.095 WI.- + 2.0 g/L

50.0 [] 0.191 g/L + 2.0 g/l._

0 0.318 WI-. + 2.0 g/L 0

40.0

I.. 30.0

~, 20.0

10.0

0.0 I I I I

0.0 10.0 20.0 30.0 40.0 50.0

X/0.67 + ([CIT]+[ISO])/0.87 (g/L)

Fig. 11. Testing the batch model of Eq. (4) for glucose uptake in con-

tinuous culture.

CONCLUSIONS

Citric and isocitric acids were produced in batch and single-stage con-

tinuous culture under ammonia limitation. Batch fermentation results

showed slightly overlapping regions of growth and production but, for the

most part, the regions were separated. In continuous culture, production

and growth occurred simultaneously because of the depletion of ammonia.

Specific production rates of acids in batch culture were constant but

varied in continuous culture depending on conditions. Continuous experi-

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

508 Klasson, Clausen, and Gaddy

Table 2

Rates and Yields for Citric Acid Production by S. lipolytica from Glucose

YX/N Yx/c YA~C

g/g h g/g g/g g/g

Batch, present work 0.053 28.2 0.67 0.87

Continuous, present work 0-0.11 28.24 0.67 0.61

Enzminger et al. (4) 0.045 0.86

Cell recycle

Enzminger et al. (4) 0.040 0.63

Batch

Aiba et al. (8) 0.037 0.32 0.40

CSTR

Maddox et al. (17) 0.070 0.51

Batch

Maddox et al. (17) 0.010 0.70

Gel immobilization

Briffaud et al. (10) 0.041-0.05 22.9 0.31-0.42 0.75

Batch

aAt zero dilution rate.

ments ran for over 1000 h, showing no apparent mutations of the yeast. A

simple model to predict growth and production was used in batch culture

and the same type of model applied for growth in continuous culture. Acid

production in continuous culture was probably affected by the ammonia

concentration per cell.

REFERENCES

1. Bouchard, E. F., and Merritt, E. G. (1979), Kirk-Othmer Enzyclopedia of Chemi-

cal Technology, vol. 6, Wiley, New York, p. 150.

2. Rohr, M., Kubicek, C. P., and Kominek, J. (1983), Biotechnology, vol. 3,

Rehm, H.-J. and Reed, G., eds., Verlag Chemie, Weinheim, p. 419.

3. Miall, L. M. (1978), EconomicMicrobiology, vol. 2, Rose, A. H., ed., Academic,

New York, p. 47.

4. Enzminger, J. D. and Asenjo, J. A. (1986), Biotechnol. Lett. 8(1), 7.

5. Charles Pfizer, Inc. (1974), Brit. Pat. 1,369,295.

6. Mitsui Sugar Co., Ltd. (1974), Brit. Pat. 1,354,192.

7. Miall, L. M. and Parker, G. F. (1975), German Pat. 2,429,224.

8. Aiba, S. and Matsuoka, M. (1979), Biotechnol. Bioeng. 21, 1373.

9. Aiba, S. and Matsuoka, M. (1978), Eur. J. Appl. Microbiol. Biotechnol. 5, 247.

10. Briffaud, J. and Engasser, J.-M. (1979), Biotechnol. Bioeng. 21, 2083.

11. Behrens, U., Thiersch, A., Weissbrodt, E., and Stottmeister, U. (1987), Acta

Biotechnol. 7(2), 179.

12. Summers, J. B. (1924), J. Biol. Chem. 62(2), 287.

Applied Biochemistry and Biotechnology Vol. 20/21, 1989

Production of Citric Acid 509

13. Marier, J. R. and Boulet, M. (1958), J. Dairy Sci. 41(7), 1683.

14. Stern, J. R. (1957), Methods in Enzymology, vol. 3, Colwick, S. P., and

Kaplan, N. O., eds., Academic, New York, p. 425.

15. Roels, J. A. (1983), Energetics and Kinetics in Biotechnology, Elsevier Biomedi-

cal Press, New York, p. 241.

16. Bailey, J. E. and Ollis, D. F. (1977), Biochemical Engineering Fundamentals,

McGraw-Hill, New York, p. 359.

