Professional Documents

Culture Documents

98 Dodge Ram Truck SM SCS

98 Dodge Ram Truck SM SCS

Uploaded by

Eduardo MacMasterCopyright:

Available Formats

You might also like

- Honda Element LX 2009 Sistema de Carga (Charging System) Completo PDFDocument28 pagesHonda Element LX 2009 Sistema de Carga (Charging System) Completo PDFRubenNo ratings yet

- SCR Drive Troubleshooting PDFDocument14 pagesSCR Drive Troubleshooting PDFsorangel_123No ratings yet

- Rsg2100 NC DatasheetDocument11 pagesRsg2100 NC DatasheetJose Fernando Perdomo BolañosNo ratings yet

- Power Plant Control and Instrumentation SpecificationDocument179 pagesPower Plant Control and Instrumentation Specificationpingolia67% (3)

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- Avensis Intake System PDFDocument19 pagesAvensis Intake System PDFMladen VidovićNo ratings yet

- Pajero 1991 Cruise Control SystemDocument28 pagesPajero 1991 Cruise Control SystemnadaNo ratings yet

- EvacDocument1 pageEvacMansur KhanNo ratings yet

- Cruise Control System: 1994 Volvo 960Document17 pagesCruise Control System: 1994 Volvo 960Varun VaxNo ratings yet

- 121 2AZ-FE Engine Control System - Throttle BodyDocument8 pages121 2AZ-FE Engine Control System - Throttle BodydanielmaycarazoNo ratings yet

- SUN Compression TesterDocument8 pagesSUN Compression TesterWongstorn DamrongmaneeNo ratings yet

- Biffi 2Document6 pagesBiffi 2Goutham KSNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- 93FWD 8uDocument6 pages93FWD 8uChristian MartinezNo ratings yet

- 40 - Automatic TransmissionDocument50 pages40 - Automatic TransmissionDevo UvtNo ratings yet

- 4 Tec Diagnostic ProceduresDocument26 pages4 Tec Diagnostic ProceduresDiego Lozano G.No ratings yet

- Emissions Control SystemsDocument15 pagesEmissions Control SystemsTharsikan singamNo ratings yet

- Intake and ExhaustDocument14 pagesIntake and ExhaustJOVEO MANONGSONGNo ratings yet

- System Component Tests Chevrolet S10Document19 pagesSystem Component Tests Chevrolet S10Maxi Sardi100% (1)

- Gascon Systems Auto Change-Over Manifold Maintenance InstructionsDocument11 pagesGascon Systems Auto Change-Over Manifold Maintenance InstructionsNasro JuvNo ratings yet

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- Basic Testing PDFDocument7 pagesBasic Testing PDFOskars ŠtālsNo ratings yet

- Troubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilersDocument27 pagesTroubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilerswarthogwillieNo ratings yet

- Ansul R102 Inspection DirectionsDocument9 pagesAnsul R102 Inspection DirectionsjoefivekillerNo ratings yet

- Chime Warning/Reminder System: Description and Operation Headlamps Left OnDocument2 pagesChime Warning/Reminder System: Description and Operation Headlamps Left OnRoberto VazquezNo ratings yet

- XXXX 1997 Chevrolet Pickup K1500: I - System/Component Tests - 5.0L XXXX Highlighted Article TextDocument28 pagesXXXX 1997 Chevrolet Pickup K1500: I - System/Component Tests - 5.0L XXXX Highlighted Article TextJose Gabriel Diaz100% (1)

- L45425en BDocument4 pagesL45425en BJerNo ratings yet

- Evacuating: Quick Disconnect Adapter Charging HoseDocument1 pageEvacuating: Quick Disconnect Adapter Charging HoseHarshad NaringrekarNo ratings yet

- ChargingDocument17 pagesChargingjasonphxNo ratings yet

- Start-Up and Check-Out Procedures For Submersible Pumps: (Step-By-Step Procedures Courtesy of SWPA)Document5 pagesStart-Up and Check-Out Procedures For Submersible Pumps: (Step-By-Step Procedures Courtesy of SWPA)Diego Nicolás FERNANDEZNo ratings yet

- Single & Dual Load Sensing, Accumulator Charging ValveDocument8 pagesSingle & Dual Load Sensing, Accumulator Charging Valvetystar_21No ratings yet

