Professional Documents

Culture Documents

NFPA 25 Fire Protection Equipment Testing Recommendations and Frequencies PDF

NFPA 25 Fire Protection Equipment Testing Recommendations and Frequencies PDF

Uploaded by

MatthewOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NFPA 25 Fire Protection Equipment Testing Recommendations and Frequencies PDF

NFPA 25 Fire Protection Equipment Testing Recommendations and Frequencies PDF

Uploaded by

MatthewCopyright:

Available Formats

NFPA 25 Fire Protection Equipment Testing Recommendations and

Frequencies

Fire Pumps:

Fire pumps should be test started via the automatic starting mechanism weekly (pump churn

tests) and flow tested annually.

· Electric motor driven fire pumps should be run for at least 10 min. Pump suction and

discharge pressures should be recorded and the pump

· Diesel driven fire pumps should be run for at least 30 min. at rated speed. Pump suction and

discharge pressures should be recorded. In addition, the fuel tank level should be checked

and maintained at least 3/4 full, the quality and quantity of crankcase oil should be checked

and the batteries and battery charger should be inspected for proper operating conditions.

Other components and conditions should be checked as per NFPA 20 and NFPA 25.

· The fire pump should be annually flow tested at near 100% and 150% rated conditions.

Automatic Sprinkler and Fire Protection Control Valves:

Automatic sprinkler and fire protection control valves should be visually inspected for the locked

and open position on a monthly basis.

Post indicating valves (PIV’s) and wall post indicating valves (WPIV’s) should be physically

tested at least annually and semi-annually if tampered. All valves should be fully closed and re-

opened annually.

All valves should be individually listed on the fire inspection report.

A responsible employee and alternate should be assigned so the inspections are performed

properly. Completed inspection records should be reviewed by management for correction of

any noted deficiencies and kept on file.

Waterflow Alarms:

These should be tested quarterly by flowing from the Inspector’s Test Connection for each

system.

Alarms should be received from the central station alarm company, which should be contacted

before (to alert them of the tests) and after (to confirm all signals were received) the tests are

performed.

Valve Tamper Alarms:

These should be tested semi-annually. Each fire protection control valve should be partially or

fully shut and re-opened to confirm the valve tamper alarms are functioning properly. Alarms

should be received from the central station alarm company, which should be contacted before (to

alert them of the tests) and after (to confirm all signals were received) the tests are performed.

2 in. Drain Flow Tests:

Main or 2 in. drain flow tests should be performed for each individual sprinkler riser and should

be completed at least annually.

Flow alarms may be transmitted to the central station alarm company, which should be contacted

before (to alert them of the tests) and after the tests are performed.

Dry Pipe Sprinkler Systems:

Recorded trip tests of each dry pipe valve should be performed annually.

Preaction Sprinkler Systems:

Recorded trip tests of each preaction/deluge valve should be performed annually.

Fire Doors:

All fire doors should be visually inspected weekly and tested annually.

Other General Fire Inspection and Housekeeping Items:

Inspections should be conducted for all other fire protection equipment and general conditions.

A responsible employee and alternate should be assigned so the inspections are performed

properly. Completed inspection records should be reviewed by management for correction of

any noted deficiencies and kept on file.

Housekeeping items related to fire protection include:

· Maintaining a minimum 3 ft. clearance between ceiling sprinklers and rack storage

· Maintaining a minimum 3 ft. clearance between combustible storage and all electrical

panels/equipment

· Maintaining a minimum 5 ft. clearance between combustible storage and all heating units

or heat producing equipment

· Maintaining a minimum 5 ft. clearance between storage and fire doors

· Aisles between racks should be maintained free of storage

You might also like

- MSL Compressor Msf-300n Rev.03 EngDocument36 pagesMSL Compressor Msf-300n Rev.03 EngMatthew100% (1)

- Suppliers Database UAE MECHDocument20 pagesSuppliers Database UAE MECHNaveen Diggai100% (1)

- Visual Inspection Checklist For Electrical Safety: Portable Electrical Equipment Yes NoDocument2 pagesVisual Inspection Checklist For Electrical Safety: Portable Electrical Equipment Yes NoAhmed Zahran100% (1)

- Emergency Lighting - Cooper PDFDocument94 pagesEmergency Lighting - Cooper PDFgilbertomjcNo ratings yet

- NFPA 25 Training-Mehboob Shaikh (CFPS, CFI, AMIE)Document137 pagesNFPA 25 Training-Mehboob Shaikh (CFPS, CFI, AMIE)Mostafizur Rahman100% (1)

- 10 Point Check List Foam System Rev 02Document7 pages10 Point Check List Foam System Rev 02jackson100% (1)

