Professional Documents

Culture Documents

Wall Mount Substructure Guide PDF

Wall Mount Substructure Guide PDF

Uploaded by

SpenCopyright:

Available Formats

You might also like

- Usdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideDocument2 pagesUsdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideMohd Shahrul Irwan Mohd ZinNo ratings yet

- Hybrid House Construction Seminar ReportDocument29 pagesHybrid House Construction Seminar ReportMahaManthra100% (1)

- Quality Control ProcedureDocument11 pagesQuality Control ProcedureYash Sharma100% (2)

- Diamond Pro Installation Instructions 73 3603 - MkEwMVV3YDocument2 pagesDiamond Pro Installation Instructions 73 3603 - MkEwMVV3YJake PetersNo ratings yet

- Retrofit InstructionsDocument13 pagesRetrofit InstructionsQUOC HANo ratings yet

- Packed: Distillation. Improvement Control. of Phase Channeling in ColumnsDocument3 pagesPacked: Distillation. Improvement Control. of Phase Channeling in ColumnsMARIO KONSACHRISTIAN 171424017No ratings yet

- Water For The World: Table 1. Sample Materials List For A Reinforced Concrete CisternDocument7 pagesWater For The World: Table 1. Sample Materials List For A Reinforced Concrete CisternGreen Action Sustainable Technology GroupNo ratings yet

- Assignment No.1 PATULAYDocument7 pagesAssignment No.1 PATULAYpeter vanderNo ratings yet

- Installation Manual: 4" Angle Series Top of Pole MountDocument8 pagesInstallation Manual: 4" Angle Series Top of Pole MountbcenergiesNo ratings yet

- HS3000 Installation GuideDocument7 pagesHS3000 Installation GuideT-BuzzardNo ratings yet

- Concrete Masonry ConstructionDocument9 pagesConcrete Masonry ConstructionSAMSON, Dadajem C.No ratings yet

- Schacher Confined Masonry Handout Engl 23307Document16 pagesSchacher Confined Masonry Handout Engl 23307Diana Matilda CrișanNo ratings yet

- Pipe Spacing From Perisher Handbook PG 194Document8 pagesPipe Spacing From Perisher Handbook PG 194Asif Haq100% (1)

- The Compound Gothic Design: String LinesDocument12 pagesThe Compound Gothic Design: String LinesmarinerNo ratings yet

- 30 209FPManualDocument32 pages30 209FPManualEzequiel VásquezNo ratings yet

- E, F & G Series Centrifugals: Installation InstructionsDocument8 pagesE, F & G Series Centrifugals: Installation InstructionsjhonNo ratings yet

- Tubing and Fitting AmirDocument48 pagesTubing and Fitting AmirAMIRNo ratings yet

- AVD 08d Masonry PatternDocument12 pagesAVD 08d Masonry Patternabinash SethiNo ratings yet

- Line Out of BuildingDocument2 pagesLine Out of Buildingbemd_aliNo ratings yet

- Read Online Textbook Show Your Worth Shelmina Babai Abji Ebook All Chapter PDFDocument22 pagesRead Online Textbook Show Your Worth Shelmina Babai Abji Ebook All Chapter PDFjohn.willis550100% (4)

- EWC Max I ManualDocument12 pagesEWC Max I ManualDương Tiến TháiNo ratings yet

- Diy Moto Shell Garage ManualDocument5 pagesDiy Moto Shell Garage ManualDaniel GhimiciNo ratings yet

- Am-3844a 2x1 HD Elevator Assembly Guide 2 PDFDocument7 pagesAm-3844a 2x1 HD Elevator Assembly Guide 2 PDFCar N WheelsNo ratings yet

- Antena LoopDocument4 pagesAntena Loopalexcivi100% (1)

- Armando Paredes: Project BasicsDocument6 pagesArmando Paredes: Project BasicsdamoccaNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationBrian LukeNo ratings yet

- COLUMNASDocument10 pagesCOLUMNASRoger Geronimo Jiménez100% (1)

- Bailey Bridge 7Document8 pagesBailey Bridge 7guillermoNo ratings yet

- Install A Concealed Conduit Wiring System - A Step by Step GuideDocument12 pagesInstall A Concealed Conduit Wiring System - A Step by Step Guidedirsubdfliq.comNo ratings yet

