Professional Documents

Culture Documents

Receipt Routing For Inventory & Purchasing

Receipt Routing For Inventory & Purchasing

Uploaded by

karthik r0 ratings0% found this document useful (0 votes)

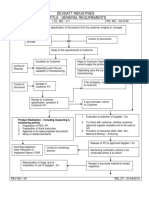

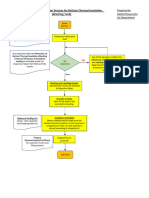

18 views1 pageThe document outlines 5 different receipt routing options for inventory and purchasing, including direct delivery from the organization or supplier, delivery with inspection by internal personnel, and standard or expedited delivery from suppliers either directly to inventory or with quality inspection. It provides details on the receipt and verification processes, material handling, and quality inspection steps for each of the 5 options. The goal is to efficiently receive and process inventory and purchases while ensuring quality standards are met.

Original Description:

Original Title

Receipt_Routing

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines 5 different receipt routing options for inventory and purchasing, including direct delivery from the organization or supplier, delivery with inspection by internal personnel, and standard or expedited delivery from suppliers either directly to inventory or with quality inspection. It provides details on the receipt and verification processes, material handling, and quality inspection steps for each of the 5 options. The goal is to efficiently receive and process inventory and purchases while ensuring quality standards are met.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

18 views1 pageReceipt Routing For Inventory & Purchasing

Receipt Routing For Inventory & Purchasing

Uploaded by

karthik rThe document outlines 5 different receipt routing options for inventory and purchasing, including direct delivery from the organization or supplier, delivery with inspection by internal personnel, and standard or expedited delivery from suppliers either directly to inventory or with quality inspection. It provides details on the receipt and verification processes, material handling, and quality inspection steps for each of the 5 options. The goal is to efficiently receive and process inventory and purchases while ensuring quality standards are met.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

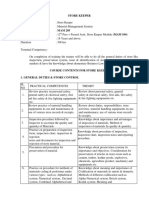

Receipt Routing for Inventory & Purchasing

Receiving Section

Source Gate of Org. Sub - Inventory Remarks

before Sub_Inventory

Material delivered directly. The vehicle will not

1. Org - Direct No entry in Oracle for matl. stop at gate and

This is preferred if the client do not want to monitor the cost and time involved in this transfer. Movement. Receiving Section

Consigment identified by Inter Gate personnel will

Org shipment number Consignment opened and

inspect DC and Shipment Acceptable qty delivered to

2. Org - Intransit verified for qty and physical

number and generate sub-inventory

damage

receipt number

TT : Receive TT : Deliver

This is preferred for

DC verified against PO

3. Supplier - No verification at Receiving renowned suppliers

qty and receipt made for

Direct section. and urgent

qty supplied.

requirment.

TT : Receive & Deliver

DC verified against PO Consignment opened and

4. Supplier - Acceptable qty delivered to

qty and receipt made for verified for qty and physical

Standard sub-inventory

qty supplied. damage

TT : Receive TT : Deliver

DC verified against PO Inspection team called and a

5. Supplier -

qty and receipt made for quality check performed as per

Inspection

qty supplied. norms.

TT : Receive TT : Inspect

Oracle quality needs to be installed for performing

inspection. If Quality module is not sold, set the profile Material segregated as

QA : PO Inspection = Oracle Purchasing. Accepted and Rejected

Rejected qty will be either Company's quality

Receipt considered as closed at Receipt ( TT : Reveive) Accepted is delivered to returned to Supp. or check norms

or Delivered ( TT : Deliver) or Inspected ( TT : Inspect) Sub_Inventory. delivered to Sub-Inv as per followed during

Requester's final decision. inspection.

TT : Deliver

You might also like

- Sop PurchasingDocument11 pagesSop Purchasinghr multicraft100% (6)

- SOP For Fixed Assets MainagementDocument12 pagesSOP For Fixed Assets MainagementJAK Group100% (1)

- P2P PresentationDocument21 pagesP2P PresentationAnjana VarnwalNo ratings yet

- SOP Payments and Claims ULDocument5 pagesSOP Payments and Claims ULfaizaldalimiNo ratings yet

- Centralized ProcurementDocument18 pagesCentralized Procurementkarthik rNo ratings yet

- Presentation of GeneratorDocument18 pagesPresentation of Generatorapi-3834081100% (1)

- Flow Chart For Purchase Procedure Followed in Manufacturing ConcernsDocument1 pageFlow Chart For Purchase Procedure Followed in Manufacturing Concernsviren_rockyNo ratings yet