- Fire Sprinkler System Maintenance ChecklistDocument2 pagesFire Sprinkler System Maintenance ChecklistKevin Pagayaman100% (2)

- CAPITANO MARINER User Jan 2009Document62 pagesCAPITANO MARINER User Jan 2009MatthewNo ratings yet

- 8-3 Rubber TireDocument22 pages8-3 Rubber TireFernando Katayama0% (1)

- Fire Safety Full ReportDocument30 pagesFire Safety Full ReportNoor Asni100% (1)

- Foam CalculationsDocument8 pagesFoam CalculationsAnonymous BJ9omO86% (7)

- FMDS0711 PDFDocument16 pagesFMDS0711 PDFDaniel GalvezNo ratings yet

- Inspection and Testing 05Document12 pagesInspection and Testing 05Nasrul AdliNo ratings yet

- PropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USDocument9 pagesPropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USSteve VelardeNo ratings yet

- Fire System Inspection Requirements NFPADocument11 pagesFire System Inspection Requirements NFPAJeff100% (2)

- Fire Alarm System Maintenance 3Document1 pageFire Alarm System Maintenance 3renvNo ratings yet

- Fire Pumps - Inspection, Testing and MaintenanceDocument2 pagesFire Pumps - Inspection, Testing and Maintenancesunilarora9999No ratings yet

- RT Fire Alarm Systems Care and Maintenance PDFDocument6 pagesRT Fire Alarm Systems Care and Maintenance PDFAndres RamirezNo ratings yet

- FDAS System Maintenance AvescoDocument8 pagesFDAS System Maintenance AvescoRizalino BrazilNo ratings yet

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNo ratings yet

- Novec 1230 Fire Suppression SystemDocument1 pageNovec 1230 Fire Suppression SystemvivekvpsfeNo ratings yet

- Inspection Testing and Preventive Maintenance For Fire Protection SystemsDocument14 pagesInspection Testing and Preventive Maintenance For Fire Protection Systemsardhianhk-1100% (1)

- Testing & Commissioning Method Statement For Fire Fighting PumpsDocument4 pagesTesting & Commissioning Method Statement For Fire Fighting Pumpsvin ssNo ratings yet

- Sofco Nfpa 25 FormDocument5 pagesSofco Nfpa 25 FormVin BdsNo ratings yet

- All Nfpa Codes and Standards PDF FreeDocument16 pagesAll Nfpa Codes and Standards PDF Freeing100% (1)

- Fire Hydrant Flow Test - NFPA 291 & AWWA M17Document21 pagesFire Hydrant Flow Test - NFPA 291 & AWWA M17Nikita Kadam100% (1)

- Appendix - Fire Protection Preventive Maintenance ScheduleDocument5 pagesAppendix - Fire Protection Preventive Maintenance Schedulemohamed attiaNo ratings yet

- NFPA 25 Form AES 5.4 ITM Electric Fire Pump Annual 2013 - 4 of 7Document1 pageNFPA 25 Form AES 5.4 ITM Electric Fire Pump Annual 2013 - 4 of 7Mark Louie GuintoNo ratings yet

- T&C Fire Suppression FM 200Document5 pagesT&C Fire Suppression FM 200walitedisonNo ratings yet

- Sprinkler and SystmesDocument4 pagesSprinkler and SystmesridwanNo ratings yet

- Fire Protection Test ProcedureDocument7 pagesFire Protection Test Procedurekunalji_jainNo ratings yet

- Fire Pump Itm ChecklistDocument4 pagesFire Pump Itm ChecklistImranNo ratings yet

- Conveyor Belt Fire Protection System (+)Document6 pagesConveyor Belt Fire Protection System (+)Adis KaweNo ratings yet

- Preventive Maintenance of FDAS and Sprinkler SystemDocument6 pagesPreventive Maintenance of FDAS and Sprinkler SystemchocostarfishNo ratings yet

- UNC Fire Protection System Impairment Procedures 6 17Document7 pagesUNC Fire Protection System Impairment Procedures 6 17Sigit MahardikaNo ratings yet

- Alarm Check Valve PurposeDocument36 pagesAlarm Check Valve PurposeAbdul Majeed KottaNo ratings yet

- Fire Pump Check ListDocument1 pageFire Pump Check ListArafat Robin100% (2)

- Fire Hydrant SpecsDocument14 pagesFire Hydrant SpecsGie Mak100% (2)

- Fire Pump Routine Checklist NFPA 20Document2 pagesFire Pump Routine Checklist NFPA 20Mouayed ZeadanNo ratings yet

- FM Fire Pump Inspection Checklist and Form-DikonversiDocument24 pagesFM Fire Pump Inspection Checklist and Form-DikonversiMochammad Maulana Suwardo100% (1)