- Out A A: Vertical Wall. With Section YouDocument1 pageOut A A: Vertical Wall. With Section YoureacharunkNo ratings yet

- How To Make and Install A Floor-Based Unit: Option: Make Toe-Kick BaseDocument1 pageHow To Make and Install A Floor-Based Unit: Option: Make Toe-Kick BasereacharunkNo ratings yet

- LACASA STANDARD CHINESE EYE Brick Roof Tile AnchoringDocument6 pagesLACASA STANDARD CHINESE EYE Brick Roof Tile AnchoringScribdTranslationsNo ratings yet

- Air Agitation SystemsDocument4 pagesAir Agitation SystemsEdnaldo GonzagaNo ratings yet

- DB 212 Assembly and Mounting Instructions (Andrew)Document4 pagesDB 212 Assembly and Mounting Instructions (Andrew)Alexander Nuñez CastilloNo ratings yet

- Flexible Hose Ins.+Test.Document3 pagesFlexible Hose Ins.+Test.Filip NikolevskiNo ratings yet

- W1005: Small Jetway Type 1 Building InstructionsDocument4 pagesW1005: Small Jetway Type 1 Building InstructionsIndra KusumaNo ratings yet

- RCC Design TipsDocument9 pagesRCC Design Tipssatoni12No ratings yet

- PergolaInstallGuide v2Document8 pagesPergolaInstallGuide v2آلاء محمد عبدالعزيزNo ratings yet

- Procedure of Setting OutDocument4 pagesProcedure of Setting OutMaryam Mansor83% (6)

- New Doc 2018-11-29 10.59.30Document28 pagesNew Doc 2018-11-29 10.59.30Juan Ismael Carmona RodríguezNo ratings yet

- Tlo1b2 Horiz Distance - TapingDocument3 pagesTlo1b2 Horiz Distance - TapingMichael LeroNo ratings yet

- Site Clearance Before Excavation For Foundation: Marking The Foundation OutlineDocument4 pagesSite Clearance Before Excavation For Foundation: Marking The Foundation Outlinechandanteja.pNo ratings yet

- STAGES of ConstructionDocument34 pagesSTAGES of ConstructionMahmoud ShakerNo ratings yet

- Mr. Installer InstructionsDocument8 pagesMr. Installer InstructionsCláudio SilvaNo ratings yet

- One-Masted SloopDocument3 pagesOne-Masted Sloopbearbullride10No ratings yet

- 00 - Restringing GuideDocument3 pages00 - Restringing GuideAlain ReiherNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Conventional ConstructionDocument13 pagesConventional ConstructionEzra GarciaNo ratings yet

- Testing of Bored Pile Inclination: Borehole AxisDocument5 pagesTesting of Bored Pile Inclination: Borehole AxisshihabNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationMudassar KhanNo ratings yet

- Structural Tips / Thumb RulesDocument7 pagesStructural Tips / Thumb Ruleswindspace3No ratings yet

- JLMS Access Floor For 590-22Document10 pagesJLMS Access Floor For 590-22Christine TanNo ratings yet

- Structural TipsDocument7 pagesStructural Tipsbalacr3No ratings yet

- New Doc 2018-11-29 10.59.30Document29 pagesNew Doc 2018-11-29 10.59.30Juan Ismael Carmona RodríguezNo ratings yet

- Lesson 4 - Wall and Partition FrameDocument11 pagesLesson 4 - Wall and Partition FrameROMNICK HANDAYANNo ratings yet

- Slump TestDocument1 pageSlump TestChristina De MesaNo ratings yet

- SJW-H Leak Clamp Installation InstructionDocument2 pagesSJW-H Leak Clamp Installation InstructionSarwat Naim SiddiquiNo ratings yet

- Small Unit AquaponicsDocument15 pagesSmall Unit AquaponicsMeme Here100% (1)

- Practical Stair Building and Handrailing: By the square section and falling line systemFrom EverandPractical Stair Building and Handrailing: By the square section and falling line systemNo ratings yet

- Stair-Building and the Steel Square: A Manual of Practical Instruction in the Art of Stair-Building and Hand-Railing, and the Manifold Uses of the Steel SquareFrom EverandStair-Building and the Steel Square: A Manual of Practical Instruction in the Art of Stair-Building and Hand-Railing, and the Manifold Uses of the Steel SquareNo ratings yet

