Professional Documents

Culture Documents

General Construction Notes: Schedule of Concrete Hollow Block and Ceramic Block Reinforcement

General Construction Notes: Schedule of Concrete Hollow Block and Ceramic Block Reinforcement

Uploaded by

Dominic Robiso DatuinCopyright:

Available Formats

You might also like

- United Valve Comparison Awwa c515 Awwa c509Document2 pagesUnited Valve Comparison Awwa c515 Awwa c509itovarsilva100% (2)

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- 600mm Dia Test PileDocument1 page600mm Dia Test PileRohith Baddela100% (1)

- Test Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des ChargesDocument9 pagesTest Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des Chargesclaudio5475No ratings yet

- Pile Conditions: Input Quantities Value Units CommentDocument18 pagesPile Conditions: Input Quantities Value Units CommentFidel Rodriguez HerrerosNo ratings yet

- General Structural Notes Page 2Document1 pageGeneral Structural Notes Page 2piyadang16No ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Existing Culvert C405 - Temporary Supports DetailsDocument1 pageExisting Culvert C405 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Existing Culvert C409 - Temporary Supports DetailsDocument1 pageExisting Culvert C409 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Existing Culvert C401 - Temporary Supports DetailsDocument1 pageExisting Culvert C401 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- Existing Culvert C407 - Temporary Supports DetailsDocument1 pageExisting Culvert C407 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder PortDocument1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Portalezandro del rossiNo ratings yet

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59Document1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59alezandro del rossiNo ratings yet

- FL DS 1023Document1 pageFL DS 1023basemapNo ratings yet

- Existing Culvert C440 - Temporary Supports DetailsDocument1 pageExisting Culvert C440 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- F H J K L M N AP 1.1: Demo Plan Legend Demolition Plan LegendDocument3 pagesF H J K L M N AP 1.1: Demo Plan Legend Demolition Plan LegendmaresdaNo ratings yet

- Engr Micheal STRDocument12 pagesEngr Micheal STRUmar SaiduNo ratings yet

- General Structural Notes Page 1Document1 pageGeneral Structural Notes Page 1piyadang16No ratings yet

- Specification: Foundation PlanDocument1 pageSpecification: Foundation PlanRenzelNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- Footing Schedule Column Schedule: WF-O1 C1Document1 pageFooting Schedule Column Schedule: WF-O1 C1Bj GutierrezNo ratings yet

- BT 2ND PageDocument1 pageBT 2ND PageRyan AbuzoNo ratings yet

- Manzanero Structural PlanDocument3 pagesManzanero Structural PlanANGELIZA DONCILLONo ratings yet

- Anthony Wanjiku Revised StructuralDocument1 pageAnthony Wanjiku Revised Structuralpatrickmore09No ratings yet

- General Notes: Makati - Mandaluyong BridgeDocument1 pageGeneral Notes: Makati - Mandaluyong BridgegregNo ratings yet

- CHECK in Erection DrawingDocument34 pagesCHECK in Erection DrawingAMIT TIWARINo ratings yet

- Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkDocument1 pageStructural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkOladunni AfolabiNo ratings yet

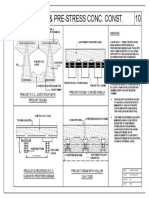

- 10 Precast - Pre-Stress Conc - ConstDocument1 page10 Precast - Pre-Stress Conc - ConstChhaganNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- Design of 33 SQM HousingDocument1 pageDesign of 33 SQM HousingDJNo ratings yet

- Mansilingan Structural PDFDocument6 pagesMansilingan Structural PDFSyre Yan Moscoso Tubale100% (1)

- Acm TSC VS MF DWG ST 2001Document1 pageAcm TSC VS MF DWG ST 2001Aecom IndiaNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- Plumbing Notes:: Plumbing Legend and SymbolsDocument1 pagePlumbing Notes:: Plumbing Legend and SymbolsRobee Ocampo100% (1)

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- 2024 - Powerhouse-Roadway Detailed DesignDocument1 page2024 - Powerhouse-Roadway Detailed Designadonis bibatNo ratings yet

- 85 Welwyn Ave Schematic 01052022Document2 pages85 Welwyn Ave Schematic 01052022Joseph MunawarNo ratings yet

- Poster BC - Bored PileDocument1 pagePoster BC - Bored PileZaim Adli100% (1)

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- 04 Structural DrawingsDocument10 pages04 Structural DrawingszeipoibjasNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Slab Layout: DWG No 190811 DDocument14 pagesSlab Layout: DWG No 190811 DSaiful IslamNo ratings yet

- St. Luke's: RemarksDocument1 pageSt. Luke's: RemarksErwin Sto'domingoNo ratings yet

- Structural Plan PDFDocument10 pagesStructural Plan PDFPaul Anjelo MilagrosaNo ratings yet

- (4.) Beams & Slabs 5.reinforcement:: General NotesDocument1 page(4.) Beams & Slabs 5.reinforcement:: General NotesVirendra ChavdaNo ratings yet

- Construction Notes:: Revisions Project Date Owner Sheet Contents by Sheet NoDocument1 pageConstruction Notes:: Revisions Project Date Owner Sheet Contents by Sheet NoEmorej GameplayNo ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- Ekene Semi Detached StructuralDocument18 pagesEkene Semi Detached StructuralNwachukwu PrinceNo ratings yet