17. Maddox, I. S. and Kingston, P. J. (1983), Biotechnol. Lett. 5(12), 795.

Applied Biochemistry and Biotechnology Vol. 2 0 / 2 I, 1989

You might also like

- Industrial Waste Water TreatmentDocument102 pagesIndustrial Waste Water TreatmentSaishiva Sukkala100% (1)

- Guidelines For Potato Farming in Zimbabwe: ©ziminvestors 2015 EditionDocument27 pagesGuidelines For Potato Farming in Zimbabwe: ©ziminvestors 2015 EditionAleck Mutiba100% (3)

- Acido LacticoDocument9 pagesAcido LacticoJuan Victor ChampeNo ratings yet

- Glutamic Acid 2 PDFDocument8 pagesGlutamic Acid 2 PDFneelNo ratings yet

- ScribdDocument9 pagesScribdSrinivas ReddyNo ratings yet

- Batch and Fed-Batch Production of Butyric Acid by Clostridium Butyricum ZJUCBDocument5 pagesBatch and Fed-Batch Production of Butyric Acid by Clostridium Butyricum ZJUCBapi-3743140No ratings yet

- Factors Regulating Production of Glucose Oxidase by Aspergillus NigerDocument5 pagesFactors Regulating Production of Glucose Oxidase by Aspergillus NigerI. Murali KrishnaNo ratings yet

- Aem00154 0187Document8 pagesAem00154 0187HonganhNo ratings yet

- 4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyDocument6 pages4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyOmar KHELILNo ratings yet

- Hanson 1972Document20 pagesHanson 1972Công Thành KiềuNo ratings yet

- Proponoic AcidDocument7 pagesProponoic AcidAnonymous SUbBZzNo ratings yet

- Single Cell ProductionDocument5 pagesSingle Cell Productioncha lieNo ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNo ratings yet

- El Sheekh2012Document8 pagesEl Sheekh2012Hoài Nam PhanNo ratings yet

- Continuous and Batch Cultures of Escherichia Coli KJ134 For Succinic Acid Fermentation: Metabolic Flux Distributions and Production CharacteristicsDocument10 pagesContinuous and Batch Cultures of Escherichia Coli KJ134 For Succinic Acid Fermentation: Metabolic Flux Distributions and Production CharacteristicsSyed ShahNo ratings yet

- Gluconic AcidDocument11 pagesGluconic AcidpalkybdNo ratings yet

- Chen 1996Document4 pagesChen 1996mplatonosNo ratings yet

- Sem Mod Cinet 2Document3 pagesSem Mod Cinet 2Jaza VlogsNo ratings yet

- High-Efficient Production of Citric Acid by Aspergillus Niger From High Concentration of Substrate Based On The Staged-Addition Glucoamylase StrategyDocument9 pagesHigh-Efficient Production of Citric Acid by Aspergillus Niger From High Concentration of Substrate Based On The Staged-Addition Glucoamylase StrategyAndriyani YaniNo ratings yet

- Gluconic Acid: Properties, Applications and Microbial ProductionDocument13 pagesGluconic Acid: Properties, Applications and Microbial ProductionDavid KehindeNo ratings yet

- Pilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourceDocument6 pagesPilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourcekopisusumantapNo ratings yet

- Production of L-Glutamic Acid by Immobilized Cell Reactor of The BacteriumDocument6 pagesProduction of L-Glutamic Acid by Immobilized Cell Reactor of The BacteriumTavo JGNo ratings yet

- Production of Biosurfactant From Torulopsis: BombicolaDocument4 pagesProduction of Biosurfactant From Torulopsis: BombicolaSui GenerisNo ratings yet

- Improvement of Yarrowia Lipolytica Lipase ProductionDocument4 pagesImprovement of Yarrowia Lipolytica Lipase ProductionjuanNo ratings yet

- The Response of Brewing Yeast To Acid WashingDocument9 pagesThe Response of Brewing Yeast To Acid WashingGary SadavageNo ratings yet

- Optimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003Document6 pagesOptimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003jmrozo3No ratings yet

- Repeated PH-stat Fed-Batch Fermentation For RhamnolipidDocument9 pagesRepeated PH-stat Fed-Batch Fermentation For Rhamnolipidsidikmar1425No ratings yet

- Influence of The Nitrogen Source On Saccharomyces Cerevisiae Anaerobic Growth and Product FormationDocument9 pagesInfluence of The Nitrogen Source On Saccharomyces Cerevisiae Anaerobic Growth and Product FormationGeraldiineDuqueSalazarNo ratings yet

- 95428-Article Text-246569-1-10-20131017Document7 pages95428-Article Text-246569-1-10-20131017احمد الدلالNo ratings yet

