Professional Documents

Culture Documents

M002-Job Procedure Ag Piping

M002-Job Procedure Ag Piping

Uploaded by

Vijayaraman Rajendran100%(1)100% found this document useful (1 vote)

626 views8 pagesLARSEN and TOUBRO LIMITED - E&C DIVISION HYDRO CARBON CONSTRUCTION AND PIPELINES DOCUMENT TITLE JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Original Description:

Original Title

M002-job procedure ag piping

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLARSEN and TOUBRO LIMITED - E&C DIVISION HYDRO CARBON CONSTRUCTION AND PIPELINES DOCUMENT TITLE JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(1)100% found this document useful (1 vote)

626 views8 pagesM002-Job Procedure Ag Piping

M002-Job Procedure Ag Piping

Uploaded by

Vijayaraman RajendranLARSEN and TOUBRO LIMITED - E&C DIVISION HYDRO CARBON CONSTRUCTION AND PIPELINES DOCUMENT TITLE JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

LARSEN & TOUBRO LIMITED - E&C DIVISION HYDRO CARBON CONSTRUCTION AND PIPELINES

LOBS QUALITY UPGRADATION PROJECT AT HPeL REFINERY, MAHUL J MUMBAI

DOCUMENT TITLE

JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION

1

Prepared by Verified by

Iss ued for JE Approval

17/12/2008

Issued for JE Comments

11111/2008

MPM ARA

o

Rev

Date

Description

nOCNO.

L T ILOBS/HPCLIPP/JP IM002

REV. 1

LARSEN & TOUBROLTD

JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION

DOC 0.: LT /LOBS I HPCL I PP / JP / M 002 REV NO: 1

DATE: 21.8.2008

Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Customer: MJS Hindustan Petroleum Corporation Limited, Mumbai.

CONTENTS

1. SCOPE

2. REFERENCE

3. WELDING AND WELDER QUALIFICATION

4. MATERIAL HANDLING AND STORAGE

5. FABRICATION

6. ERECTION

7. INSPECTION

8.FLuSmNG

9. HYDROTESTING

10. DOCUMENTATION

17112/2008

ISSUED FOR JECOMMENTS

PREPARED BY

REV.NO

REVISION DESCRiPTION

DATE

/~

CHECKED BY

Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Customer: l'v1IS Hindustan Petroleum Corporation Limited, Mumbai.

DOC NO.: LT (LOBS ( HPCL ( PP I JP I M 002 REV NO: I

DATE: 21.8.2008

JOB PROCEDURE FOR ABOVE GROUND PIPING F ABRICA TION AND ERECTION

LARSEN & TOUBROLTD

1. SCOPE:

The following procedure describes the methods to be followed in step by step during fabrication and erection of above ground piping.

2. REFERENCE:

1. Project Specification No.3188- LSS-l 04 REV O.

2. Project specification No. 3188-LSS-I05 REV O.

3. Project specification No. 3188-LSS-l 06 REV O.

3. WELDING AND WELDER QUALIFICATION:

1. All welding procedures to be employed in the job shall be qualified as per ASME SEC IX and Procedure qualification record for the same shall be maintained at site.

2. All welder to be employed in the job shall be qualified as per the approved relevant WPS and Standard ASrvtE SEC IX

3. Welding electrodes and filler wires shall conform to the approved WPS. Welding ~ consumables shall be of the make approved by Owner I PMC.

4. Electrode qualification Records shall be submitted to PMC for verification.

4. MATERIAL HANDLING AND STORAGE:

1. Materials (Pipes and Fittings) shall be received and stacked separately grade wise and size wise at the stacking yard by the stores supervisor. A separate colour code shall be given for each grade and shall be marked on the pipes. The pipes shall be stacked over the proper wooden blocks with end cover caps. All Flanges and other fittings shall be properly placed in wooden boxes and due care shall be taken to protect the raise face and end faces and also the colour code shall be given for fitting, flanges etc.

2. Material Test certificates for all materials shall be reviewed and correlated with the particular items by QC Engineer and Material Inspection Report for the same shall be maintained.

