Professional Documents

Culture Documents

2-Way Slab

2-Way Slab

Uploaded by

Bunny HopperOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2-Way Slab

2-Way Slab

Uploaded by

Bunny HopperCopyright:

Available Formats

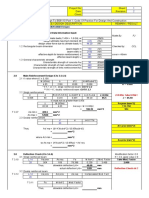

Slab Design: Using Direct Design Method Judgement: OK

Lnb = 2.70 m.

Cs Msb Cs

C1 G1 C2

Cs Interior Beam

Lna = Msa Interior Beam Edge Beam

1.70 m. La = 2.00 m.

G3 G4

Cs

Edge Beam

C3 G2 C4

Lb = 3.00 m.

General Slab Geometry Loads:

Short Span, La = 2.00 m. Dead Load = 1.94 kPa

Long Span, Lb = 3.00 m. Live Load = 6 kPa

Span Ration (Lb/La)= 1.5 Service Load = 10.94 kPa

thickness = 125 mm. Ultimate Load = 15.528 kPa

Two-Way Slab

db for short dir. = 16 mm. db for Long dir. = 16 mm.

Material Property:

Type of Concrete: Normal weight concrete

Modification factor: 1.00

fc' : 20.7 Mpa

fy : 414 Mpa

Es : 200,000 Mpa

Ec : 21383.7088 Mpa

ρc : 2,440 kg/m3 (1440<=ρc<=2560)

ϒc : 24 kN/m3

n (Es/Ec): 9

Reduction Factor (bending) : 0.90

Reduction Factor (Shear) : 0.75

Support Geometry:

Girder Size Beam Width Height

G1 250 450

G2 250 450

G3 250 450

G4 250 450

Column Size Short Dir. Long Dir.

C1 300 300

C2 300 300

C3 300 300

C4 300 300

Clear Short Span (maximum of the following):

1. La -C1/2 - C3/2

1.7 m.

2. La - C2/2 - C4/2

1.7 m.

3. 0.65La

1.3 m.

Lna = 1.7 m.

Clear Long Span (maximum of the following):

1. Lb -C1/2 - C3/2

2.7 m.

2. Lb - C2/2 - C4/2

2.7 m.

3. 0.65Lb

1.95 m.

Lnb = 2.7 m.

Clear Span Ratio (ß) : Lnb/Lna = 1.59

Clear Cover : 20.00 mm.

Column Strip, Cs = min(0.25Lb, 0.25La)

Cs = 0.5 m.

Middle Strip Along Short Direction, Msa :

Msa = La - 2Cs

= 1 m.

Middle Strip Along Long Direction, Msb :

Msb = Lb - 2Cs

= 2 m.

Check For Minimum thickness:

Check for flexural stiffness ratio:

Summary:

Direction Short Direction Long Direction

Side 3 4 1 2

Location Interior Beam Edge Beam Interior Beam Edge Beam

Beam Type T-Beam T-Beam T-Beam T-Beam

Beam, Ib (mm4) 2584932631.34058 2389736599.39236 3040783110.1191 2584932631.34

Slab, Is (mm4) 488281250 244140625 325520833.33333 162760416.667

Flexural Stiffness 5.294 9.788 9.341 15.882

αf1 = Ib/Is

αf2 9.341 9.341 5.294 5.294

l1 2.00 m. 2.00 m. 3.00 m. 3.00 m.

l2 3.00 m. 3.00 m. 2.00 m. 2.00 m.

f1l2/αf2l1 1.275 2.358 0.784 1.333

Judgement: OK OK OK OK

αfm = (αf1 + αf2 + αf3 + αf4)/4

= 10.076

Minimum Thickness for Short Direction:

for αfm <= 0.2

for fy <= 280

tmin = max[Lnb/36, 125]

= 125.00 mm.

for fy > 280 and fy <=420

tmin = max[Lnb/{33-[(420-fy)(33-36)/(420-280)]},125]

= 125.00 mm.

for fy > 420, and fy <=520

tmin = max[Lnb/{31-[(520-fy)(31-33)/(520-420)]},125]

= 125.00 mm.