- Wang e Yang 2015Document10 pagesWang e Yang 2015Aline HunoNo ratings yet

- Differences in Rate of Ruminal Hydrogenation of C18 Fatty Acids in Clover and RyegrassDocument7 pagesDifferences in Rate of Ruminal Hydrogenation of C18 Fatty Acids in Clover and RyegrassMiguel Hulfan FoxNo ratings yet

- Hojo 1999Document11 pagesHojo 1999Berk YüzerNo ratings yet

- Bioetanol 1Document9 pagesBioetanol 1Ezequiel QuinterosNo ratings yet

- Alcoholic Fermentation With Different Initial Glucose Concentration Using Immobilized Yeast in Calcium Alginate GelDocument7 pagesAlcoholic Fermentation With Different Initial Glucose Concentration Using Immobilized Yeast in Calcium Alginate GelViệt Euro ĐinhNo ratings yet

- Effect of PH, Agitation and Aeration On Hyaluronic Acid Production Bystreptococcus ZooepidemicusDocument6 pagesEffect of PH, Agitation and Aeration On Hyaluronic Acid Production Bystreptococcus ZooepidemicusJesus C. MendozaNo ratings yet

- Kinetic Simple GoodDocument11 pagesKinetic Simple GoodReza MahoorNo ratings yet

- Ac Citrico 1Document14 pagesAc Citrico 1Maximiliano Rodriguez RiveroNo ratings yet

- Anti Fungal in BreadDocument6 pagesAnti Fungal in BreadRufa Lara MendezNo ratings yet

- Ethanol Production in A Hollow Fiber Bioreactor Using Saccharomyces CerevisiaeDocument5 pagesEthanol Production in A Hollow Fiber Bioreactor Using Saccharomyces CerevisiaeJose CarlosNo ratings yet

- Biotechnology Progress - 2008 - Lenihan - Developing An Industrial Artemisinic Acid Fermentation Process To Support TheDocument7 pagesBiotechnology Progress - 2008 - Lenihan - Developing An Industrial Artemisinic Acid Fermentation Process To Support The774hzz9zd8No ratings yet

- Bioproduction of Hydrogen by Simultaneous SaccharificationDocument8 pagesBioproduction of Hydrogen by Simultaneous SaccharificationProfessor Douglas TorresNo ratings yet

- Aplicacion FermentacionDocument11 pagesAplicacion FermentacionKarenNo ratings yet

- Gluconic Acid Production Under VaryingDocument5 pagesGluconic Acid Production Under VaryingHygor PachecoNo ratings yet

- Improvements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase ProductionDocument16 pagesImprovements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase Productionguime27No ratings yet

- App// D: O., Microbiology BiotechnologyDocument4 pagesApp// D: O., Microbiology BiotechnologyRoger FernandezNo ratings yet

- Succinic Acid 3Document6 pagesSuccinic Acid 3mafechuNo ratings yet

- Optimization of Cell Growth and Poly (Glutamic Acid) Production in Batch Fermentation by Bacillus SubtilisDocument4 pagesOptimization of Cell Growth and Poly (Glutamic Acid) Production in Batch Fermentation by Bacillus Subtilisjona_spNo ratings yet

- Chromocult Coliform PDFDocument4 pagesChromocult Coliform PDFAndres GalárragaNo ratings yet

- Yigitoglu FOKDYRNWCL46033Document7 pagesYigitoglu FOKDYRNWCL46033Fu Shun WongNo ratings yet

- Hiperproduccion de Acido ButiricoDocument27 pagesHiperproduccion de Acido ButiricoCarlos Baca SanchezNo ratings yet

- 10 1007@s002530051232 PDFDocument9 pages10 1007@s002530051232 PDFBarbara Catalina Gomez PerezNo ratings yet

- Fermentation of Glycerol by Clostridium Pasteurianum - Batch and Continuous Culture StudiesDocument9 pagesFermentation of Glycerol by Clostridium Pasteurianum - Batch and Continuous Culture StudiesMauricio AragónNo ratings yet

- Production of Ethanol From MolassesDocument5 pagesProduction of Ethanol From MolassesKrishna PotluriNo ratings yet

- Soriano Perez2011 PDFDocument5 pagesSoriano Perez2011 PDFtienmNo ratings yet

- Rhodototula Glutinis BiodieselDocument5 pagesRhodototula Glutinis BiodieseljrmattarNo ratings yet

- Fermentation 04 00079Document9 pagesFermentation 04 00079CHIRANJEEVINo ratings yet

- Food Chemistry: K. Fujioka, T. ShibamotoDocument5 pagesFood Chemistry: K. Fujioka, T. ShibamotoAjiNo ratings yet

- Qureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodDocument12 pagesQureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodschall0No ratings yet

- Microbial Sensing in FermentationFrom EverandMicrobial Sensing in FermentationSatinder K. BrarNo ratings yet

- BP301 (T) Pharmaceutical Organic chemistry-II Unit-Iv: PolynuclearhydrocarbonsDocument27 pagesBP301 (T) Pharmaceutical Organic chemistry-II Unit-Iv: PolynuclearhydrocarbonsSUBHASISH DASHNo ratings yet

- IMDG Class 1-9Document53 pagesIMDG Class 1-9Rheymart FloresNo ratings yet

- Micro Techniques 1Document38 pagesMicro Techniques 1يوسف إبراهيمNo ratings yet

- (NF) (MT6317) Introduction and Generalities of LipidsDocument14 pages(NF) (MT6317) Introduction and Generalities of LipidsJC DomingoNo ratings yet

- JawapanKeseluruhan 2-FlattenedDocument70 pagesJawapanKeseluruhan 2-FlattenedFikri RaisNo ratings yet

- Fphar 12 768268Document25 pagesFphar 12 768268Araceli Anaya AlvaradoNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/23Document20 pagesCambridge International AS & A Level: CHEMISTRY 9701/23nickole.taruc022807No ratings yet

- Module 1: Acid-Base Titration 1. What Is The Difference Between Endpoint and Equivalence Point?Document12 pagesModule 1: Acid-Base Titration 1. What Is The Difference Between Endpoint and Equivalence Point?Angela ReyesNo ratings yet

- REPORTDocument15 pagesREPORTyatharthsharmaschool2009No ratings yet

- Chapter 19 NHDocument89 pagesChapter 19 NH蔡易斈No ratings yet

- Wpt-2 AssingmentDocument21 pagesWpt-2 AssingmentNakib Ibna BasharNo ratings yet

- CoversionDocument12 pagesCoversionSunil KumarNo ratings yet

- Alpha Tocopheron in Red Bell PepperDocument5 pagesAlpha Tocopheron in Red Bell PepperIsabel ElizondoNo ratings yet

- Timbasol WA Phthalo Blue-English (UK ROI)Document9 pagesTimbasol WA Phthalo Blue-English (UK ROI)El bosque del TallacNo ratings yet

- Removal of Benzene From GasolineDocument24 pagesRemoval of Benzene From GasolineNicholas Cecil Munsami100% (1)

- Antimicrobial Properties of Honey: Zafar H. Israili, MS, PHDDocument20 pagesAntimicrobial Properties of Honey: Zafar H. Israili, MS, PHDdhirazhrNo ratings yet

- Formula Number of Equivalents Equivalent Weight Positive IonsDocument3 pagesFormula Number of Equivalents Equivalent Weight Positive IonsAhmed Khalid HussainNo ratings yet

- Intensification of Yam-Starch Based Biodegradable Bioplastic Film With Bentonite For Food Packaging Application (2022)Document12 pagesIntensification of Yam-Starch Based Biodegradable Bioplastic Film With Bentonite For Food Packaging Application (2022)Mahmoud BelabbassiNo ratings yet

- Aiims - Biochemistry Q&ADocument198 pagesAiims - Biochemistry Q&APrahladRao KulkarniNo ratings yet

- Benefits of Betaine in Laying Hen DietsDocument3 pagesBenefits of Betaine in Laying Hen Dietswl cNo ratings yet

- Icient Treatment of Oil Sands PDocument36 pagesIcient Treatment of Oil Sands PLuqmanNo ratings yet

- Ghosh 2023 Eggplant-SFB-GeraniolDocument16 pagesGhosh 2023 Eggplant-SFB-Geraniolkk singhNo ratings yet

- Chimiaadmin,+2009 0327Document4 pagesChimiaadmin,+2009 0327Crystal DaiNo ratings yet

- Linen ImportantDocument24 pagesLinen ImportantabhijitNo ratings yet

- Laboratory Worksheet 2 Buffers and Buffer CapacityDocument3 pagesLaboratory Worksheet 2 Buffers and Buffer CapacityRALPH EDELWEISS GAPASINNo ratings yet

- ANA Hardener 90121 SG6NDocument10 pagesANA Hardener 90121 SG6NAgung Wahyu WidodoNo ratings yet

- Module 10Document22 pagesModule 10Andrew Dela CruzNo ratings yet

- Conduction and Breakdown in Pure & Commercial LiquidsDocument10 pagesConduction and Breakdown in Pure & Commercial LiquidsSumaira SaifNo ratings yet