Professional Documents

Culture Documents

Product Data: Turbinol X

Product Data: Turbinol X

Uploaded by

dedyhidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Data: Turbinol X

Product Data: Turbinol X

Uploaded by

dedyhidCopyright:

Available Formats

Turbinol X

Premium Turbine Lubricant

Product Data

Description

The BP Turbinol X turbine oil range of lubricants is based upon premium quality mineral oils enhanced with rust

and oxidation inhibitiors to give maximum protection at high temperatures.

Application

Turbinol X grades are recommended for industrial gas turbines where the lubricant is likely to be exposed to very high

localised temperatures. They are also suitable for the lubrication of steam turbines and Combined Cycle generating

systems where the steam and gas turbines share a common oil supply.

Turbinol X grades possess superior air release performance, good resistance to foaming and excellent water

separation

properties.

The Turbinol X range is fully compatible with nitrile, silicone and fluropolymer seal materials.

Turbinol X grades meet the requirements of:

British Standard BS 489

DIN 51515-1 and -2

GEK 32568F (ISO 32)

GEK 107395A (ISO 32)

Alstom HTDG 90 117 (formerly ABB) (ISO 32 and 46)

Siemens TLV 9013 04 and 05 (ISO 32 and 46)

Advantages

Superior resistance to oxidation & thermal degradation provides a very long life lubricant because of low deposit /

lacquer formation.

Superior air release properties mean they meet the requirements of all turbine manufacturers.

Excellent water separation and corrosion inhibition mean reduced down time through prolonged lubricant life and

increased equipment reliability.

Suitable for the lubrication of both gas and steam turbines makes them suitable for combined cycle generating

stations.

Typical Characteristics

Turbinol Turbinol Turbinol

Name Method Units

X 32 X 46 X 68

ISO Viscosity Grade - - 32 46 68

ISO 12185, ASTM

Relative Density at 15°C - 0.86 0.86 0.87

D4052

ISO 3104, ASTM

Kinematic Viscosity at 40°C mm2/s 32 46 68

D445

ISO 3104, ASTM

Kinematic Viscosity at 100°C mm2/s 5.7 7.1 9.5

D445

Typical Characteristics

Turbinol X Turbinol X Turbinol

Name Method Units

32 46 X 68

ISO 2909, ASTM

V i s c o s i t y I n d e x - >100 >100 >100

D2270

Foam Sequence I ISO 6247, ASTM

ml 10/0 10/0 10/0

(tendency/stability) D892

ISO 9120, ASTM

Air Release at 50°C minutes 2 2 3

D3427

Demulsification IP 19 seconds 60 60 90

ISO 3016,

Pour Point °C/ °F -15/ 5 -15/ 5 -12/ 10

ASTM D97

ISO 2592,

Flash Point, COC °C/ °F 222/ 432 234/ 453 234/ 453

ASTM D92

Total Acid Number ISO 6619, ASTM

mg KOH/g 0.05 0.05 0.05

(Potentiometric) D664

Rust Test (24hrs synthetic sea ISO 7210, ASTM

- Pass Pass Pass

water) D665B

RPVOT ASTM D2272 minutes >1000 >1000 >1000

Copper Corrosion (3hrs at ISO 2160, ASTM

- 1 max 1 max 1 max

100°C) D130

TOST Test, to 2 mg KOH/g ASTM D943 hours >10000 >10000 >10000

Subject to usual manufacturing instructions.

Additional Information

The BP Turbinol X range is classified as non-hazardous according to the criteria of Work Safe Australia. However, in line

with safe handling practices, it is recommended that the handling instructions outlined in the Castrol Material Safety Data

Sheet be followed.

The BP Turbinol X range is classified as a C2 combustible liquid for storage and handling purposes. Store in a cool, dry,

well-ventilated area out of direct sunlight. Avoid sparks, flames and other ignition sources. Store away from incompatible

materials such as materials that support combustion (oxidising materials). Reference should be made to Australian

Standard AS1940 - The storage and handling of flammable and combustible liquids.

