Professional Documents

Culture Documents

Make To Stock

Make To Stock

Uploaded by

Vikram JanardhanamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Make To Stock

Make To Stock

Uploaded by

Vikram JanardhanamCopyright:

Available Formats

Make to Stock:

Discrete Manfacturing discusses more in Make to Stock, where business will forecast the demand and

produce the finished good and maintain it in the warehouse.Whenever business gets actual demand

they the sell the finished goods.

Configure to Order:

In CTO business doesnt produce the FG based on the forecast,instead get the order from the customer

and then business will go for production.

So After getting actual demand business will produce the quantity. The actual demand comes from Sales

order in the application. Sales order quantity is actual demand.

First sales order is prepared and then Manufactuing WO is created and against the sales order pick and

ship is preformed.

CTO

Based on the customer requirement, FG good is prepared. The reason is a product can be configured in

to multiple ways and shipped to the customer. Eg: laptop having different configuration.

1. ATO: Assemble to Order

Assemble the FG in the ware house and directly shipped to the customer location

2. PTO: Pick to Order

Components are shipped to the customer location and the FG is assembled in customer location. Eg: AC

machine.

ATO: Create SO -->configure SO ( selecting the customer requirement )--> Book SO --> Progress SO

-->submit Auto create Final Assembly Orders program ( sales order data transfered to Discrete Job

ORder ) -->Find Auto generated Discrete Job -->create Move ORder --> Create material transactions -->

Complete DJ --> pick release --> Ship confirm

Sensitivity: Internal & Restricted

ATO Setup

Define Model Bill:

under one model we maintain options and option will be provided to customer and customer can select

the options.

N number of level Model bill can be maintained under the same model bill only ( 60 level is maximum in

Oracle Application )

1. Define ATO Model Item:

Inv -> Items -->Master Items --> Choose the Org ( Eg: CPU )

Model item is not stockable item as we have multiple options.

Apply template --> ATO Model

Disable Stockable and Transactable check box

Enabled BOM allowed

Disable Build in WIP

OM it is not Shippable

Now save the form. Assign the item to Org.

2. Define ATO Optional class Item

Inv--> Items --> Master item ( Eg: HArd disk )

Sensitivity: Internal & Restricted

Template : ATO Option Class

This is also not stockable item.

Disable Stockable and Transactable check box

Enabled BOM allowed

Disable Build in WIP

OM it is not Shippable

Save the item -->Org Assignment

Repeat the same for all the Option class item ( eg: Processor, Memory Disk )

3.Define Standard Components ( 500 GB hard disk,1 TB Hard Disk, i5 processor, i7 processor )

This can be Purchased item or Finished goods

Inv--> Items --> Masters items

Template --> Purchased Goods or Finished Goods.

This will be stockable and transactable and shippable.

BILL Setup

1.ATO_MODEL Bill Item ( CPU )

2.ATO Option class item ( Hard Disk )

3.Standard component (Purchasable or FG )

4.BOM Parameter Setup

For CTO parameter is mandatory.

Choose the item validation org and open the BOM parameter

Sensitivity: Internal & Restricted

Number method: Append the Sequence

5. Define Optional Class bill ( Hard disk having 500 GB and I TB component - Purchased or FG items )

Enable Optional check box under OM tab.

6. Define ATP Model Bill ( CPU having Optional class bill, hard disk and processor )

Enable Optional check box under OM tab.

7. Check the Indented Bill ---> All the level of BOM will be visible.

8. We can transfer ATO Optional class bills from one org to another org.

We can copy bill from one to org--> tools copy bill

9. Assing required work flows to line level transaction type

OM-->Setup --> Transaction Types --> Define---> Select F11 ---> Query Transaction type as Mixed -->After

querying Click Assign Line Flows button -->Select ( line invoice item) --> Selct item type: included Item -->

select Process Name: Line flow Generic.