- Mace Ar 10 B1 02Document1 pageMace Ar 10 B1 02Syead OwaisNo ratings yet

- AS05Document1 pageAS05Vic NairaNo ratings yet

- Main Gate and Boundary Wall PDFDocument13 pagesMain Gate and Boundary Wall PDFwali mustafaNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- Unit 17 Lighting LayoutDocument1 pageUnit 17 Lighting Layoutnikkoelbao96No ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- Pre-Cast ConstructionDocument1 pagePre-Cast ConstructionAshish SharmaNo ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- BR 30 StrengtheningDocument1 pageBR 30 Strengtheningdesign MridcNo ratings yet

- Actual As of Feb. 26,2024Document1 pageActual As of Feb. 26,2024zab0414No ratings yet

- Master of Ceremonies Welcome Martinez - Beltran Nuptials: (Any Favorite Song/s of The Groom And/or The Bride)Document5 pagesMaster of Ceremonies Welcome Martinez - Beltran Nuptials: (Any Favorite Song/s of The Groom And/or The Bride)Dominic Robiso DatuinNo ratings yet

- John Paul SingsonDocument2 pagesJohn Paul SingsonDominic Robiso DatuinNo ratings yet

- Vincent Claudius P. Perea: EducationDocument2 pagesVincent Claudius P. Perea: EducationDominic Robiso DatuinNo ratings yet

- P.1. Bill of MaterialsDocument50 pagesP.1. Bill of MaterialsDominic Robiso DatuinNo ratings yet

- In A Constant Head Permeability Test in The LaboratoryDocument6 pagesIn A Constant Head Permeability Test in The LaboratoryDominic Robiso DatuinNo ratings yet

- The Construction Project: University of Rizal SystemDocument5 pagesThe Construction Project: University of Rizal SystemDominic Robiso DatuinNo ratings yet

- Research Critique: University of Rizal SystemDocument9 pagesResearch Critique: University of Rizal SystemDominic Robiso DatuinNo ratings yet

- M.2. Carpentry WorksDocument26 pagesM.2. Carpentry WorksDominic Robiso DatuinNo ratings yet

- Narrative Report FinalDocument53 pagesNarrative Report FinalDominic Robiso DatuinNo ratings yet

- Datuin, Dominic R. Ce - V October 11, 2019 CE 11: Highway EngineeringDocument2 pagesDatuin, Dominic R. Ce - V October 11, 2019 CE 11: Highway EngineeringDominic Robiso DatuinNo ratings yet

- General Preliminaries: EarthworksDocument3 pagesGeneral Preliminaries: EarthworksDominic Robiso DatuinNo ratings yet

- Actual Perspective: TLA 211.96 SQ.MDocument8 pagesActual Perspective: TLA 211.96 SQ.MDominic Robiso DatuinNo ratings yet

- Bill of MaterialsDocument2 pagesBill of MaterialsDominic Robiso DatuinNo ratings yet

- Proposed Traffic Management Scheme For Liwasang Jose NDocument12 pagesProposed Traffic Management Scheme For Liwasang Jose NDominic Robiso DatuinNo ratings yet

- Roof Details Description Computation Vaue UnitDocument6 pagesRoof Details Description Computation Vaue UnitDominic Robiso DatuinNo ratings yet

- Problem and Its BackgroundDocument15 pagesProblem and Its BackgroundDominic Robiso DatuinNo ratings yet

- CE 18: Construction Methods and Project Management Assignment No. 3Document3 pagesCE 18: Construction Methods and Project Management Assignment No. 3Dominic Robiso DatuinNo ratings yet

- Plumbing Layout Isometric View: A. P. Garcia & AssociatesDocument1 pagePlumbing Layout Isometric View: A. P. Garcia & AssociatesDominic Robiso DatuinNo ratings yet

- Ground Floor Plan Second Floor Plan Third Floor Plan Penthouse Floor Plan Attic Floor PlanDocument1 pageGround Floor Plan Second Floor Plan Third Floor Plan Penthouse Floor Plan Attic Floor PlanDominic Robiso DatuinNo ratings yet

- Actual Perspective: TLA 211.96 SQ.MDocument5 pagesActual Perspective: TLA 211.96 SQ.MDominic Robiso DatuinNo ratings yet

- Kwik Bolt 3 Exp Anchor Hilti PDFDocument21 pagesKwik Bolt 3 Exp Anchor Hilti PDFarturoncNo ratings yet

- SiliconesDocument19 pagesSiliconesprabhuNo ratings yet

- hssc1201t SecquizDocument2 pageshssc1201t SecquizKingProNo ratings yet

- GEST 79 76 Edition 4Document26 pagesGEST 79 76 Edition 4روشان فاطمة روشانNo ratings yet

- Status of Macro and Micro Nutrients in Selected Soils of Moshi Rural District, Kilimanjaro Tanzania: Case Study of Mboni, Kyou and Makami Chini Villages.Document44 pagesStatus of Macro and Micro Nutrients in Selected Soils of Moshi Rural District, Kilimanjaro Tanzania: Case Study of Mboni, Kyou and Makami Chini Villages.DANIEL ISDORYNo ratings yet

