Professional Documents

Culture Documents

Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019

Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019

Uploaded by

MehoCopyright:

Available Formats

You might also like

- IIR FilterDocument26 pagesIIR FilterKyax Ginaheeq100% (1)

- Manual Panel DDocument28 pagesManual Panel DRoberto Sanchez Zapata100% (1)

- RCA - Mechanical - Seal - 1684971197 2Document20 pagesRCA - Mechanical - Seal - 1684971197 2HungphamphiNo ratings yet

- API 510 PV Inspection ChecklistDocument9 pagesAPI 510 PV Inspection ChecklistSreekumar SNo ratings yet

- Ite M Completed Comments: Tank Out-Of-Service Inspection ChecklistDocument14 pagesIte M Completed Comments: Tank Out-Of-Service Inspection Checklistmindbag100% (1)

- Tank in Service Inspection ChecklistDocument8 pagesTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Ac Spindle DL-SCZDocument96 pagesAc Spindle DL-SCZBa DuyNo ratings yet

- Solar Mobile ChargerDocument39 pagesSolar Mobile ChargerWhada86% (7)

- Part2 Secs6-7Document10 pagesPart2 Secs6-7Alexis GaitanNo ratings yet

- Troubleshooting of Mechanical Seals PDFDocument5 pagesTroubleshooting of Mechanical Seals PDFNasser KhattabNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- Part2 Sec5Document8 pagesPart2 Sec5Alexis GaitanNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Rig Audit Check ListDocument24 pagesRig Audit Check ListMohamed ElhagrassyNo ratings yet

- I & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDocument11 pagesI & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDanel GonzalezNo ratings yet

- 801 I.1.3 Man Rider Winch Product Maintenance InformationDocument14 pages801 I.1.3 Man Rider Winch Product Maintenance InformationPedro SanchezNo ratings yet

- Maintenance: Rotor Interval Ref. No. NotesDocument11 pagesMaintenance: Rotor Interval Ref. No. NotesEduardo AcostaNo ratings yet

- SGT - Le.09 Horizontal & Vertical Plate ClampsDocument2 pagesSGT - Le.09 Horizontal & Vertical Plate ClampsryangillespieNo ratings yet

- Solutions - For - Cracked - Block BESSER PDFDocument11 pagesSolutions - For - Cracked - Block BESSER PDFJosé C. Canche David100% (1)

- Location: Date of InspectionDocument1 pageLocation: Date of InspectionMohan VadiveluNo ratings yet

- Chain InspectionDocument4 pagesChain Inspectionadhi nrNo ratings yet

- Section 5. Visual Corrosion Inspection Guide For AircraftDocument2 pagesSection 5. Visual Corrosion Inspection Guide For AircraftblackhawkNo ratings yet

- Manrider Manual MODEL # FA150KGIMR12AIH-CEDocument16 pagesManrider Manual MODEL # FA150KGIMR12AIH-CESamuel Perez0% (1)

- Manual 600 NEWDocument5 pagesManual 600 NEWabhayuietNo ratings yet

- Tabla Tension Correas Gates PDFDocument4 pagesTabla Tension Correas Gates PDFHarold BurgosNo ratings yet

- Mte13ii Oc77 - 1331 X009 06 299 1 001 - 0Document3 pagesMte13ii Oc77 - 1331 X009 06 299 1 001 - 0Miguel Puma SuclleNo ratings yet

- TM 9-1005-211-34 Pistol .45 Caliber Automatic 1911A1 2 of 2 Jun 1964Document27 pagesTM 9-1005-211-34 Pistol .45 Caliber Automatic 1911A1 2 of 2 Jun 1964sappernco1No ratings yet

- MHD56305 Ed3Document16 pagesMHD56305 Ed3mukhtarahmadaNo ratings yet

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- US DockageDocument23 pagesUS DockageHolban IonutNo ratings yet

- CBC AuditDocument4 pagesCBC Auditfrenz2kiranNo ratings yet

- Inspection Procedure: Zig ZagDocument3 pagesInspection Procedure: Zig ZagAli Ben AmorNo ratings yet

- Type ValveDocument64 pagesType ValveJepri MarpaungNo ratings yet

- Annual Checklist For Inspection / Preventive Maintenance of Eot CranesDocument3 pagesAnnual Checklist For Inspection / Preventive Maintenance of Eot CranesAmarnath DhageNo ratings yet