tmin = 125.00

for αfm > 0.2 and αfm <= 2.0

h = Lna(0.8+fy/1400)/[36+5ß(αfm-0.2)]

h = 16.27

h= 125.00

h = 125.00

for αfm > 0.2 (maximum of)

tmin = Lna(0.8+fy/1400)/36+9ß

= 37.02 mm.

tmin = 90.00 mm.

use tmin = 90.00

Minimum Thickness for Long Direction:

for αfm <= 0.2

for fy <= 280

tmin = max[Lna/36, 125]

= 125.00

for fy > 280 and fy >=420

tmin = max[Lna/{33-[(420-fy)(33-36)/(420-280)]},125]

= 125.00

for fy > 420, and fy <=520

tmin = max[Lna/{31-[(520-fy)(31-33)/(520-420)]},125]

= 125.00

tmin = 125.00

for αfm > 0.2 and αfm <= 2.0

h = Lnb(0.8+fy/1400)/[36+5ß(αfm-0.2)]

h = 25.83

h= 125.00

h = 125.00

for αfm > 0.2 (maximum of)

tmin = Lnb(0.8+fy/1400)/36+9ß

= 58.80 mm.

tmin = 90.00 mm.

use tmin = 90.00

Minimum thickness for Long Direction = 90 mm.

Mimimum thickness for Short Direction = 90 mm.

Provide thickness = 90 mm. OK

Shear Check:

Short Direction Long Direction

Direction

Side 3 4 1 2

height d(mm) 97 97 81 81

width b(mm) 1000 1000 1000 1000

ΦVc (kN) 56.27 56.27 46.99 46.99

αf1 5.294 9.788 9.341 15.882

l2/l1 1.500 1.500 0.667 0.667

α1l2/l1 7.941 14.683 6.228 10.588

load Wu, kPa 15.528 15.528 15.528 15.528

length x, (m.) 0.778 0.778 1.294 1.294

Vu (kN) 12.081 12.081 20.093 20.093

Ratio 0.215 0.215 0.428 0.428

Judgement OK OK OK OK

Torsional stiffness for Edge Beam and End Span

3 4 1 2

x1 250 250 250 250

y1 450 450 450 450

x2 90 90 90 90

y2 325 325 325 325

C 1588634400 1588634400 1588634400 1588634400

ßt 1.627 3.254 2.440 4.880

Interior Negative Moments

L2/L1 0.50 1.00 2.00

αf1L2/L1 = 0 75 75 75

αf1L2/L1 > 1.0 90 75 45

Interior Positive Moments

L2/L1 0.50 1.00 2.00

αf1L2/L1 = 0 60 60 60

αf1L2/L1 > 1.0 90 75 45

Design Moment for Interior Beams;

I. Total Factored Static Moment: Mo

Short Span:

Wu(Lb)[max(Lna,0.65La]2/8

Long Span: Wu(La)[max(Lnb,0.65Lb]2/8

Wu(La)[max(Lnb,0.65Lb]2/8 Short Long

3 4 1 2

Mo (kN-m.) - - - -

II. Interior Spans:

Negative Moments (65% Mo) - - - -

Positive Moments (35% Mo) - - - -

III. Column Srips:

1. Interior Negative Moment:

a. Column Strip % Distribution - - - -

(-) Moment - - - -

a.1. Beam % Distribution - - - -

(-) Moment - - - -

a.2. Slab % Distribution - - - -

(-) Moment - - - -

b. Middle Strip % Distribution - - - -

(-) Moment - - - -

2. Positive Moment:

a. Column Strip % Distribution - - - -

(+) Moment - - - -

a.1. Beam % Distribution - - - -

(+) Moment - - - -

a.2. Slab % Distribution - - - -

(+) Moment - - - -

b. Middle Strip % Distribution - - - -

(+) Moment - - - -

Design Moment for Edge Beams;

I. Total Factored Static Moment: Mo

Short Span:

Wu(Lb/2 + bw/2)(Lnb2)/8

Long Span:

