Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsUnited States Patent (19) : (21) Appl. No.: 261,163

United States Patent (19) : (21) Appl. No.: 261,163

Uploaded by

DeisyThis patent describes a cookie that contains both an oil-based interior filling and a water-based interior filling. When the cookie is heated in a microwave oven, the water-based filling expands and exudes out through the top of the cookie, flowing down the exterior surfaces. This produces a cookie that resembles a volcano erupting. The cookie is shelf-stable at room temperature but heating activates the water-based filling to expand out of the cookie.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Snack 4Document13 pagesSnack 4Thùy LinhNo ratings yet

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument6 pagesUnited States Patent (191: (11) Patent Number: (45) Date of PatentWalther Ayrton Uman PalaciosNo ratings yet

- PATENT - Shelf Stable Ready-to-eat-Rice ProcessDocument3 pagesPATENT - Shelf Stable Ready-to-eat-Rice ProcessrecordoffruitNo ratings yet

- Us20100119661a1 PDFDocument4 pagesUs20100119661a1 PDFbabithyNo ratings yet

- United States Patent (19) : Zeller, Grand-Lancy, Both ofDocument6 pagesUnited States Patent (19) : Zeller, Grand-Lancy, Both ofRijad LičinaNo ratings yet

- United States Patent (19) : (45) Date of Patent: Dec. 25, 1984Document5 pagesUnited States Patent (19) : (45) Date of Patent: Dec. 25, 1984Meli ChiambaNo ratings yet

- 12 Steps of Bread BakingDocument2 pages12 Steps of Bread BakingHalima LukmanaNo ratings yet

- Pan Release AgentDocument5 pagesPan Release AgentCharaf ZAHIRINo ratings yet

- United States PatentDocument6 pagesUnited States PatentRahani HyugaNo ratings yet

- Blow On BlowDocument7 pagesBlow On BlowElisabeth GreyNo ratings yet

- Aerated Food ProductDocument22 pagesAerated Food ProductbasssingaNo ratings yet

- United States Patent (19) : Stephen Et AlDocument6 pagesUnited States Patent (19) : Stephen Et Aldylan tikoyNo ratings yet

- Usd PatenDocument5 pagesUsd PatenAdy PrasetyoNo ratings yet

- Brian Project FinalDocument21 pagesBrian Project Finalreuben simiyuNo ratings yet

- United States Patent (19) : (11 Patent Number: 4,759,934 45) Date of Patent: Jul. 26, 1988Document5 pagesUnited States Patent (19) : (11 Patent Number: 4,759,934 45) Date of Patent: Jul. 26, 1988Rijad LičinaNo ratings yet

- Weaver Et Al. (1990) Patent Method of Particulate ConsolidationDocument5 pagesWeaver Et Al. (1990) Patent Method of Particulate ConsolidationAfif IzwanNo ratings yet

- United States Patent (19) (11 3,961,424: Elerath (45) June 8, 1976Document3 pagesUnited States Patent (19) (11 3,961,424: Elerath (45) June 8, 1976Yanpiero BalladoresNo ratings yet

- The Matson PatentDocument4 pagesThe Matson PatentMinnesota Public RadioNo ratings yet

- US4737372Document4 pagesUS4737372qwerandom2No ratings yet

- UNIT5 Technology of Bread MakingDocument12 pagesUNIT5 Technology of Bread MakingS ENo ratings yet

- UNIT II - Basic BakingDocument33 pagesUNIT II - Basic Bakingyf6xy8b2jpNo ratings yet

- Soap MakingDocument14 pagesSoap MakingEmanuel MoralesNo ratings yet

- Bread DocumentDocument11 pagesBread DocumentSherice CampbellNo ratings yet

- FritasDocument4 pagesFritasSantiago MejíaNo ratings yet

- Patent NougatDocument13 pagesPatent NougatTarak ZayaniNo ratings yet

- Freeze Dried Cottage Cheese Making - PatentDocument3 pagesFreeze Dried Cottage Cheese Making - PatentChandrima JashNo ratings yet

- Us 1505592Document4 pagesUs 1505592api-190559452No ratings yet

- 1 Basic Steps in BakingDocument18 pages1 Basic Steps in BakingChristina BinoboNo ratings yet

- United States Patent (19) : 75) Inventors: Bruce W. Brown Virgil E. Copple 57Document7 pagesUnited States Patent (19) : 75) Inventors: Bruce W. Brown Virgil E. Copple 57Omer MukhtarNo ratings yet

- Lp6 Ro TVL He BPP Ncii Grade 11 Q1.revisedDocument6 pagesLp6 Ro TVL He BPP Ncii Grade 11 Q1.revisedSalgie Sernal0% (1)

- April 29, 1947. M - Cqntesso 2,419,822Document3 pagesApril 29, 1947. M - Cqntesso 2,419,822sterlingNo ratings yet

- Frying of Foods: Vassiliki Oreopoulou, Magdalini Krokida, and Dimitris Marinos-KourisDocument22 pagesFrying of Foods: Vassiliki Oreopoulou, Magdalini Krokida, and Dimitris Marinos-KourisNoel GatbontonNo ratings yet

- United States Patent (19: Yamazaki Et AlDocument3 pagesUnited States Patent (19: Yamazaki Et AlJunaid AhmedNo ratings yet

- United States Patent (19) : Lommi Et Al. (45) Date of Patent: Mar 18, 1997Document4 pagesUnited States Patent (19) : Lommi Et Al. (45) Date of Patent: Mar 18, 1997Marina ButuceaNo ratings yet

- How Are Aero Chocolate Bars Made and How Did They Get All The Bubbles in An Aero Chocolate BarDocument2 pagesHow Are Aero Chocolate Bars Made and How Did They Get All The Bubbles in An Aero Chocolate BarPramurtta Shourjya MajumdarNo ratings yet

- Bread and Pastry PDFDocument12 pagesBread and Pastry PDFKenneth P PablicoNo ratings yet

- Module 9 W 15-16Document3 pagesModule 9 W 15-16Maeann RuizNo ratings yet

- What Is BakingDocument2 pagesWhat Is Bakingdinh huy truongNo ratings yet

- United States Patent (19) : 11 Patent Number: (45) Date of PatentDocument3 pagesUnited States Patent (19) : 11 Patent Number: (45) Date of PatentLuis BejaranoNo ratings yet

- US5375563Document5 pagesUS5375563xyz7890No ratings yet

- CHAPTER 9 Steps in BreadmakingDocument19 pagesCHAPTER 9 Steps in BreadmakingFriza mae GarciaNo ratings yet

- Paper No.: 12 Paper Title: Food Packaging Technology Module - 16: Packaging of Snack FoodsDocument7 pagesPaper No.: 12 Paper Title: Food Packaging Technology Module - 16: Packaging of Snack FoodsM SNo ratings yet

- United States Patent (19) : Patent Number: Date of Patent: 45)Document13 pagesUnited States Patent (19) : Patent Number: Date of Patent: 45)leo06031314No ratings yet

- United States Patent (19) : TaskinenDocument6 pagesUnited States Patent (19) : TaskinenKSXNo ratings yet

- SITHCCC019 CorrectionDocument12 pagesSITHCCC019 CorrectionRohan ShresthaNo ratings yet

- PRP - Cleaning and SanitisationDocument1 pagePRP - Cleaning and Sanitisationsumon.dey.1494No ratings yet

- Us 4341803Document7 pagesUs 4341803Ria LestariNo ratings yet

- Module 13 Thermal ApplicationDocument15 pagesModule 13 Thermal ApplicationMitchille Getizo100% (1)