- Strength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionFrom EverandStrength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionNo ratings yet

- Pianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsFrom EverandPianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsRating: 5 out of 5 stars5/5 (2)

- Palladio by Vilas Javdekar Is Located inDocument9 pagesPalladio by Vilas Javdekar Is Located inChetna BhanwalNo ratings yet

- Analysis of Rates: Unit 3Document46 pagesAnalysis of Rates: Unit 3abhishek bhure100% (1)

- Mr. Talal Saleh Al Baker VillaDocument1 pageMr. Talal Saleh Al Baker VillaCharlton JimenezNo ratings yet

- Types of Living Room DesignsDocument9 pagesTypes of Living Room DesignsSteven CoolerNo ratings yet

- Ground Floor Textbook PDFDocument50 pagesGround Floor Textbook PDFimanolkioNo ratings yet

- The Future of Precast Concrete in Low-Rise HousingDocument62 pagesThe Future of Precast Concrete in Low-Rise HousingJose ManjooranNo ratings yet

- Azw Catalogue 2018 5Document22 pagesAzw Catalogue 2018 5Nurhayati Muhamad NorNo ratings yet

- Cold Form Inspector ChecklistDocument16 pagesCold Form Inspector ChecklistbooboosdadNo ratings yet

- Stone CladdingDocument46 pagesStone CladdingSahaj Mitra100% (1)

- Allowable Stress Design of Concrete Masonry PilastersDocument7 pagesAllowable Stress Design of Concrete Masonry PilastersReinaldo Andrei SalazarNo ratings yet

- Case Study of AcousticsDocument24 pagesCase Study of Acousticsmayuresh barbarwarNo ratings yet

- Heat Load CalculationsDocument6 pagesHeat Load CalculationsHoney Tiwari0% (1)

- AWC-DCA3-Fire-Resistance-Rated Wood-Frame Wall, Floor and Ceiling Assemblies-20210209Document28 pagesAWC-DCA3-Fire-Resistance-Rated Wood-Frame Wall, Floor and Ceiling Assemblies-20210209LarryHNo ratings yet

- NV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support SystemDocument16 pagesNV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support Systemart cafeNo ratings yet

- Outside Air Louver Sizing GuideDocument15 pagesOutside Air Louver Sizing GuideorazuNo ratings yet

- NHBRC Questions and AnswersDocument43 pagesNHBRC Questions and Answersu13152930No ratings yet

- Lecture 18 Shear Walls, Deep Beams and Corbels (B&W)Document37 pagesLecture 18 Shear Walls, Deep Beams and Corbels (B&W)wajid100% (1)

- Construction Methods For Low-Cost HousingDocument13 pagesConstruction Methods For Low-Cost HousingJayanth B RNo ratings yet

- KAQ Exterior Wall Brochure EN RZ PDF-Version 150519Document72 pagesKAQ Exterior Wall Brochure EN RZ PDF-Version 150519PedroNo ratings yet

- IFC Phase 2Document16 pagesIFC Phase 2ipwaikinNo ratings yet

- Is 13935Document26 pagesIs 13935Ashaprava MohantaNo ratings yet

- Means of Escape Part IIDocument6 pagesMeans of Escape Part IIrmaffireschool100% (2)

- M6 Cost Estimate (Academic Block) 2017 1.00 TSFDocument342 pagesM6 Cost Estimate (Academic Block) 2017 1.00 TSFShams KhattakNo ratings yet

- SR 057 PDFDocument67 pagesSR 057 PDFRrrrrrrNo ratings yet

- Chapter 2Document54 pagesChapter 2ali3 ALAA100% (3)

- Shear Wall and Diagrid SystemDocument47 pagesShear Wall and Diagrid SystemAashi GuptaNo ratings yet

- ABSTRACTDocument46 pagesABSTRACTOpensource projextsNo ratings yet

Wall Mount Substructure Guide PDF

Wall Mount Substructure Guide PDF

Uploaded by

SpenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Mount Substructure Guide PDF

Wall Mount Substructure Guide PDF

Uploaded by

SpenCopyright:

Available Formats

NPN-410X/ZPN-1000 Series Wall-Mount Substructure Quick Guide Page 1 of 1

The standard NPN-410X/ZPN-1000 display b. A string level can be used if a laser level is unavailable. Mark the

substructure is vertical aluminum tubing tube positions and install all vertical tubes. Mount each tube to

with mounting pass-through holes and the wall with one screw and secure a string line taut across all

shims for attachment to a wall or vertical tubes. It is recommended to run two string lines per vertical

equivalent structure. The panels are tube. This method will show the highest point of the wall. Shim all

self-drilled into the vertical tubes at four remaining tubes to touch the string line.

points per panel. The tubes must be

vertically level, or plumb, on the face 3. Fill the required hole(s) in the tubes. Refer to Figure 3. In

and sides, horizontally level on the seismic-affected regions, two holes per panel height must be filled. In

top/bottom across multiple tubes, all other regions, only one hole per panel height is required. Refer to the

vertically flat along each tube, and contract-specific Shop Drawing for details on how many holes to fill.

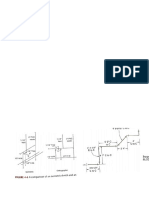

horizontally flat across multiple tubes. 4. Attach the tube (center tube first) Figure 8: Check Plumbness Figure 9: Check Plumbness

Tubes come in two different types and use a large level to ensure the

(panel-to-panel tubes and narrow side of the tube is level. Refer to 7. Check the flatness at the top and bottom of the tubes (Figure 10),

tubes for the far-left and far-right edges Figure 4. Tubes will recess 1/4" from along the height of the tubes (Figure 11), and diagonally across the

of the display face) in nine different both the top and bottom of the tubes (Figure 12), measuring across three tubes at a time, to ensure

sizes ranging from one panel high to display. Refer to Figure 5. it does not exceed the max out of flat of 1/16" and there is no rocking.

a maximum of nine panels high. Refer Each individual tube should be level within 1/4" from the lowest to

Ensure the tube is positioned highest point along the entire vertical length of the display tube(s). If

to Figure 1. Each panel height has two vertically within 1/4" of the

mounting pass-through holes. Figure 1: Tube Type the tube does not meet the level with a gap greater than 1/4" or if there

specifications on the Shop Drawing. is rocking, add shims to the affected tubes to bring them into spec.

1. Attach 3/4" plywood to the wall before substructure attachment if the Start the tube mounting hardware

holes in the tubes do not line up with studs on the wall. Other wall through the tube into the wall, but do

materials such as concrete should not require the 3/4" plywood, but not tighten down. Figure 4: Verify Plumb First Tube

refer to the contract-specific Shop Drawing for verification.

2. Check the wall for flatness and levelness with a laser level (or a level

and string if a laser level is not available). Refer to Figure 2.

Figure 5: Tube on Panel (Top View)

5. Add shims on the started hardware

between the tube and the wall and

use a level to ensure the tube

remains plumb to the wall and flat Figure 10: Check Figure 11: Check Figure 12: Check

over the entire length of the tube. Flatness Flatness Flatness

1 Refer to Figure 6. If the appropriate

8. Re-level any individual vertical tube

amount of shims is not used, the wall

that was adjusted but do not remove

anchors can bow.

2 the shims that were added to make

the tube faces flat to each other.

Note: The shims on the left and Repeat this step, incrementing one

right tubes should be tube to the right or left so all tubes in

oriented so the the display are plumb, level to each

tail/tag sticks out behind other, and flat to each other. After

the display and out of this has been verified, tighten down

sight when the display the tube hardware to the wall.

1: Mounting pass-through hole

2: Additional mounting pass-through is fully installed. Refer to 9. Repeat Steps 1-8 if additional rows of

hole for seismic-affected regions Figure 6: Verify Figure 7: Shim

Figure 7. tubes are required. Space the tubes Figure 13: Install Second Row

Plumbness Orientation

Figure 2: Marked Tube Positions Figure 3: Attach Tube approximately 1/2" apart vertically.

6. Repeat Steps 1-5 to attach the remaining tubes to the right and left Refer to Figure 13. Tighten down the hardware and quality check the

a. A three-plane laser level is preferred. Set the Z-plane a set distance of the center tube. Level each tube separately. Refer to Figure 8 and plumbness and flatness.

from the wall. Mark the tube positions and make note of the high Figure 9. Place shims between the wall and the tube until the tube is

and low points of the wall along the tube screw position. plumb. Each individual tube should be level within 1/4" from the lowest After the tube hardware is tightened down and the tubes are level and

to highest point along the entire vertical length of the display tube(s). flat, begin panel installation. Refer to the appropriate Installation & Service

Quick Guide: NPN-4100 (DD3830324), NPN-4101 (DD4133945), NPN-4102

(DD4174150), or ZPN-1000 (DD4175845).