Wu(La/2 + bw/2)(Lna2)/8 Short Long

3.00 4.00 1.00 2.00

Mo (kN-m.) - - - -

II. Interior Spans:

Negative Moments (65% Mo) - - - -

Positive Moments (35% Mo) - - - -

III. Column Srips:

1. Interior Negative Moment:

a. Column Strip % Distribution - - - -

(-) Moment - - - -

a.1. Beam % Distribution - - - -

(-) Moment - - - -

a.2. Slab % Distribution - - - -

(-) Moment - - - -

b. Middle Strip % Distribution - - - -

(-) Moment - - - -

2. Positive Moment:

a. Column Strip % Distribution - - - -

(+) Moment - - - -

a.1. Beam % Distribution - - - -

(+) Moment - - - -

a.2. Slab % Distribution - - - -

(+) Moment - - - -

b. Middle Strip % Distribution - - - -

(+) Moment - - - -

Design Moment for Exterior Beams;

I. Total Factored Static Moment: Mo

Short Span:

Wu(Lb)[max(Lna,0.65La]2/8

Long Span: Wu(La)[max(Lnb,0.65Lb]2/8

Wu(La)[max(Lnb,0.65Lb]2/8 Short Long

3.00 4.00 1.00 2.00

Mo (kN-m.) 16.83 16.83 28.30 28.30

II. End Span

Factor Interior (-) moment 0.70 0.70 0.70 0.70

Factor (+) moment 0.57 0.57 0.57 0.57

Factor Exteriro (-) moment 0.16 0.16 0.16 0.16

Interior Negative Moment 11.78 11.78 19.81 19.81

Positive Moment 9.59 9.59 16.13 16.13

Exterior Negative Moment 2.69 2.69 4.53 4.53

III. Column Srips:

1. Interior Negative Moment:

a. Column Strip % Distribution 60.00 60.00 85.00 85.00

(-) Moment 7.07 7.07 16.84 16.84

a.1. Beam % Distribution 85.00 85.00 85.00 85.00

(-) Moment 6.01 6.01 14.31 14.31

a.2. Slab % Distribution 15.00 15.00 15.00 15.00

(-) Moment 1.06 1.06 2.53 2.53

b. Middle Strip % Distribution 40.00 40.00 15.00 15.00

(-) Moment 4.71 4.71 2.97 2.97

2. Positive Moment:

a. Column Strip % Distribution 60.00 60.00 85.00 85.00

(+) Moment 5.76 5.76 13.71 13.71

a.1. Beam % Distribution 85.00 85.00 85.00 85.00

(+) Moment 4.89 4.89 11.65 11.65

a.2. Slab % Distribution 15.00 15.00 15.00 15.00

(+) Moment 0.86 0.86 2.06 2.06

b. Middle Strip % Distribution 40.00 40.00 15.00 15.00

(+) Moment 3.84 3.84 2.42 2.42

3. Exterior Negative Moment

a. Column Strip % Distribution 60.00 60.00 85.00 85.00

(-) Moment 1.62 1.62 3.85 3.85

a.1. Beam % Distribution 85.00 85.00 85.00 85.00

(-) Moment 1.37 1.37 3.27 3.27

a.2. Slab % Distribution 15.00 15.00 15.00 15.00

(-) Moment 0.24 0.24 0.58 0.58

b. Middle Strip % Distribution 40.00 40.00 15.00 15.00

(-) Moment 1.08 1.08 0.68 0.68

Slab Number: S2 Date: October 20, 2020

Project Name: Proposed 2-Storey Market With Roof Deck Designed by: Engr. June-June Santos