- Chemistry Form 3 End Term 1 2024Document14 pagesChemistry Form 3 End Term 1 2024osiemojjNo ratings yet

- The First Transition SeriesDocument127 pagesThe First Transition Seriesapi-3734333100% (6)

- IB HL Chemistry - Chapter 5 Thermochemistry - EnthalpyDocument7 pagesIB HL Chemistry - Chapter 5 Thermochemistry - Enthalpy14nganhc10% (1)

- What FCC Catalyst Tests ShowDocument5 pagesWhat FCC Catalyst Tests ShowPraveen KumarNo ratings yet

- Organic Chemistry Keywords - 1. Crossword Answers.Document2 pagesOrganic Chemistry Keywords - 1. Crossword Answers.sjNo ratings yet

- Concrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsDocument10 pagesConcrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsShakeel WaseemNo ratings yet

- Volkmann Vacuum Conveying Brochure 2017 US PDFDocument36 pagesVolkmann Vacuum Conveying Brochure 2017 US PDFJose DuranNo ratings yet

- List of Products Certified - Ghana Standarads BoardDocument6 pagesList of Products Certified - Ghana Standarads Boardsaisridhar99No ratings yet

- CP Training1Document272 pagesCP Training1faisalqr100% (2)

- Journal of Natural Fibers PDFDocument16 pagesJournal of Natural Fibers PDFKalusu Raman100% (1)

- Solid Mechanics Short Questions and AnswersDocument61 pagesSolid Mechanics Short Questions and Answerssampathsiddam77% (31)

- STD 142Document58 pagesSTD 142Salil DasNo ratings yet

- Static Analysis of Bajaj Pulsar 150 CC Crankshaft Using ANSYSDocument7 pagesStatic Analysis of Bajaj Pulsar 150 CC Crankshaft Using ANSYSCristian JavierNo ratings yet

- ULSD Production - Improved Feed Stream QualityDocument6 pagesULSD Production - Improved Feed Stream Qualitysaleh4060No ratings yet

- Multiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyDocument109 pagesMultiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyLong BuiNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- 26 HiLiteDocument36 pages26 HiLitedencave1No ratings yet

- ASTM A307: ScopeDocument2 pagesASTM A307: ScopetylerstearnsNo ratings yet

- Petronas Technical Standards: Cathodic Protection System For Metallic Piping (Amendments/ Supplements To NACE SP0169)Document11 pagesPetronas Technical Standards: Cathodic Protection System For Metallic Piping (Amendments/ Supplements To NACE SP0169)Abd.Buhari Abd.GalimNo ratings yet

- Lesson 3 Properties of Liquids and IMFDocument47 pagesLesson 3 Properties of Liquids and IMFHillary Faith GregoryNo ratings yet

- Indones. J. Chem., 2022, 22 (1), 171 - 178: AbstractDocument8 pagesIndones. J. Chem., 2022, 22 (1), 171 - 178: AbstractDyah Ayu LarasatiNo ratings yet

- Starplast Spray-Applied-Plaster Data SheetDocument5 pagesStarplast Spray-Applied-Plaster Data SheetEng Mohammad OmariNo ratings yet

General Construction Notes: Schedule of Concrete Hollow Block and Ceramic Block Reinforcement

General Construction Notes: Schedule of Concrete Hollow Block and Ceramic Block Reinforcement

Uploaded by

Dominic Robiso DatuinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Construction Notes: Schedule of Concrete Hollow Block and Ceramic Block Reinforcement

General Construction Notes: Schedule of Concrete Hollow Block and Ceramic Block Reinforcement

Uploaded by

Dominic Robiso DatuinCopyright:

Available Formats

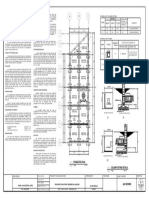

GENERAL CONSTRUCTION NOTES

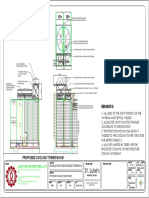

NOTES ON CONCRETE HOLLOW BLOCK WALLS DOWEL BARS TO NOTES ON CONCRETE WALLS NOTES ON CONSTRUCTION JOINTS IN CONCRETE

FLR. SLAB OR BEAM

MATCH VERT. BARS

1. UNLESS OTHERWISE SHOWN IN PLANS ALL CONCRETE HOLLOW BLOCKS AND CERAMIC BLOCKS 1. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING SCHEDULE OF WALL 1. WHERE A CONSTRUCTION JOINT IS TO BE MADE, THE SURFACE OF CONCRETE SHALL BE

SHALL BE REINFORCED AS SHOWN IN THE SCHEDULE OF CONCRETE HOLLOW BLOCKS AND CERAMIC REINFORCEMENT UNLESS OTHERWISE INDICATED IN THE PLANS. CLEANED AND ALL LAITANCE AND STANDING WATER REMOVED. SHEAR KEY SHALL BE

(DOWEL)

PROVIDED AT THE JOINT.

4.00

BLOCK REINFORCEMENT.