- Friki FestivalDocument6 pagesFriki FestivalJean Carlos MottaNo ratings yet

- United States Patent (19) : Burger (45) Apr. 24, 1979Document17 pagesUnited States Patent (19) : Burger (45) Apr. 24, 1979Mustafa ŞENNo ratings yet

- BPP Module 3Document24 pagesBPP Module 3Neil Jean Marcos Bautista100% (2)

- Bakery Products ProcessDocument13 pagesBakery Products ProcessrakhigoelNo ratings yet

- Plan Rhia BPPDocument32 pagesPlan Rhia BPPJohn Ellis LacsamanaNo ratings yet

- Edible Speech Cue CardsDocument2 pagesEdible Speech Cue Cardsred velvetNo ratings yet

- LP5 - RO - TLE HE BPP Grade 9 10 Q1 Edited - FinalizedDocument9 pagesLP5 - RO - TLE HE BPP Grade 9 10 Q1 Edited - Finalizedgemuel imperialNo ratings yet

- Patents Soap MakingDocument7 pagesPatents Soap MakingNoviNo ratings yet

- Buko PieDocument5 pagesBuko PieCarmie Dela RosaNo ratings yet

- Sithccc019 - Learner ResourceDocument75 pagesSithccc019 - Learner ResourcemafuNo ratings yet

- US5900457Document8 pagesUS5900457SUBRAMANIAN SNo ratings yet

- MR - Biryani MenueDocument2 pagesMR - Biryani Menuebittuj68No ratings yet

- Georgian MenuDocument4 pagesGeorgian MenuFarley ElliottNo ratings yet

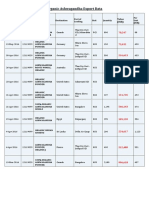

- Export DataDocument20 pagesExport DatamanjushreeNo ratings yet

- Linds Food Menu - Ramadhan 2023Document24 pagesLinds Food Menu - Ramadhan 2023Ampel BersinergiNo ratings yet

- Brown Stew Pork Shoulder Recipe - NYT CookingDocument2 pagesBrown Stew Pork Shoulder Recipe - NYT CookingbernbilazonNo ratings yet

- Specific GravityDocument7 pagesSpecific Gravityjucar fernandezNo ratings yet

- Diagnostic BPPDocument5 pagesDiagnostic BPPRichele R. ValenciaNo ratings yet

- Mushroom MasalaDocument13 pagesMushroom MasalajaithilagarajNo ratings yet

- Ajwain ArbiDocument2 pagesAjwain ArbiPrachi GuptaNo ratings yet

- Modern Pastry and Plated Dessert Techniques 1561412512 PDFDocument73 pagesModern Pastry and Plated Dessert Techniques 1561412512 PDFĐặng Trần Trường GiangNo ratings yet

- +919840956389-Diet PlanDocument3 pages+919840956389-Diet PlanXI132 B.Srinithi XI-DNo ratings yet

- ChandPalace Parsippany MenuDocument5 pagesChandPalace Parsippany Menuhkm_gmat4849No ratings yet

- Moz CookbookDocument112 pagesMoz CookbookEleonoreNo ratings yet

- Iqbal Foods Ramadan Flyer 2024.Document6 pagesIqbal Foods Ramadan Flyer 2024.samira.vashiNo ratings yet

- Satvasiri Price List - Jan-22 (Natural's) : Item Category Item Name Sale Price Item Category Item Name Sale PriceDocument1 pageSatvasiri Price List - Jan-22 (Natural's) : Item Category Item Name Sale Price Item Category Item Name Sale PriceDeepak Gowda SNo ratings yet

- Arroz-Ingredients: QuantityDocument8 pagesArroz-Ingredients: QuantityDeepak BillaNo ratings yet

- Datasheet OverView 2019Document2 pagesDatasheet OverView 2019SA100% (1)

- Children's MenuDocument7 pagesChildren's MenuNicole RaducuNo ratings yet

- Bul-Go-Gi: Grilled Marinated BeefDocument1 pageBul-Go-Gi: Grilled Marinated BeefAzrinna BasriNo ratings yet

- Kapha Pacifying FoodsDocument12 pagesKapha Pacifying FoodsSaiPriya KumarNo ratings yet

- Cereal TechnologyDocument28 pagesCereal Technologynabila OktavianiNo ratings yet

- Stones Style 140 WineDocument2 pagesStones Style 140 WineTemet NoscheNo ratings yet

- Date Quantity Sold Transaction Revenue Sales Price/unit Item CodeDocument13 pagesDate Quantity Sold Transaction Revenue Sales Price/unit Item CodeDeepika DhimanNo ratings yet

- Plant Based Christmas A Glow Diaries Ebook by Liz DouglasDocument40 pagesPlant Based Christmas A Glow Diaries Ebook by Liz Douglasanjara13No ratings yet

- 1.1 Prepare Bake Cakes and FillingsDocument14 pages1.1 Prepare Bake Cakes and FillingsArlene RubeneciaNo ratings yet

- Smoke Points of Various FatsDocument2 pagesSmoke Points of Various FatsRiccardo MuccardoNo ratings yet

- Easy Hot and Sour Wonton Soup (酸汤馄饨) - Curated KitchenwareDocument2 pagesEasy Hot and Sour Wonton Soup (酸汤馄饨) - Curated KitchenwareChristos ChristouNo ratings yet

- CBLM - BPP Prepare and Produce Bakery 1 EditedDocument98 pagesCBLM - BPP Prepare and Produce Bakery 1 EditedEarl Rylman Atillo100% (5)

- Kintaromenu NewDocument45 pagesKintaromenu NewDimas PrasetyoNo ratings yet

- Papa-Johns-Allergen-Guide Gramme IngredientDocument2 pagesPapa-Johns-Allergen-Guide Gramme IngredientAlgerian AmazighNo ratings yet

United States Patent (19) : (21) Appl. No.: 261,163

United States Patent (19) : (21) Appl. No.: 261,163

Uploaded by

Deisy0 ratings0% found this document useful (0 votes)

6 views7 pagesThis patent describes a cookie that contains both an oil-based interior filling and a water-based interior filling. When the cookie is heated in a microwave oven, the water-based filling expands and exudes out through the top of the cookie, flowing down the exterior surfaces. This produces a cookie that resembles a volcano erupting. The cookie is shelf-stable at room temperature but heating activates the water-based filling to expand out of the cookie.

Original Description:

Original Title

OREO

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a cookie that contains both an oil-based interior filling and a water-based interior filling. When the cookie is heated in a microwave oven, the water-based filling expands and exudes out through the top of the cookie, flowing down the exterior surfaces. This produces a cookie that resembles a volcano erupting. The cookie is shelf-stable at room temperature but heating activates the water-based filling to expand out of the cookie.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

6 views7 pagesUnited States Patent (19) : (21) Appl. No.: 261,163

United States Patent (19) : (21) Appl. No.: 261,163

Uploaded by

DeisyThis patent describes a cookie that contains both an oil-based interior filling and a water-based interior filling. When the cookie is heated in a microwave oven, the water-based filling expands and exudes out through the top of the cookie, flowing down the exterior surfaces. This produces a cookie that resembles a volcano erupting. The cookie is shelf-stable at room temperature but heating activates the water-based filling to expand out of the cookie.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

United States Patent (19) 11 Patent Number: 4,948,602

Boehm et al. 45 Date of Patent: Aug. 14, 1990

54 FILLED COOKE 4,579,744 4/1986 Thulin et al. ... ........... 426/283

4,596,713 6/1986 Burdette. ... 426/07

75 Inventors: Donald G. Boehm, Mt. Kisco, N.Y.; 4,613,508 9/1986 Shishido...... ... 426/281

Richard D. Fazzolare, Randolph, 4,693,899 9/1987 Hong et al. ........................... 426/94

N.J. 4,752,494 6/1988 Tang et al. .......................... 426/573

4,762,723 8/1988 Strong ................................. 426/283

73 Assignee: Nabisco Brands, Inc., East Hanover,

N.J. FOREIGN PATENT DOCUMENTS

(21) Appl. No.: 261,163 61-56973 12/1986 Japan.