FLEXURE REINFORCEMENT ALONG LONG DIRECTION

Interior Beam

C1 C2

G1

Interior -2.53 / 2 2.06 / 2 -0.58 / 2

Column Strip -1.265 1.03 -0.29 A

-2.97 / 2 2.42 / 2 -0.68 / 2

-1.485 1.21 -0.34

Middle Strip

G3

Interior Beam

-2.97 / 1 2.42 / 1

Edge Beam

-0.68 / 1

G4 B

-2.97 2.42 -0.68

Exterior

C

Column Strip -2.53 / 1 2.06 / 1 -0.58 / 1

-2.53 2.06 -0.58

C3 C4

G2

Edge Beam

ROW A ROW B ROW C

Flexure Reinforcement

TOP BOTTOM TOP BOTTOM TOP BOTTOM

Mu -1.265 1.03 -5.94 4.84 -2.53 2.06

Slab Width 375 375 1000 1000 375 375

tprovided 125 125 125 125 125 125

cc 20 20 20 20 20 20

fc' 20.7 20.7 20.7 20.7 20.7 20.7

fy 414 414 414 414 414 414

Φ 0.90 0.90 0.90 0.90 0.90 0.90

ß1 0.85 0.85 0.85 0.85 0.85 0.85

d 81 81 81 81 81 81

Ru 0.57 0.47 1.01 0.82 1.14 0.93

ρcalc 0.00140 0.00114 0.00250 0.00203 0.00286 0.00231

ρmin 0.00187 0.00151 0.00333 0.00270 0.00338 0.00307

ρmax 0.01548 0.01548 0.01548 0.01548 0.01548 0.01548

ρreq. 0.00187 0.00151 0.00333 0.00270 0.00338 0.00307

As req. 87.472 70.998 416.216 337.196 158.514 144.006

nomimal db 16 16 16 16 16 16

No. of Bars 1 1 3 2 1 1

Max. Spacing 250 250 250 250 250 250

Spacing Provided 200 200 200 200 200 200

Judgement OK OK OK OK OK OK

Flexure Reinforcement for whole Slab Width:

No. of bottom bars 10

No. of top bars 10

Asprov. For bottom bars 2010.62

Asprov. For top bars 2010.62

ρprov for bottom bars 0.01418

ρprov for top bars 0.01418

Ratio in bottom bars 0.27464

Ratio in top Bars 0.32935

Judgement OK

Crack Control Check:

ROW A ROW B ROW C

TOP BOTTOM TOP BOTTOM TOP BOTTOM

Mservice 0.8912351880474 0.7256697578568 4.1849304482226 3.4099433281814 1.7824703760948 1.4513395157136

k 0.3935070520898 0.3935070520898 0.3935070520898 0.3935070520898 0.3935070520898 0.3935070520898

fs 29.393340185062 23.932917304833 51.757838151957 42.173053309002 58.786680370124 47.865834609666

Crack Spacing 2850 3500 1600 1975 1425 1750

Judgement OK OK OK OK OK OK

FLEXURE REINFORCEMENT ALONG SHORT DIRECTION

D E F

Interior Exterior

Middle Strip

Column Strip Column Strip

Interior Beam

C1 G1 C2

-1.06 / 2 -4.71 / 2 -4.71 / 1 -1.06 / 1

-0.53 -2.355 -4.71 -1.06

Interior Beam 0.86 / 2 3.84 / 2 3.84 / 1 0.86 / 1 Edge Beam

0.43 1.92 3.84 0.86

G3 G4

-0.24 / 2 -1.08 / 2 -1.08 / 1 -0.24 / 1

-0.12 -0.54 -1.08 -0.24

C3 G2

C4

Edge Beam

ROW D ROW E ROW F

Flexure Reinforcement

TOP BOTTOM TOP BOTTOM TOP BOTTOM

Mu -0.53 0.43 -9.42 7.68 -1.06 0.86

Slab Width 375 375 2000 2000 375 375

tprovided 125 125 125 125 125 125

cc 20 20 20 20 20 20

fc' 20.7 20.7 20.7 20.7 20.7 20.7

fy 414 414 414 414 414 414

Φ 0.90 0.90 0.90 0.90 0.90 0.90

ß1 0.85 0.85 0.85 0.85 0.85 0.85

d 97 97 97 97 97 97

Ru 0.17 0.14 0.56 0.45 0.33 0.27

ρcalc 0.00041 0.00033 0.00137 0.00111 0.00081 0.00066

ρmin 0.00054 0.00044 0.00182 0.00148 0.00108 0.00088

ρmax 0.01548 0.01548 0.01548 0.01548 0.01548 0.01548

ρreq. 0.00054 0.00044 0.00182 0.00148 0.00108 0.00088

As req. 25.254 20.470 454.004 369.015 50.753 41.101

nomimal db 16 16 16 16 16 16

No. of Bars 1 1 3 2 1 1

Max. Spacing 250 250 250 250 250 250

Spacing Provided 200 200 200 200 200 200

Judgement OK OK OK OK OK OK

Flexure Reinforcement for whole Slab Width:

No. of bottom bars 15

No. of top bars 15

Asprov. For bottom bars 3015.93

Asprov. For top bars 3015.93

ρprov for bottom bars 0.01131

ρprov for top bars 0.01131

Ratio in bottom bars 0.14277

Ratio in top Bars 0.17574

Judgement OK

Crack Control Check:

ROW D ROW E ROW F

TOP BOTTOM TOP BOTTOM TOP BOTTOM

Mservice 0.373402885111 0.302949510562 6.636707882535 5.410819165379 0.746805770222 0.605899021123

k 0.360700519059 0.360700519059 0.360700519059 0.360700519059 0.360700519059 0.360700519059

fs 10.63944166434 8.631999840876 35.45644120686 28.90716225782 21.27888332867 17.26399968175

Crack Spacing 7875 9725 2350 2900 3925 4850

Judgement OK OK OK OK OK OK

15-16 dia. @ 10-16 dia. @

200mm. o.c. 200mm. o.c.

15-16 dia. @ Lb

200mm. o.c.

10-16 dia. @

200mm. o.c.

You might also like

- DPWH 2015 DGCS Vol 6Document359 pagesDPWH 2015 DGCS Vol 6Shara Mae de Mesa100% (1)

- Structural Analysis TemplateDocument1 pageStructural Analysis TemplateChristian Noel YanesNo ratings yet

- ScantlingDocument39 pagesScantlingSky R100% (1)

- Metal Deck 2 WayDocument3 pagesMetal Deck 2 Waymjfprgc0% (1)

- Slab S2 @RD AnalysisDocument1 pageSlab S2 @RD AnalysisMark Christian Esguerra100% (1)

- Slab Design Slab C8Document1 pageSlab Design Slab C8Mark Christian Esguerra100% (1)

- Appendix 5 DoneDocument36 pagesAppendix 5 Donearnoldleorenz17No ratings yet

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 pagesDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNo ratings yet

- One-Way Slab (CONTINOUS) - ACI - Code - Good OKDocument18 pagesOne-Way Slab (CONTINOUS) - ACI - Code - Good OKjdpdeleonNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- Slab Design Roof DeckDocument54 pagesSlab Design Roof DeckKolen LalongisipNo ratings yet

- 2WAY Slab Design TOMAS 2Document4 pages2WAY Slab Design TOMAS 2kingazure31No ratings yet

- 13 One Way Ribbed SlabDocument24 pages13 One Way Ribbed SlabKhalil FanousNo ratings yet

- Slab Design 1 WayDocument16 pagesSlab Design 1 WaySayavi Nicole Sayavi NickNo ratings yet

- Beamcolumn Capacity CheckDocument14 pagesBeamcolumn Capacity CheckshaimenneNo ratings yet

- Stuctural Analysis of TwoDocument16 pagesStuctural Analysis of TwoGalahan SoloNo ratings yet

- Structural Analysis 222Document5 pagesStructural Analysis 222ome hinigaran0% (1)

- Flat PlateDocument9 pagesFlat PlateMostafizur RahmanNo ratings yet

- Slab DesignDocument54 pagesSlab DesignKolen LalongisipNo ratings yet

- Parking #2 3-35Document1 pageParking #2 3-35Arra JoseNo ratings yet

- Design of Singly Reinforced RCC T-Beam Girder: M Value 10.0Document3 pagesDesign of Singly Reinforced RCC T-Beam Girder: M Value 10.0Rudranath BhattacharyaNo ratings yet

- Floor Slab DesignDocument3 pagesFloor Slab DesignAnonymous jLLjBdrNo ratings yet

- Slab S3 PDFDocument1 pageSlab S3 PDFMark Christian EsguerraNo ratings yet

- 6x7 NegDocument1 page6x7 NegAKSHAYNo ratings yet

- Bibi Design of SlabsDocument16 pagesBibi Design of SlabsMICHAEL MAHINAYNo ratings yet

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersDocument2 pagesS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- Whalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MDocument1 pageWhalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MWilliam ProvidoNo ratings yet

- Slab PresentationDocument6 pagesSlab PresentationJoemarie MartinezNo ratings yet

- Design of Two-Way SlabDocument1 pageDesign of Two-Way Slabpobre3nga3bataNo ratings yet