Spillage: SMALL - 20 LITRES OR LESS

Soak up on Castrol Diatomaceous Earth or similar inert oil absorbent. Arrange for disposal through an

approved facility.

LARGE - GREATER THAN 20 LITRES

Contain as soon as possible, remove by best means available and arrange recycling (preferred) or

disposal through an approved facility.

BP, Turbinol X and the BP logo are trademarks of BP Australia Pty Ltd, used under license.

This data sheet and the information it contains is believed to be accurate as of the date of printing. However, to the extent that it is permissible by law to exclude warranties and

representations, no warranty or representation, express or implied, is made as to its accuracy or completeness. Data provided is based on standard tests under laboratory conditions

and is given as a guide only. Users are advised to ensure that they refer to the latest version of this data sheet.

It is the responsibility of the user to evaluate and use products safely, to assess suitability for the intended application and to comply with all applicable laws and regulations. Material

Safety Data Sheets are available for all our products and should be consulted for appropriate information regarding storage, safe handling, and disposal of the product. See

www.msds.bp.com.au No responsibility is taken by either BP plc or its subsidiaries for any damage or injury resulting from abnormal use of the material, from any failure to adhere to

recommendations, or from hazards inherent in the nature of the material. All products, services and information supplied are provided under our standard conditions of sale. You

should consult our local representative if you require any further information.

BP Australia Pty Limited, GPO Box 5222, Melbourne VIC 3001

Technical Advice Line 1300 139 700 / Customer Service 1300 1300 27

www.bp.com.au

Page 2 of 2 3 September 2013 : turbinol x range 000000 2013 09 Aus replaces turbinol x 450290 2011 07

You might also like

- Tank CleaningDocument24 pagesTank CleaningVipin Somasekharan100% (6)

- Mercedes-Benz Model, Chassis, Engine Guide 1946-1996Document32 pagesMercedes-Benz Model, Chassis, Engine Guide 1946-1996kevnwong83% (24)

- A Guide To Part F of The Northern Ireland BuildingDocument20 pagesA Guide To Part F of The Northern Ireland BuildingSamuel FuentesNo ratings yet

- 35 DT Mini Skid Owner & PartsDocument70 pages35 DT Mini Skid Owner & PartsYew LimNo ratings yet

- 03 RT-Flex DesignDocument8 pages03 RT-Flex DesignPrince Mathew100% (2)

- Aircol MR46Document2 pagesAircol MR46Ricardo ZuimNo ratings yet

- Perfecto X RangeDocument2 pagesPerfecto X RangekronthNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- PDS Perfecto XEPDocument3 pagesPDS Perfecto XEP邢焕震No ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Wepp bxdm63Document2 pagesWepp bxdm63Arthur Sanda LayukNo ratings yet

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- Turbine EngDocument1 pageTurbine EngPeter_Phee_341No ratings yet

- Aircol HC 7, HC 10Document2 pagesAircol HC 7, HC 10Vladislav TrempoletsNo ratings yet

- Tds Total Preslia 46 693 202003 enDocument2 pagesTds Total Preslia 46 693 202003 enhalasanNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- Castrol Hyspin AWS HX RangeDocument2 pagesCastrol Hyspin AWS HX RangeGunco TirNo ratings yet

- Perfecto T 46 Superclean: DescriptionDocument2 pagesPerfecto T 46 Superclean: DescriptionCarlos Esteban GironNo ratings yet

- TGSB (M) Turbine OilDocument3 pagesTGSB (M) Turbine OilQuy NguyenNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Castrol Magna SW32Document2 pagesCastrol Magna SW32CHARLSTON BAPTISTANo ratings yet

- Castrol Alphasyn HTX RangeDocument2 pagesCastrol Alphasyn HTX RangeVusal HasanovNo ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- TDS - Cartenex Oil T 121Document2 pagesTDS - Cartenex Oil T 121hanafiajaNo ratings yet