VERIFY ARCHITECTURAL

1. ALL JOINTS AND CELLS

2. PROVIDE 150mm X 300mm STIFFENER COLUMN REINFORCEMENT WITH 4-12mm WITH 6mmØ TIES AT CONTAINING REINFORCING

BARS SHALL BE FILLED

WALL REINFORCEMENT VERTICAL MAIN REINFORCEMENTS TO BE

150mm ON CENTER WHERE CONCRETE HALLOW BLOCK TERMINATES AND AT EVERY 3.0M LENGTH THICKNESS SECTION CONTINUOUS (TOP & BOTT, BARS)

WITH CONCRETE GROUT HORIZONTAL VERTICAL REMARKS

OF CONCRETE HOLLOW BLOCK WALLS UNLESS NOTED IN STRUCTURAL PLANS. 2. FOR REINFORCEMENTS SEE 100mm Ø10mm @ 250mm O.C. Ø10mm @ 300mm O.C. HORIZONTAL BARS VERT. WHERE JOINTS IS AT POINT OF

CONSTRUCTION NOTES. BARS MAIN REINFORCEMENTS

125mm Ø10mm @ 250mm O.C. Ø10mm @ 250mm O.C. AT CENTER VERTICAL STRESS, PROVIDE SHEAR RODS

HORIZ. TO BE CONTINUOUS

WITH ENGINEERS APPROVAL

150mm Ø12mm @ 300mm O.C. Ø12mm @ 300mm O.C. BARS STAGGERED OUT BARS

SCHEDULE OF CONCRETE HOLLOW BLOCK AND CERAMIC BLOCK REINFORCEMENT Ø10X1000 LONG

(DOWEL)

30 BAR DIA. 50 30 BAR DIA. @ 300 O.C.

D/3

4.00

BLOCK

THICKNESS

REINFORCEMENT NOTES 1-Ø16 CONT. HOR BARS (MIN.) (MIN.)

t/3

FOR FLOOR SLAB ONLY REINFORCING BARS SHALL HAVE 25mm CLEAR CONCRETE COVER FROM FACE OF WALL EXCEPT 40

HORIZONTAL VERTICAL A. MINIMUM LAPS AT SPLICE = 0.25M

FOR WALLS IN CONTACT WITH THE GROUND WHERE A MINIMUM OF 60mm SHALL BE PROVIDED,

D/3

B. PROVIDE RIGHT ANGLED REINFORCEMENT

75 mm 10mmØ @ 600mm O.C. 10mmØ @ 600mm O.C. AND FOR EXPOSED FACES OF FORMED WALLS WHERE THE MINIMUM SHALL BE 50mm CLEAR.

t/3

AT CORNERS 0.92M LONG

t

125 mm 10mmØ @ 600mm O.C. 10mmØ @ 600mm O.C. C. WHERE CHB OR CER. BLK. WALL DOWELS

JOIN COL. R.C. BEAMS AND WALL DOWELS 2. CARRY VERTICAL BARS AT LEAST 60mm ABOVE FLOOR LEVEL TO PROVIDE FOR SPLICES WHEN

BEAM SLAB

D/3

t/3

150 mm 10mmØ @ 600mm O.C. 10mmØ @ 600mm O.C. WITH THE SAME SIZE AS VERT. OR HOR.

REINFORCEMENTS SHALL BE PROVIDED

TYP. SECTION ON MASONRY NECESSARY STOP AT 50mm BELOW TOP SLAB OR SOLID BAND WHERE THE WALL ENDS VERTICAL

AND HORIZONTAL BARS SHALL BE SPLICED BY LAPPING S DISTANCE EQUAL TO 30 DIAMETERS

200 mm 12mmØ @ 600mm O.C. 12mmØ @ 600mm O.C. AND WIRED SECURELY WITH 16 G.I. WIRE PROVIDED THAT SPLICES IN ADJACENT BARS ARE

PARTITION REINFORCEMENTS STAGGERED AT LEAST 1.50M.O.C.

TYPICAL SLAB & BEAM

3. UNLESS OTHERWISE NOTED IN THE PLANS. ALL OPENINGS IN WALLS 250mm OR THICKER SHALL

BE REINFORCED AROUND WITH 2-20mmØ BARS FOR 225mm, 200mm, 175mm, 150mm, USE CONSTRUCTION JOINT DET.

2-16mmØ FOR 125mm AND 100mm WALLS. USE 2-12mmØ BARS. ALL WALLS SPANNING

SHALL HAVE VERTCAL REINFORCEMENT BENT TO A U-FORM LIKE STIRRUPS AND SPACED

REINFORCING CONCRETE LINTEL BEAM IN SEE CONSTRUCTION NOTES ACCORDING TO THE SCHEDULE UNLESS OTHERWISE NOTED (SEE FIG.1)

FOR MASONRY WALL REIN-

CONCRETE BLOCK WALLS FIN. FLR. LVL.

FORCEMENTS (TYPICAL)

VARIES

LINTELS IN BLOCK WALLS

CLEAR TOTAL MIN. HEIGHT R E I N F O R C E M E N T NAT. GRD. LVL

SPAN LENGTH fc LINTEL DOWEL BARS TO MATCH

600 (MIN.)

("L") (L+0.40M) (MPa) (MM) BOTTOM TOP STIRRUPS CHB VERTICAL BARS

Ø10 BOTT. BARS 4-Ø16 VERT. BARS

1.20M 1.60M 200 1- Ø10 1- Ø10 Ø6mm @ 200mm @ 300 O.C.