- Firealarm Design ChecklistDocument2 pagesFirealarm Design ChecklistMuros Intra100% (1)

- Alarmline Linear Heat Detection Power PointDocument27 pagesAlarmline Linear Heat Detection Power PointCris Javicho100% (1)

- What Is A Fire Sprinkler Inspection?Document2 pagesWhat Is A Fire Sprinkler Inspection?Amalia Istighfarah100% (1)

- 302 Hydrant TestDocument5 pages302 Hydrant Testsmartleo_waloNo ratings yet

- Contractor'S Material and Test Certificate Fire Sprinkler SystemsDocument4 pagesContractor'S Material and Test Certificate Fire Sprinkler SystemsToufik MedjNo ratings yet

- Testing & Commissioning Checklist Fire HydrantDocument2 pagesTesting & Commissioning Checklist Fire HydrantTorre 11 Departamento 1808No ratings yet

- FM 200 TestingDocument12 pagesFM 200 Testingkazimali786No ratings yet

- Fire Alarm MaintenanceDocument2 pagesFire Alarm Maintenancesamantha1966No ratings yet

- Report of Inspection, Testing & Maintenance of Standpipe SystemsDocument8 pagesReport of Inspection, Testing & Maintenance of Standpipe SystemsCubzlookNo ratings yet

- Automatic Fire Suppression SystemsDocument1 pageAutomatic Fire Suppression Systemsnvenkat.narayanNo ratings yet

- ATEX StandardDocument4 pagesATEX StandardharmlesdragonNo ratings yet

- Pocket Guide To Inspection Testing and Maintaining Fire ProtectionDocument99 pagesPocket Guide To Inspection Testing and Maintaining Fire ProtectionBabak HajizadehNo ratings yet

- Fire Alarm System Record of CompletionDocument4 pagesFire Alarm System Record of CompletionJohn simpsonNo ratings yet

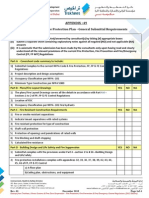

- Check List For FiCheck List For Fire Protection Planre Protection PlanDocument4 pagesCheck List For FiCheck List For Fire Protection Planre Protection Planismail_gdiNo ratings yet

- Fire Alarm Routine Checklist NFPA 72Document2 pagesFire Alarm Routine Checklist NFPA 72Rajamurugan Kumaravel100% (2)

- 2013 Esser CatalogDocument364 pages2013 Esser CatalogArman Ul Nasar100% (2)

- Chemguard Bladder Tank Maintenance and Inspection ManualDocument8 pagesChemguard Bladder Tank Maintenance and Inspection Manualkkchung123No ratings yet

- Fire Pump Compliance MatrixDocument5 pagesFire Pump Compliance Matrixshakil612No ratings yet

- T&C Procedure Grease Interceptors Vida Ok 13sept2020Document115 pagesT&C Procedure Grease Interceptors Vida Ok 13sept2020Gopa KumarNo ratings yet

- Inspection Form For Fire PumpDocument6 pagesInspection Form For Fire PumpRonny Aja100% (1)

- Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument6 pagesCheck List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- Maintenance CareDocument7 pagesMaintenance CareNursyafika JasmiNo ratings yet

- Preventive Maintenance PlanDocument16 pagesPreventive Maintenance PlanAugust Hari0% (1)

- Technical Notice SLS 6 Rev 2 - Fire Protection Systems Appliances and Compressed Gas Cylinder - Periodic Inspection Maintenance and TestingDocument17 pagesTechnical Notice SLS 6 Rev 2 - Fire Protection Systems Appliances and Compressed Gas Cylinder - Periodic Inspection Maintenance and TestingLuke WilsonNo ratings yet

- Fire Pumps SopDocument7 pagesFire Pumps SopPankaj PandeyNo ratings yet

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocument11 pagesGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Fire Protection MaintenanceDocument4 pagesFire Protection MaintenanceFridaytenAprilSalinasNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 173.220Document1 pagePipeline and Hazardous Materials Safety Admin., DOT 173.220MatthewNo ratings yet

- 49cfr172 101Document181 pages49cfr172 101MatthewNo ratings yet

- Bma Information Bulletin No. 29 Emergency Escape Breathing Devices (Eebd)Document3 pagesBma Information Bulletin No. 29 Emergency Escape Breathing Devices (Eebd)MatthewNo ratings yet

- The Gaylord Installation, Operation & Maintenance Manual For "Elx" Series HoodsDocument35 pagesThe Gaylord Installation, Operation & Maintenance Manual For "Elx" Series HoodsMatthewNo ratings yet

- Fire BA and EEBDDocument9 pagesFire BA and EEBDMatthewNo ratings yet

- Bma Information Bulletin No. 97 Fire Fighting EquipmentDocument6 pagesBma Information Bulletin No. 97 Fire Fighting EquipmentMatthewNo ratings yet