- 5-Ti Mi 0018Document11 pages5-Ti Mi 0018Electrical TRDSERNo ratings yet

- MisiaDocument1 pageMisiaDante WilliamsNo ratings yet

- MAINTENANCE CHECKLIST Centrifuge CD 518 FH CF-1Document2 pagesMAINTENANCE CHECKLIST Centrifuge CD 518 FH CF-1shamsheer ikramNo ratings yet

- 1 GeneralDocument77 pages1 GeneraljulijubiloNo ratings yet

- Time Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckDocument17 pagesTime Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckWalter TorenaNo ratings yet

- Part2 Sec4Document11 pagesPart2 Sec4Alexis GaitanNo ratings yet

- V-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612Document9 pagesV-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612pablo7890No ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Draft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch LayoutDocument5 pagesDraft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch Layoutexam proNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument9 pagesGroup 2 Major Component: 1. Main PumpMauricio CalixtoNo ratings yet

- Main Switch Panel IntakeDocument4 pagesMain Switch Panel IntakeMohammed Sayeeduddin100% (1)

- Weekly Maintenance On Hydra RackerDocument4 pagesWeekly Maintenance On Hydra Rackermohamed hamedNo ratings yet

- M00006-1-1520-280-PMD Main Rotor Pylon SectionDocument6 pagesM00006-1-1520-280-PMD Main Rotor Pylon SectionabuzaidNo ratings yet

- Smi 292Document28 pagesSmi 292Sourav NandiNo ratings yet

- 40 - Appendix HDocument10 pages40 - Appendix HMahmoud Zakaria BadraNo ratings yet

- Section 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication InspectionDocument25 pagesSection 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication Inspectionabdelhadi houssinNo ratings yet

- MM y ServicioDocument82 pagesMM y Serviciojesus francoNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpChristian VicenteNo ratings yet

- PIRMH Chain Inspection PIDocument4 pagesPIRMH Chain Inspection PIRicardoNo ratings yet

- Knuckle Nose Wear and Stretch Limit: IF KNCKLE DOESN'T PASS THIS GAUGE, Replace The KnuckleDocument5 pagesKnuckle Nose Wear and Stretch Limit: IF KNCKLE DOESN'T PASS THIS GAUGE, Replace The KnuckleWheel Bogie Parel WSNo ratings yet

- sd8 Valve Cut SectionDocument1 pagesd8 Valve Cut SectionVEERAMANINo ratings yet

- Inspire 1 Maintenance ManualV1.0 enDocument2 pagesInspire 1 Maintenance ManualV1.0 enVICTOR H.No ratings yet

- Preventative Maintenance ChecklistDocument1 pagePreventative Maintenance ChecklistAllan Jose ReyesNo ratings yet

- Preventative Maintenance ChecklistDocument1 pagePreventative Maintenance ChecklistRonny ChipeNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument14 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Diff ADR233A - V2 - BESTDocument15 pagesDiff ADR233A - V2 - BESTtoogooodNo ratings yet

- Electrical System, Self-DiagnosisDocument93 pagesElectrical System, Self-DiagnosisZatovonirina RazafindrainibeNo ratings yet

- Priyanka - Junior JavaScript DeveloperDocument2 pagesPriyanka - Junior JavaScript DeveloperMadhav GarikapatiNo ratings yet

- Ecm 0555 080 0703Document17 pagesEcm 0555 080 0703Anderson megusta el juegoNo ratings yet

- Installation Guide - Veria Control t45Document8 pagesInstallation Guide - Veria Control t45Florin BaczoniNo ratings yet

- Co Module V 2020Document34 pagesCo Module V 2020jinto0007No ratings yet

- What Is The Difference Between RF and If Frequency - QuoraDocument3 pagesWhat Is The Difference Between RF and If Frequency - QuoraEngr Saleem Chandio0% (1)

- Mospec: 1N4001 THRU 1N4007Document3 pagesMospec: 1N4001 THRU 1N4007biswanath jenaNo ratings yet

- Aragon IridiumDocument1 pageAragon Iridiumkramanathan_3No ratings yet

- 7255Document24 pages7255khawar mukhtarNo ratings yet

- Ac To DC Converter Project ReportDocument75 pagesAc To DC Converter Project ReportPranav Tripathi79% (14)