250

1.50M 1.90M 14.0 200 1- Ø10 1- Ø10 Ø6mm @ 200mm 4-Ø16 VERT. BARS

550

1.80M 2.20M 200 1- Ø12 1- Ø10 Ø6mm @ 200mm 3-Ø10 BOTT. BARS

550

DOOR

2.10M 2.50M 250 1- Ø12 1- Ø10 Ø6mm @ 200mm 400 OPENING NOTE:

2.40M 2.90M 17.0 250 1- Ø12 1- Ø10 Ø6mm @ 200mm PROVIDE THESE ADDITIONAL BARS FOR

2.70M 3.10M 250 1- Ø16 1- Ø12 Ø10mm @ 200mm ALL OPENINGS PLUS BARS (NOT SHOWN)

PARALLEL TO SIDE OF OPENING 38mm

3.00M 3.40M 300 1- Ø16 1- Ø12 CLEAR

Ø10mm @ 200mm 550 EQUAL TO THE NUMBER OF TERMINATED

3.30M 3.70M 20.0 300 1- Ø16 1- Ø12 Ø10mm @ 200mm 550 BARS AT OPENING

3.60M 4.00M 300 1- Ø20 1- Ø12 Ø10mm @ 200mm

SEE ARCHITECTURAL & MECHANICAL

PLANS FOR SLAB OPENING LOCATION.

DOWEL TO MATCH

CHB VERT. BARS TYPICAL CONNECTION DETAIL

OF R.C WALL AT CORNERS

12 THK. EXPANSION JOINT 300

(DOWEL)

WITH MASTIC FILLER 1-Ø16 VERT. BARS (TYP.)

400

CHB WALL FIN. FLR. LVL 250

TYPICAL EXTERIOR WINDOW & DOOR OPENING

1 -Ø16 VERT. BARS

FOR SIZE AND SPACING

OF HOR. & VERT. BARS

NOTES ON WELDS

SEE CONSTRUCTION NOTES 1. USE E70xx ELECTRODES FOR ALL MEMBERS WELDED.

CHB WALL 3-Ø10 BARS (AS SHOWN)

Ø10 BOTT, BARS @ 300 O.C.

NOTES OF STIRRUPS

2. WELDS SHALL DEVELOP THE FULL STRENGTH OF MEMBERS JOINED UNLESS OTHERWISE

FOR SIZE AND SPACING 400

SHOWN OR DETAILED IN THE DRAWINGS. 1. ALL REINFORCEMENT SHALL BE BENT COLD UNLESS OTHERWISE PERMITTED BY THE

OF HOR. & VERT. BARS STRUCTURAL ENGINEER.

SEE CONSTRUCTION NOTES.

2. REINFORCEMENT PARTIALLY EMBEDDED IN CONCRETE SHALL NOT BE FILLED BENT, EXCEPT

CORNER WALL OPENING OR END WALL NOTES ON STRUCTURAL STEEL AS SHOWN IN THE DESIGN DRAWING OR PERMITTED BY THE STRUCTURAL ENGINEER.

1. STRUCTURAL STEEL TO BE USED FOR FABRICATION AND ERECTION OF THIS STRUCTURE SHALL 3. TIES & CLOSE STIRRUPS MUST BE BENT AT 135 .

COMPLY WITH ALL THE PERTINENT PROVISION OF AISC SPECIFICATION FOR THE DESIGN,

1 -Ø16 VERT. BARS R.C. COLUMN OR WALL FABRICATION AND ERECTION OF STRUCTURAL STEEL FOR BUILDING LATEST EDITION.

DOWEL TO MATCH

12 THK. EXPANSION JOINT DOWEL BARS TO MATCH CHB VERT. BARS 2. ALL STRUCTURAL STEEL SHAPES SHALL CONFORM TO ASTM A36 STRUCTURAL STEEL UNLESS

CHB HOR. BARS OTHERWISE INDICATED. L

WITH MASTIC FILLER WHERE DEPRESSED

D + 2db

SLAB OCCURS

CHB WALL 12 THK. EXPANSION JOINT 3. ALL WELDED CONNECTIONS SHALL DEVELOP THE FULL STRENGTH OF THE MEMBERS CONNECTED. 135 HOOKS

L

WITH MASTIC FILLER 300

(DOWEL)

(TYP.) 4. UNLESS OTHERWISE SPECIFIED ALL WELDING RODS SHALL CONFORM AWS E60 ELECTRODES.

400

4db or 65mm

D

(DOWEL)

5. ALL BOLTS USED UNLESS OTHERWISE SPECIFIED SHALL BE ASTM A 307 BLOTS.

400

6d

D

b

180 END HOOKS

250

FOR SIZE AND SPACING

OF HOR. & VERT. BARS 400

SEE CONSTRUCTION NOTES.

(DOWEL) 3-Ø10 BARS (AS SHOWN)

Ø10 BOTT, BARS @ 300 O.C.

NOTES ON EMBEDDED PIPES

INTERSECTION WALL INTERSECTING R.C. COL. OR WALL 400

A. ALL EMBEDDED PIPES FOR UTILITIES, ETC. THAT PASS THRU BEAMS SHALL NOT EXCEED 100mm

2db

L

db

IN DIAMETER OR 1/3 BEAM DEPTH WHICHEVER IS LESS, UNLESS OTHERWISE APPROVED IN

WRITING BY THE STRUCTURAL ENGINEER.