Assign Line flow button --> Select line invoice item---> Select Item Type: configured Item --> Select

PRocess Name: Line Flow - Configuration--> Select start date

Assign Line flow button --> Select line invoice item---> Select Item Type: ATO Item--> Select PRocess

Name: Line Flow - ATO Item -> Select start date

Assign Line flow button --> Select line invoice item---> Select Item Type: ATO Model--> Select PRocess

Name: Line Flow - ATO Model-> Select start date

Now finally save the Transaction Type form

CREATE SALES ORDER

Sensitivity: Internal & Restricted

OM--> Order,Returns --> Sales Order -->

Under Under Order Information tab and Main tab

Select the customer name.

under Other tab

Select the Warehouse

*Now click Line Items Tab

*Select the Order Item --> ATO Model Item defined in Bill --> Select the quantity---> Select Configurator

button---> Configurator form will open---> You can select the Option class item defined under the Model

item ( either 500 GB hard disk or 1 TB)

*Now click Preview Configurtion --> to view the final configration --> Select the buttom Finish.

*Now all the Option class which was selected is visible in Line item tab.

*Now Click Select Book Order Button.All the line status will be booked.

*Keep the cursor in ATO Model item --> Select Actions Button --> Select Progress Order --> Create

Configration - Eligible --> Select OK

Now Configured item will get generated.

In BOM Parameter --> IF we choose Append with Sequence then the configured item will triger a

number againt the ATO model item

IF we choose Replace with Sequence then the confugured item wll triger only the number and ATO

Model Item will not be visible

Sensitivity: Internal & Restricted

*Now check the Line Status

Configured item will be in supply Eligible. Note down the sales order number.

*We can check the Configured item automatically generated in Item master screen which is created by

the system.

*The same we can notice configured item BOM which we selected in Sales order in Bill screen.

Till now we have selected the customer requirement in Sales Order now this should be produced in

Manfacturing.

* SUBMIT CREATE FINAL ASSEMBLY ORDER PROGRAM

OM--> View--> Request --> Submit a new request --> %Auto Create Final Assembly Orders

Enter the sales Order

Enter Load Type: Both Configired and non-configured Orders

Enter the Status: this status will be visible in Manfacturing Discrete Job

Submit the request.

Once completed a additional program will generated and get completed. Assemble to Order Mass Load

Report. This output will have Job number and Configured item will be displayed.

*Got to WIP ---> Discrete Job --> Find the Job

*Job will be opened with Released stauts

Only components will be visible and supply type will be push and we need to perform material

transaction manually. Onhand will be 0.

Sensitivity: Internal & Restricted

Operation will not be available for this job. If we want we can manually create Operations. This is not

mandatory to do. If no operation is required then we can directly complete the WO.

*To create Manual operation --> WIP --> Discrete Jobs --> Operations --> Select the Job orders -->

Choose the Operations.

*You can change the supply type of the Job WIP --> Discrete Jobs --> Chose Material Requirement

-->update to Operation Pull --> item will be issued upon completion of the operation

*We can select the Finished good subinventory.

*Adjust Onhand of the Quantity.

Inventory --> Transactions --> misscellenous transactions --> misceelenous receipt--> Select the item

Once onhand is increased. The sub inventory can be added toDiscrete Job Operations

*Create Move Transaction to perform the operations

WIP--> Move Transactions --> Move Transactions --> Select job number --> Select the transaction type as

move--> Queue to To move --> Choose the quantity --> Click Save.

*Create Completion Transactions

WIP --> Material Transactions -->Completion Transactions

After Performing the WIP completion transaction, if we check the sales order line status

Sensitivity: Internal & Restricted

OM --> Orders, Returns --> Query the number --> We can notice all the item will be booked but only the

configured item will be in Awaiting shipping.

*Pick and Ship

OM--> Shiping --> Transactions--> Select the Order number --> Select button Find.

Select the button Pick and ship and close the form.