DD3922077 201 Daktronics Drive

Rev 03 Brookings, SD 57006-5128

16 April 2020 www.daktronics.com/support

800.325.8766

You might also like

- Usdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideDocument2 pagesUsdhs / Uscbp / Basc "Best Practice" 8-Point Ocean Container Security Inspection GuideMohd Shahrul Irwan Mohd ZinNo ratings yet

- Hybrid House Construction Seminar ReportDocument29 pagesHybrid House Construction Seminar ReportMahaManthra100% (1)

- Quality Control ProcedureDocument11 pagesQuality Control ProcedureYash Sharma100% (2)

- Diamond Pro Installation Instructions 73 3603 - MkEwMVV3YDocument2 pagesDiamond Pro Installation Instructions 73 3603 - MkEwMVV3YJake PetersNo ratings yet

- Retrofit InstructionsDocument13 pagesRetrofit InstructionsQUOC HANo ratings yet

- Packed: Distillation. Improvement Control. of Phase Channeling in ColumnsDocument3 pagesPacked: Distillation. Improvement Control. of Phase Channeling in ColumnsMARIO KONSACHRISTIAN 171424017No ratings yet

- Water For The World: Table 1. Sample Materials List For A Reinforced Concrete CisternDocument7 pagesWater For The World: Table 1. Sample Materials List For A Reinforced Concrete CisternGreen Action Sustainable Technology GroupNo ratings yet

- Assignment No.1 PATULAYDocument7 pagesAssignment No.1 PATULAYpeter vanderNo ratings yet

- Installation Manual: 4" Angle Series Top of Pole MountDocument8 pagesInstallation Manual: 4" Angle Series Top of Pole MountbcenergiesNo ratings yet

- HS3000 Installation GuideDocument7 pagesHS3000 Installation GuideT-BuzzardNo ratings yet

- Concrete Masonry ConstructionDocument9 pagesConcrete Masonry ConstructionSAMSON, Dadajem C.No ratings yet

- Schacher Confined Masonry Handout Engl 23307Document16 pagesSchacher Confined Masonry Handout Engl 23307Diana Matilda CrișanNo ratings yet

- Pipe Spacing From Perisher Handbook PG 194Document8 pagesPipe Spacing From Perisher Handbook PG 194Asif Haq100% (1)

- The Compound Gothic Design: String LinesDocument12 pagesThe Compound Gothic Design: String LinesmarinerNo ratings yet

- 30 209FPManualDocument32 pages30 209FPManualEzequiel VásquezNo ratings yet

- E, F & G Series Centrifugals: Installation InstructionsDocument8 pagesE, F & G Series Centrifugals: Installation InstructionsjhonNo ratings yet

- Tubing and Fitting AmirDocument48 pagesTubing and Fitting AmirAMIRNo ratings yet

- AVD 08d Masonry PatternDocument12 pagesAVD 08d Masonry Patternabinash SethiNo ratings yet

- Line Out of BuildingDocument2 pagesLine Out of Buildingbemd_aliNo ratings yet

- Read Online Textbook Show Your Worth Shelmina Babai Abji Ebook All Chapter PDFDocument22 pagesRead Online Textbook Show Your Worth Shelmina Babai Abji Ebook All Chapter PDFjohn.willis550100% (4)

- EWC Max I ManualDocument12 pagesEWC Max I ManualDương Tiến TháiNo ratings yet

- Diy Moto Shell Garage ManualDocument5 pagesDiy Moto Shell Garage ManualDaniel GhimiciNo ratings yet

- Am-3844a 2x1 HD Elevator Assembly Guide 2 PDFDocument7 pagesAm-3844a 2x1 HD Elevator Assembly Guide 2 PDFCar N WheelsNo ratings yet

- Antena LoopDocument4 pagesAntena Loopalexcivi100% (1)

- Armando Paredes: Project BasicsDocument6 pagesArmando Paredes: Project BasicsdamoccaNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationBrian LukeNo ratings yet