- Pajero Full 2008 15Document81 pagesPajero Full 2008 15Antonio Gaspar100% (1)

- Dosificatore V-LineDocument14 pagesDosificatore V-LinemadpadoNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- Horns: Description and OperationDocument6 pagesHorns: Description and OperationLilisbethBasantaNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- DTC P2757 Torque Converter Clutch Pressure Control Solenoid Performance (Shift Solenoid Valve Slu)Document2 pagesDTC P2757 Torque Converter Clutch Pressure Control Solenoid Performance (Shift Solenoid Valve Slu)limadacarlosNo ratings yet

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoeNo ratings yet

- Instruction Manual - Series 70CV2000 Chloromatic Valve Used With Series 70-4400 & FX4400 Gas Dispensing SystemsDocument6 pagesInstruction Manual - Series 70CV2000 Chloromatic Valve Used With Series 70-4400 & FX4400 Gas Dispensing SystemsSỹ TháiNo ratings yet

- PL Horns 8G - 1Document4 pagesPL Horns 8G - 1Pelis CloneNo ratings yet

- Wiper WasherDocument35 pagesWiper WasherNhatNo ratings yet

- Windshield Wipers and WashersDocument6 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- Epc100e OM 5 06Document73 pagesEpc100e OM 5 06Roland LamoureuxNo ratings yet

- Electric SystemDocument78 pagesElectric SystemHarry Wart Wart100% (2)

- Sfi System (1Gr-Fe) : On-Vehicle InspectionDocument2 pagesSfi System (1Gr-Fe) : On-Vehicle InspectionRodrigo VillagraNo ratings yet

- Power Steering System: Section 6ADocument13 pagesPower Steering System: Section 6AJarry PotterNo ratings yet

- Arca Valve Manual - 830 POSITIONERDocument13 pagesArca Valve Manual - 830 POSITIONERAtul bhabad0% (1)

- European Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Document4 pagesEuropean Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Sergio RodriguezNo ratings yet

- 641 Series Installation and Operation Instruction: Proportional Control ValveDocument4 pages641 Series Installation and Operation Instruction: Proportional Control ValveBhethhoNo ratings yet

- Capital Controls Chloromatic Series 70AV2000: Gas Control Valve For Pressurized AmmoniaDocument4 pagesCapital Controls Chloromatic Series 70AV2000: Gas Control Valve For Pressurized AmmoniaFranco ArellanoNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Throttle Body On-Vehicle InspectionDocument2 pagesThrottle Body On-Vehicle InspectionNate VanNo ratings yet

- Combination Meter: Problem Symptoms TableDocument12 pagesCombination Meter: Problem Symptoms TableMusat Catalin-MarianNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPEng.Gihad EladlNo ratings yet

- Phase Antiphase Boost Control PDFDocument2 pagesPhase Antiphase Boost Control PDFNugrahaNo ratings yet

- Diagnostic InstructionsDocument4 pagesDiagnostic Instructionsjosecuellar69100% (1)

- Kana - Bfc-10-Ch-Std-Ga-Ec-110 VacDocument6 pagesKana - Bfc-10-Ch-Std-Ga-Ec-110 VacJiyaul HaqueNo ratings yet

- Altronic GSVDocument8 pagesAltronic GSVhamadaNo ratings yet

- Checkout ProcedureDocument16 pagesCheckout ProcedureMichael GonzalezNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 98 Dodge Ram Truck SM cr1Document1 page98 Dodge Ram Truck SM cr1Eduardo MacMasterNo ratings yet

- 98 Dodge Ram Truck SM 4Document1 page98 Dodge Ram Truck SM 4Eduardo MacMasterNo ratings yet

- History of The HornDocument5 pagesHistory of The HornEduardo MacMaster100% (1)

- 01 2015 BuildBlock Technical Installation Manual Small 20151007Document115 pages01 2015 BuildBlock Technical Installation Manual Small 20151007Eduardo MacMasterNo ratings yet

- Multiple Tonguing ExercisesDocument3 pagesMultiple Tonguing ExercisesEduardo MacMasterNo ratings yet

- AltissimoDocument1 pageAltissimoEduardo MacMasterNo ratings yet

- User Manual Achook-1080, G726A, UM0084 - LatestDocument24 pagesUser Manual Achook-1080, G726A, UM0084 - Latestprajith555No ratings yet