3. Piping log book to be maintained

~

PREPARED BY

/~

CHECKED BY

ISSUED FOR

l 1711212008 IE C011MENTS

REV.NO

DATE

REVISION DESCRIPTION

DOC 0.: LT I LOBS I HPCL / PP I JP / M 002 REV NO: 1

DATE: 21.8.2008

JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION

Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Customer: MIS Hindustan Petroleum Corporation Limited, Murnbai.

LARSEN & TOUBROLTD

4. PMI test as required by Project Specification shall be conducted for the alloy steel materials after the receipt of materials at stores.

5. FABRICATION:

1. AU piping fabrication shall be strictly carried out as per AFC Drawings and a copy of the same shall be available at site in all time.

2. Materials to be used in fabrication shall be strictly as per piping material specification and class mentioned in AFC Drawings.

3. Pipes shall be marked as per dimension mentioned in the ISO - Drawings for spool fabrication. CS pipes and alloy steel pipes having chromium content less than 5% shall be cut by gas cutting process. All other alloy steel and SS pipes (> 5% Cr) shall be cut either by grinding or by pipe cutter process. All scales present after gas cutting shall be completely removed and edges shall be properly ground smooth.

4. Edge preparations for pipes, fitting shall be properly prepared and fit up shall be carried out with C - Clamps I tack welding I C - Cleats directly on root by qualified welders.

5. Carbon steel C-clamps shall be used for carbon steel pipes and Carbon steel C-clamps buttered with specific grade of electrode shall be used for specific alloy steel and SS - C - Clamps shall be used for stainless steel pipes.

6. All fit-ups shall be identified by joint nos. and the same shall be marked by hard punch near by joints on carbon and alloy steel pipes and by paint on stainless steel pipes. The spool pieces shall be marked with Line No. I ISO. Drg. No. for the ease of traceability during erection. Spool number to be marked on the pipe spool & identification tags shall be provided.

7. Mitre bends shall be fabricated as per Piping Material Specification. All 90 deg. mitres shall be 4- piece 3-weld type and 45 deg. mitres shall be 3- piece 2-weld type unless otherwise specified and NDT requirements shall be as per Project specifications.

8. Due care shall be taken during welding of joints by qualified welder to avoid / minimize distortion.

@iV. /~

PREPARED CHECKED

BY BY

ISSUED FOR JECOMMENTS

17/12/2008

REV.NO

REVISION DESCRIPTION

DATE

DOC NO.: LT / LOBS / HPeL / PP / JP / M 002 REV NO: 1

DAIE: 21.8.2008

JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION

Project: LOBS Quality Up gradation Project Consultant: MJS Jacobs Engineering India Private Ltd ..

Customer: MIS Hindustan Petroleum Corporation Limited, Mumbai,

LARSEN & TOUBROLTD

9. After the completion of welding, the weld joints shall be dressed if necessary, and visual inspection shall be carried out as per latest edition of applicable codes and standards. All necessary NDT's / P\VHT as requires by specification shall be carried out and after satisfactory completion of the same shall be released along with spool release note for further process.

16. ERECTION:

1. The spool pieces, released for erection, shall be erected on pipe racks as per relevant AFC Drawings. Before erection the spool pieces shall be confirmed that no foreign materials are being present inside the pipes.

2. The elevation, pipe-to-pipe distance, pipe to structural distance shall be closely followed as per the dimension mentioned in drawing.

3. The pipelines shall be aligned with the existing tolerance and field weld fit ups and welding shall be carried out. The aligned pipelines shall be provided with all necessary pipe supports such as guides,saddles, anchors etc as mentioned in the drawing. No temporary supports shall be used.

4. Proper care shall be taken during flange connection so that flanges can be bolted together without any undue stresses. The flanges shall be straddled to the normal center lines and shall be true and perpendicular to the axis of pipe. The flange connection welding of pipeline along with static I rotary equipment shall be carried out after the alignment and grouting of equipment is completed.

5. All temporary attachments / tack welding made on pipes for erection convenience shall be removed and ground smooth. DP test to be carried out.