22 Filed: Oct. 21, 1988 Primary Examiner-Donald E. Czaja

Assistant Examiner-Mary S. Mims

511 Int. Cl. ............................................. A21D 15/OO

52 U.S. C. ...................................... 426/94; 426/281; 57 ABSTRACT

426/283; 426/237; 426/242; 426/243 A baked cookie is produced having a two phase interior

58 Field of Search ................. 426/94, 281, 283, 237, filling. There is an oil based interior filling and a water

426/243, 242 based interior filling. The oil based interior filling coats

56 References Cited at least part of the interior of the biscuit and enhances

U.S. PATENT DOCUMENTS the taste of the cookie. Upon this cookie being heated in

a microwave oven the water based filling expands and

1,817,114 8/1931. Valenta . exudes out through the top of the cookie flowing down

3,450,538 6/1969 McKown et al. ...................... 99/81 the exterior surfaces of the cookie and coating these

3,764,715 10/1973 Henthorn et al. ... ... 426/273 surfaces. This cookie is produced by co-extruding a

3,830,948 8/1974 Fischer et al... ... 426/28 dough and the oil based filling. The dough piece is than

4,104,405 8/1978 Forkner ................................ 426/94 baked whereby there is formed a hollow interior sec

4,209,536 6/1980 Dogliotti............................... 426/94 tion. It is this hollow interior section that is then filled

4,251,551 2/1981 Van Hulle et al. .................... 426/94

4,409,250 10/1983 Van Hulle et al. ... ... 426/242 with the water based filling.

4,525,367 6/1985 Allison ............. ... 426/394

4,563,358 1/1986 Mercer et al. ........................ 426/89 18 Claims, No Drawings

4,948,602 2

1.

sandwich cookie that is sold under the registered trade

FILLED COOKE mark OREO. These sandwich cookies have also been

coated with various chocolate and fudge coatings. Con

BACKGROUND OF THE INVENTION sequently, at this point in time filled cookies of the sand

This invention relates to filled cookies. More particu 5 wich type, and filled cookies of the sandwich type

larly, this invention relates to filled cookies where upon which are enrobed in a chocolate or fudge coating are

heating in a microwave oven part of the filling con known. However, these cookies are fully prepared by

tained in the cookie expands upwardly through the top the manufacturer with no further steps of preparation

of the cookie and spreads downwardly along the out remaining for the consumer. Further these cookies are

side surfaces of the cookie. O consumed at room temperature.

The present cookie is a type of cookie which when In U.S. Pat. No. 4,104,405 there is disclosed a food

baked has the appearance of a volcano erupting. What is product which is comprised of an edible shell of cooked

occurring is that part of the filling within the cookie is dough having an expanded confection extending

expanding due to the energy being applied and is heated 15

around or bonded to the shell. The shell itself can be an

and flowing upwardly through openings or through a ice cream cone. This expanded confection is preferably

weakened area in the top of the cookie, and then flows produced by molding the expanded confection in place

downwardly along the cooler outside portion of the on the edible shell. The molded section can contain

cookie. As the filling cools it increases in viscosity and marshmallow and hard candy bits. This molded section

the downward flow decreases. The end result is a is expanded through the use of a partial vacuum. The

cookie that was originally in the shape of a volcano and 20

partial vacuum causes included air and gases to expand

which now has part of the filling of the cookie distrib and to impart an expanded confection layer to the upper

uted around the outside of the cookie. However, if it is surface of the shell.

not desired to heat the cookie and have part of the U.S. Pat. No. 4,525,369 discloses a technique for ex

filling exude from the cookie, it can be consumed di 25

panding a food product by the rapid reduction of pres

rectly from the package. sure on the food product. The food product to be ex

The present cookies are unique in that they are shelf panded will have a water content of about 5 to 50% by

stable at room temperature for extended periods of time. weight. Upon heating and the rapid release of pressure

The biscuit portion of the cookie is fully baked with the the water expands as steam and causes the food product

consumer only heating the cookie in a microwave oven to expand. It is a rapid reduction of pressure that causes

to have the filing flow out of the cookie and down the 30

exterior surface. However the consumer will still get the food to expand and not merely a heating. Various

much of the taste and effect of fresh baked cookies. food products can be expanded using this technique.

There is also the advantage that this is a very unique U.S. Pat. No. 4,596,713 discloses a method for prepar

cookie. When the cookie is placed in the oven it is fully ing popcorn where the popcorn is coated with a flavor

baked and contains both a flavored oil based filler and a 35 ant which is contained in a separate packet during the

flavored water based filler. The flavored water based popcorn cooking cycle. As the popcorn containing

filler is placed on the oil based filler and is the primary package is heated in a microwave oven the portion that

ingredient which expands upon the application of heat contains the additive or flavorant becomes heated and

and exudes from the top of the cookie. However, there the part of the package in which it is contained ruptures.

is a partial coating of the oil based filler on the inside of 40 Upon rupturing the additive or flavorant is coated onto

the cookie. While the water based filler in the cookie is the expanding popcorn. The mechanism here that is

expanding and flowing down the outside of the cookie used in producing an expanded coated product is for a

the biscuit portion of the cookie is being warmed. After part of the package to rupture and to spread the flavor

heating, the cookie is partially cooled prior to being ant or other additive.

consumed for the reason is that the oil based filler 45 U.S. Pat. No. 4,693,899 discloses a method for prepar

within the cookie and the remaining water based filler ing a filled, cooked dough product. The composite

in the cookie remain at elevated temperatures with consists of an uncooked, yeast leavened, sugar contain

some cooling advisable before consumption. ing dough around a cooked freeze/thaw stable viscous

In this cookie there must be a combination of an oil filling comprised of food ingredients and a sauce there

based filler and of a water based filler. If only a water 50 for containing a water-binding carbohydrate. The prod

based filler were to be used the cookie would not have uct is reheated prior to consumption. The reheating

as long a shelf life. It is also possible that too much of comprises conventional oven heating either simulta

the water based filler would exude from the top of the neously with or following microwave heating. This

cookie. It is also the case that an emulsion type of filler heats the product, creates an outer crust and returns the

cannot be as effectively utilized. Again, the reason is 55 frozen product to the appearance and texture of the

that there could be an excessive exuding of the filler freshly cooked product. In this patent there is disclosed

from the cookie. It is therefore necessary that there be a filled dough product where the dough will not get

a combination of an oil based filling and a water based soggy and lose its texture. However, there is no expan

filling. The oil based filling will remain in the cookie as sion of the filler material. The filler material is thawed,

a control of the amount that exudes on heating and will 60 but remains within the dough portion of the baked

in addition contribute to the taste of the cookie. Since good.

the water based filling is activated at a lower tempera In addition there are filled hard dough biscuits such

ture than the oil based filling it will thus expand and as those that are disclosed in U.S. Pat. No. 4,613,508. In

flow from the cookie at a lower temperature. This latter this patent there is disclosed the baking of a biscuit

factor is also important so that the cookies can be con 65 which upon baking will expand with a percentage of

sumed fairly soon after baking. leavening in excess of 280. What is produced is a hollow