- Group 21Document19 pagesGroup 21Simi15No ratings yet

- Process Flow Chart PDFDocument2 pagesProcess Flow Chart PDFSerkan CebeciogluNo ratings yet

- 4.2 Documents Under GST, Books & RecordsDocument45 pages4.2 Documents Under GST, Books & Recordsvenkatesh grietNo ratings yet

- CRM Slide 12-6-12 2Document1 pageCRM Slide 12-6-12 2zha khanNo ratings yet

- Letter of CreditDocument49 pagesLetter of CreditPratheepThankarajNo ratings yet

- McCAMISH HelpDocument39 pagesMcCAMISH HelpSrinivas BalledaNo ratings yet

- TOC and Substantive Test Cyle Expenditure and Disbursement CycleDocument6 pagesTOC and Substantive Test Cyle Expenditure and Disbursement CycleGirl langNo ratings yet

- RFQ Format Goods and ServicesDocument3 pagesRFQ Format Goods and ServicesPedro FerreiraNo ratings yet

- Itp WeldDocument2 pagesItp WeldHarshaVeeragandhamNo ratings yet

- Sub Process: Purchased Parts, Pass Through, Material ManagementDocument2 pagesSub Process: Purchased Parts, Pass Through, Material ManagementNikhilesh NaikNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- DocumentedDocument2 pagesDocumentedMahmoud KhalifaNo ratings yet

- Trai Qa R 45 Process Audit - FormatDocument5 pagesTrai Qa R 45 Process Audit - FormatRS MANIKANDANNo ratings yet

- Flowchart For SDM ProcessDocument5 pagesFlowchart For SDM ProcessSpencer BrianNo ratings yet

- Group 2 - MC Business TransformationDocument7 pagesGroup 2 - MC Business Transformationmonamihanah0300No ratings yet

- Toaz - Info Itp For PVC Conduits PRDocument6 pagesToaz - Info Itp For PVC Conduits PRehtesham khanNo ratings yet

- Pt. Patco Elektronik Teknologi Standard Operating Procedure PurchasingDocument8 pagesPt. Patco Elektronik Teknologi Standard Operating Procedure Purchasingmochammad iqbal100% (1)

- Purchase and Disbursement CycleDocument30 pagesPurchase and Disbursement CycleVenus Lyka LomocsoNo ratings yet

- Supplier Invoice Adjustments: Accrue On Receipt Adjustment Support in PA - PJ - PF.LDocument10 pagesSupplier Invoice Adjustments: Accrue On Receipt Adjustment Support in PA - PJ - PF.LrahuldisyNo ratings yet

- 08.03.02 - Quality Assurance - Supply Material R2Document5 pages08.03.02 - Quality Assurance - Supply Material R2tanmayascribdNo ratings yet

- SOP For Handling of Rejected Raw MaterialDocument6 pagesSOP For Handling of Rejected Raw Materialanoushia alviNo ratings yet

- Purch Blueprint 01022022Document6 pagesPurch Blueprint 01022022ronimagtoto.rmmNo ratings yet

- Topic6 S Purch Inv Pay CycleDocument14 pagesTopic6 S Purch Inv Pay CycleWei ZhangNo ratings yet

- A Typical Procurement Process For High Valued ItemsDocument1 pageA Typical Procurement Process For High Valued Itemskarthik rNo ratings yet

- P2P & AP ProcessDocument2 pagesP2P & AP ProcessCHIRAG CHOKSINo ratings yet

- Flow Chart 0: Overall Flow For Normal Purchase ProcedureDocument1 pageFlow Chart 0: Overall Flow For Normal Purchase ProceduremanishdgNo ratings yet

- Itp - BPDocument3 pagesItp - BPMohammed EssamNo ratings yet

- To Unload Goods and Manage Their LocationDocument4 pagesTo Unload Goods and Manage Their LocationasdfqwerNo ratings yet

- BP070 UcilDocument43 pagesBP070 UcilSrikanth PeriNo ratings yet

- SOP - PU - 02 PurchasingDocument2 pagesSOP - PU - 02 PurchasingHarits As SiddiqNo ratings yet

- The Expense CycleDocument6 pagesThe Expense CycleConner BeckerNo ratings yet

- Inventory Control PurchasingDocument6 pagesInventory Control PurchasingConner BeckerNo ratings yet

- Bottom Thermal Insulation (Washing Tank) Flow ChartDocument1 pageBottom Thermal Insulation (Washing Tank) Flow ChartKhawarizmi SuraniNo ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- 0703 Vendor Selection & ControlDocument13 pages0703 Vendor Selection & ControlSundara Rajan RamakrishnanNo ratings yet