- Product SpecificationsDocument3 pagesProduct SpecificationsS BashaNo ratings yet

- The Art and Science of Measuring The Winding Resistance of Power Transformers Oleh W.Iwansiw, P.EngDocument6 pagesThe Art and Science of Measuring The Winding Resistance of Power Transformers Oleh W.Iwansiw, P.EngMeghavahinaNo ratings yet

- Properties of Transducers: Underwater Sound Sources and ReceiversDocument55 pagesProperties of Transducers: Underwater Sound Sources and ReceiversZippo NguyễnNo ratings yet

- Industrial Drives and Applications Important QuestionsDocument2 pagesIndustrial Drives and Applications Important Questionsjyothin683100% (1)

- Model: Oti 7-12 No.:: Iso 9001 Iso 14001 TLCDocument2 pagesModel: Oti 7-12 No.:: Iso 9001 Iso 14001 TLCOrlando GómezNo ratings yet

- Woodward Easygen-2000 Configuration-Manual en 2017Document339 pagesWoodward Easygen-2000 Configuration-Manual en 2017Iweriebor ElvisNo ratings yet

- Harmonics Free Series Reactor Flux Compensated Magnetic AmplifierDocument4 pagesHarmonics Free Series Reactor Flux Compensated Magnetic Amplifiermv_mallik75% (4)

- Ultra Schematic #1Document1 pageUltra Schematic #1zoz LMGNo ratings yet

- Compactline Easy Antenna, Ultra High Performance, Dual Polarized, 2 FTDocument3 pagesCompactline Easy Antenna, Ultra High Performance, Dual Polarized, 2 FTLuciano Silvério LeiteNo ratings yet

- DSEE400 Configuration Suite PC Software ManualDocument126 pagesDSEE400 Configuration Suite PC Software ManualKabul SandhuNo ratings yet

- Schneider Copper - July 2024 Price ListDocument2 pagesSchneider Copper - July 2024 Price ListforestpcNo ratings yet

- Electrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTDocument28 pagesElectrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTStefano FavaroNo ratings yet

- Types of Main Memory: 1-Read-Write or Random Access Memory (RAM)Document4 pagesTypes of Main Memory: 1-Read-Write or Random Access Memory (RAM)Sarmad Salih Jawad AlkodaryNo ratings yet

- Sanken IC Regulators (2000)Document354 pagesSanken IC Regulators (2000)PelotaDeTrapoNo ratings yet

- Surtron 160 Diathermy BrochureDocument4 pagesSurtron 160 Diathermy BrochurebikouvoNo ratings yet

- Show PDFDocument73 pagesShow PDFTuhina bhuiyaNo ratings yet

Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019

Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019

Uploaded by

MehoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019

Table 4. Minimum Frequent Inspections Type of Service Item: 192063792 Rev AA April 2019

Uploaded by

MehoCopyright:

Available Formats

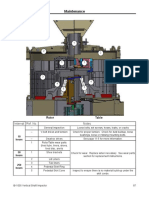

Table 4.

Minimum Frequent

Inspections

TYPE OF SERVICE ITEM

)

Normal Heavy Severe

a) Brake for evidence of slippage.

¿ b) Control functions for proper operation.

Monthly

;s c) Hooks for damage, cracks, twists, excessive throat opening, latch engagement and latch

O O operation - see page 18.

- see page 20.

) e) Load chain for proper reeving and twists.

) Table S. Minimum Periodic Inspections

TYPE OF SERVICE ITEM

Normal Heavy Severe a) All items listed in Table 4 for frequent inspections.

b) External evidence of loose screws, bolts or nuts.

c) External evidence of worn, corroded, cracked or distorted hook block, suspension

screws,gears, bearings and dead end block and chain pin.

d) External evidence of damage to hook retaining nut and pin. Also check the upper suspension

adapter making sure it is fully seated in the hoist frame and that both screws are tight.

e) External evidence of damage or excessive wear of the liftwheel and hook block sheave

chain pockets. Widening and deepening of the pockets may cause the chain to lift-up in the

pocket and result in binding between liftwheel and chain guides or between the sheave and

hook block. Also, check the chain guide for wear or burring where the chain enters the hoist.