Sensitivity: Internal & Restricted

Sensitivity: Internal & Restricted

You might also like

- TCL Service ManualDocument42 pagesTCL Service Manualsachin50% (2)

- Production Kitting Using WM-PP Interface: Setting Up SAP WM PP Interface Is Covered in This Online SAP WM Training CourseDocument6 pagesProduction Kitting Using WM-PP Interface: Setting Up SAP WM PP Interface Is Covered in This Online SAP WM Training Courseanon_672875766No ratings yet

- 1z0 071 PDFDocument7 pages1z0 071 PDFAlyan AirikNo ratings yet

- OSP - Document Wip Outside ProcessingDocument28 pagesOSP - Document Wip Outside Processingsaqi22100% (1)

- Config Documet Sap PPDocument22 pagesConfig Documet Sap PPSandeep Kumar PraharajNo ratings yet

- Where To Find The User Exits On Sales and Distribution Along With Functionality?Document97 pagesWhere To Find The User Exits On Sales and Distribution Along With Functionality?Sourav KumarNo ratings yet

- SAP PP-PI Process Flow DocsDocument25 pagesSAP PP-PI Process Flow Docsjnsingh1234589% (27)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- Revit 2020 Fundamentals For StructureDocument62 pagesRevit 2020 Fundamentals For StructureNoureddine100% (1)

- Final Ato, Pto, CtoDocument32 pagesFinal Ato, Pto, Ctokmurali321No ratings yet

- Rework in Production Planning: ScenarioDocument4 pagesRework in Production Planning: ScenarioMinal TripathiNo ratings yet

- Ato CycleDocument61 pagesAto CycleChidambaram nagappanNo ratings yet

- BAPI Good GIDocument18 pagesBAPI Good GIJalal Masoumi Kozekanan100% (1)

- Abis Processing Steps 18 02 11Document9 pagesAbis Processing Steps 18 02 11sanjay kapoorNo ratings yet

- Service Order ProcessingDocument22 pagesService Order ProcessingDayanandamurthy100% (2)

- ReworkDocument6 pagesReworkShashank Mani Tripathi100% (1)

- Wip Osp SetupDocument3 pagesWip Osp SetupMohan Kumar NagalingamNo ratings yet

- Wip Osp SetupDocument2 pagesWip Osp SetupyounomeNo ratings yet

- Collective OrderDocument26 pagesCollective Orderrvk386No ratings yet

- The Subcon Process in SAP Purchasing Modules: Subcontracting ProcessingDocument10 pagesThe Subcon Process in SAP Purchasing Modules: Subcontracting ProcessingSaulNo ratings yet

- FI To MM IntegrationDocument8 pagesFI To MM Integrationsurendra100% (1)

- Define Company Code: Customizing DocumentDocument42 pagesDefine Company Code: Customizing Documentnilanjan_ibsNo ratings yet

- Study O2CDocument3 pagesStudy O2Cneerohil3No ratings yet

- Configuring The Stock Transport Order: Reset Set Zero Count For Physical InventoryDocument26 pagesConfiguring The Stock Transport Order: Reset Set Zero Count For Physical Inventoryprasadj423No ratings yet

- Basic Subcontracting ProcessDocument16 pagesBasic Subcontracting ProcessDhiraj GanwirNo ratings yet

- WM Roadmap - Prasanth - Naidu334 Satish334Document4 pagesWM Roadmap - Prasanth - Naidu334 Satish334prasanthNo ratings yet

- Sap StoDocument6 pagesSap StoPavanARKNo ratings yet

- STO ProcessDocument6 pagesSTO ProcessSantosh KumarNo ratings yet

- Ship Set Doc-Scenario 3Document17 pagesShip Set Doc-Scenario 3Vamshidhar ReddyNo ratings yet

- Internal Sales Order: WWW - Code4change - Co.inDocument10 pagesInternal Sales Order: WWW - Code4change - Co.inMadhu Sudan ReddyNo ratings yet

- Outside Processing Based Requisition Purchase OrderDocument11 pagesOutside Processing Based Requisition Purchase OrderSanthosh KumarNo ratings yet