- 9608 - s19 - QP - 21 PaperDocument16 pages9608 - s19 - QP - 21 Paperfaizan majidNo ratings yet

- UNV EZStation Datasheet (V1.6)Document3 pagesUNV EZStation Datasheet (V1.6)mbkfetNo ratings yet

- Co-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Department of Information Technology ApprovalDocument4 pagesCo-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Department of Information Technology ApprovalSenthil RNo ratings yet

- CSS Background 4rDocument3 pagesCSS Background 4rapple12zsxxNo ratings yet

- Di PressionDocument1 pageDi PressionpjrkrishnaNo ratings yet

- 17MB26 ServismanualDocument61 pages17MB26 ServismanualCarlos GonçalvesNo ratings yet

- Need Help! Fanuc 11 CRT ProblemsDocument4 pagesNeed Help! Fanuc 11 CRT ProblemsindustronicaNo ratings yet

- 9866 0004 01 - Cop Rc45 and Cop Rc45 HD Sales Brochure - HighDocument4 pages9866 0004 01 - Cop Rc45 and Cop Rc45 HD Sales Brochure - HighPaula ArrascaetaNo ratings yet

- Sci Journal ListDocument42 pagesSci Journal Listchetan1nonlyNo ratings yet

- Jungheinrich EFG 213-320 Operating Manual PDFDocument109 pagesJungheinrich EFG 213-320 Operating Manual PDFAndy100% (1)

- Sensor Based Automated Irrigation System With Iot A Technical ReviewDocument4 pagesSensor Based Automated Irrigation System With Iot A Technical ReviewJhanina CapicioNo ratings yet

- International Conference On Chemistry and Material Science (IC2MS) 2017Document8 pagesInternational Conference On Chemistry and Material Science (IC2MS) 2017Ahmad FudhailNo ratings yet

- Purdue Data Science Master Program Slimupv2Document28 pagesPurdue Data Science Master Program Slimupv2Samir Yadav100% (1)

- ABB-RingCore-przekladniki EN - 13-06Document16 pagesABB-RingCore-przekladniki EN - 13-06TetianaNo ratings yet

- Opa 615Document34 pagesOpa 615contrasterNo ratings yet

- Preventive Maintenance Using Reliability Centred MDocument29 pagesPreventive Maintenance Using Reliability Centred MGiovanni GiudiceNo ratings yet

- Thesis DC MotorDocument6 pagesThesis DC Motorspqeyiikd100% (2)

- How To Increase TX Power Signal Strength of WiFiDocument10 pagesHow To Increase TX Power Signal Strength of WiFiMarko Perić Ledeni KikiNo ratings yet

- (CESURVE) M10 EarthworksDocument93 pages(CESURVE) M10 EarthworksMaya LangitNo ratings yet

- Drilling Systems BrochureDocument8 pagesDrilling Systems BrochureBeniamine SarmientoNo ratings yet

- Information Level EA ArtifactsDocument32 pagesInformation Level EA ArtifactsDon XiaoNo ratings yet

- Transcend WP-T800-001-1096Document2 pagesTranscend WP-T800-001-1096Maximiliano1989100% (1)

- TSLOTS Catalog WebsiteDocument256 pagesTSLOTS Catalog WebsiteAnirudh SabooNo ratings yet

- Condition MonitoringDocument20 pagesCondition MonitoringKhalaf GaeidNo ratings yet

- REV REV REV Revision Revision Revision Engineer: Engineer: Engineer: Date Date DateDocument94 pagesREV REV REV Revision Revision Revision Engineer: Engineer: Engineer: Date Date DateAshutosh PendkarNo ratings yet

- Digital Design Interview Questions & AnswersDocument6 pagesDigital Design Interview Questions & AnswersSucharitha ReddyNo ratings yet

- Remote Terminal Unit RTU560: For Energy System OperationDocument16 pagesRemote Terminal Unit RTU560: For Energy System Operationzarun1No ratings yet

98 Dodge Ram Truck SM SCS

98 Dodge Ram Truck SM SCS

Uploaded by

Eduardo MacMasterOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

98 Dodge Ram Truck SM SCS

98 Dodge Ram Truck SM SCS

Uploaded by

Eduardo MacMasterCopyright:

Available Formats

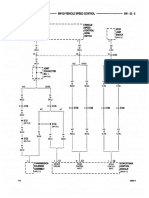

BR SPEED CONTROL SYSTEM 8H - 3

DIAGNOSIS AND TESTING (Continued)

ON-BOARD DIAGNOSTIC TEST FOR SPEED

SWITCH

CONTROL SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the speed control

system, making sure they are operational. A Diagnos-

tic Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some circuits are checked continu-

ously and some are checked only under certain con-

ditions. SWITCH RESISTANCE BETWEEN

POSITION PINS 1 AND 2

For DTC information, refer to Diagnostic Trouble

909 ohms

Codes i n Group 25, Emission Control System. This ON

+/- 9 ohms

w i l l include a complete list of DTC's including DTC's

for the speed control system. 6650 ohms

SET

+/- 66 ohms

SPEED CONTROL SWITCHES RESUME/ACCEL

15,400 ohms

+/-154 ohms

For complete speed control system diagnosis, refer

Oohms

to the appropriate Powertrain Diagnostic Procedures CANCEL

(CLOSED CIRCUIT)

manual. To test each of the speed control switches

2940 ohms

only, refer to the following: COAST

+/- 29 ohms 80a53490

WARNING: B E F O R E ATTEMPTING T O D I A G N O S E ,

R E M O V E OR INSTALL ANY A I R B A G S Y S T E M O R Fig. 1 Speed Control Switch Continuity (Typical

R E L A T E D S T E E R I N G W H E E L AND S T E E R I N G C O L - Switch Shown)

UMN C O M P O N E N T S , Y O U M U S T F I R S T D I S C O N - (2) Start engine and observe gauge at idle. Vac-

N E C T AND I S O L A T E T H E B A T T E R Y N E G A T I V E uum gauge should read at least ten inches of mer-

( G R O U N D ) C A B L E . WAIT 2 M I N U T E S F O R S Y S T E M cury.

CAPACITOR TO DISCHARGE B E F O R E FURTHER (3) I f vacuum is less than ten inches of mercury,

S Y S T E M S E R V I C E . FAILUR E TO DO S O C O U L D determine source of leak. Check vacuum line to

R E S U L T IN A C C I D E N T A L A I R B A G D E P L O Y M E N T engine for leaks. Also check actual engine intake

A N D P O S S I B L E P E R S O N A L INJURY. manifold vacuum. I f manifold vacuum does not meet

this requirement, check for poor engine performance

(1) Disconnect negative battery cable. Wait 2 min- and repair as necessary.

utes for airbag system capacitor to discharge. (4) I f vacuum line to engine is not leaking, check

(2) Remove the two speed control switch modules for leak at vacuum reservoir. To locate and gain

from steering wheel. Refer to the removal/installation access to reservoir, refer to Vacuum Reservoir Remov-

section for procedures. al/Installation i n this group. Disconnect vacuum line

(3) Check continuity of each individual speed con- at reservoir and connect a hand-operated vacuum

trol switch module as shown i n chart (Fig. 1). I f OK, pump to reservoir fitting. Apply vacuum. Reservoir

reinstall switch. I f not OK, replace switch module vacuum should not bleed off. I f vacuum is being lost,

assembly. replace reservoir.

(5) Verify operation of one-way check valve and

STOP LAMP SWITCH check i t for leaks.

For continuity checks and switch adjustment, refer (a) Locate one-way check valve. The valve is

to Group 5, Brakes. located i n vacuum line between vacuum reservoir

and engine vacuum source. Disconnect vacuum

VACUUM SUPPLY TEST hoses (lines) at each end of valve.

(b) Connect a hand-operated vacuum pump to

Gasoline Powered Engines:

reservoir end of check valve. Apply vacuum. Vac-

On gasoline powered engines: actual engine vac-

uum should not bleed off. I f vacuum is being lost,

uum, a vacuum reservoir, a one-way check valve and

replace one-way check valve.

vacuum lines are used to supply vacuum to the speed

(c) Connect a hand-operated vacuum pump to

control servo.

vacuum source end of check valve. Apply vacuum.