Severely worn or damaged parts should be replaced.

f} External evidence of excessive wear of brake parts, and AC brake adjustment - see page 22. )

g) External evidence of pitting or any deterioration of contactor contacts. Check the operation

of the control station making sure the buttons operate freely and do not stick in either

h) Inspect the electrical cords and cables and control station enclosure for damaged insulation.

Yearly

wear and operation. Also check suspension adapter screws for proper tightness - see page 11.

Inspect the loose end link, loose end screw and dead end block on double reeved units. Replace worn or distorted parts.

position.

k) Inspect the suspension lug or hook for excess free play or rotation. Replace worn parts as

evidenced by excess free play or rotation.

l) Inspect for signs of lubricant leaks at the gasket between the gear housing and back frame.

tighten screws holding back frame to gear housing. If leak persists, repack housing and

gears with grease and install a new gasket.

m) On the Models RT, RT-2, RRT and RRT-2:

1. Inspect shackle and lug pins for wear. Replace if worn.

2. Check dead end screw in lower hook black for wear and tightness*.

3. Check shackle pin for proper seating in groove of load bracket.

4. Inspect cloverleaf plate on bottom of sheave hanger for wear or burring. Replace if worn.

5. Inspect sheave stud nut and seat for wear. Replace if worn or damaged.

*When tightening the special, dead end socket head screw, it should be held firmly in place and torqued from the nut end only to avoid damage

to the screw and/or dead end chain link (Refer to step J on page 45).

18 192063792 Rev AA April 2019

You might also like

- IIR FilterDocument26 pagesIIR FilterKyax Ginaheeq100% (1)

- Manual Panel DDocument28 pagesManual Panel DRoberto Sanchez Zapata100% (1)

- RCA - Mechanical - Seal - 1684971197 2Document20 pagesRCA - Mechanical - Seal - 1684971197 2HungphamphiNo ratings yet

- API 510 PV Inspection ChecklistDocument9 pagesAPI 510 PV Inspection ChecklistSreekumar SNo ratings yet

- Ite M Completed Comments: Tank Out-Of-Service Inspection ChecklistDocument14 pagesIte M Completed Comments: Tank Out-Of-Service Inspection Checklistmindbag100% (1)

- Tank in Service Inspection ChecklistDocument8 pagesTank in Service Inspection ChecklistAhmadiBinAhmad100% (3)

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Ac Spindle DL-SCZDocument96 pagesAc Spindle DL-SCZBa DuyNo ratings yet

- Solar Mobile ChargerDocument39 pagesSolar Mobile ChargerWhada86% (7)

- Part2 Secs6-7Document10 pagesPart2 Secs6-7Alexis GaitanNo ratings yet

- Troubleshooting of Mechanical Seals PDFDocument5 pagesTroubleshooting of Mechanical Seals PDFNasser KhattabNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- Part2 Sec5Document8 pagesPart2 Sec5Alexis GaitanNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Rig Audit Check ListDocument24 pagesRig Audit Check ListMohamed ElhagrassyNo ratings yet

- I & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDocument11 pagesI & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDanel GonzalezNo ratings yet

- 801 I.1.3 Man Rider Winch Product Maintenance InformationDocument14 pages801 I.1.3 Man Rider Winch Product Maintenance InformationPedro SanchezNo ratings yet

- Maintenance: Rotor Interval Ref. No. NotesDocument11 pagesMaintenance: Rotor Interval Ref. No. NotesEduardo AcostaNo ratings yet

- SGT - Le.09 Horizontal & Vertical Plate ClampsDocument2 pagesSGT - Le.09 Horizontal & Vertical Plate ClampsryangillespieNo ratings yet

- Solutions - For - Cracked - Block BESSER PDFDocument11 pagesSolutions - For - Cracked - Block BESSER PDFJosé C. Canche David100% (1)

- Location: Date of InspectionDocument1 pageLocation: Date of InspectionMohan VadiveluNo ratings yet

- Chain InspectionDocument4 pagesChain Inspectionadhi nrNo ratings yet

- Section 5. Visual Corrosion Inspection Guide For AircraftDocument2 pagesSection 5. Visual Corrosion Inspection Guide For AircraftblackhawkNo ratings yet

- Manrider Manual MODEL # FA150KGIMR12AIH-CEDocument16 pagesManrider Manual MODEL # FA150KGIMR12AIH-CESamuel Perez0% (1)

