Professional Documents

Culture Documents

P.014902-G-21095-M545 - Manjeet Argo FS - 22.10.2020 PDF

P.014902-G-21095-M545 - Manjeet Argo FS - 22.10.2020 PDF

Uploaded by

Khur KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P.014902-G-21095-M545 - Manjeet Argo FS - 22.10.2020 PDF

P.014902-G-21095-M545 - Manjeet Argo FS - 22.10.2020 PDF

Uploaded by

Khur KhanCopyright:

Available Formats

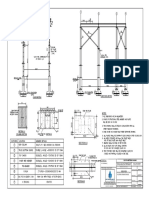

REFERENCE DRAWING

EMERGENCY GATE .23TH. & 1.8M.HIGH LCV UNLOADING S.NO DRAWING TITLE DRAWING NO.

1.2M WIDE BRICK MAS WALL POINT

40000mm

14100 EXAUST PIPE FITTED WITH OPEN AGRI. LAND UPTO 300M. M/S MANJEET ARGO FILLING STATION, PROPOSED LAY-OUT

SPARK ARRESTOR

3000 2600 2500 3000 3000

TOILET DPS PLAN OF FILLING STATION AT KHASRA NO.188, VILL-

FLP FLP

40000mm

900

GEN. ROOM E 1 CHAINA RURIYA, PARGANA & TEHSIL-POWAYAN ON DRG.NO. HPC/LKO

BOOSTER COMPRESSOR E

N F G

ELEC. ROOM LUBE STORE

2250

P V S

3000

3000

450 SCMH ELECTRIC DRIVEN EM O (4.0X3.5M.) NIGOHI - POWAYAN ROAD DIST.- SHAHJAHANPUR

2350

WITH CASCADE ON TOP

FDN. SIZE (4300x2600)

DCP

10KG

L.NO.: P/CC/UP/14/4371(P 127773)

7500mm

.23TH. & 1.8M.HIGH WATER CB

1000 750

850 1000

CO2 FLOODING

BRICK MAS WALL SYSTEM

10300

NOTES

4300

15750mm 8500mm ACCT. DEALER'S OPEN AGRI. LAND

PLATFORM

MOVABLE

12500

DCP

LCV

ROOM SALES 1. ALL DIMENSIONS ARE IN MILLIMETERS AND LEVELS ARE IN METERS.

7000

7Mx3M

10KG ROOM UPTO 300M.

N F G

P V S

ROOM KHASRA NO.188 2. FOLLOW WRITTEN DIMENSIONS ONLY. DO NOT SCALE THE DRAWING.

40000mm

40000mm

m DPS

EM O

3NO.VENT PIPES 4M.HIGH 00m TOILET

CB SITE FOR H.P.C.L.F/S OPEN LAND 3. THE PROPOSED CNG FACILITIES ARE DESIGNED IN ACCORDANCE WITH THE FOLLOWING CODE

3000

4 0

6131mm

V R ELEC ROOM LUBE STORE

& 4M.CLEAR ALL AROUND FLP

UPTO 300M. AND GUIDELINES:

6500mm

E

Y/L WATER CB 3.1. OISD - 226 & OISD 179

AIR

600 1000

2500

COMP. E

2200

ACCT. DEALER'S FLP 3.2. PNGRB GUIDELINES FOR CITY GAS DISTRIBUTION

FLP

ROOM ROOM SALES 4M WIDE GATE E

VIEW OF THE SALES BUILDING

16 K/L MS U/G TANK IN E/PIT KERB WALL 0.25M.

ROOM 1500 1400 3.3. NZS 5425 - 1980

CB (SCALE-1:100)

TH.& 0.30M.HIGH 3.4. GAS CYLINDER RULES - 2016.(GOVT. OF INDIA)

24495

(2.0X5.409M.)APP.CCE.NO.

P-6(3) 60 OF 6/10/2005 1500mm 5100 2500 4000 2500 3.5. GUIDE LINES OF CHIEF CONTROLLER OF EXPLOSIVE.