There are various filled cookies in the market place. hard biscuit. This hollow hard biscuit is then filled with

The most famous of the filled cookies is probably the a filling, such as a chocolate or chocolate cream filling,

4,948,602

3 4.

by means of needle injection. In needle injection a nee of the biscuit. The oil based filler also helps to prevent

dle in the form of a hypodermic needle inserts the filling the water based filler from becoming partially dried out

into the biscuit. with the result that a decreased amount would exude

This patent puts several constraints on the type of from the biscuit under microwave heating.

dough that can be utilized in order to form the hard 5 The biscuit portion of the cookie can be of various

biscuit. It is stated that it is not desirable to use a cereal types. This can be a white biscuit cake, a chocolate

dough containing proportions of ingredients such as a biscuit cake or a graham biscuit cake. The biscuit por

cereal dough used for producing soda crackers or tion of the cookie is formulated from ingredients that

cream crackers. It is also stated that if a cereal dough is are known in the art of cookie making. In the first step

prepared with excess sugar, for example, as a cereal O the desired cookie dough is fully mixed. After the

dough prepared by mixing 40 parts by weight of sugar, cookie dough has been mixed it is co-extruded with the

15 parts by weight of oil or fat and 17 parts by weight oil based filler. During the co-extrusion step the oil

of water with 100 parts by weight of wheat flour the based filler is encapsulated within the biscuit dough.

resulting baked product will be hard and will give poor These biscuit dough pieces containing encapsulated oil

feeling during eating. In the instance where the cereal 5 based filler are then baked. During baking the biscuit

dough is prepared with an excess of oil or fat the result portion of the co-extrusion expands to about 1.5 to 2 or

ing baked product will be crumbly, and thus susceptible more times its original size. This then provides for addi

to breaking-up during the step of the injection of the tional spacing within the biscuit. It is this additional

filler. If it is desired to decrease the amount of sugar and spacing that is then filled with the water based filler.

oil or fat and instead to increase the proportion of over The water based filler is injected into the biscuit by

all water in order to adjust the hardness of the cereal means of needle injection. The cookie is now in a condi

dough there will result a baked product which is also tion of having been fully prepared for subsequent con

susceptable to breaking during the step of the injection sumption by the consumer, or heating and consumption

of the filler. In this patent it is therefore prescribed to by the consumer.

use from about 10 to 30 parts by weight of sugar, 10 to 25 DETALED DESCRIPTION OF THE

25 parts by weight of oil or fat and 35 to 20 parts by INVENTION

weight of water per 100 parts by weight of cereal flour.

This is the composition that is noted to produce biscuits The present filled cookie is very unique in that the

which are sufficiently hard so that they can withstand consumer will complete the preparation of the cookie

the penetration of a filling needle without breaking. 30 and during the heating of the cookie some of the con

However, even though this is a filled cookie in U.S. tained filler will exude out of the top of the cookie and

Pat. No. 4,613,508 it is a filled cookie that is purchased coat down along the outer sides of the cookie. In many

in a fully prepared condition. Also the filling remains instances the cookie will have the shape of a volcano

within the biscuit. This is in contrast to the present and when the cookie is heated and the filler exudes from

invention wherein the filled cookie is heated in a micro 35 the cookie it is suggestive of a volcano erupting. The

wave oven by the consumer so that the consumer can net result is a hot filled cookie which has part of the

have the advantage of having the taste of hot fresh contained filling down along the outside of the biscuit

baked cookies. surface. This has the advantage of spreading the fla

vored water based filler over the exterior surfaces of the

BRIEF DESCRIPTION OF THE INVENTION 40 cookie to provide for a better taste and appearance. In

The present invention is directed to a baked filled addition, there is the aspect of the consumer having a

cookie which upon further heating will have some of meaningful input into the preparation of the cookie. The

the contained filling exude out of the top of the cookie cookie can be formulated from a number of different

and to flow down the outer sides of the cookie. The types of flavored doughs. The objective is to produce a

cookie itself in some ways has the appearance of a vol 45 hard biscuit. This biscuit can be white and vanilla based,

cano. The cookie contains within its structure an oil chocolate based, or graham based. The main require

based flavored filler and a water based flavored filler. ment for the dough is that upon baking that it will rise

The oil based flavored filler is situated under the water so that a water based filling can be inserted into the

based filler and also at least partially coats the inner newly created space. The cookie itself is an outer biscuit

walls of the biscuit. Above the water based filler there 50 portion which is at least partially coated on its interior

are either one or more small openings or a scribed surface with an oil based filler. This oil based filler coats

weakened area. It is through these openings, and/or the at least some of the interior surface of the cookie, with

scribed weakened area that the expanding water based the remainder sitting in the bottom of the cookie, leav

filler will exude from the cookie. ing a center void area for the insertion of the water

During the final preparation of the cookie the cookie 55 based filler. After the biscuit with the oil based filler is

is heated in a microwave oven. At an initial stage the baked the water based filler is inserted into the cookie

biscuit portion of the cookie becomes heated followed by means of a needle injection technique. The finished

by the exuding of the water based filler down the outer cookie contains one or more holes in the top portion of

sides of the biscuit portion. The oil based filler will the cookie or a scribed weakened part in the top portion

essentially remain within the cookie. The reason is that 60 of the cookie. This is provided so that when the water

it would take an increased temperature for the oil based based filler expands upon the application of heat that it

filler to become sufficiently heated to also exude from will exude out of the cookie at certain places and flow

the cookie. down the outside of the cookie.

A primary function of the oil based filler, besides Upon the purchase of the cookies the consumer need

providing an enhanced taste, is to provide the cookie 65 only place the cookies in a microwave oven. As the

with an extended shelflife. This cookie will be stored at cookie or cookies are heated the water based filler will

room temperature. The oil based filler is the filler that is undergo an expanding type of reaction and cause a

in contact with a substantial part of the interior portion portion of the water based filler to exude out of the

4,948,602

5 6

upper opening or weakend area opening and down the pieces. After the preparation of the dough there must be

outside of the cookie. After the cookies have been prepared the oil based filler. This is the case since the

heated they are removed from the oven and cooled for cookie dough and the oil based filler are coextruded to

a period of time before consumption. The cookies usu form the biscuits. The oil based filler consists of a mix

ally must be cooled since the filling within the cookie is ture of fine granulated sugar, vegetable oil, peanut oil,

still at an elevated temperature. hazel nut paste, dry whole milk powder, monoglycer

In the manufacture of the present cookies three dif. ide, lecithin and flavorant. The flavorant can be vanil

ferent ingredients must be separately prepared. These lin, chocolate, cocoa, a fruit flavorant, such as straw

are the biscuit dough, the oil based filler and the water berry, cherry, orange, lemon, lime or the like, a nut

based filler. A typical vanilla based biscuit dough will 10 flavorant such as peanut, cashew, almond or the like or

contain wheat flour, sugar, vegetable shortening, corn mint. Essentially any type of flavorant, or mixture of

syrup, dry whey, whole eggs, salt, egg albumen, starch, flavorants can be used so as to impart a particular taste.