(1) Disconnect vacuum hose at speed control servo

Vacuum should flow through valve. I f vacuum is

and install a vacuum gauge into the disconnected

not flowing, replace one-way check valve. Seal the

hose.

fitting at opposite end of valve w i t h a finger and

You might also like

- Honda Element LX 2009 Sistema de Carga (Charging System) Completo PDFDocument28 pagesHonda Element LX 2009 Sistema de Carga (Charging System) Completo PDFRubenNo ratings yet

- SCR Drive Troubleshooting PDFDocument14 pagesSCR Drive Troubleshooting PDFsorangel_123No ratings yet

- Rsg2100 NC DatasheetDocument11 pagesRsg2100 NC DatasheetJose Fernando Perdomo BolañosNo ratings yet

- Power Plant Control and Instrumentation SpecificationDocument179 pagesPower Plant Control and Instrumentation Specificationpingolia67% (3)

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- Avensis Intake System PDFDocument19 pagesAvensis Intake System PDFMladen VidovićNo ratings yet

- Pajero 1991 Cruise Control SystemDocument28 pagesPajero 1991 Cruise Control SystemnadaNo ratings yet

- EvacDocument1 pageEvacMansur KhanNo ratings yet

- Cruise Control System: 1994 Volvo 960Document17 pagesCruise Control System: 1994 Volvo 960Varun VaxNo ratings yet

- 121 2AZ-FE Engine Control System - Throttle BodyDocument8 pages121 2AZ-FE Engine Control System - Throttle BodydanielmaycarazoNo ratings yet

- SUN Compression TesterDocument8 pagesSUN Compression TesterWongstorn DamrongmaneeNo ratings yet

- Biffi 2Document6 pagesBiffi 2Goutham KSNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- 93FWD 8uDocument6 pages93FWD 8uChristian MartinezNo ratings yet

- 40 - Automatic TransmissionDocument50 pages40 - Automatic TransmissionDevo UvtNo ratings yet

- 4 Tec Diagnostic ProceduresDocument26 pages4 Tec Diagnostic ProceduresDiego Lozano G.No ratings yet

- Emissions Control SystemsDocument15 pagesEmissions Control SystemsTharsikan singamNo ratings yet

- Intake and ExhaustDocument14 pagesIntake and ExhaustJOVEO MANONGSONGNo ratings yet

- System Component Tests Chevrolet S10Document19 pagesSystem Component Tests Chevrolet S10Maxi Sardi100% (1)

- Gascon Systems Auto Change-Over Manifold Maintenance InstructionsDocument11 pagesGascon Systems Auto Change-Over Manifold Maintenance InstructionsNasro JuvNo ratings yet

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- Basic Testing PDFDocument7 pagesBasic Testing PDFOskars ŠtālsNo ratings yet

- Troubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilersDocument27 pagesTroubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilerswarthogwillieNo ratings yet

- Ansul R102 Inspection DirectionsDocument9 pagesAnsul R102 Inspection DirectionsjoefivekillerNo ratings yet

- Chime Warning/Reminder System: Description and Operation Headlamps Left OnDocument2 pagesChime Warning/Reminder System: Description and Operation Headlamps Left OnRoberto VazquezNo ratings yet

- XXXX 1997 Chevrolet Pickup K1500: I - System/Component Tests - 5.0L XXXX Highlighted Article TextDocument28 pagesXXXX 1997 Chevrolet Pickup K1500: I - System/Component Tests - 5.0L XXXX Highlighted Article TextJose Gabriel Diaz100% (1)

- L45425en BDocument4 pagesL45425en BJerNo ratings yet

- Evacuating: Quick Disconnect Adapter Charging HoseDocument1 pageEvacuating: Quick Disconnect Adapter Charging HoseHarshad NaringrekarNo ratings yet

- ChargingDocument17 pagesChargingjasonphxNo ratings yet

- Start-Up and Check-Out Procedures For Submersible Pumps: (Step-By-Step Procedures Courtesy of SWPA)Document5 pagesStart-Up and Check-Out Procedures For Submersible Pumps: (Step-By-Step Procedures Courtesy of SWPA)Diego Nicolás FERNANDEZNo ratings yet

- Single & Dual Load Sensing, Accumulator Charging ValveDocument8 pagesSingle & Dual Load Sensing, Accumulator Charging Valvetystar_21No ratings yet

- Pajero Full 2008 15Document81 pagesPajero Full 2008 15Antonio Gaspar100% (1)