- FlowchartDocument1 pageFlowchartSharmaine manobanNo ratings yet

- Procurement Cloud - Consigned InventoryDocument14 pagesProcurement Cloud - Consigned Inventorysujit nayakNo ratings yet

- Question: Where Will The Goods Be Forwarded?Document2 pagesQuestion: Where Will The Goods Be Forwarded?em cortezNo ratings yet

- Support AppDocument1 pageSupport Appbad boyNo ratings yet

- Receiving Inspection Checklist Details & Sub-AssemblyDocument7 pagesReceiving Inspection Checklist Details & Sub-AssemblyMohamedNo ratings yet

- Receiving of Raw & Pacheging Material SOPDocument6 pagesReceiving of Raw & Pacheging Material SOPanoushia alviNo ratings yet

- AEB15 SM C18 v3Document33 pagesAEB15 SM C18 v3Aaqib Hossain100% (1)

- Rawmaterials Inward ProcessDocument12 pagesRawmaterials Inward ProcessKrushna MishraNo ratings yet

- Cathodic Protection System Inspection and Test PlanDocument10 pagesCathodic Protection System Inspection and Test PlanNoor A QasimNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Summary SIA Ch.13 - Expenditure CycleDocument3 pagesSummary SIA Ch.13 - Expenditure CycleAthiyya Nabila AyuNo ratings yet

- Revenue Cycle (Part I)Document34 pagesRevenue Cycle (Part I)Rosario TaguinotNo ratings yet

- Control Domain Sub-Domain Risk Number Risk Descripti On Control Objective Control Referenc E# Control Descripti On Test Procedur e Evidence RequiredDocument44 pagesControl Domain Sub-Domain Risk Number Risk Descripti On Control Objective Control Referenc E# Control Descripti On Test Procedur e Evidence RequiredAayushi PradhanNo ratings yet

- Raw Material & Packing MaterialDocument6 pagesRaw Material & Packing MaterialM Shahzad Azam KhanNo ratings yet

- Contractor: Client:: Project TitleDocument2 pagesContractor: Client:: Project TitlePrasanna Kumar100% (1)

- QCR W 2036Document1 pageQCR W 2036Madhan KannanNo ratings yet

- Process Overview - Power Transmission & Distribution BusinessDocument17 pagesProcess Overview - Power Transmission & Distribution BusinesssachinNo ratings yet

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- Supplier Guide To Isupplier PortalDocument24 pagesSupplier Guide To Isupplier Portalkarthik rNo ratings yet

- Very Good - Pls Check DO-70Document58 pagesVery Good - Pls Check DO-70karthik rNo ratings yet

- Good Isupplier User Guide ENDocument32 pagesGood Isupplier User Guide ENkarthik rNo ratings yet

- Pls Read - Prospective Supplier Registration User Manual-ENDocument28 pagesPls Read - Prospective Supplier Registration User Manual-ENkarthik rNo ratings yet

- Automatic Approval For Imported Standard Purchase Orders: An Oracle White Paper June 2002Document11 pagesAutomatic Approval For Imported Standard Purchase Orders: An Oracle White Paper June 2002karthik rNo ratings yet

- SLM UI Refactoring: Responsibility/Men U Change Done Comments/Queri Es Remark SDocument11 pagesSLM UI Refactoring: Responsibility/Men U Change Done Comments/Queri Es Remark Skarthik rNo ratings yet

- Major Tables and Relationships For Costing April 2010Document50 pagesMajor Tables and Relationships For Costing April 2010karthik rNo ratings yet

- What Is The PDF File Path For PO OutputDocument1 pageWhat Is The PDF File Path For PO Outputkarthik rNo ratings yet

- Otl Ak111Document54 pagesOtl Ak111karthik rNo ratings yet

- Requisition Change Order WF DetailsDocument23 pagesRequisition Change Order WF Detailskarthik rNo ratings yet

- 01 Org Creation ProcedureDocument1 page01 Org Creation Procedurekarthik rNo ratings yet

- OAS INV UserguideDocument87 pagesOAS INV Userguidekarthik rNo ratings yet

- BASF Saudi Arabia NEWDocument5 pagesBASF Saudi Arabia NEWkarthik rNo ratings yet

- A Typical Procurement Process For High Valued ItemsDocument1 pageA Typical Procurement Process For High Valued Itemskarthik rNo ratings yet

- PO CompareDocument1 pagePO Comparekarthik rNo ratings yet

- Document Security, Routing and ApprovalDocument36 pagesDocument Security, Routing and Approvalkarthik rNo ratings yet