- Column Design: U U U C y Ys K KDocument2 pagesColumn Design: U U U C y Ys K Ksalman0% (1)

- Slab DesignDocument6 pagesSlab DesignKanchan Raja SinghNo ratings yet

- Roof 2Document1 pageRoof 2Aek JanNo ratings yet

- Asaad PDFDocument3 pagesAsaad PDFKabir RahmaniNo ratings yet

- Ribbed Slab Design-1Document2 pagesRibbed Slab Design-1HAITHAM ALI100% (2)

- T Beams (Final)Document8 pagesT Beams (Final)April Loureen Dale TalhaNo ratings yet

- One-Way SlabDocument18 pagesOne-Way SlabnathhnanNo ratings yet

- Flat Slab Design: I. Preliminary Design For Slab Thickness As Per Table 9.5 (C)Document3 pagesFlat Slab Design: I. Preliminary Design For Slab Thickness As Per Table 9.5 (C)arkitravel onthegoNo ratings yet

- Valid Design: Design of Two Way Slab (S-1)Document1 pageValid Design: Design of Two Way Slab (S-1)Pipoy ReglosNo ratings yet

- Analysis and Design of Multi Storey BuildingDocument36 pagesAnalysis and Design of Multi Storey Buildingdev6483% (12)

- Tugas 02 - Beton LanjutDocument2 pagesTugas 02 - Beton LanjutsalmanNo ratings yet

- Design of Slab On Grade at Basement, SOGDocument5 pagesDesign of Slab On Grade at Basement, SOGJohn Harold CastroNo ratings yet

- Design of Slab: F5F6G5G6Document2 pagesDesign of Slab: F5F6G5G6AKSHAYNo ratings yet

- 2 Way Slab DesignDocument6 pages2 Way Slab DesignAditya singhNo ratings yet

- Slab DesignDocument15 pagesSlab Designbsce.kionisala.agapitobNo ratings yet

- Reinforced Concrete Two Way SlabDocument3 pagesReinforced Concrete Two Way SlabMark Brien Vincent YbañezNo ratings yet

- One - Way Slab: Design SpecificationsDocument4 pagesOne - Way Slab: Design Specificationssetiawan hendroNo ratings yet

- Design of Floor (Slab 5) : La LBDocument12 pagesDesign of Floor (Slab 5) : La LBAyreesh Mey Spnt100% (1)

- 11 CulvertDesign v22Document2 pages11 CulvertDesign v22Lee See VoonNo ratings yet

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- Two way slabDocument2 pagesTwo way slabGazi Nazmul HoqueNo ratings yet

- Roof 1Document1 pageRoof 1Aek JanNo ratings yet

- Fy 276 Mpa: Formula For Transferring The Weight of Slab To BeamDocument19 pagesFy 276 Mpa: Formula For Transferring The Weight of Slab To Beamraymark mendozaNo ratings yet

- NAM - Design of Slab AnalysisDocument30 pagesNAM - Design of Slab AnalysisRasul AmirolNo ratings yet

- Design of Critical Two-Way SlabDocument8 pagesDesign of Critical Two-Way SlabBevelyn Manalo100% (1)

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- Eng - Mohamed Sayed Mohamed: Flat SlabDocument12 pagesEng - Mohamed Sayed Mohamed: Flat SlabYasinta Rizka FNo ratings yet

- Perancangan BautDocument10 pagesPerancangan BautBayu WibisonoNo ratings yet

- Steel Structure DesignDocument12 pagesSteel Structure DesignTalha tahirNo ratings yet

- Design of One-Way SlabDocument2 pagesDesign of One-Way SlabJm CampitanNo ratings yet

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsFrom EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsNo ratings yet

- Location Map-K0410+192l PDFDocument1 pageLocation Map-K0410+192l PDFBunny HopperNo ratings yet

- Location Map-K0410+167rDocument1 pageLocation Map-K0410+167rBunny HopperNo ratings yet

- Msce 514 PS1Document5 pagesMsce 514 PS1Bunny HopperNo ratings yet

- Summary of Approved Budget For The Contract: Department of Public Works and HighwaysDocument31 pagesSummary of Approved Budget For The Contract: Department of Public Works and HighwaysBunny HopperNo ratings yet