D

TYPICAL CONNECTION DETAIL OF MANSORY WALL TYP. CHB FOOTING DETAILS B. NO PASS SHALL BE ALLOWED TO PASS THRU BEAMS VERTICALLY. L

90 HOOKS

(WHERE APPLICABLE) C. NO PIPES SHALL BE EMBEDDED IN COLUMNS.

90 END HOOKS

L1

200(MIN) 200(MIN)

FOR SIZE AND SPACING

Ø10 STIRRUPS OF HOR. & VERT. BARS

@ 150 O.C. SEE CONSTRUCTION NOTES

VERIFY DEPRESSION

(DOWEL)

30 BAR DIA. 30 BAR DIA.

400

DOWEL BARS TO MATCH (min.) (min.) MAIN BAR END HOOKS STIRRUP AND TIE HOOKS

D=FOR BEAM

CHB WALL CHB VERT. BARS

t= FOR SLAB

( ALL GRADES ) (ALL GRADES)

2 - Ø12 TOP BARS 180 HOOK 9O HOOK 180 HOOK 9O HOOK

BAR SIZE DIA. BAR SIZE DIA.

200

1-Ø16 VERT. (DEFORMED) (mm) (DEFORMED) (mm)

BARS TYPICAL D+2bd L L D+2bd L L

2 - Ø12 TOP BARS

10mm Ø 60 75 125 150 10mm Ø 40 125 85 100

D=FOR BEAM 12mm Ø 75 100 150 200 12mm Ø 50 165 115 115

SECTION 2t=FOR SLAB

16mm Ø 95 125 175 250 16mm Ø 65 200 140 150

FIN. FLR. LVL 30 BAR DIA.

(min.) 20mm Ø 115 150 200 300 20mm Ø 115 250 165 300

25mm Ø 150 200 230 450 25mm Ø 150 365 230 405

ELEVATION

TYP. DETAIL FOR BEAM 28mm Ø 240 300 350 550

300 335 450 600

TYPICAL DET. OF LINTEL BEAM AT CHB WALL OPENING OR SLAB CHANGE SOFFIT 32mm Ø

You might also like

- United Valve Comparison Awwa c515 Awwa c509Document2 pagesUnited Valve Comparison Awwa c515 Awwa c509itovarsilva100% (2)

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- 600mm Dia Test PileDocument1 page600mm Dia Test PileRohith Baddela100% (1)

- Test Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des ChargesDocument9 pagesTest Method: Renault Automobiles Standardisation DQSC - S / Department 00621 Section Normes Et Cahiers Des Chargesclaudio5475No ratings yet

- Pile Conditions: Input Quantities Value Units CommentDocument18 pagesPile Conditions: Input Quantities Value Units CommentFidel Rodriguez HerrerosNo ratings yet

- General Structural Notes Page 2Document1 pageGeneral Structural Notes Page 2piyadang16No ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Existing Culvert C405 - Temporary Supports DetailsDocument1 pageExisting Culvert C405 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Existing Culvert C409 - Temporary Supports DetailsDocument1 pageExisting Culvert C409 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- Existing Culvert C401 - Temporary Supports DetailsDocument1 pageExisting Culvert C401 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- Existing Culvert C407 - Temporary Supports DetailsDocument1 pageExisting Culvert C407 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder PortDocument1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Portalezandro del rossiNo ratings yet

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59Document1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59alezandro del rossiNo ratings yet

- FL DS 1023Document1 pageFL DS 1023basemapNo ratings yet

- Existing Culvert C440 - Temporary Supports DetailsDocument1 pageExisting Culvert C440 - Temporary Supports DetailsFurkan SaydamNo ratings yet

- F H J K L M N AP 1.1: Demo Plan Legend Demolition Plan LegendDocument3 pagesF H J K L M N AP 1.1: Demo Plan Legend Demolition Plan LegendmaresdaNo ratings yet

- Engr Micheal STRDocument12 pagesEngr Micheal STRUmar SaiduNo ratings yet

- General Structural Notes Page 1Document1 pageGeneral Structural Notes Page 1piyadang16No ratings yet

- Specification: Foundation PlanDocument1 pageSpecification: Foundation PlanRenzelNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- Footing Schedule Column Schedule: WF-O1 C1Document1 pageFooting Schedule Column Schedule: WF-O1 C1Bj GutierrezNo ratings yet

- BT 2ND PageDocument1 pageBT 2ND PageRyan AbuzoNo ratings yet

- Manzanero Structural PlanDocument3 pagesManzanero Structural PlanANGELIZA DONCILLONo ratings yet

- Anthony Wanjiku Revised StructuralDocument1 pageAnthony Wanjiku Revised Structuralpatrickmore09No ratings yet

- General Notes: Makati - Mandaluyong BridgeDocument1 pageGeneral Notes: Makati - Mandaluyong BridgegregNo ratings yet

- CHECK in Erection DrawingDocument34 pagesCHECK in Erection DrawingAMIT TIWARINo ratings yet

- Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkDocument1 pageStructural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkOladunni AfolabiNo ratings yet

- 10 Precast - Pre-Stress Conc - ConstDocument1 page10 Precast - Pre-Stress Conc - ConstChhaganNo ratings yet