- Department of Marine Services and Merchant Shipping (Adoms) : IMO MSC 1/circ. 1277Document2 pagesDepartment of Marine Services and Merchant Shipping (Adoms) : IMO MSC 1/circ. 1277MatthewNo ratings yet

- AeroguardDocument12 pagesAeroguardMatthewNo ratings yet

- 1982 04 01 - t140 10 - 1Document47 pages1982 04 01 - t140 10 - 1MatthewNo ratings yet

- (Uvdw) Whloolvwh $ .Rpsuhvvrueorfn - ,. - ,. 6sduh Sduwv Fdwdorjxh $ &rpsuhvvru Eorfn - ,. - ,. /LVWH GH SLQFHV $ %orf Frpsuhvvhxu - ,.Document54 pages(Uvdw) Whloolvwh $ .Rpsuhvvrueorfn - ,. - ,. 6sduh Sduwv Fdwdorjxh $ &rpsuhvvru Eorfn - ,. - ,. /LVWH GH SLQFHV $ %orf Frpsuhvvhxu - ,.MatthewNo ratings yet

- Ik100 120 II EnglishDocument134 pagesIk100 120 II EnglishMatthewNo ratings yet

- LW320 E AL Nautic EDocument144 pagesLW320 E AL Nautic EMatthewNo ratings yet

- LW Sparepart Lw450eDocument59 pagesLW Sparepart Lw450eMatthew100% (1)

- Inbal Control ValvesDocument4 pagesInbal Control ValvesNelson Eduardo Zárate SalazarNo ratings yet

- MEPF Tenant Concerns FAQ ManualDocument25 pagesMEPF Tenant Concerns FAQ ManualScherraine Khrys CastillonNo ratings yet

- Asme A 13.1Document13 pagesAsme A 13.1Eswin Paico de la Cruz100% (1)

- Research Work 4 ME 417L (2P.M-8P.M SATURDAY)Document7 pagesResearch Work 4 ME 417L (2P.M-8P.M SATURDAY)Norman AntonioNo ratings yet

- Greater Hyderabad Municipal Corporation: Building Permit Order Town Planning SectionDocument4 pagesGreater Hyderabad Municipal Corporation: Building Permit Order Town Planning SectionMadhusudan MadhuNo ratings yet

- AGN 014 - Marine Alternators: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDocument5 pagesAGN 014 - Marine Alternators: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesariwibowoNo ratings yet

- Topic 7 Fire Protection SystemDocument158 pagesTopic 7 Fire Protection SystemAlan Jade de LeonNo ratings yet

- Eton Fire Web PDFDocument12 pagesEton Fire Web PDFs.senthil nathanNo ratings yet

- TCVN 7336-2003 Fire Protection Automatic Sprinkler System (En)Document24 pagesTCVN 7336-2003 Fire Protection Automatic Sprinkler System (En)canniumNo ratings yet

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFUday KumarNo ratings yet

- Contractor Performance AssessmentDocument25 pagesContractor Performance Assessmentusernaga84No ratings yet

- Technical Data Sheet: Model MA2 Accelerator: 1. DescriptionDocument7 pagesTechnical Data Sheet: Model MA2 Accelerator: 1. DescriptionDjapaNo ratings yet

- NFPA 25 - ITM-TaggingDocument10 pagesNFPA 25 - ITM-TaggingMEHBOOB SHAIKHNo ratings yet

- LayMore 6hc - 8hc SweeperDocument2 pagesLayMore 6hc - 8hc SweeperAlvaroValdebenitoValenzuela100% (1)

- 181-1-2 Water Motor GongDocument4 pages181-1-2 Water Motor GongCkaal74No ratings yet

- Fire Safety Log Book: Premises DetailsDocument26 pagesFire Safety Log Book: Premises DetailsGarth ChambersNo ratings yet

- TFP725 08 2016Document8 pagesTFP725 08 2016Jun AntonioNo ratings yet

- EG307 Fire Protection Systems Rev. 1Document18 pagesEG307 Fire Protection Systems Rev. 1Ali MehrpourNo ratings yet

- Mogas TankDocument4 pagesMogas Tankrhannie garciaNo ratings yet

- Dyna PacDocument32 pagesDyna PacGianmarcosNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument242 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- Blazemaster Cost Saving ReportDocument14 pagesBlazemaster Cost Saving ReportPooja shettyNo ratings yet

- FG Valves Catalogue 4ppDocument4 pagesFG Valves Catalogue 4ppInternational companyNo ratings yet

- MD Yusuf HvacDocument4 pagesMD Yusuf HvacMOHAMMED YUSUFNo ratings yet