Professional Documents

Culture Documents

Quality Assurance Plan For Turnouts: Assembly

Quality Assurance Plan For Turnouts: Assembly

Uploaded by

sukumar bhowmickOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan For Turnouts: Assembly

Quality Assurance Plan For Turnouts: Assembly

Uploaded by

sukumar bhowmickCopyright:

Available Formats

Quality Assurance Plan For Turnouts: Assembly

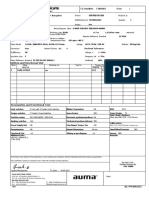

Item Description: Assembly Raw Material: UIC 60 Kg Rail Shop: Machine Shop

Specification: IRS T-10/2000

Sl. No. Operation Details Machine Feature Dimensions Mode of Inspection Test to be Remarks

Description Performed

1 Switch Assembly Manually Switch As per relevant drg. By Tape & Gauge N.A.

2 Internal Inspection Manually Final switch As per relevant Drg.& Specification By Tape, Scale & Gauges N.A.

3 Final Inspection Manually Final switch As per relevant Drg.& Specification By Tape, Scale & Gauges N.A.

4 Painting of Switches Manually Final switch As per IRS T-10/2000 Visual N.A.

5 Punching & Stenciling Manually Final switch As per IRS T-10/2000 Visual N.A.

6 Packing Manually Final switch As per IRS T-10/2000 Visual N.A.

7 Dispatched to Consignee Manually Final switch As per PO. Visual N.A.

8 Color Identification Each switch is marked with separate color for its deviation at the end face of Rail for its easy identification. White Color – LH; Black Color - RH

9 Marking Marking on Switch is done according to IRS T-10-2000 / Our Manufacturing Mark

10 Painting The finished goods after being passed by Inspecting Engineer are painted in accordance with clause no. 8.1, 8.2 & 8.3 IRS-T-10/2000. One

heavy coat of ready mixed paint red led, priming IS:102-1991. One coat of ready mixed verdigil green paint as per ISC 280 to IS: 117-1988, for

90 UTS Rails.

All slide chairs, bearing plates, CI casings, Tie-plates and other mild steel components shall, after inspection and approval, shall be painted

with temporary corrosion preventive fluids hard film, solvent type to IS:1153-1990 and shall not be packed until the film has dried to an

elastic film free from tackiness.

11 Stenciling of Switch details & After Painting the Switch, details & firm Monogram are stenciled with white paint in accordance with IRS-T-10/2000.

Firm Monogram

You might also like

- Applications Manual: Honda/Acura Immobiliser SystemDocument17 pagesApplications Manual: Honda/Acura Immobiliser Systemaoh1226No ratings yet

- Panasonic AG-DV7 Sec - 01Document13 pagesPanasonic AG-DV7 Sec - 01Nazo FsNo ratings yet

- ITP C 006 Concrete SlipformDocument7 pagesITP C 006 Concrete SlipformAnil Pottekkat100% (1)

- Beautiful Homes GuideDocument28 pagesBeautiful Homes Guidemsdixit2006100% (2)

- Cpar ExamDocument4 pagesCpar ExamJoseph Mondo�edo100% (1)

- 7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDDocument8 pages7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDAnonymous dH3DIEtzNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: 132kV BUSBAR & INTEGRATED BF Protection PanelDocument39 pagesCommissioning Service Department Commissioning Standard Test Formats Description: 132kV BUSBAR & INTEGRATED BF Protection PanelsaiNo ratings yet

- Vendor Document Cover SheetDocument75 pagesVendor Document Cover Sheetmujahed_muhammedNo ratings yet

- Electric Devices and Sensors: Section Di09Document7 pagesElectric Devices and Sensors: Section Di09LucasNo ratings yet

- F Series 2002Document4 pagesF Series 2002mario rosasNo ratings yet

- Design Data & References: Unit Tag StationDocument12 pagesDesign Data & References: Unit Tag StationAdnan AttishNo ratings yet

- CL-NG-6460-002-021 Checklist For Station Service Transformer Commissioning Rev02Document4 pagesCL-NG-6460-002-021 Checklist For Station Service Transformer Commissioning Rev02ahmed.fawzy.alalfy2050No ratings yet

- 8BFF-C01+R2 - K230Document6 pages8BFF-C01+R2 - K230wazakifyNo ratings yet

- DCDB - Function TestDocument5 pagesDCDB - Function TestAmr ElkadyNo ratings yet