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- Design of 33 SQM HousingDocument1 pageDesign of 33 SQM HousingDJNo ratings yet

- Mansilingan Structural PDFDocument6 pagesMansilingan Structural PDFSyre Yan Moscoso Tubale100% (1)

- Acm TSC VS MF DWG ST 2001Document1 pageAcm TSC VS MF DWG ST 2001Aecom IndiaNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- Plumbing Notes:: Plumbing Legend and SymbolsDocument1 pagePlumbing Notes:: Plumbing Legend and SymbolsRobee Ocampo100% (1)

- General Notes: 2 Installation DetailDocument1 pageGeneral Notes: 2 Installation DetailMary FelicianoNo ratings yet

- 2024 - Powerhouse-Roadway Detailed DesignDocument1 page2024 - Powerhouse-Roadway Detailed Designadonis bibatNo ratings yet

- 85 Welwyn Ave Schematic 01052022Document2 pages85 Welwyn Ave Schematic 01052022Joseph MunawarNo ratings yet

- Poster BC - Bored PileDocument1 pagePoster BC - Bored PileZaim Adli100% (1)

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- 04 Structural DrawingsDocument10 pages04 Structural DrawingszeipoibjasNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Slab Layout: DWG No 190811 DDocument14 pagesSlab Layout: DWG No 190811 DSaiful IslamNo ratings yet

- St. Luke's: RemarksDocument1 pageSt. Luke's: RemarksErwin Sto'domingoNo ratings yet

- Structural Plan PDFDocument10 pagesStructural Plan PDFPaul Anjelo MilagrosaNo ratings yet

- (4.) Beams & Slabs 5.reinforcement:: General NotesDocument1 page(4.) Beams & Slabs 5.reinforcement:: General NotesVirendra ChavdaNo ratings yet

- Construction Notes:: Revisions Project Date Owner Sheet Contents by Sheet NoDocument1 pageConstruction Notes:: Revisions Project Date Owner Sheet Contents by Sheet NoEmorej GameplayNo ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- Ekene Semi Detached StructuralDocument18 pagesEkene Semi Detached StructuralNwachukwu PrinceNo ratings yet

- Mace Ar 10 B1 02Document1 pageMace Ar 10 B1 02Syead OwaisNo ratings yet

- AS05Document1 pageAS05Vic NairaNo ratings yet

- Main Gate and Boundary Wall PDFDocument13 pagesMain Gate and Boundary Wall PDFwali mustafaNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- Unit 17 Lighting LayoutDocument1 pageUnit 17 Lighting Layoutnikkoelbao96No ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- Pre-Cast ConstructionDocument1 pagePre-Cast ConstructionAshish SharmaNo ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- BR 30 StrengtheningDocument1 pageBR 30 Strengtheningdesign MridcNo ratings yet

- Actual As of Feb. 26,2024Document1 pageActual As of Feb. 26,2024zab0414No ratings yet

- Master of Ceremonies Welcome Martinez - Beltran Nuptials: (Any Favorite Song/s of The Groom And/or The Bride)Document5 pagesMaster of Ceremonies Welcome Martinez - Beltran Nuptials: (Any Favorite Song/s of The Groom And/or The Bride)Dominic Robiso DatuinNo ratings yet

- John Paul SingsonDocument2 pagesJohn Paul SingsonDominic Robiso DatuinNo ratings yet

- Vincent Claudius P. Perea: EducationDocument2 pagesVincent Claudius P. Perea: EducationDominic Robiso DatuinNo ratings yet

- P.1. Bill of MaterialsDocument50 pagesP.1. Bill of MaterialsDominic Robiso DatuinNo ratings yet

- In A Constant Head Permeability Test in The LaboratoryDocument6 pagesIn A Constant Head Permeability Test in The LaboratoryDominic Robiso DatuinNo ratings yet

- The Construction Project: University of Rizal SystemDocument5 pagesThe Construction Project: University of Rizal SystemDominic Robiso DatuinNo ratings yet

- Research Critique: University of Rizal SystemDocument9 pagesResearch Critique: University of Rizal SystemDominic Robiso DatuinNo ratings yet

- M.2. Carpentry WorksDocument26 pagesM.2. Carpentry WorksDominic Robiso DatuinNo ratings yet

- Narrative Report FinalDocument53 pagesNarrative Report FinalDominic Robiso DatuinNo ratings yet

- Datuin, Dominic R. Ce - V October 11, 2019 CE 11: Highway EngineeringDocument2 pagesDatuin, Dominic R. Ce - V October 11, 2019 CE 11: Highway EngineeringDominic Robiso DatuinNo ratings yet

- General Preliminaries: EarthworksDocument3 pagesGeneral Preliminaries: EarthworksDominic Robiso DatuinNo ratings yet

- Actual Perspective: TLA 211.96 SQ.MDocument8 pagesActual Perspective: TLA 211.96 SQ.MDominic Robiso DatuinNo ratings yet

- Bill of MaterialsDocument2 pagesBill of MaterialsDominic Robiso DatuinNo ratings yet

- Proposed Traffic Management Scheme For Liwasang Jose NDocument12 pagesProposed Traffic Management Scheme For Liwasang Jose NDominic Robiso DatuinNo ratings yet

- Roof Details Description Computation Vaue UnitDocument6 pagesRoof Details Description Computation Vaue UnitDominic Robiso DatuinNo ratings yet