- Tribol CH 1421 RangeDocument4 pagesTribol CH 1421 RangeNoche de EstrellasNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Shell Morlina s2 B 100Document4 pagesShell Morlina s2 B 100PT Tunggal Karya PratamaNo ratings yet

- Bpxe 8XLV4CDocument2 pagesBpxe 8XLV4CLakshmanan SekarNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Aceite Castrol Tribol 290 Conveyor Lubricant 2Document2 pagesAceite Castrol Tribol 290 Conveyor Lubricant 2carlos pachecoNo ratings yet

- Castrol Hyspin VG Range: DescriptionDocument2 pagesCastrol Hyspin VG Range: DescriptionBruno RussoNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Pds Bardahl HVP c7 SyntheticDocument2 pagesPds Bardahl HVP c7 SyntheticFaisal Maulana SafiiNo ratings yet

- Alphasyn GS: DescriptionDocument2 pagesAlphasyn GS: Descriptioncool_ddNo ratings yet

- S-Oil+hydro+fluid TDS PDFDocument1 pageS-Oil+hydro+fluid TDS PDFphucdc095041No ratings yet

- HT - Tribol GR 100-2PDDocument3 pagesHT - Tribol GR 100-2PDRomulo Davila GarciaNo ratings yet

- Shell Catenex T 121Document2 pagesShell Catenex T 121Jorge Arrieta TorresNo ratings yet

- T 90 Ep2 S: Motor Vehicle Transmission OilDocument1 pageT 90 Ep2 S: Motor Vehicle Transmission Oilrobertjob34No ratings yet

- Wepp bpzs8fDocument2 pagesWepp bpzs8fArthur Sanda LayukNo ratings yet

- Optimus Turbine Oil 2Document1 pageOptimus Turbine Oil 2kennethNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- PDS Perfecto T 32Document2 pagesPDS Perfecto T 32Fathan AdnanNo ratings yet

- Nyco Grease GN 3058Document1 pageNyco Grease GN 3058Virender KumarNo ratings yet

- Castrol Hyspin AWS RangeDocument2 pagesCastrol Hyspin AWS RangeVusal HasanovNo ratings yet

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 pagesCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuNo ratings yet

- Hyspin AWS 15Document2 pagesHyspin AWS 15nargueNo ratings yet

- Castrol Perfecto XEP RangeDocument3 pagesCastrol Perfecto XEP Rangeanibal_rios_rivasNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- Castrol Tribol Cs 890Document3 pagesCastrol Tribol Cs 890carlos pachecoNo ratings yet

- TGF - (M) 32 Extreme Pressure Gas Turbine OilDocument3 pagesTGF - (M) 32 Extreme Pressure Gas Turbine OilQuy NguyenNo ratings yet

- Quintolubric® 888 68Document2 pagesQuintolubric® 888 68Cédric LOUISNo ratings yet

- L-TSELF Long Service Life Extreme Pressure Turbine OilDocument3 pagesL-TSELF Long Service Life Extreme Pressure Turbine OilQuy NguyenNo ratings yet

- PDS Bardahl XTC S5 SyntheticDocument1 pagePDS Bardahl XTC S5 SyntheticFaisal Maulana SafiiNo ratings yet

- L-TSE Turbine OilDocument3 pagesL-TSE Turbine OilYoong TanNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- (EN) Alpha EP RangeDocument1 page(EN) Alpha EP RangemartinNo ratings yet

- Nyco Grease GN 22 Air4222Document1 pageNyco Grease GN 22 Air4222muhammad_andinovaNo ratings yet

- Hercules EngDocument1 pageHercules EngTAREK HAMADNo ratings yet

- Wepp BqcracDocument2 pagesWepp BqcracAdham TunggalNo ratings yet

- Optigear EP 150Document3 pagesOptigear EP 150Franklin JprstNo ratings yet

- Properties of Fluids Unit DimensionsDocument49 pagesProperties of Fluids Unit DimensionsSangetha ChelladoraiNo ratings yet