- P2 V23079 Relay: 108-98002 Sept 06 Rev. D Ecoc: Jm10Document14 pagesP2 V23079 Relay: 108-98002 Sept 06 Rev. D Ecoc: Jm10Audio Semiconductores SACNo ratings yet

- Function Test - Accs 13.8kvDocument11 pagesFunction Test - Accs 13.8kvAmr ElkadyNo ratings yet

- Line Diff - p546Document9 pagesLine Diff - p546shanthikumaravel100% (1)

- DTC P0300 Random/Multiple Cylinder Misfire Detected: Circuit DescriptionDocument6 pagesDTC P0300 Random/Multiple Cylinder Misfire Detected: Circuit DescriptionsalusfrankNo ratings yet

- Duplex Filter: 1. FeaturesDocument6 pagesDuplex Filter: 1. Featuresmostafa aliNo ratings yet

- Canon Service LetterDocument2 pagesCanon Service LetterFinito TheEndNo ratings yet

- Robot 150 013314Document254 pagesRobot 150 013314jbarcelocamacho100% (1)

- Technical Specifications: Enviropol Engineers Pvt. LTDDocument17 pagesTechnical Specifications: Enviropol Engineers Pvt. LTDArvind KumarNo ratings yet

- 8BFF-C03+R1 - K110Document4 pages8BFF-C03+R1 - K110MahdiNo ratings yet

- 330C Plano Electrico PDFDocument2 pages330C Plano Electrico PDFRICHARDNo ratings yet

- PDFDocument1 pagePDFravigurajapuNo ratings yet

- Check List Primary InjectionDocument7 pagesCheck List Primary Injectionمحمد عادلNo ratings yet

- Load Shedding - Function TestDocument9 pagesLoad Shedding - Function TestratheeshkumardNo ratings yet

- Function Test 132kv Avc PanelDocument9 pagesFunction Test 132kv Avc PanelratheeshkumardNo ratings yet

- 7sd522 SiemensDocument17 pages7sd522 SiemensSanthosh Kumar VinayagamNo ratings yet

- Liquid Level Indicator: For Hermetically Sealed Oil Filled Distribution TransformerDocument2 pagesLiquid Level Indicator: For Hermetically Sealed Oil Filled Distribution TransformerSathish Kumar ANo ratings yet

- 0603 ResistorDocument20 pages0603 Resistorram dhukeNo ratings yet

- Monitor Sony E100Document41 pagesMonitor Sony E100pepitito22No ratings yet

- Supply Specification For Synthetic Lube Oil Plate Cooler ConsoleDocument11 pagesSupply Specification For Synthetic Lube Oil Plate Cooler ConsoleFazliJaafarNo ratings yet

- TR Differential Ret670Document19 pagesTR Differential Ret670Mahdi AlamriNo ratings yet

- 7SJ62 - Directional PH OCDocument3 pages7SJ62 - Directional PH OCSanthosh Kumar VinayagamNo ratings yet

- TR Differential Ret670 Y YDocument19 pagesTR Differential Ret670 Y Ym khNo ratings yet

- 73014TL Service Protocol L-Service (Annual) 2019-10-01Document1 page73014TL Service Protocol L-Service (Annual) 2019-10-01sunthron somchaiNo ratings yet

- RECN - 2211 - ZED10 - ZED10FX - Improve Noise and Stability of Mic PreDocument2 pagesRECN - 2211 - ZED10 - ZED10FX - Improve Noise and Stability of Mic PreLalo JonerNo ratings yet

- Vibration Analysis Report Thyssenkrupp: Elevator GearboxDocument4 pagesVibration Analysis Report Thyssenkrupp: Elevator GearboxSameer HussainNo ratings yet

- Monitoring Unit With Alarm Function and Data Collections: AK-SM 350Document2 pagesMonitoring Unit With Alarm Function and Data Collections: AK-SM 350Edson HenriqueNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Low Impedance Busbar Protection Relay Type - 7Ss522Document17 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Low Impedance Busbar Protection Relay Type - 7Ss522Arun KumarNo ratings yet

- VF003 - Level Gauge (ALL) PDFDocument21 pagesVF003 - Level Gauge (ALL) PDFPhạm Tấn PhướcNo ratings yet