6. All vents and drains as mentioned in the drawing shall be provided on pipelines. The holes made for vents I drains shall be ground smooth and free of bur before erection of vents / drains and same shall be made by drilling.

7. Valves shall be installed with the spindle / actuator in the direction / orientation as mentioned in the drawing. Proper care shall be taken to ensure that globe valves, check valves and other unidirectional valves are installed with the "Flow direction arrow" on the valve body towards the correct direction.

ISSUED FOR JECOMMENTS

PREPARED BY

./~ -;;.uc::f?v-

~ CHECKED BY

1

17/12/2008

REV.NO

REVISION DESCRIPTION

DATE

DOCNO.: LT / LOBS I HPCL I PP I JP I M 002 REV NO: 1

DATE: 21.8.2008

JOB PROCEDURE FOR ABOVE GROUND PIPING FABRlCATION AND ERECTIO

ISSUED FOR ~ £" ~~ t pJ~9--~",. ~·ID";.;?~

1 17112/2008 JE COMMENTS - ~. jf;.'~~;< -_':<;

1~--~---1~~~~+---~~~~~~--4--PRE~·=PB~AREy~=D-+~C~HE~BC~yKE==D~~~~'~~~~~~~~~II ._~::

REV.NO DATE REVISION DESCRIPTION .. ~ "'K \IJ:::=d:. ~

~ ~.

Project: LOBS Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd,

Customer: MIS Hindustan Petroleum Corporation Limited, Mumbai.

LARSEN & TOUBROLTD

8. All bolts and nuts shall be supplied as per Project specifications and proper care shall be taken during storage. Wherever the bolts and nuts are to be tightened with torque wrench the same shall be tightened as per the requirement of Client I PMC,

7. INSPECTION:

I

1, All welds shall be visually inspected as per ANSI B31.3.

2. The NDT / PMI I PWHT as requires by specification shall be carried out on weld joints as per approved ITP and relevant procedures.

3. Defects which are being found unacceptable shall be removed by chipping I grinding and shall be re-welded by qualified welders. The repaired joints shall be re-tested as per relevant tests and shall be confirmed that the defect is completely removed.

4. All repairs shall be brought to the knowledge of clients Engineer In charge before repairing and approval for the same shall be received.

8.FLUSffiNG:

1. Flushing shall be done for all piping after the completion of erection and NDT's but before hydro testing with water or air to clean the pipe of all dirt, debris and any other foreign materials.

2. Wherever water flushing is desirable the same shall be carried out with utility water pressure. Air flushing shall be carried out with compressed air at a maximum pressure of 50psi. Potable water shall be used for flushing CS and SS. For flushing of SS lines, the chlorine content of water shall be less than 20 ppm with prior approval from the client.

3. All highly precise instruments, control valves; safety valves, screens / meshes of strainers shall be removed from pipelines before flushing.

4. The flushing shall be carried out with the quick opening valve installed on the line permanently or temporarily for as many times as required to the extent possible that the pipeline is cleaned and free of debris.

DOC NO.: LT / LOBS I HPCL / PP / JP / M 002 REV NO: 1

DATE: 21.8.2008

JOB PROCEDURE FOR ABOVE GROUND PIPING FABRICATION AND ERECTION

LARSEN & TOUBROLTD

Project: LOBS Quality Up gradation Project

I Consultant: MIS Jacobs Engineering India Private Ltd.

Customer: MIS Hindustan Petroleum Corporation Limited, Mumbai.

5. Due care shall be taken during flushing so that any adjacent structural near by flushing line or other agencies work shall not be damaged.

6. The flushing record shall be maintained for each line after completion of flushing by QC Engineer.

7. Safe plan of action and safety precaution to be taken.

9. HYDROTESTING:

1. A punch list showing details of line which includes the status of various inspections carried out during installation, NDT's, PWHT, PM!, etc shall be submitted to PMC for hydro test clearance.

2. Hydrostatic test shall be carried out for pipeline using water having maximum chlorine content of 50 ppm forJ;§_piping and 15-20 ppm for SS piping.