- Co2 Specification Guide For Analytical StepsDocument8 pagesCo2 Specification Guide For Analytical StepsMarcelo OjedaNo ratings yet

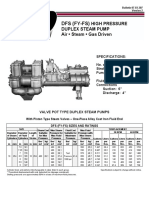

- Dfs (Fy-Fs) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenDocument2 pagesDfs (Fy-Fs) : High Pressure Duplex Steam Pump Air - Steam - Gas DrivenMaria Julieta Calderon OrtizNo ratings yet

- Extractores Mecanicos e Hidraulicos CATDocument39 pagesExtractores Mecanicos e Hidraulicos CATHenryMonteagudoParedes0% (1)

- Fuels - Densities and Specific VolumesDocument1 pageFuels - Densities and Specific VolumesSaeed MohammedNo ratings yet

- Pour Point of Petroleum Products: Standard Test Method ForDocument10 pagesPour Point of Petroleum Products: Standard Test Method ForAdela Dea PerdaniNo ratings yet

- Unit 4 Fluidization PDFDocument6 pagesUnit 4 Fluidization PDFMark FenixNo ratings yet

- Buku Paleo GoodDocument10 pagesBuku Paleo GoodMuhammad GandhiNo ratings yet

- 2013 CASE IH Tractor Parts CatalogDocument124 pages2013 CASE IH Tractor Parts CatalogBordei Alina67% (6)

- Eclipse HandbookDocument118 pagesEclipse Handbook23Otter100% (2)

- SPEC-Aid 8Q462 Turbine Fuel Stabilizer and Detergent Additive by GE Power & WaterDocument2 pagesSPEC-Aid 8Q462 Turbine Fuel Stabilizer and Detergent Additive by GE Power & WaterJim Lee ClimateViewer100% (1)

- Gas Composition Requirements GMS9000Document2 pagesGas Composition Requirements GMS9000July E. Maldonado M.No ratings yet

- Fire Extinguishers RatingDocument18 pagesFire Extinguishers RatingBasem TamNo ratings yet

- Laurito-STOICHIOMETRY of Fuel Combustion Etc.Document66 pagesLaurito-STOICHIOMETRY of Fuel Combustion Etc.James Nevin Go73% (11)

- EquipmentDocument9 pagesEquipmentSolehah OmarNo ratings yet

- Principles and Practice of Flow Meter Engineering - L K SpinkDocument231 pagesPrinciples and Practice of Flow Meter Engineering - L K SpinkAlberto Marsico33% (3)

- The Steam Engine.: 1-Basic PrinciplesDocument4 pagesThe Steam Engine.: 1-Basic PrinciplesKristian Marlowe OleNo ratings yet

- Fire Extinguisher-TrainingDocument30 pagesFire Extinguisher-TrainingManoj Rana100% (2)

- Excercises Ae17Document12 pagesExcercises Ae17Honie Liane Tagose VillamorNo ratings yet

- Flow Formulas: For Computing Gas and Liquid Flow Through Regulators and ValvesDocument4 pagesFlow Formulas: For Computing Gas and Liquid Flow Through Regulators and ValvesAhmed AbdelatyNo ratings yet

- 797F - Kenr8379-02Document6 pages797F - Kenr8379-02Marco Antonio Pampa CondoriNo ratings yet

- AspenTech's Solutions For Engineering Design and ConstructionDocument13 pagesAspenTech's Solutions For Engineering Design and Constructionluthfi.kNo ratings yet

- CV Joint GreaseDocument4 pagesCV Joint GreaseRaghvendra D. ManikwarNo ratings yet

- Electrolysis PresentationDocument24 pagesElectrolysis PresentationsaeikipNo ratings yet

- Owner's Manual: Snow ThrowerDocument49 pagesOwner's Manual: Snow ThrowerLeigh Castle DalmannNo ratings yet