- Supervisor HierarchyDocument1 pageSupervisor Hierarchykarthik rNo ratings yet

- Inventory Carrying CostDocument3 pagesInventory Carrying CostqwertyNo ratings yet

- Syllabus Store KeeperDocument4 pagesSyllabus Store KeeperAlok KumarNo ratings yet

- SCM 16 Transportation Management - Part-2Document11 pagesSCM 16 Transportation Management - Part-2swagat mohapatra100% (1)

- Cost Accounting and Cost ManagementDocument2 pagesCost Accounting and Cost ManagementshengNo ratings yet

- A Study On Inventory Management at Anantha PVC Pipes PVT LTD, AnanthapurDocument8 pagesA Study On Inventory Management at Anantha PVC Pipes PVT LTD, AnanthapurEditor IJTSRDNo ratings yet

- Chapter 9 Page 412Document13 pagesChapter 9 Page 412Ruby Amor DoligosaNo ratings yet

- ACC116-Chapter 2Document41 pagesACC116-Chapter 2SHARIFAH NOORAZREEN WAN JAMURINo ratings yet

- Material Costing Theory and NumericalsDocument10 pagesMaterial Costing Theory and NumericalsJash SanghviNo ratings yet

- Om FinalDocument37 pagesOm FinalAkliluNo ratings yet

- Brady Company Uses Normal Costing in Its Job Costing System TheDocument1 pageBrady Company Uses Normal Costing in Its Job Costing System Thetrilocksp SinghNo ratings yet

- Tutorial 8 QsDocument9 pagesTutorial 8 QsDylan Rabin PereiraNo ratings yet

- Exercise2 InventoriesDocument1 pageExercise2 InventoriesBeliz GüneyNo ratings yet

- C9 (MC) - Cost Accounting by Carter (Part2)Document3 pagesC9 (MC) - Cost Accounting by Carter (Part2)AkiNo ratings yet

- MBA 542 Inventory Exercise IIIDocument5 pagesMBA 542 Inventory Exercise IIISinem DüdenNo ratings yet

- CFAS Chap 11 Sol To Prob 11 2 Inventory Change in Acctng Policesestimates and ErrorsDocument1 pageCFAS Chap 11 Sol To Prob 11 2 Inventory Change in Acctng Policesestimates and ErrorsIce CreamNo ratings yet

- Inspection Audit and Inventory Control in Hospital Material Management PDFDocument17 pagesInspection Audit and Inventory Control in Hospital Material Management PDFAdnan RAHATNo ratings yet

- Accounting Information System - Chapter 5 - ReviewerDocument8 pagesAccounting Information System - Chapter 5 - ReviewerSecret LangNo ratings yet

- Materials Management & Inventory Control-6Document6 pagesMaterials Management & Inventory Control-6Rajat Suri100% (1)

- POM Final ExamDocument6 pagesPOM Final ExamREIGN EBONY ANNE AGUSTINNo ratings yet

- CH0303Document2 pagesCH0303Mark Michael LegaspiNo ratings yet

- Bimrew MeleseDocument91 pagesBimrew Meleseobsinan dejeneNo ratings yet

- Quiz 4 - With Answers Part IIDocument6 pagesQuiz 4 - With Answers Part IIjanus lopezNo ratings yet

- Toyota Systeme ProductionDocument25 pagesToyota Systeme Productionmed amine mnasserNo ratings yet

- Purchasing and Supply Management 15th Edition Johnson Solutions ManualDocument19 pagesPurchasing and Supply Management 15th Edition Johnson Solutions Manualdavidphillipsmcyaqbeogf100% (30)

- UNIT III-Financial Aspects of Inventory StrategyDocument17 pagesUNIT III-Financial Aspects of Inventory StrategyMonica Lorevella NegreNo ratings yet

- Review in Midterm Examination - Acc 204Document18 pagesReview in Midterm Examination - Acc 204Diane Marinel De LeonNo ratings yet

- Topic 1 Introduction To WarehousingDocument12 pagesTopic 1 Introduction To WarehousingmainaNo ratings yet

- Attempt All Questions 2. Cheating Is Strictly Forbidden 3. Switch Your Mobile PhoneDocument2 pagesAttempt All Questions 2. Cheating Is Strictly Forbidden 3. Switch Your Mobile Phonesamuel debebeNo ratings yet

- Inventory: 1. IAS 2 InventoriesDocument7 pagesInventory: 1. IAS 2 InventoriesHikmət RüstəmovNo ratings yet

- Chapter 21Document3 pagesChapter 21kamau samuelNo ratings yet