- Series I - F210: The of DispensingDocument4 pagesSeries I - F210: The of DispensingNester satulilaNo ratings yet

- Red670 Distance Line DifferentialDocument23 pagesRed670 Distance Line DifferentialRatheesh KumarNo ratings yet

- YF_datasheetDocument3 pagesYF_datasheetwaleed.engr361No ratings yet

- RS 013 July 2014 (Welder Test Run Sheet Andhika Rolando)Document1 pageRS 013 July 2014 (Welder Test Run Sheet Andhika Rolando)Muhammad Fitransyah Syamsuar PutraNo ratings yet

- TestData HF01267 001Document32 pagesTestData HF01267 001pernetiNo ratings yet

- Sony Wa1 Chassis Klv27hr3 LCD TV SMDocument54 pagesSony Wa1 Chassis Klv27hr3 LCD TV SMIvan Leonardo Acevedo GalanNo ratings yet

- Emtr Servicing Reconditioning of 1 Unit 1.6 KW, Cyclo Drive Motor, 440V, 3phase PPR No. 32278Document4 pagesEmtr Servicing Reconditioning of 1 Unit 1.6 KW, Cyclo Drive Motor, 440V, 3phase PPR No. 32278HazelNo ratings yet

- Circuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionDocument4 pagesCircuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionJuanloNo ratings yet

- GS Control Offer of LT Panel For Lucknow ProjectDocument5 pagesGS Control Offer of LT Panel For Lucknow ProjectGautam MishraNo ratings yet

- Calibration SampleDocument1 pageCalibration SamplejoaoNo ratings yet

- Sylvania Mod 6420feDocument52 pagesSylvania Mod 6420fepata saladaNo ratings yet

- b3 Molg NFG DIGITAL MY2013Document11 pagesb3 Molg NFG DIGITAL MY2013RHETT BUTLERNo ratings yet

- 7SR1587 Voltage and Frequency RelayDocument4 pages7SR1587 Voltage and Frequency RelayAnonymous dH3DIEtzNo ratings yet

- ACList 20180808Document3 pagesACList 20180808mahmood750No ratings yet

- LockadaptorDocument2 pagesLockadaptorEOINo ratings yet

- Line Differential Red670Document12 pagesLine Differential Red670Ashish ChughNo ratings yet

- Sylvania Srt2232x Service ManualDocument56 pagesSylvania Srt2232x Service ManualIgnatius ReillyNo ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- Comparison of Flexural Analysis Methodologies: NotesDocument2 pagesComparison of Flexural Analysis Methodologies: Notessukumar bhowmickNo ratings yet

- Subject: Far Limiting Values For Various Material Properties of Ballast As Per Specification (LotDocument1 pageSubject: Far Limiting Values For Various Material Properties of Ballast As Per Specification (Lotsukumar bhowmickNo ratings yet

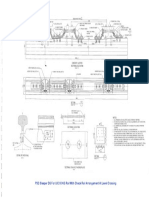

- Drawing of PSC Sleeper For Level X-Ing With UIC 60 KG RailDocument1 pageDrawing of PSC Sleeper For Level X-Ing With UIC 60 KG Railsukumar bhowmickNo ratings yet

- HIV-AIDS Awareness ProgrammeDocument1 pageHIV-AIDS Awareness Programmesukumar bhowmickNo ratings yet

- Handling, Stacking, Shipment and Transporting of RailsDocument1 pageHandling, Stacking, Shipment and Transporting of Railssukumar bhowmickNo ratings yet

- Quality Assurance Plan For TWSDocument1 pageQuality Assurance Plan For TWSsukumar bhowmickNo ratings yet

- Process Flow Chart - Raw MaterialsDocument1 pageProcess Flow Chart - Raw Materialssukumar bhowmickNo ratings yet

- Process Flow Chart - Manufacturing TS: Rejected, Sent Back To SupplierDocument1 pageProcess Flow Chart - Manufacturing TS: Rejected, Sent Back To Suppliersukumar bhowmickNo ratings yet

- Fabricating Tongue RailDocument1 pageFabricating Tongue Railsukumar bhowmickNo ratings yet

- MAPEH 9 2nd Quarter ExamDocument2 pagesMAPEH 9 2nd Quarter ExamLouie Ric Fisco100% (1)

