Professional Documents

Culture Documents

WPS 127 Suppoting

WPS 127 Suppoting

Uploaded by

GobinderSinghSidhu0 ratings0% found this document useful (0 votes)

45 views2 pagesOriginal Title

WPS 127 SUPPOTING

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

45 views2 pagesWPS 127 Suppoting

WPS 127 Suppoting

Uploaded by

GobinderSinghSidhuCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

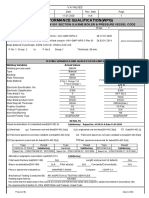

LEADER VALVES LIMITED & LEADER EXPORTS (JALANDHAR)

Ref. No. GAF-7.5.1713

Issue Date 20.10.2010

RADIOGRAPHIC EXAMINATION REPORT Revision No. 02

Revision Date 78/2013

[Total Page 7

RT Procedure No & Revision : QA/P/6.2.4/02 Rev. 03 Pages: 1 off

Report No. : RT/CS/IQAWPSIS/127 Report Date : 22-09-2014 _ [Date of Test : 27-09-2014

[Customer Name : M/s Leader Valves Ltd. [Heat No. : NA litem : Welded Test Plate

[Drawing No. : NA inspection By : BVIS JOut Side DialSize:200x150x1 4mm

[Base Material Type : ASTM A 105 lWeld Process:GTAW=SWAW _|Weld Reinforcement : NA

[Base Material Thickness : 14mm. [Stage of Test : Welded [Area Covered: Weld+HAZ

7-276 of ASME Sec V

[Code Spec.:ASME Sec V Ar.2, ASTM E-94 & E-142 Ref Std.:

[Code / Acceptance Standard : ASME Sec IX

RADIOGRAPHIC PARAMETERS

[Source Type : XRAY Ir. 192/C0-60___ [KV Used (FOR X-RAY) - KV Ir.192 Source Activity : 2001

[Source Focal Spot Size : 2.7mmx1.2mm [No. of Exposure : 1 |Visible Hole : 2T

IQ Placement : Source / Film Side IQ Type : Wire / Hole IQI Designation : 20Th & Set B

Film Brand/Make : Kodak Film Type : NDT-7

intensifying Screen : Lead

[Location Marker : Source / Firm Side

ISFD : 500mm

[Density : 20-40 [Sensitivity : 2-27

[Ug : 0.5mm [Back scattered : B

[Processing Temp.: 20°C

Viewing : Single/Doubie image

[Film Size : As Below

Segment | Size ‘Observation Result

1 _ [Welded Test Piate AB | 1244" NSI ‘Accept

|WPS No. : QAWPS/JS/127

lwesi27

LEADER VALVES LTD.

\

Auk EVALUATED BY sate

i LEADER LVL

oes eae

[R.K.| INSPECTION & TESTING SERVICES

Office : C-42, Manak Vihar Extn. (Tihar) CENTRAL BOILERS BOARD Works yeas ee

Subhash Nagar, New Delhi-110018 (Govt. of India) Approved Phase-ll, New iS

: S f ; :011- 2 +01-11- 7

Tel : 011-25121201, 011-28122201 WORK TEST REPORT(F/MCT/05/00) Ph:011-28114161 Fax : +91-11-2512251

RK/0914/LVL/25A

T.M. REGD,

REPORT NO

CUSTOMER: — M/s LEADER VALVES LTD.; S-3,S-4, INDUSTRIAL TOWN, JALANDHAR-4,

REF: LETTER : DT. 20.09.2014

DESC.: 14MM THICK SINGLE *V’ JOINT BUTT WELDED COUPON PLATE SAMPLE FOR PROCEDURE QUALIFICATION TEST AS PER ASME SEC IX.

SAMPLE ID.: | WPS NO. 127, WELDER NAME: AYODH SINGH, FILLER WIRE: ER70S2 MATERIAL OF CONSTRUCTION: ASTM A105

INSPECTION AUTHORITY: M/s LT.S. MECHANICAL TEST REPORT DATE OF TESTING: 25.09.2014

Id. Mark Ultimate Gauge Elongated HARDNESS SURVEY

Gauge Size in Area Yield Yield Ultimate | Tensile Length Length Elongation Reduced Reduction SCALE: VICKERS

MM MN? Load Stress Load Stress on MM % Dia In Area LOAD: 10KGS

KN N/MM? KN N/MM? MM MM % TEST STD: ASTM E-92

(Fig. | OBSERVATIONS :

i. = * * : B Ss iT ET Y LS aN

111 19.00X14.12Thk. | 268.28 137.5 513 ROKEN AT PARENT METAL / DUCTILE as PEL D CRO SECTION

TT2 19.08X14.08Thk. | 268.65 - - 138.0 514. | BROKEN AT PARENT METAL / DUCTILE AT WELD ZONE:

187,187, 191,189,186,190

GUIDED BEND TEST (COLD) OVER MANDREL $ = 4t X 180°(FIGURE QW 466.1/466.2) OF ASME SEC IX. AT HEAT AFFECTED ZONE:

RBI__| ROOTBEND - SATISFACTORY 175,179,179,177,181,180

RB2__| ROOT BEND - SATISFACTORY

FBI _| FACE BEND - SATISFACTORY AT PARENT METAL:

FB2__| FACE BEND - SATISFACTORY 163,165

CHARPY V NOTCH IMPACT TEST SIZE X10.X55MM;CVN 2MMDEEP TEST TEMP.: °C TEST STD: ASTM —A 370

CODE SAMPLE ID. VALUES IN JOULES(J)

(1) (i) (I) AVG

: | - | NA : : |

CHEMICAL ANALYSIS

Id. Mark C% Si% Mn% P% S% | Ni% cr% Mo% | Al% | Co% | Cu% Ti% V%

Conformity to Required Speen. ; YES / NO/ NOT EVALUATED

Tested byt

sings :

\

‘ ~

1

election of samples not done by M/s.RKITS

relates only to the samples submitted.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dig Clamp Meter dcm002Document3 pagesDig Clamp Meter dcm002GobinderSinghSidhuNo ratings yet

- Route SheetDocument2 pagesRoute SheetGobinderSinghSidhuNo ratings yet

- Gulfspic 1391 Revised TCDocument33 pagesGulfspic 1391 Revised TCGobinderSinghSidhuNo ratings yet

- OH&S Documents ChecklistDocument6 pagesOH&S Documents ChecklistGobinderSinghSidhuNo ratings yet

- "Master List of Documents": PlansDocument7 pages"Master List of Documents": PlansGobinderSinghSidhuNo ratings yet

- Wps 130Document4 pagesWps 130GobinderSinghSidhuNo ratings yet

- Gas Cylinders DetailDocument1 pageGas Cylinders DetailGobinderSinghSidhuNo ratings yet

- Qw-484 Welder Performance Qualification (WPQ) : SEE QW-301 Section Ix, Asme Boiler & Pressure Vessel CodeDocument8 pagesQw-484 Welder Performance Qualification (WPQ) : SEE QW-301 Section Ix, Asme Boiler & Pressure Vessel CodeGobinderSinghSidhuNo ratings yet

- Summary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)Document1 pageSummary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)GobinderSinghSidhuNo ratings yet

- Cswip Renewal FormDocument4 pagesCswip Renewal FormGobinderSinghSidhu0% (1)

- Ioc ApiDocument3 pagesIoc ApiGobinderSinghSidhuNo ratings yet