water and a chemical leavening agent. A chocolate Based on 100 parts by weight of fine granulated sugar

based dough will contain essentially the same ingredi the composition for a chocolate flavorant filler will

ents but with the addition of cocoa and chocolate liquor 15 contain from about 46 to 65 parts by weight of vegeta

flavorants. Based on 100 parts by weight of wheat flour ble oil, such as soybean oil, from about 30 to 40 parts by

the vanilla biscuit dough will contain about 20 to 35 weight of cocoa, from about 25 to 40 parts by weight of

parts by weight of fine granulated sugar, about 20 to 30 peanut oil, from about 12 to 20 parts by weight of hazel

parts by weight of vegetable shortening, about 12 to 25 nut paste, from about 4 to 10 parts by weight of dry

parts by weight of corn syrup, and about 0.5 to 2 parts 20 whole milk powder, from about 4 to 8 parts by weight

by weight of each of dry whey, dry whole eggs, salt, of a monoglyceride, and from about 0.5 to 2 parts by

egg albumen, starch and chemical leavening agent. The weight of lecithin. These ingredients are then mixed

vanilla dough composition will also contain about 15 to together. The order of addition and mixing is not criti

20 parts by weight of water. The major ingredients for cal. However, the vegetable oil and lecithin are usually

the chocolate dough are very similar as for a vanilla 25 added last. After mixing all of the ingredients except the

dough. The main differences are in the added flavor vegetable oil and lecithin this mixture is then transferred

ants. In the formation of the dough all of the ingredients to three roll milling equipment and further processed.

except the water, flour and chemical leavening agent At this point the vegetable oil and lecithin are added.

are mixed to form a cream like substance. This includes The oil based chocolate filler is then stored in a suitable

the mixing of the fine ground sugar, vegetable shorten 30 container for subsequent use.

ing, starches, corn syrup, whey powder, salt, cocoa and The water based filler consists of two primary ingre

other flavors, dry whole eggs and dry egg albumin. dients. One of the ingredients is the marshmallow syrup.

These are mixed together in a high shear mixer. After The other ingredient is the flavored filler. The marsh

these substances have been thoroughly mixed, which mallow syrup is prepared by mixing 100 parts by weight

will take from about 3 to 15 minutes depending on the 35 of corn syrup with about 170 to 200 parts by weight of

mixture, the water is added and the intensity of mixing high fructose corn syrup, about 2 to 6 parts by weight of

is decreased. The mixing is continued until the water is gelatin, up to about 0.5 parts by weight of vanillin and

fully mixed into the creamed mixture. At this point the from about 10 to 20 parts by weight of water. In order

flour and chemical leavening agent are added and the to make the marshmallow syrup, the corn syrup and

low intensity mixing is continued. This is continued for high fructose corn syrup are heated together and mixed.

a time of about 2 to 10 minutes until the dry flour and These are heated to a temperature of about 115 F. to

chemical leavening agent have been thoroughly mixed about 140°F. After the corn syrup mixture has reached

into the dough. At this point the dough is fully formed this temperature then a mixture of the gelatin, vanillin

and is allowed a resting time of about 10 to 25 minutes. and water are added to the corn syrup mixture. After

If it is desired to have a graham biscuit type of prod 45 the addition is complete the final mixture is flowed to a

uct a similar formulation is utilized with the exception holding tank and maintained at about 85 F. to 95 F.

that graham flour is substituted for part of the wheat This marshmallow filler can be used alone or mixed

flour and that honey and molasses are substituted for with various flavorants. Any of the flavorants that can

some of the corn syrup and for some of the fine granu be mixed with the oil based filler can be used with the

lated sugar. Based on 100 parts by weight of flour 50 water based filler. The same flavorant can be used in the

wherein the graham flour can constitute from about 20 oil based filler and the water based filler or different

to 40 parts by weight of the flour mixture there is added flavorants can be used in each to impart a unique taste.

15 to 25 parts by weight of sugar, 8 to 15 parts by One flavorant with which the marshmallow syrup

weight of vegetable shortening, 6 to 15 parts of weight may be utilized is a chocolate flavorant to form a choco

of molasses and/or honey, 5 to 10 parts by weight of 55 late filler. Based on 18 parts by weight of fine granu

high fructose corn syrup, 2 to 4 parts by weight of a lated sugar the chocolate filler consists of about 4 to 6

leavening agent, 1 to 2 parts by weight of salt and 15 to parts by weight of tapioca starch, about 3 to 7 parts by

25 parts by weight of water. The technique of forming weight of powdered dextrose monohydrate, about 2 to

the graham biscuit dough is very similar to that utilized 4 parts by weight of cocoa, about 0.25 to 1 part of salt,

for forming the vanilla dough or the chocolate dough. 60 a minor amount of natural chocolate flavor, about 15 to

The only difference is that ammonium bicarbonate is 20 parts by weight of high fructose corn syrup, about 25

used as a component of the chemical leavening agent to 35 parts by weight of corn syrup, about 15 to 25 parts

and this is added with the water rather than with the by weight of water, about 4 to 8 parts by weight of

dry flour ingredients. chocolate liquor, about 3 to 7 parts by weight of cocoa

No sheeting or other processing is required in the 65 compound, about 10 to 15 parts by weight of vegetable

processing of the dough. After the dough is formed it shortening, and a minor amount of lecithin. These ingre

can be allowed to set for a period of time before it is fed dients when properly mixed and blended will produce

to the extruder to make the oil based filling filled dough the water based chocolate filler for the cookie. The

4,948,602 8

7

mixing technique consists of mixing the dry ingredients The present invention will now be discussed with

in a kettle. These consist of mixing together the fine reference to the following examples.

granulated sugar, tapioca starch, powered dextrose EXAMPLE 1.

monohydrate, cocoa, salt, lecithin, and natural choco

late flavor. Added to this blend is the high fructose corn 5 This example illustrates how to make a vanilla cookie

syrup, the corn syrup and water. These are mixed under dough.

heating to produce a uniform blend. After these ingredi A vanilla cookie dough was made by mixing 27.75

ents have been fully blended a portion of the marshmal pounds of fine granulated sugar, 26 pounds of vegetable

low syrup is added to this chocolate filler mixture and shortening, 1.5 pounds of starch, 18 pounds of corn

further mixed. These are the primary ingredients in the 10 syrup, 1.75 pounds of dry whey powder, 1.4 pounds of

manufacture of the present cookie. The next step is to salt, 1.75 pounds of dry whole eggs, 1 pound of dry egg

form the cookie itself. albumin and minor amounts of vanilla and cocoa flavor

In the formation of the cookie itself, the cookie dough ants. These ingredients were mixed under high shear

and the oil based filler are co-extruded. Any convenient conditions to form a mixture with a cream consistency.

co-extrusion apparatus can be used but a Rheon co 15 Mixing time was about 5 minutes. Seven pounds of

extruder has been found to be very useful. In the co water was then added and the water blended into the

extrusion process the oil based filler is extruded within cream mixture. Then the 100 pounds of flour and 2.1

the biscuit dough and the co-extrusions continuously pounds of chemical leavening agent were added. Mix

separated from the extrusion die by means of a cutting ing was continued until a tacky dough mass was pro

wire or iris. The net result is a dough piece with a fat 20

duced. This dough was suitable for use in the co-extru

based chocolate interior filling. These dough pieces are sion process to make the present cookies.

severed to produce dough pieces which are approxi

mately 13 inches in diameter and about g inches high. EXAMPLE 2

However, they can be produced in other sizes. These This example illustrates how to make a chocolate

dough pieces are than baked in an oven for about 3 to 10 25

cookie dough.

minutes at a temperature of about 300 F. to 400 F. The procedure of Example 1 was repeated except

During this period of time the biscuit dough gets baked. that 12 pounds of cocoa and 1 pound of chocolate liquor