- COLUMNASDocument10 pagesCOLUMNASRoger Geronimo Jiménez100% (1)

- Bailey Bridge 7Document8 pagesBailey Bridge 7guillermoNo ratings yet

- Install A Concealed Conduit Wiring System - A Step by Step GuideDocument12 pagesInstall A Concealed Conduit Wiring System - A Step by Step Guidedirsubdfliq.comNo ratings yet

- Out A A: Vertical Wall. With Section YouDocument1 pageOut A A: Vertical Wall. With Section YoureacharunkNo ratings yet

- How To Make and Install A Floor-Based Unit: Option: Make Toe-Kick BaseDocument1 pageHow To Make and Install A Floor-Based Unit: Option: Make Toe-Kick BasereacharunkNo ratings yet

- LACASA STANDARD CHINESE EYE Brick Roof Tile AnchoringDocument6 pagesLACASA STANDARD CHINESE EYE Brick Roof Tile AnchoringScribdTranslationsNo ratings yet

- Air Agitation SystemsDocument4 pagesAir Agitation SystemsEdnaldo GonzagaNo ratings yet

- DB 212 Assembly and Mounting Instructions (Andrew)Document4 pagesDB 212 Assembly and Mounting Instructions (Andrew)Alexander Nuñez CastilloNo ratings yet

- Flexible Hose Ins.+Test.Document3 pagesFlexible Hose Ins.+Test.Filip NikolevskiNo ratings yet

- W1005: Small Jetway Type 1 Building InstructionsDocument4 pagesW1005: Small Jetway Type 1 Building InstructionsIndra KusumaNo ratings yet

- RCC Design TipsDocument9 pagesRCC Design Tipssatoni12No ratings yet

- PergolaInstallGuide v2Document8 pagesPergolaInstallGuide v2آلاء محمد عبدالعزيزNo ratings yet

- Procedure of Setting OutDocument4 pagesProcedure of Setting OutMaryam Mansor83% (6)

- New Doc 2018-11-29 10.59.30Document28 pagesNew Doc 2018-11-29 10.59.30Juan Ismael Carmona RodríguezNo ratings yet

- Tlo1b2 Horiz Distance - TapingDocument3 pagesTlo1b2 Horiz Distance - TapingMichael LeroNo ratings yet

- Site Clearance Before Excavation For Foundation: Marking The Foundation OutlineDocument4 pagesSite Clearance Before Excavation For Foundation: Marking The Foundation Outlinechandanteja.pNo ratings yet

- STAGES of ConstructionDocument34 pagesSTAGES of ConstructionMahmoud ShakerNo ratings yet

- Mr. Installer InstructionsDocument8 pagesMr. Installer InstructionsCláudio SilvaNo ratings yet

- One-Masted SloopDocument3 pagesOne-Masted Sloopbearbullride10No ratings yet

- 00 - Restringing GuideDocument3 pages00 - Restringing GuideAlain ReiherNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Conventional ConstructionDocument13 pagesConventional ConstructionEzra GarciaNo ratings yet

- Testing of Bored Pile Inclination: Borehole AxisDocument5 pagesTesting of Bored Pile Inclination: Borehole AxisshihabNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationMudassar KhanNo ratings yet

- Structural Tips / Thumb RulesDocument7 pagesStructural Tips / Thumb Ruleswindspace3No ratings yet

- JLMS Access Floor For 590-22Document10 pagesJLMS Access Floor For 590-22Christine TanNo ratings yet

- Structural TipsDocument7 pagesStructural Tipsbalacr3No ratings yet

- New Doc 2018-11-29 10.59.30Document29 pagesNew Doc 2018-11-29 10.59.30Juan Ismael Carmona RodríguezNo ratings yet

- Lesson 4 - Wall and Partition FrameDocument11 pagesLesson 4 - Wall and Partition FrameROMNICK HANDAYANNo ratings yet

- Slump TestDocument1 pageSlump TestChristina De MesaNo ratings yet

- SJW-H Leak Clamp Installation InstructionDocument2 pagesSJW-H Leak Clamp Installation InstructionSarwat Naim SiddiquiNo ratings yet

- Small Unit AquaponicsDocument15 pagesSmall Unit AquaponicsMeme Here100% (1)