- Manual 600 NEWDocument5 pagesManual 600 NEWabhayuietNo ratings yet

- Tabla Tension Correas Gates PDFDocument4 pagesTabla Tension Correas Gates PDFHarold BurgosNo ratings yet

- Mte13ii Oc77 - 1331 X009 06 299 1 001 - 0Document3 pagesMte13ii Oc77 - 1331 X009 06 299 1 001 - 0Miguel Puma SuclleNo ratings yet

- TM 9-1005-211-34 Pistol .45 Caliber Automatic 1911A1 2 of 2 Jun 1964Document27 pagesTM 9-1005-211-34 Pistol .45 Caliber Automatic 1911A1 2 of 2 Jun 1964sappernco1No ratings yet

- MHD56305 Ed3Document16 pagesMHD56305 Ed3mukhtarahmadaNo ratings yet

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- US DockageDocument23 pagesUS DockageHolban IonutNo ratings yet

- CBC AuditDocument4 pagesCBC Auditfrenz2kiranNo ratings yet

- Inspection Procedure: Zig ZagDocument3 pagesInspection Procedure: Zig ZagAli Ben AmorNo ratings yet

- Type ValveDocument64 pagesType ValveJepri MarpaungNo ratings yet

- Annual Checklist For Inspection / Preventive Maintenance of Eot CranesDocument3 pagesAnnual Checklist For Inspection / Preventive Maintenance of Eot CranesAmarnath DhageNo ratings yet

- 5-Ti Mi 0018Document11 pages5-Ti Mi 0018Electrical TRDSERNo ratings yet

- MisiaDocument1 pageMisiaDante WilliamsNo ratings yet

- MAINTENANCE CHECKLIST Centrifuge CD 518 FH CF-1Document2 pagesMAINTENANCE CHECKLIST Centrifuge CD 518 FH CF-1shamsheer ikramNo ratings yet

- 1 GeneralDocument77 pages1 GeneraljulijubiloNo ratings yet

- Time Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckDocument17 pagesTime Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckWalter TorenaNo ratings yet

- Part2 Sec4Document11 pagesPart2 Sec4Alexis GaitanNo ratings yet

- V-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612Document9 pagesV-Belt and Timing Belt Installation and Maintenance: SERVICE EXPRESS 1-800-829-6612pablo7890No ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Draft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch LayoutDocument5 pagesDraft Maintenance Check List For 220Mm Point Machine (Clamp Type) Installed at Thick Web Switch Layoutexam proNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument9 pagesGroup 2 Major Component: 1. Main PumpMauricio CalixtoNo ratings yet

- Main Switch Panel IntakeDocument4 pagesMain Switch Panel IntakeMohammed Sayeeduddin100% (1)

- Weekly Maintenance On Hydra RackerDocument4 pagesWeekly Maintenance On Hydra Rackermohamed hamedNo ratings yet

- M00006-1-1520-280-PMD Main Rotor Pylon SectionDocument6 pagesM00006-1-1520-280-PMD Main Rotor Pylon SectionabuzaidNo ratings yet

- Smi 292Document28 pagesSmi 292Sourav NandiNo ratings yet

- 40 - Appendix HDocument10 pages40 - Appendix HMahmoud Zakaria BadraNo ratings yet

- Section 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication InspectionDocument25 pagesSection 3: Maintenance Instructure: Cleaning Fastening Aligment Lubrication Inspectionabdelhadi houssinNo ratings yet

- MM y ServicioDocument82 pagesMM y Serviciojesus francoNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpChristian VicenteNo ratings yet

- PIRMH Chain Inspection PIDocument4 pagesPIRMH Chain Inspection PIRicardoNo ratings yet

- Knuckle Nose Wear and Stretch Limit: IF KNCKLE DOESN'T PASS THIS GAUGE, Replace The KnuckleDocument5 pagesKnuckle Nose Wear and Stretch Limit: IF KNCKLE DOESN'T PASS THIS GAUGE, Replace The KnuckleWheel Bogie Parel WSNo ratings yet

- sd8 Valve Cut SectionDocument1 pagesd8 Valve Cut SectionVEERAMANINo ratings yet

- Inspire 1 Maintenance ManualV1.0 enDocument2 pagesInspire 1 Maintenance ManualV1.0 enVICTOR H.No ratings yet

- Preventative Maintenance ChecklistDocument1 pagePreventative Maintenance ChecklistAllan Jose ReyesNo ratings yet