3. The hydro static pressure during hydro test shall be as indicated in line list or as instructed by PMC.

4. The testing line shall be started to fill water from the lowest point by keeping all vents in open condition for the release of air. The vents at various points shall be kept open until all the air entrapments are completely removed and the corresponding portion of pipeline is being completely filled with water.

5. After the line is completely filled with water the pipeline shall be started to pressurize gradually up to the testing pressure as indicated in line list or as instructed by PMC.

6. Pressure gauge used during test shall be of duly calibrated having accuracy maximum of 2% of full scale reading. The line shall be mounted with minimum of two pressure gauges during testing, one at the highest point and another one near by pressurizing point at lowest. P,,\M '

7. The pressurized pipeline shall be offered to PMC Engineer In-charge for inspection.

ISSUED FOR JECOMMENTS

17/12/2008

PREPARED BY

REVISION DESCRIPTION

REV.NO

DATE

DOC NO.: LT I LOBS I HPCL ! PP / JP / M 002 REV NO: 1

DATE: 21.8.2008

JOB PROCEDURE FOR ABOVE GROUND PIPING F ABRICA TION AND ERECTION

Project: LOB S Quality Up gradation Project Consultant: MIS Jacobs Engineering India Private Ltd.

Customer: MJS Hindustan Petroleum Corporation Limited, Mumbai.

LARSEN & TOUBROLTD

8. Test pressure shall be maintained for sufficient length of time so that all the weld joints shall be inspected for leakage. All the weld joints shall be cleaned by wire brushing / buffing before flushing / testing.

9. After successful completion of inspection the pressure shall be released gradually and water shall be discharged. All vents and drains shall remain open till the completion of draining.

10. Any repair I defect noticed during testing shall be repaired up to the satisfaction of Engineer In-charge and test shall be repeated.

11. A record showing the details of test shall be maintained by QC Engineer after successful completion of hydro test

10. DOCUMENTATION:

A dozzier compiling of all test reports carried out during fabrication, installation, NDT's and testing shall be documented and submitted to PMC before handing over of pipelines.

t@D i ~C£

PREPARED CHECKED

BY BY

ISSUED FOR JECOMMENTS

17112/2008

REV.NO

DATE

REVISION DESCRIPTION

You might also like

- Method Statement For Ss PipingDocument11 pagesMethod Statement For Ss Pipingbrijesh shah67% (3)

- FRP Fabrication, Installation and Repair ProcedureDocument3 pagesFRP Fabrication, Installation and Repair Procedurearchalys4u100% (1)

- Piping Design Requirements PDFDocument6 pagesPiping Design Requirements PDFkarunaNo ratings yet

- Tanks - Addition of Shell Nozzles by Hot TappingDocument2 pagesTanks - Addition of Shell Nozzles by Hot TappingJuan DelacruzNo ratings yet

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Document18 pagesPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- (0153) 4664-MSP-008 Fired HeatersDocument16 pages(0153) 4664-MSP-008 Fired HeatersSixto Gerardo100% (1)

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDocument1 pageProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananNo ratings yet

- 03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantDocument40 pages03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantmahmoudNo ratings yet

- Scope of Work-Fabrication of Heat ExchangersDocument3 pagesScope of Work-Fabrication of Heat ExchangersAsad KhanNo ratings yet

- 6 44 0005 A2Document25 pages6 44 0005 A2S.selvakumarNo ratings yet

- B - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersDocument22 pagesB - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersAnitNo ratings yet

- 50 190 RC e 03100Document6 pages50 190 RC e 03100ThirukkumaranBalasubramanianNo ratings yet

- Requisition of PumpDocument8 pagesRequisition of PumpGunturMudaAliAkbarNo ratings yet

- Strainer DescriptionDocument321 pagesStrainer DescriptionChirag ShahNo ratings yet

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Document7 pagesTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNo ratings yet

- A545-6-44-0016 - Rev-3 NDT NEW SPECDocument20 pagesA545-6-44-0016 - Rev-3 NDT NEW SPECSaheb YadavNo ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Compiled Vol IIDocument69 pagesCompiled Vol IIashish.mathur1No ratings yet