- Practical Stair Building and Handrailing: By the square section and falling line systemFrom EverandPractical Stair Building and Handrailing: By the square section and falling line systemNo ratings yet

- Stair-Building and the Steel Square: A Manual of Practical Instruction in the Art of Stair-Building and Hand-Railing, and the Manifold Uses of the Steel SquareFrom EverandStair-Building and the Steel Square: A Manual of Practical Instruction in the Art of Stair-Building and Hand-Railing, and the Manifold Uses of the Steel SquareNo ratings yet

- Strength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionFrom EverandStrength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionNo ratings yet

- Pianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsFrom EverandPianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsRating: 5 out of 5 stars5/5 (2)

- Palladio by Vilas Javdekar Is Located inDocument9 pagesPalladio by Vilas Javdekar Is Located inChetna BhanwalNo ratings yet

- Analysis of Rates: Unit 3Document46 pagesAnalysis of Rates: Unit 3abhishek bhure100% (1)

- Mr. Talal Saleh Al Baker VillaDocument1 pageMr. Talal Saleh Al Baker VillaCharlton JimenezNo ratings yet

- Types of Living Room DesignsDocument9 pagesTypes of Living Room DesignsSteven CoolerNo ratings yet

- Ground Floor Textbook PDFDocument50 pagesGround Floor Textbook PDFimanolkioNo ratings yet

- The Future of Precast Concrete in Low-Rise HousingDocument62 pagesThe Future of Precast Concrete in Low-Rise HousingJose ManjooranNo ratings yet

- Azw Catalogue 2018 5Document22 pagesAzw Catalogue 2018 5Nurhayati Muhamad NorNo ratings yet

- Cold Form Inspector ChecklistDocument16 pagesCold Form Inspector ChecklistbooboosdadNo ratings yet

- Stone CladdingDocument46 pagesStone CladdingSahaj Mitra100% (1)

- Allowable Stress Design of Concrete Masonry PilastersDocument7 pagesAllowable Stress Design of Concrete Masonry PilastersReinaldo Andrei SalazarNo ratings yet

- Case Study of AcousticsDocument24 pagesCase Study of Acousticsmayuresh barbarwarNo ratings yet

- Heat Load CalculationsDocument6 pagesHeat Load CalculationsHoney Tiwari0% (1)

- AWC-DCA3-Fire-Resistance-Rated Wood-Frame Wall, Floor and Ceiling Assemblies-20210209Document28 pagesAWC-DCA3-Fire-Resistance-Rated Wood-Frame Wall, Floor and Ceiling Assemblies-20210209LarryHNo ratings yet

- NV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support SystemDocument16 pagesNV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support Systemart cafeNo ratings yet

- Outside Air Louver Sizing GuideDocument15 pagesOutside Air Louver Sizing GuideorazuNo ratings yet

- NHBRC Questions and AnswersDocument43 pagesNHBRC Questions and Answersu13152930No ratings yet

- Lecture 18 Shear Walls, Deep Beams and Corbels (B&W)Document37 pagesLecture 18 Shear Walls, Deep Beams and Corbels (B&W)wajid100% (1)

- Construction Methods For Low-Cost HousingDocument13 pagesConstruction Methods For Low-Cost HousingJayanth B RNo ratings yet

- KAQ Exterior Wall Brochure EN RZ PDF-Version 150519Document72 pagesKAQ Exterior Wall Brochure EN RZ PDF-Version 150519PedroNo ratings yet

- IFC Phase 2Document16 pagesIFC Phase 2ipwaikinNo ratings yet

- Is 13935Document26 pagesIs 13935Ashaprava MohantaNo ratings yet

- Means of Escape Part IIDocument6 pagesMeans of Escape Part IIrmaffireschool100% (2)

- M6 Cost Estimate (Academic Block) 2017 1.00 TSFDocument342 pagesM6 Cost Estimate (Academic Block) 2017 1.00 TSFShams KhattakNo ratings yet

- SR 057 PDFDocument67 pagesSR 057 PDFRrrrrrrNo ratings yet

- Chapter 2Document54 pagesChapter 2ali3 ALAA100% (3)

- Shear Wall and Diagrid SystemDocument47 pagesShear Wall and Diagrid SystemAashi GuptaNo ratings yet

- ABSTRACTDocument46 pagesABSTRACTOpensource projextsNo ratings yet