However, more importantly the chemical leavening were added to the mixture of fine granulated sugar,

agent in the dough has become activated. As a result the shortening and other ingredients. These were then all

dough pieces rise with the interior surface becoming at 30

mixed together to form the cream mixture. In the sec

least partially coated with the encapsulated oil filler ond step 36 pounds of water was added to this mixture

with the bulk of the filler on the inner bottom surface of and blended into the cream mixture. The flour and the

the cookie. There is also produced a void space within chemical leavening agent were then added and the mix

each of the cookies. The water based filler material is

the injected into the biscuit to essentially fill the biscuit. 35 ing continued. The result is a chocolate dough that can

One or more holes are placed in the top of the biscuit be co-extruded with a filler material.

and or a weakened area is provided. This is for the EXAMPLE 3

exuding of the water based filler during the subsequent

heating step by the consumer. This example illustrates how to make a marshmallow

There are many ingredients that are utilized in the Syrup.

various parts of this present cooking process. As has 100 pounds of a regular corn syrup and 189 pounds of

been discussed the biscuit portion can be a vanilla bis a high fructose corn syrup were heated to 130 F. A

cuit, a chocolate biscuit, or a graham biscuit. Likewise second solution was prepared consisting of 4.1 pounds

the use of other types of biscuits are possible. It is only of gelatin, 0.25 pounds of vanillin and 15.25 pounds of

necessary that the cookie dough be coextrudable and 45 water. This second solution was mixed and added to the

that it has the property of rising to form an interior mixture of corn syrup and high fructose corn syrup.

space upon the activation of a chemical leavening agent. This marshmallow syrup was then stored at about 88

Likewise in the production of the oil based filler, water F. to 90' F. prior to usage.

based filler and the marshmallow syrup the various EXAMPLE 4

ingredients can be modified with regard to amounts or 50

functional equivalents can be utilized for the substances This example illustrates how to make the oil base

that have been enumerated. Those in the art are aware filler material.

of various substances that are functional equivalents for Fine granulated sugar in an amount of 100 pounds

those that have been discussed herein. However, all was mixed with 35 pounds of cocoa, 7 pounds of dry

such equivalent substances and amounts of substances 55 whole milk powder, 16.5 pounds of hazel nut paste, 33

that would give the same results are within a scope of pounds of peanut oil, 5.75 pounds of monoglyceride, 35

the present invention. pounds of red dutched cocoa and minor amounts of

As has been pointed out above the invention is di vanilla and chocolate flavorants. These ingredients

rected to a very particular cookie. This particular were mixed to form a paste and transformed to three

cookie will exude a water based filler from the top area 60 roll milling equipment and processed through three

of the cookie during a microwave oven cooking by the passes. 56.8 pounds of soybean oil and 1.2 pounds of

consumer. The net result is a hot filled cookie which has lecithin were added and the full mixture mixed to inte

some of the previously contained filling now coating grate the soybean oil and lecithin. After mixing, this oil

the exterior surface of the biscuit portion of the cookie. based filler is stored in a sealed container for use.

This in essence is a type of a home made cookie. The 65 EXAMPLE 5

operations performed by the consumer consist of heat

ing the cookie and fully changing the appearance of the This example illustrates how to make the water based

cookie. filler for the cookie.

4,948,602

10

Fine granulated sugar in an amount of 18 pounds was cookies were removed from the microwave oven and

dry blended with 6.7 pounds of tapioca starch, 5 pounds cooled. They have a fresh home baked taste.

of dextrose monohydrate, 3 pounds of red dutched What is claimed is:

cocoa, 0.5 pounds of salt and 0.125 pounds of natural 1. A cookie comprising a baked dough-based shell

chocolate flavor. After these ingredients have been containing therein at least two filters, said cookie hav

blended, 18 pounds of a high fructose corn syrup, 30 ing a weakened portion or at least one opening on its

pounds of regular corn syrup and 20 pounds of water upper surface so that during a subsequent heating step at

were added to the blend and the mixture heated at at least one of said filters can flow from said weakened

mospheric pressure in a steam jacketed kettle at about portion or opening and at least partially coat the outer

270° to 280 F. for 20 to 25 minutes. The steam pressure surface of the cookie, at least one of said filters being an

is about 3 to 6 pounds per square inch. The mixture has 10 oil based filter and at least one of said filters being a

a soluble solids content of at least 77%. water based filter.

With the heating discontinued 6 pounds of chocolate 2. A cookie as in claim 1 wherein said water based

liquor, 5 pounds of cocoa compound, 13.5 pounds of filter is located on said oil based filter and said water

shortening and 0.125 pounds of lecithin are added while 15 based filter exudes from the cookie upon heating.

the mixture cools. The mixture was in the form of a 3. A cookie as in claim 1 wherein said upper surface

liquid and was maintained in storage for use. has at least one opening.

In order to make the water based filler 25% by 4. A cookie as in claim 1 wherein said oil based filter

weight of the marshmallow mix of Example 3 was in and said water based filter each contain a flavorant.

corporated with 75% by weight of the chocolate filler 5. A cookie as in claim 4 wherein said flavorant is

of this Example 5 which was at a temperature of about 20 selected from the group consisting of vanilla, chocolate,

105 F. to 110 F. These were thoroughly mixed and fruits, nuts, mint and mixtures thereof.

used for injection into the cookies. 6. A cookie as in claim 4 wherein said water based

EXAMPLE 6 filter contains marshmallow.

This example illustrates the making of the filled 25 7. A method of making cookies which contain fillers,

cookie. said cookie having a weakened portion or at least one

The dough of Example 1 and the oil based filler of opening in the upper portion thereof, comprising sub

Example 4 were fed to a Rheon co-extruder using an iris jecting said cookies to heat whereby at least one of said

cutter. The outer co-extruded layer is the dough layer fillers within said cookies overflows through the upper

and the inner co-extruded layer was the fat based filler. 30 weakened portion or at least one opening to thereby at

The co-extruded pieces were formed to a size of 1 least partially coat the outside surface of the cookies, at

inches in diameter and inches in height. The dough least one filler being an oil based filler and at least one

weight is about 8 grams per dough piece and the filler filler being a water based filler.

weight about 6 grams per dough piece. The extruded 8. A method as in claim 7 wherein primarily said

dough pieces were baked for about 7 minutes at about water based filler exudes from the cookie during heat

350 F. The moisture content of the baked pieces was 35 ling.

4.5 to 5.5 weight percent. 9. A method wherein said heat is provided by micro

After the baked cookies emerge from the oven they wave energy.

are injected with about 3.5 grams of the water based 10. A method as in claim 8 wherein said fillers contain

filler of Example 5. This water based filler was added by a flavorant selected from the group consisting of va

means of needle injection. There will also at this time be nilla, chocolate, fruits, nuts, mint and mixtures thereof.

placed on the cookie a number of small holes or a weak 11. A method as in claim 7 wherein said water based

ened area. This is to permit the water based filler to filler contains marshmallow.

exude from the top of the cookie during the final bak 12. A method of making a filled cookie comprising:

ing. The final cookie will have a count of about 26 to 28 (a) co-extruding a dough and an oil based filler to

cookies per pound. 45 form individual dough pieces;

(b) baking the individual dough pieces whereby the

EXAMPLE 7 dough pieces expand to form additional space

This example illustrates how to make a graham bis within the dough pieces and said oil based filler

cuit for the filled cookies. coats at least part of the interior surface of said

In this embodiment 40 pounds of wheat flour, 30 50

dough pieces; and

pounds of graham flour, 21 pounds of fine granulated (c) injecting a water based filler into the baked dough

sugar, 12.5 pounds of vegetable shortening, 9.5 pounds pieces.

of molasses, 7.5 pounds of high fructose corn syrup and 13. A method as in claim 12 wherein the top of said

1.25 pounds of salt were mixed in a low shear mixer to baked dough pieces have at least one opening there

produce a cream consistency mixture. This mixing re through.