- Dosificatore V-LineDocument14 pagesDosificatore V-LinemadpadoNo ratings yet

- Data-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasDocument5 pagesData-Tech 1995 Nissan Pickup - Motor Sistema Controles - 3.0L Pruebas BasicasRubenNo ratings yet

- Horns: Description and OperationDocument6 pagesHorns: Description and OperationLilisbethBasantaNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- DTC P2757 Torque Converter Clutch Pressure Control Solenoid Performance (Shift Solenoid Valve Slu)Document2 pagesDTC P2757 Torque Converter Clutch Pressure Control Solenoid Performance (Shift Solenoid Valve Slu)limadacarlosNo ratings yet

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoeNo ratings yet

- Instruction Manual - Series 70CV2000 Chloromatic Valve Used With Series 70-4400 & FX4400 Gas Dispensing SystemsDocument6 pagesInstruction Manual - Series 70CV2000 Chloromatic Valve Used With Series 70-4400 & FX4400 Gas Dispensing SystemsSỹ TháiNo ratings yet

- PL Horns 8G - 1Document4 pagesPL Horns 8G - 1Pelis CloneNo ratings yet

- Wiper WasherDocument35 pagesWiper WasherNhatNo ratings yet

- Windshield Wipers and WashersDocument6 pagesWindshield Wipers and WashersPelis CloneNo ratings yet

- Epc100e OM 5 06Document73 pagesEpc100e OM 5 06Roland LamoureuxNo ratings yet

- Electric SystemDocument78 pagesElectric SystemHarry Wart Wart100% (2)

- Sfi System (1Gr-Fe) : On-Vehicle InspectionDocument2 pagesSfi System (1Gr-Fe) : On-Vehicle InspectionRodrigo VillagraNo ratings yet

- Power Steering System: Section 6ADocument13 pagesPower Steering System: Section 6AJarry PotterNo ratings yet

- Arca Valve Manual - 830 POSITIONERDocument13 pagesArca Valve Manual - 830 POSITIONERAtul bhabad0% (1)

- European Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Document4 pagesEuropean Instruction Manual Series 215 Solenoid Valve Gas Shut Off de de 5288058Sergio RodriguezNo ratings yet

- 641 Series Installation and Operation Instruction: Proportional Control ValveDocument4 pages641 Series Installation and Operation Instruction: Proportional Control ValveBhethhoNo ratings yet

- Capital Controls Chloromatic Series 70AV2000: Gas Control Valve For Pressurized AmmoniaDocument4 pagesCapital Controls Chloromatic Series 70AV2000: Gas Control Valve For Pressurized AmmoniaFranco ArellanoNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Throttle Body On-Vehicle InspectionDocument2 pagesThrottle Body On-Vehicle InspectionNate VanNo ratings yet

- Combination Meter: Problem Symptoms TableDocument12 pagesCombination Meter: Problem Symptoms TableMusat Catalin-MarianNo ratings yet

- Duplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPDocument2 pagesDuplex "Space Saver" Lubricated Rotary Vane Medical Vacuum Systems 7.5 Through 10 HPEng.Gihad EladlNo ratings yet

- Phase Antiphase Boost Control PDFDocument2 pagesPhase Antiphase Boost Control PDFNugrahaNo ratings yet

- Diagnostic InstructionsDocument4 pagesDiagnostic Instructionsjosecuellar69100% (1)

- Kana - Bfc-10-Ch-Std-Ga-Ec-110 VacDocument6 pagesKana - Bfc-10-Ch-Std-Ga-Ec-110 VacJiyaul HaqueNo ratings yet

- Altronic GSVDocument8 pagesAltronic GSVhamadaNo ratings yet

- Checkout ProcedureDocument16 pagesCheckout ProcedureMichael GonzalezNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 98 Dodge Ram Truck SM cr1Document1 page98 Dodge Ram Truck SM cr1Eduardo MacMasterNo ratings yet

- 98 Dodge Ram Truck SM 4Document1 page98 Dodge Ram Truck SM 4Eduardo MacMasterNo ratings yet

- History of The HornDocument5 pagesHistory of The HornEduardo MacMaster100% (1)

- 01 2015 BuildBlock Technical Installation Manual Small 20151007Document115 pages01 2015 BuildBlock Technical Installation Manual Small 20151007Eduardo MacMasterNo ratings yet