- Preventative Maintenance ChecklistDocument1 pagePreventative Maintenance ChecklistRonny ChipeNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument14 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Diff ADR233A - V2 - BESTDocument15 pagesDiff ADR233A - V2 - BESTtoogooodNo ratings yet

- Electrical System, Self-DiagnosisDocument93 pagesElectrical System, Self-DiagnosisZatovonirina RazafindrainibeNo ratings yet

- Priyanka - Junior JavaScript DeveloperDocument2 pagesPriyanka - Junior JavaScript DeveloperMadhav GarikapatiNo ratings yet

- Ecm 0555 080 0703Document17 pagesEcm 0555 080 0703Anderson megusta el juegoNo ratings yet

- Installation Guide - Veria Control t45Document8 pagesInstallation Guide - Veria Control t45Florin BaczoniNo ratings yet

- Co Module V 2020Document34 pagesCo Module V 2020jinto0007No ratings yet

- What Is The Difference Between RF and If Frequency - QuoraDocument3 pagesWhat Is The Difference Between RF and If Frequency - QuoraEngr Saleem Chandio0% (1)

- Mospec: 1N4001 THRU 1N4007Document3 pagesMospec: 1N4001 THRU 1N4007biswanath jenaNo ratings yet

- Aragon IridiumDocument1 pageAragon Iridiumkramanathan_3No ratings yet

- 7255Document24 pages7255khawar mukhtarNo ratings yet

- Ac To DC Converter Project ReportDocument75 pagesAc To DC Converter Project ReportPranav Tripathi79% (14)

- Product SpecificationsDocument3 pagesProduct SpecificationsS BashaNo ratings yet

- The Art and Science of Measuring The Winding Resistance of Power Transformers Oleh W.Iwansiw, P.EngDocument6 pagesThe Art and Science of Measuring The Winding Resistance of Power Transformers Oleh W.Iwansiw, P.EngMeghavahinaNo ratings yet

- Properties of Transducers: Underwater Sound Sources and ReceiversDocument55 pagesProperties of Transducers: Underwater Sound Sources and ReceiversZippo NguyễnNo ratings yet

- Industrial Drives and Applications Important QuestionsDocument2 pagesIndustrial Drives and Applications Important Questionsjyothin683100% (1)

- Model: Oti 7-12 No.:: Iso 9001 Iso 14001 TLCDocument2 pagesModel: Oti 7-12 No.:: Iso 9001 Iso 14001 TLCOrlando GómezNo ratings yet

- Woodward Easygen-2000 Configuration-Manual en 2017Document339 pagesWoodward Easygen-2000 Configuration-Manual en 2017Iweriebor ElvisNo ratings yet

- Harmonics Free Series Reactor Flux Compensated Magnetic AmplifierDocument4 pagesHarmonics Free Series Reactor Flux Compensated Magnetic Amplifiermv_mallik75% (4)

- Ultra Schematic #1Document1 pageUltra Schematic #1zoz LMGNo ratings yet

- Compactline Easy Antenna, Ultra High Performance, Dual Polarized, 2 FTDocument3 pagesCompactline Easy Antenna, Ultra High Performance, Dual Polarized, 2 FTLuciano Silvério LeiteNo ratings yet

- DSEE400 Configuration Suite PC Software ManualDocument126 pagesDSEE400 Configuration Suite PC Software ManualKabul SandhuNo ratings yet

- Schneider Copper - July 2024 Price ListDocument2 pagesSchneider Copper - July 2024 Price ListforestpcNo ratings yet

- Electrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTDocument28 pagesElectrical System Earthing Design Philosophy: Prelude Floating LNG PROJECTStefano FavaroNo ratings yet

- Types of Main Memory: 1-Read-Write or Random Access Memory (RAM)Document4 pagesTypes of Main Memory: 1-Read-Write or Random Access Memory (RAM)Sarmad Salih Jawad AlkodaryNo ratings yet

- Sanken IC Regulators (2000)Document354 pagesSanken IC Regulators (2000)PelotaDeTrapoNo ratings yet

- Surtron 160 Diathermy BrochureDocument4 pagesSurtron 160 Diathermy BrochurebikouvoNo ratings yet

- Show PDFDocument73 pagesShow PDFTuhina bhuiyaNo ratings yet