- Problem and Its BackgroundDocument15 pagesProblem and Its BackgroundDominic Robiso DatuinNo ratings yet

- CE 18: Construction Methods and Project Management Assignment No. 3Document3 pagesCE 18: Construction Methods and Project Management Assignment No. 3Dominic Robiso DatuinNo ratings yet

- Plumbing Layout Isometric View: A. P. Garcia & AssociatesDocument1 pagePlumbing Layout Isometric View: A. P. Garcia & AssociatesDominic Robiso DatuinNo ratings yet

- Ground Floor Plan Second Floor Plan Third Floor Plan Penthouse Floor Plan Attic Floor PlanDocument1 pageGround Floor Plan Second Floor Plan Third Floor Plan Penthouse Floor Plan Attic Floor PlanDominic Robiso DatuinNo ratings yet

- Actual Perspective: TLA 211.96 SQ.MDocument5 pagesActual Perspective: TLA 211.96 SQ.MDominic Robiso DatuinNo ratings yet

- Kwik Bolt 3 Exp Anchor Hilti PDFDocument21 pagesKwik Bolt 3 Exp Anchor Hilti PDFarturoncNo ratings yet

- SiliconesDocument19 pagesSiliconesprabhuNo ratings yet

- hssc1201t SecquizDocument2 pageshssc1201t SecquizKingProNo ratings yet

- GEST 79 76 Edition 4Document26 pagesGEST 79 76 Edition 4روشان فاطمة روشانNo ratings yet

- Status of Macro and Micro Nutrients in Selected Soils of Moshi Rural District, Kilimanjaro Tanzania: Case Study of Mboni, Kyou and Makami Chini Villages.Document44 pagesStatus of Macro and Micro Nutrients in Selected Soils of Moshi Rural District, Kilimanjaro Tanzania: Case Study of Mboni, Kyou and Makami Chini Villages.DANIEL ISDORYNo ratings yet

- Chemistry Form 3 End Term 1 2024Document14 pagesChemistry Form 3 End Term 1 2024osiemojjNo ratings yet

- The First Transition SeriesDocument127 pagesThe First Transition Seriesapi-3734333100% (6)

- IB HL Chemistry - Chapter 5 Thermochemistry - EnthalpyDocument7 pagesIB HL Chemistry - Chapter 5 Thermochemistry - Enthalpy14nganhc10% (1)

- What FCC Catalyst Tests ShowDocument5 pagesWhat FCC Catalyst Tests ShowPraveen KumarNo ratings yet

- Organic Chemistry Keywords - 1. Crossword Answers.Document2 pagesOrganic Chemistry Keywords - 1. Crossword Answers.sjNo ratings yet

- Concrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsDocument10 pagesConcrete Columns Reinforced by Glass Fiber Reinforced Polymer RodsShakeel WaseemNo ratings yet

- Volkmann Vacuum Conveying Brochure 2017 US PDFDocument36 pagesVolkmann Vacuum Conveying Brochure 2017 US PDFJose DuranNo ratings yet

- List of Products Certified - Ghana Standarads BoardDocument6 pagesList of Products Certified - Ghana Standarads Boardsaisridhar99No ratings yet

- CP Training1Document272 pagesCP Training1faisalqr100% (2)

- Journal of Natural Fibers PDFDocument16 pagesJournal of Natural Fibers PDFKalusu Raman100% (1)

- Solid Mechanics Short Questions and AnswersDocument61 pagesSolid Mechanics Short Questions and Answerssampathsiddam77% (31)

- STD 142Document58 pagesSTD 142Salil DasNo ratings yet

- Static Analysis of Bajaj Pulsar 150 CC Crankshaft Using ANSYSDocument7 pagesStatic Analysis of Bajaj Pulsar 150 CC Crankshaft Using ANSYSCristian JavierNo ratings yet

- ULSD Production - Improved Feed Stream QualityDocument6 pagesULSD Production - Improved Feed Stream Qualitysaleh4060No ratings yet

- Multiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyDocument109 pagesMultiferroic Materials and Magnetoelectric Physics: Symmetry, Entanglement, Excitation, and TopologyLong BuiNo ratings yet

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavNo ratings yet

- 26 HiLiteDocument36 pages26 HiLitedencave1No ratings yet

- ASTM A307: ScopeDocument2 pagesASTM A307: ScopetylerstearnsNo ratings yet

- Petronas Technical Standards: Cathodic Protection System For Metallic Piping (Amendments/ Supplements To NACE SP0169)Document11 pagesPetronas Technical Standards: Cathodic Protection System For Metallic Piping (Amendments/ Supplements To NACE SP0169)Abd.Buhari Abd.GalimNo ratings yet

- Lesson 3 Properties of Liquids and IMFDocument47 pagesLesson 3 Properties of Liquids and IMFHillary Faith GregoryNo ratings yet

- Indones. J. Chem., 2022, 22 (1), 171 - 178: AbstractDocument8 pagesIndones. J. Chem., 2022, 22 (1), 171 - 178: AbstractDyah Ayu LarasatiNo ratings yet

- Starplast Spray-Applied-Plaster Data SheetDocument5 pagesStarplast Spray-Applied-Plaster Data SheetEng Mohammad OmariNo ratings yet