- #Finals #TASK7: Sculpture and Architecture ProjectDocument4 pages#Finals #TASK7: Sculpture and Architecture ProjectMalia LiamNo ratings yet

- A. Choose The Correct Answer by Crossing A, B, C, D, or E!Document15 pagesA. Choose The Correct Answer by Crossing A, B, C, D, or E!Devi Lathean ShabarNo ratings yet

- 5 Building Items 2004-05Document29 pages5 Building Items 2004-05sclbscplNo ratings yet

- Artifact 1 Anjie GbadeboDocument3 pagesArtifact 1 Anjie Gbadeboapi-595116860No ratings yet

- The Ebony TowerDocument5 pagesThe Ebony Towernanasi.tundeNo ratings yet

- STD Visco Pigment PasteDocument40 pagesSTD Visco Pigment PasteRahmah IdrisNo ratings yet

- NullDocument102 pagesNullcaneman85No ratings yet

- Cézanne and Nietzschean BecomingDocument5 pagesCézanne and Nietzschean BecomingJack PattersonNo ratings yet

- From Graffiti To Pixação: Urban Protest in BrazilDocument16 pagesFrom Graffiti To Pixação: Urban Protest in BrazilAna Sánchez TrollietNo ratings yet

- Gagosian Gallery - March 2024Document9 pagesGagosian Gallery - March 2024ArtdataNo ratings yet

- Moffett Forklift m4 20-3-25 3 Spare Parts BookDocument22 pagesMoffett Forklift m4 20-3-25 3 Spare Parts Bookravenlopez130887fbtNo ratings yet

- 2002 ChambersAndSurrealismDocument22 pages2002 ChambersAndSurrealismBailey FensomNo ratings yet

- Cute Lovely Interface by SlidesgoDocument7 pagesCute Lovely Interface by Slidesgotherese angelieNo ratings yet

- Purely Formal PaintingsDocument4 pagesPurely Formal PaintingsArcanus LorreynNo ratings yet

- National Artists in Visual ArtsDocument45 pagesNational Artists in Visual Artseverald ardalesNo ratings yet

- Analysis of Visual Symbols Application in Film and Television Animations CreationDocument3 pagesAnalysis of Visual Symbols Application in Film and Television Animations CreationGiselle Sulijanto 0905055No ratings yet

- Harry Cooper Recognizing GustonDocument33 pagesHarry Cooper Recognizing GustonolocesNo ratings yet

- Republic of The Philippines Commission On Higher Education Region V Polangui Community College Polangui, AlbayDocument3 pagesRepublic of The Philippines Commission On Higher Education Region V Polangui Community College Polangui, AlbayAtahcia AaronNo ratings yet

- Products Price List - Retail - Non - XP - February - 2020 PDFDocument24 pagesProducts Price List - Retail - Non - XP - February - 2020 PDFRahul GantaNo ratings yet

- LaserGRBL A5 M50 PRO EngravingCutting Parameter TableDocument3 pagesLaserGRBL A5 M50 PRO EngravingCutting Parameter TableJuan Diego OspinaNo ratings yet

- Gardners Art Through The Ages A Global History Volume Ii 16Th Edition PDF Full Chapter PDFDocument53 pagesGardners Art Through The Ages A Global History Volume Ii 16Th Edition PDF Full Chapter PDFsafedficaj100% (4)

- Fara Diva Mustapa Department of Quantity Surveying Department of Quantity Surveying, Faculty of Built EnvironmentDocument12 pagesFara Diva Mustapa Department of Quantity Surveying Department of Quantity Surveying, Faculty of Built EnvironmentngjasonNo ratings yet

- National Fluorescent PaintDocument3 pagesNational Fluorescent PaintAghil JoseNo ratings yet

- The Legacy of Herbert Bayer: Recent Gifts and Loans To The Aspen InstituteDocument24 pagesThe Legacy of Herbert Bayer: Recent Gifts and Loans To The Aspen InstituteThe Aspen InstituteNo ratings yet

- Estudo Dos Fundamentos de DesenhoDocument6 pagesEstudo Dos Fundamentos de DesenhoPedro FerreiraNo ratings yet

- PT G9 MapehDocument6 pagesPT G9 MapehAngelo EstreborNo ratings yet

- In An Artists StudioDocument2 pagesIn An Artists Studiopantea1381No ratings yet