- Bangladesh MGI 300TD Continuous Polyester Production Line Bottle FlakeDocument44 pagesBangladesh MGI 300TD Continuous Polyester Production Line Bottle Flakeswapon kumar shillNo ratings yet

- Jacobs Standard Specification - Piping Fabrication and ErectionDocument19 pagesJacobs Standard Specification - Piping Fabrication and Erectionalinor_tn100% (1)

- QC Dossier 1Document1 pageQC Dossier 1VishnuGKNo ratings yet

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument19 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianNo ratings yet

- Inspection Storage Tank STD 129Document42 pagesInspection Storage Tank STD 129Sanath Kumar100% (1)

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Document22 pages15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNo ratings yet

- JD Pipeline Lead EngineerDocument3 pagesJD Pipeline Lead EngineeralexrodriguezabcNo ratings yet

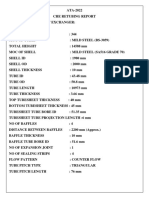

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- Pipewrap BT: DescriptionDocument2 pagesPipewrap BT: DescriptionVineet KhanduriNo ratings yet

- Method Statement For Repair Deethanizer Reflux Pump - CommentsDocument5 pagesMethod Statement For Repair Deethanizer Reflux Pump - CommentsRahmat HidayatNo ratings yet

- 5ST0307 - 017-T1-Me-Das-259 - 1 PDFDocument5 pages5ST0307 - 017-T1-Me-Das-259 - 1 PDFRishabh Verma100% (1)

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDocument10 pagesEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNo ratings yet

- How To Do A Tie-InDocument2 pagesHow To Do A Tie-Inrenjithv_4100% (1)

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFDocument29 pagesNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidNo ratings yet

- Demin Tank ReportDocument69 pagesDemin Tank Reportshahroze mustafaNo ratings yet

- 04 1 Sec IV STD Specs PipingDocument152 pages04 1 Sec IV STD Specs PipingdzungNo ratings yet

- Foam Monitor - F - 091318Document16 pagesFoam Monitor - F - 091318rusli bahtiarNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- Va1 Dec 00100 I M1D Pid 0001 PDFDocument2 pagesVa1 Dec 00100 I M1D Pid 0001 PDFAnonymous JtYvKt5XENo ratings yet

- Daily Report - XLSX 01Document1 pageDaily Report - XLSX 01kishoryawaleNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFMohamad RifkiNo ratings yet

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- On IC EnginesDocument29 pagesOn IC EnginesBabu JonnalagaddaNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 pagesDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNo ratings yet

- Closure Data PEDocument2 pagesClosure Data PEjowar100% (1)

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument7 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013No ratings yet

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocument38 pagesNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalNo ratings yet

- Colour Coding As Per BHELDocument7 pagesColour Coding As Per BHELKedar Choksi0% (1)

- Technical Specification of Flange Face Finish S-000-1360-006 - R - 0001Document3 pagesTechnical Specification of Flange Face Finish S-000-1360-006 - R - 0001Ton PhichitNo ratings yet

- Special Support in PipingDocument6 pagesSpecial Support in PipingAKHIL JOSEPHNo ratings yet

- Form 167Document239 pagesForm 167Kumar Navneet SinghNo ratings yet

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLENo ratings yet

- Heat TreatmentDocument5 pagesHeat TreatmentsheikmoinNo ratings yet

- Method Statement of Ipa-227 Piping WorksDocument5 pagesMethod Statement of Ipa-227 Piping WorksPramod kumarNo ratings yet

- Power & Water Project Method Statement For Spool Fabrication of Steel PipingDocument11 pagesPower & Water Project Method Statement For Spool Fabrication of Steel Pipinglion100_saadNo ratings yet

- MOS For Fabrication and InstallationDocument21 pagesMOS For Fabrication and InstallationDo Van HUNG100% (3)

- Method Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaDocument10 pagesMethod Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaFendik NewbieNo ratings yet