55 14. A method as in claim 12 wherein the top of said

quired about 5 minutes. Then 1.25 pounds of ammonium

bicarbonate dissolved in 21 pounds of water was added dough pieces have a weakened area on the upper sur

with low shear mixing continued for about 2 minutes. face thereof.

The flour and the chemical leavening agent were then 15. A method as in claim 12 wherein each of said

added and the mixing continued to form the final fillers contains a flavorant.

dough. This dough was then stored for use. 16. A method as in claim 13 wherein said flavorant is

EXAMPLE 8

selected from the group consisting of vanilla, chocolate,

fruits, nuts, mint and mixtures thereof.

This example illustrates the baking of the baked and 17. A method as in claim 14 wherein said dough is

filled cookies of Example 6 in a microwave oven. selected from the group consisting of vanilla doughs,

Six of the baked cookies were placed on a plastic 65 chocolate doughs and graham doughs.

sheet in a 600 watt microwave oven. The oven setting 18. A method as in claim 12 wherein said water based

was set to high. The cookie heats and the water based filler contains marshmallow.

k

filling exudes from the cookie within 20 seconds. The

UNITED STATES PATENT ANDTRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENT NO. : 4,948,602

DATED : August 14, 1990

INVENTOR(S) : Donald G. Boehm, et all

it is certified that error appears in the above-indentified patent and that said Letters Patent is hereby

Corrected as shown below:

Column 10, lines 5, 8, 10 and ll, the word "filters" should be

deleted and the word --fillers-- substituted therefor;

. . Column lo, lines ll, l2, 14, 15, 18, 19 and 24, the word "filter it

should be deleted and the word filler-- substituted therefor.

Signed and Sealed this

Third Day of August, 1993

MICHAELK. KRK

Attesting Officer Acting Commissioner of Patents and Trademarks

You might also like

- Snack 4Document13 pagesSnack 4Thùy LinhNo ratings yet

- United States Patent (191: (11) Patent Number: (45) Date of PatentDocument6 pagesUnited States Patent (191: (11) Patent Number: (45) Date of PatentWalther Ayrton Uman PalaciosNo ratings yet

- PATENT - Shelf Stable Ready-to-eat-Rice ProcessDocument3 pagesPATENT - Shelf Stable Ready-to-eat-Rice ProcessrecordoffruitNo ratings yet

- Us20100119661a1 PDFDocument4 pagesUs20100119661a1 PDFbabithyNo ratings yet

- United States Patent (19) : Zeller, Grand-Lancy, Both ofDocument6 pagesUnited States Patent (19) : Zeller, Grand-Lancy, Both ofRijad LičinaNo ratings yet

- United States Patent (19) : (45) Date of Patent: Dec. 25, 1984Document5 pagesUnited States Patent (19) : (45) Date of Patent: Dec. 25, 1984Meli ChiambaNo ratings yet

- 12 Steps of Bread BakingDocument2 pages12 Steps of Bread BakingHalima LukmanaNo ratings yet

- Pan Release AgentDocument5 pagesPan Release AgentCharaf ZAHIRINo ratings yet

- United States PatentDocument6 pagesUnited States PatentRahani HyugaNo ratings yet

- Blow On BlowDocument7 pagesBlow On BlowElisabeth GreyNo ratings yet

- Aerated Food ProductDocument22 pagesAerated Food ProductbasssingaNo ratings yet

- United States Patent (19) : Stephen Et AlDocument6 pagesUnited States Patent (19) : Stephen Et Aldylan tikoyNo ratings yet

- Usd PatenDocument5 pagesUsd PatenAdy PrasetyoNo ratings yet

- Brian Project FinalDocument21 pagesBrian Project Finalreuben simiyuNo ratings yet

- United States Patent (19) : (11 Patent Number: 4,759,934 45) Date of Patent: Jul. 26, 1988Document5 pagesUnited States Patent (19) : (11 Patent Number: 4,759,934 45) Date of Patent: Jul. 26, 1988Rijad LičinaNo ratings yet

- Weaver Et Al. (1990) Patent Method of Particulate ConsolidationDocument5 pagesWeaver Et Al. (1990) Patent Method of Particulate ConsolidationAfif IzwanNo ratings yet

- United States Patent (19) (11 3,961,424: Elerath (45) June 8, 1976Document3 pagesUnited States Patent (19) (11 3,961,424: Elerath (45) June 8, 1976Yanpiero BalladoresNo ratings yet

- The Matson PatentDocument4 pagesThe Matson PatentMinnesota Public RadioNo ratings yet

- US4737372Document4 pagesUS4737372qwerandom2No ratings yet

- UNIT5 Technology of Bread MakingDocument12 pagesUNIT5 Technology of Bread MakingS ENo ratings yet

- UNIT II - Basic BakingDocument33 pagesUNIT II - Basic Bakingyf6xy8b2jpNo ratings yet

- Soap MakingDocument14 pagesSoap MakingEmanuel MoralesNo ratings yet

- Bread DocumentDocument11 pagesBread DocumentSherice CampbellNo ratings yet

- FritasDocument4 pagesFritasSantiago MejíaNo ratings yet

- Patent NougatDocument13 pagesPatent NougatTarak ZayaniNo ratings yet

- Freeze Dried Cottage Cheese Making - PatentDocument3 pagesFreeze Dried Cottage Cheese Making - PatentChandrima JashNo ratings yet

- Us 1505592Document4 pagesUs 1505592api-190559452No ratings yet

- 1 Basic Steps in BakingDocument18 pages1 Basic Steps in BakingChristina BinoboNo ratings yet

- United States Patent (19) : 75) Inventors: Bruce W. Brown Virgil E. Copple 57Document7 pagesUnited States Patent (19) : 75) Inventors: Bruce W. Brown Virgil E. Copple 57Omer MukhtarNo ratings yet

- Lp6 Ro TVL He BPP Ncii Grade 11 Q1.revisedDocument6 pagesLp6 Ro TVL He BPP Ncii Grade 11 Q1.revisedSalgie Sernal0% (1)

- April 29, 1947. M - Cqntesso 2,419,822Document3 pagesApril 29, 1947. M - Cqntesso 2,419,822sterlingNo ratings yet

- Frying of Foods: Vassiliki Oreopoulou, Magdalini Krokida, and Dimitris Marinos-KourisDocument22 pagesFrying of Foods: Vassiliki Oreopoulou, Magdalini Krokida, and Dimitris Marinos-KourisNoel GatbontonNo ratings yet

- United States Patent (19: Yamazaki Et AlDocument3 pagesUnited States Patent (19: Yamazaki Et AlJunaid AhmedNo ratings yet

- United States Patent (19) : Lommi Et Al. (45) Date of Patent: Mar 18, 1997Document4 pagesUnited States Patent (19) : Lommi Et Al. (45) Date of Patent: Mar 18, 1997Marina ButuceaNo ratings yet

- How Are Aero Chocolate Bars Made and How Did They Get All The Bubbles in An Aero Chocolate BarDocument2 pagesHow Are Aero Chocolate Bars Made and How Did They Get All The Bubbles in An Aero Chocolate BarPramurtta Shourjya MajumdarNo ratings yet