- Multiple Tonguing ExercisesDocument3 pagesMultiple Tonguing ExercisesEduardo MacMasterNo ratings yet

- AltissimoDocument1 pageAltissimoEduardo MacMasterNo ratings yet

- User Manual Achook-1080, G726A, UM0084 - LatestDocument24 pagesUser Manual Achook-1080, G726A, UM0084 - Latestprajith555No ratings yet

- 9608 - s19 - QP - 21 PaperDocument16 pages9608 - s19 - QP - 21 Paperfaizan majidNo ratings yet

- UNV EZStation Datasheet (V1.6)Document3 pagesUNV EZStation Datasheet (V1.6)mbkfetNo ratings yet

- Co-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Department of Information Technology ApprovalDocument4 pagesCo-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Department of Information Technology ApprovalSenthil RNo ratings yet

- CSS Background 4rDocument3 pagesCSS Background 4rapple12zsxxNo ratings yet

- Di PressionDocument1 pageDi PressionpjrkrishnaNo ratings yet

- 17MB26 ServismanualDocument61 pages17MB26 ServismanualCarlos GonçalvesNo ratings yet

- Need Help! Fanuc 11 CRT ProblemsDocument4 pagesNeed Help! Fanuc 11 CRT ProblemsindustronicaNo ratings yet

- 9866 0004 01 - Cop Rc45 and Cop Rc45 HD Sales Brochure - HighDocument4 pages9866 0004 01 - Cop Rc45 and Cop Rc45 HD Sales Brochure - HighPaula ArrascaetaNo ratings yet

- Sci Journal ListDocument42 pagesSci Journal Listchetan1nonlyNo ratings yet

- Jungheinrich EFG 213-320 Operating Manual PDFDocument109 pagesJungheinrich EFG 213-320 Operating Manual PDFAndy100% (1)

- Sensor Based Automated Irrigation System With Iot A Technical ReviewDocument4 pagesSensor Based Automated Irrigation System With Iot A Technical ReviewJhanina CapicioNo ratings yet

- International Conference On Chemistry and Material Science (IC2MS) 2017Document8 pagesInternational Conference On Chemistry and Material Science (IC2MS) 2017Ahmad FudhailNo ratings yet

- Purdue Data Science Master Program Slimupv2Document28 pagesPurdue Data Science Master Program Slimupv2Samir Yadav100% (1)

- ABB-RingCore-przekladniki EN - 13-06Document16 pagesABB-RingCore-przekladniki EN - 13-06TetianaNo ratings yet

- Opa 615Document34 pagesOpa 615contrasterNo ratings yet

- Preventive Maintenance Using Reliability Centred MDocument29 pagesPreventive Maintenance Using Reliability Centred MGiovanni GiudiceNo ratings yet

- Thesis DC MotorDocument6 pagesThesis DC Motorspqeyiikd100% (2)

- How To Increase TX Power Signal Strength of WiFiDocument10 pagesHow To Increase TX Power Signal Strength of WiFiMarko Perić Ledeni KikiNo ratings yet

- (CESURVE) M10 EarthworksDocument93 pages(CESURVE) M10 EarthworksMaya LangitNo ratings yet

- Drilling Systems BrochureDocument8 pagesDrilling Systems BrochureBeniamine SarmientoNo ratings yet

- Information Level EA ArtifactsDocument32 pagesInformation Level EA ArtifactsDon XiaoNo ratings yet

- Transcend WP-T800-001-1096Document2 pagesTranscend WP-T800-001-1096Maximiliano1989100% (1)

- TSLOTS Catalog WebsiteDocument256 pagesTSLOTS Catalog WebsiteAnirudh SabooNo ratings yet

- Condition MonitoringDocument20 pagesCondition MonitoringKhalaf GaeidNo ratings yet

- REV REV REV Revision Revision Revision Engineer: Engineer: Engineer: Date Date DateDocument94 pagesREV REV REV Revision Revision Revision Engineer: Engineer: Engineer: Date Date DateAshutosh PendkarNo ratings yet

- Digital Design Interview Questions & AnswersDocument6 pagesDigital Design Interview Questions & AnswersSucharitha ReddyNo ratings yet

- Remote Terminal Unit RTU560: For Energy System OperationDocument16 pagesRemote Terminal Unit RTU560: For Energy System Operationzarun1No ratings yet