- Perpetual Inventory For: Dolibarr Erp CRMDocument4 pagesPerpetual Inventory For: Dolibarr Erp CRMElio ZerpaNo ratings yet

- Business Process Flow in Oracle Applications PDFDocument262 pagesBusiness Process Flow in Oracle Applications PDFSharret ShaNo ratings yet

- Bill of MaterialsDocument7 pagesBill of Materialsvihanjangid223No ratings yet

- Mcframe SCM NotesDocument19 pagesMcframe SCM NotesKerr PalaranNo ratings yet

- Production ExecutionDocument114 pagesProduction ExecutionVijayabhaskar PapanaNo ratings yet

- Common COGI ErrorsDocument4 pagesCommon COGI Errorsfaisalkhan55100% (1)

- SAP CS in House Repair Order ProcessDocument36 pagesSAP CS in House Repair Order ProcessPanduNaganaboina100% (1)

- Work in Progress (Wip) Batch ScenarioDocument4 pagesWork in Progress (Wip) Batch ScenarioSuraj Pratap PhalkeNo ratings yet

- Introduction To Variant Configuration With An Example ModelDocument24 pagesIntroduction To Variant Configuration With An Example ModelRahul Jain100% (1)

- How To Use BAPIDocument71 pagesHow To Use BAPIDora Babu100% (2)

- SAP SCM - Planned Order CreationDocument16 pagesSAP SCM - Planned Order CreationLokam100% (2)

- Class 1 Order To Cash Cycle Flow Part 1Document4 pagesClass 1 Order To Cash Cycle Flow Part 1సదాశివ మద్దిగిరిNo ratings yet

- Master Records & Material Master RecordsDocument8 pagesMaster Records & Material Master RecordsAshaPandaNo ratings yet

- The Integration Point Between MM and PP SD FICO QMDocument26 pagesThe Integration Point Between MM and PP SD FICO QMKevin LiuNo ratings yet

- Bill of MaterialDocument4 pagesBill of Materialonlinelearn sapNo ratings yet

- CIN (Country India Version) MM, SD, FI Module Integration: Img SettingsDocument8 pagesCIN (Country India Version) MM, SD, FI Module Integration: Img SettingsMayur KhamitkarNo ratings yet

- IDES MM Metals Scenario MTODocument9 pagesIDES MM Metals Scenario MTOaprianNo ratings yet

- ERP C A NgaDocument50 pagesERP C A NgaMINH NGUYEN THI BINHNo ratings yet

- Introduction To Variant Configuration With An Example ModelDocument12 pagesIntroduction To Variant Configuration With An Example ModelGreg Rey100% (1)

- Manufacturing Cycle in Oracle Apps R12Document15 pagesManufacturing Cycle in Oracle Apps R12saqi22No ratings yet

- SAP PP-PI Process Flow Docs111Document25 pagesSAP PP-PI Process Flow Docs111jnsingh123450% (1)

- Moustafa Hatem 17,10 Overview Inventory SetupDocument8 pagesMoustafa Hatem 17,10 Overview Inventory Setupالردود الأهلاوية علي المختلط والغرزجيةNo ratings yet

- Close Istore OrdesDocument5 pagesClose Istore OrdesAshish GuptaNo ratings yet

- Sap SD Interview Questions With Answers PDFDocument266 pagesSap SD Interview Questions With Answers PDFsapsd1082012No ratings yet

- ATO WorkflowDocument7 pagesATO WorkflowtsurendarNo ratings yet

- GTSSolution - Inventory Management For RISE CRMDocument94 pagesGTSSolution - Inventory Management For RISE CRMteguhpcNo ratings yet

- SAP Service Management: Advanced ConfigurationFrom EverandSAP Service Management: Advanced ConfigurationRating: 4.5 out of 5 stars4.5/5 (3)

- Shrova Mall 4 - The Frontend: A-to-Z e-commerce full-stack applicationFrom EverandShrova Mall 4 - The Frontend: A-to-Z e-commerce full-stack applicationNo ratings yet