- Bread and Pastry PDFDocument12 pagesBread and Pastry PDFKenneth P PablicoNo ratings yet

- Module 9 W 15-16Document3 pagesModule 9 W 15-16Maeann RuizNo ratings yet

- What Is BakingDocument2 pagesWhat Is Bakingdinh huy truongNo ratings yet

- United States Patent (19) : 11 Patent Number: (45) Date of PatentDocument3 pagesUnited States Patent (19) : 11 Patent Number: (45) Date of PatentLuis BejaranoNo ratings yet

- US5375563Document5 pagesUS5375563xyz7890No ratings yet

- CHAPTER 9 Steps in BreadmakingDocument19 pagesCHAPTER 9 Steps in BreadmakingFriza mae GarciaNo ratings yet

- Paper No.: 12 Paper Title: Food Packaging Technology Module - 16: Packaging of Snack FoodsDocument7 pagesPaper No.: 12 Paper Title: Food Packaging Technology Module - 16: Packaging of Snack FoodsM SNo ratings yet

- United States Patent (19) : Patent Number: Date of Patent: 45)Document13 pagesUnited States Patent (19) : Patent Number: Date of Patent: 45)leo06031314No ratings yet

- United States Patent (19) : TaskinenDocument6 pagesUnited States Patent (19) : TaskinenKSXNo ratings yet

- SITHCCC019 CorrectionDocument12 pagesSITHCCC019 CorrectionRohan ShresthaNo ratings yet

- PRP - Cleaning and SanitisationDocument1 pagePRP - Cleaning and Sanitisationsumon.dey.1494No ratings yet

- Us 4341803Document7 pagesUs 4341803Ria LestariNo ratings yet

- Module 13 Thermal ApplicationDocument15 pagesModule 13 Thermal ApplicationMitchille Getizo100% (1)

- Friki FestivalDocument6 pagesFriki FestivalJean Carlos MottaNo ratings yet

- United States Patent (19) : Burger (45) Apr. 24, 1979Document17 pagesUnited States Patent (19) : Burger (45) Apr. 24, 1979Mustafa ŞENNo ratings yet

- BPP Module 3Document24 pagesBPP Module 3Neil Jean Marcos Bautista100% (2)

- Bakery Products ProcessDocument13 pagesBakery Products ProcessrakhigoelNo ratings yet

- Plan Rhia BPPDocument32 pagesPlan Rhia BPPJohn Ellis LacsamanaNo ratings yet

- Edible Speech Cue CardsDocument2 pagesEdible Speech Cue Cardsred velvetNo ratings yet

- LP5 - RO - TLE HE BPP Grade 9 10 Q1 Edited - FinalizedDocument9 pagesLP5 - RO - TLE HE BPP Grade 9 10 Q1 Edited - Finalizedgemuel imperialNo ratings yet

- Patents Soap MakingDocument7 pagesPatents Soap MakingNoviNo ratings yet

- Buko PieDocument5 pagesBuko PieCarmie Dela RosaNo ratings yet

- Sithccc019 - Learner ResourceDocument75 pagesSithccc019 - Learner ResourcemafuNo ratings yet

- US5900457Document8 pagesUS5900457SUBRAMANIAN SNo ratings yet

- MR - Biryani MenueDocument2 pagesMR - Biryani Menuebittuj68No ratings yet

- Georgian MenuDocument4 pagesGeorgian MenuFarley ElliottNo ratings yet

- Export DataDocument20 pagesExport DatamanjushreeNo ratings yet

- Linds Food Menu - Ramadhan 2023Document24 pagesLinds Food Menu - Ramadhan 2023Ampel BersinergiNo ratings yet

- Brown Stew Pork Shoulder Recipe - NYT CookingDocument2 pagesBrown Stew Pork Shoulder Recipe - NYT CookingbernbilazonNo ratings yet

- Specific GravityDocument7 pagesSpecific Gravityjucar fernandezNo ratings yet

- Diagnostic BPPDocument5 pagesDiagnostic BPPRichele R. ValenciaNo ratings yet

- Mushroom MasalaDocument13 pagesMushroom MasalajaithilagarajNo ratings yet

- Ajwain ArbiDocument2 pagesAjwain ArbiPrachi GuptaNo ratings yet

- Modern Pastry and Plated Dessert Techniques 1561412512 PDFDocument73 pagesModern Pastry and Plated Dessert Techniques 1561412512 PDFĐặng Trần Trường GiangNo ratings yet

- +919840956389-Diet PlanDocument3 pages+919840956389-Diet PlanXI132 B.Srinithi XI-DNo ratings yet

- ChandPalace Parsippany MenuDocument5 pagesChandPalace Parsippany Menuhkm_gmat4849No ratings yet

- Moz CookbookDocument112 pagesMoz CookbookEleonoreNo ratings yet

- Iqbal Foods Ramadan Flyer 2024.Document6 pagesIqbal Foods Ramadan Flyer 2024.samira.vashiNo ratings yet

- Satvasiri Price List - Jan-22 (Natural's) : Item Category Item Name Sale Price Item Category Item Name Sale PriceDocument1 pageSatvasiri Price List - Jan-22 (Natural's) : Item Category Item Name Sale Price Item Category Item Name Sale PriceDeepak Gowda SNo ratings yet

- Arroz-Ingredients: QuantityDocument8 pagesArroz-Ingredients: QuantityDeepak BillaNo ratings yet

- Datasheet OverView 2019Document2 pagesDatasheet OverView 2019SA100% (1)

- Children's MenuDocument7 pagesChildren's MenuNicole RaducuNo ratings yet

- Bul-Go-Gi: Grilled Marinated BeefDocument1 pageBul-Go-Gi: Grilled Marinated BeefAzrinna BasriNo ratings yet

- Kapha Pacifying FoodsDocument12 pagesKapha Pacifying FoodsSaiPriya KumarNo ratings yet

- Cereal TechnologyDocument28 pagesCereal Technologynabila OktavianiNo ratings yet

- Stones Style 140 WineDocument2 pagesStones Style 140 WineTemet NoscheNo ratings yet

- Date Quantity Sold Transaction Revenue Sales Price/unit Item CodeDocument13 pagesDate Quantity Sold Transaction Revenue Sales Price/unit Item CodeDeepika DhimanNo ratings yet

- Plant Based Christmas A Glow Diaries Ebook by Liz DouglasDocument40 pagesPlant Based Christmas A Glow Diaries Ebook by Liz Douglasanjara13No ratings yet

- 1.1 Prepare Bake Cakes and FillingsDocument14 pages1.1 Prepare Bake Cakes and FillingsArlene RubeneciaNo ratings yet

- Smoke Points of Various FatsDocument2 pagesSmoke Points of Various FatsRiccardo MuccardoNo ratings yet

- Easy Hot and Sour Wonton Soup (酸汤馄饨) - Curated KitchenwareDocument2 pagesEasy Hot and Sour Wonton Soup (酸汤馄饨) - Curated KitchenwareChristos ChristouNo ratings yet

- CBLM - BPP Prepare and Produce Bakery 1 EditedDocument98 pagesCBLM - BPP Prepare and Produce Bakery 1 EditedEarl Rylman Atillo100% (5)

- Kintaromenu NewDocument45 pagesKintaromenu NewDimas PrasetyoNo ratings yet

- Papa-Johns-Allergen-Guide Gramme IngredientDocument2 pagesPapa-Johns-Allergen-Guide Gramme IngredientAlgerian AmazighNo ratings yet