- Design and Development of Blow Molding DieDocument15 pagesDesign and Development of Blow Molding DieRahul VatsNo ratings yet

- Approx Vertical ModifiedDocument25 pagesApprox Vertical ModifiedShafkat SaminNo ratings yet

- Steel Rebar Sizes and Weights ChartsDocument2 pagesSteel Rebar Sizes and Weights ChartsNadiah Abdul RahamanNo ratings yet

- Wrinkling StressDocument8 pagesWrinkling StressCandace FrankNo ratings yet

- Pipa/flangeDocument2 pagesPipa/flangeDimas Ageng PurnamaNo ratings yet

- BOM - MRT 7, Station 10, STP Project, UG RC Tank (Materials Needed As of April 04, 2024)Document2 pagesBOM - MRT 7, Station 10, STP Project, UG RC Tank (Materials Needed As of April 04, 2024)johnrexNo ratings yet

- 2-Irrigation NetworksDocument46 pages2-Irrigation NetworksBazi habeshaNo ratings yet

- Railway Seminar On P WayDocument256 pagesRailway Seminar On P WayAshish Goswami100% (2)

- Power Law and Log Law Velocity Profiles in Turbulent Boundary-Layer Flow: Equivalent Relations at Large Reynolds NumbersDocument2 pagesPower Law and Log Law Velocity Profiles in Turbulent Boundary-Layer Flow: Equivalent Relations at Large Reynolds NumbersManuel MejiaNo ratings yet

- Item 311Document64 pagesItem 311Jansen WongNo ratings yet

- Measurement of Fluid Flow in Pipes Using Orifice, Nozzle, and Venturi (Main Equations and Historical Background)Document17 pagesMeasurement of Fluid Flow in Pipes Using Orifice, Nozzle, and Venturi (Main Equations and Historical Background)empanadaNo ratings yet

- Hydrotest Pressure Procedure - 2023Document15 pagesHydrotest Pressure Procedure - 2023Amit HasanNo ratings yet

- First Floor Column and Shear Reinforcement and SizesDocument1 pageFirst Floor Column and Shear Reinforcement and SizesMohit VatsNo ratings yet

- California ContractorsDocument12 pagesCalifornia ContractorsJAGUAR GAMINGNo ratings yet

- Foamed Concrete ProposalDocument7 pagesFoamed Concrete ProposalDawit SolomonNo ratings yet

- Dumbbells DimensionDocument11 pagesDumbbells Dimensionhoda melhemNo ratings yet

- 1 s2.0 S0301679X20305624 MainDocument9 pages1 s2.0 S0301679X20305624 MainAnis SuissiNo ratings yet

- VKM-G (M) v1 Databook VamDocument332 pagesVKM-G (M) v1 Databook Vamlada1119No ratings yet

- BA 001 R0A (Without Mezzanine)Document1 pageBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqNo ratings yet

- Fluvial LandformsDocument125 pagesFluvial Landformsuapfa khomolaNo ratings yet

- C&Z Purlins Span TablesDocument4 pagesC&Z Purlins Span TablesNavin RamroopNo ratings yet

- State of The Art Atrium Smoke ControlDocument12 pagesState of The Art Atrium Smoke ControlBasil OguakaNo ratings yet

- Metallurgical Failure Analysis-IDocument30 pagesMetallurgical Failure Analysis-ISaurabh SinghNo ratings yet

- 06 Shallow FoundationDocument26 pages06 Shallow FoundationHukry AingNo ratings yet

- Design Considerationsof Concrete Lined ChannelsDocument12 pagesDesign Considerationsof Concrete Lined ChannelsNeha NasreenNo ratings yet

- Classified Data AnalysisDocument6 pagesClassified Data Analysiskaran976No ratings yet

- April 2024 - PSAD 18Document2 pagesApril 2024 - PSAD 18rando12345No ratings yet

- Sidesway Web Buckling of Steel BeamsDocument12 pagesSidesway Web Buckling of Steel BeamsYuth Yuthdanai100% (1)

- For Plastering, 260.00Document15 pagesFor Plastering, 260.00Hayeon KimNo ratings yet