- Automated Product Handling Systems Equipment World Summary: Market Values & Financials by CountryFrom EverandAutomated Product Handling Systems Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- Mike Operations: Installation Guide 2019.2Document36 pagesMike Operations: Installation Guide 2019.2周星星No ratings yet

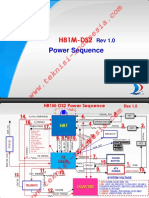

- H81M-DS2: Power SequenceDocument2 pagesH81M-DS2: Power SequenceHilario Serrano Flores100% (3)

- Lossless CompressionDocument36 pagesLossless CompressionGeHad MoheyNo ratings yet

- PoE SwitchDocument2 pagesPoE SwitchguttsaNo ratings yet

- SdmsDocument31 pagesSdmsamitNo ratings yet

- NLP Using PythonDocument50 pagesNLP Using Pythonharshit kuchhalNo ratings yet

- 5 X Appendix C Dimensional ResultsDocument5 pages5 X Appendix C Dimensional ResultsRene TapiaNo ratings yet

- Embedded System MCQDocument11 pagesEmbedded System MCQARPAN KUMAR BHANDARI100% (1)

- Implementation Guide: Aiesec HubDocument33 pagesImplementation Guide: Aiesec Hubkerrouchi mohammed yakoubNo ratings yet

- CoalescedDocument202 pagesCoalescedPau Costa FerrerNo ratings yet

- Fortiap SeriesDocument57 pagesFortiap SerieslitzolNo ratings yet

- Basic Electrical and Electronics Engineering: Dr. N. Karuppiah Dr. S. MuthubalajiDocument115 pagesBasic Electrical and Electronics Engineering: Dr. N. Karuppiah Dr. S. Muthubalajipatelvishesh545No ratings yet

- Production-Grade Control of Ingress-Egress Traffic: Why Use NGINX Ingress Controller?Document4 pagesProduction-Grade Control of Ingress-Egress Traffic: Why Use NGINX Ingress Controller?Linh Nguyễn MạnhNo ratings yet

- Med-Linket Special OfferDocument45 pagesMed-Linket Special OfferLogistica AquinoNo ratings yet

- National Assessment For Scientific Temperament & Aptitude (Nasta)Document4 pagesNational Assessment For Scientific Temperament & Aptitude (Nasta)Madhu SharmaNo ratings yet

- 06 - GSE Special ToolingDocument2 pages06 - GSE Special Tooling郝帅No ratings yet

- SVKM's Narsee Monjee Institute of Management Studies Name of School - SBM, BangaloreDocument3 pagesSVKM's Narsee Monjee Institute of Management Studies Name of School - SBM, BangaloreDIVYANSHU SHEKHARNo ratings yet

- 2023 Threat Report FinalDocument26 pages2023 Threat Report FinalJuan Carlos CortinasNo ratings yet

- ES Lab Team DetailsDocument91 pagesES Lab Team DetailsRANJITH DNo ratings yet

- Auto Arm ReportDocument8 pagesAuto Arm Reportapi-519418123No ratings yet

- Python Project Online Health Management System ReportDocument11 pagesPython Project Online Health Management System ReportD StudiosNo ratings yet

- EEE356 AnalogDigitalCommunicationDesign Q4Document8 pagesEEE356 AnalogDigitalCommunicationDesign Q4abasidNo ratings yet

- Co Over ViewDocument263 pagesCo Over Viewbhargavsap4No ratings yet

- Day 3 Privacy Impact Assessment TemplateDocument18 pagesDay 3 Privacy Impact Assessment TemplateEleazar Pelvera Chavez Jr.No ratings yet

- LDV55 SAI400TK Ficha Tecnica InglesDocument2 pagesLDV55 SAI400TK Ficha Tecnica InglesJ A García CandoNo ratings yet

- ch6 IsraDocument55 pagesch6 Israyounas125No ratings yet

- IC Agile Project Plan Template 8561Document3 pagesIC Agile Project Plan Template 8561khawjaarslanNo ratings yet