GROUND FLOOR

m 4. 75 KG, 9.0KG AND 4.5KG DCP FIRE SAFETY EQUIPMENT SHALL BE PLACED AS PER PNGRB

00m SIZE

R40 15750mm

TYPE PLOT B/L PLOT B/L GUIDELINES.

V F IN mm

8000mm

F

D S

Y/L 5. NO ELECTRIC LINE PASSING OVER THE CGS PREMISES.

ELEC.ROOM 3000X2000

6. VENT PIPE SHALL BE 3.0M HIGH FROM NEAREST PLATFORM WITH 5.0M CLEARANCE ALL ROUND.

40000mm

PETROL /DIESEL DECANTATION KM.STONE-16

CANOPY ACCT. ROOM 2115X2680

19000mm

19000mm

POINT4M. CLEAR ALL AROUND E/O HSD PUMP E/O MS PUMP NIGOHI-8KM. 7. SS TUBING SUPPORTING ARRANGEMENT SHALL BE PROVIDED AT EVERY ONE METER (MAX.).

(16X12m.) N F G

22K/L HSD U/G TANK IN E/PIT

P V S

EM O POWAYAN-16KM. P. W. D. O P E N L A N D 8. THE DIMENSIONS OF COMPRESSOR AND OTHER FACILITIES ARE INDICATIVE ONLY SHALL BE

1500mm m LUBE STORE 2580X2815

00m CONFIRMED AS PER VENDOR DRAWINGS. INTERCONNECTION OF STATION PIPING WITH SKID

DCP

(2.25X5.894M.)APP.CCE.NO.P-6 220M.

R40 17000mm

10KG

(3) 60 OF 6/10/2005 V F F

6000mm DEALER'S RM 3600X2810 SHALL BE SUIT TO SITE.

D S 9. ALL CNG EQUIPMENTS LIKE DISPENSER, STORAGE CASCADE AND COMPRESSOR IS CONNECTED

CNG DISPENSOR

2000X2000 TO POWAYAN C.L.OF 4.0M.WIDE ROAD TO NIGOHI

FOUNDATION

22K/L HSD U/G TANK IN E/PIT TOILET

16000mm

BY SS TUBES.

8000mm

6000

2500

(2.25X5.894M.)APP.CCE.NO.P-6

CANOPY

2580X3570 10. FIRE SAFETY EQUIPMENT AND TRAFFIC SIGNS FOR CNG FACILITIES SHALL BE PROVIDED AND

(3) 60 OF 6/10/2005 SALES ROOM

SITE PLAN INSTALLED BY SS TUBING CONTRACTOR.

1500mm E/O DUAL HSD PUMP 1745X900

OPEN LAND UPTO 300M.

WATER (SCALE- 1:500) 11. ALL EXISTING LIGHTING POLES SHOULD BE INSTALLED 6 MTR. AWAY FROM THE CNG EQUIPMENT

00 mm Y/L

R40 7000 1000 1020

8770

LIKE COMPRESSORS, CASCADE & DISPENSER.

V F F

12. THE STATION WILL ACT AS A DBS (DOUGHTER BOOSTER CNG STATION)

D S 17000mm 6000mm 17000mm

13. NO- SMOKING SIGN & EXPLOSIVE LICENCE NUMBER AND THE COPY OF LICENCE SHALL BE

VENT PIPE

A.C.SHEET CONSPICUOUSLY DISPLAYED AT THE FUEL STATION.

7000mm

GIRDER PURLIN 12.0M.

FILL PIPE

DIP PIPE

.65M.

SUCTION PIPE

Y/L

12000mm

P. W. D. CON./ L P. W. D. CON./ L TANK DIA CNG EQUIPMENT DETAILS

GR.LVL.

A.C. PLAIN SHEET S.NO DESCRIPTION QTY. REMARKS

EARTH FILLING

FOR FALSE

3000mm

BOOSTER COMPRESSOR 450 SCMH A) CAPACITY 600 SCMH

3M. WIDE BUFFER STRIP HOLDING DOWN B) INLET PRESSURE 250 TO 14 BARG

Y/L 1 BLOCK SIZE : 4300 X 2600 MM ELECTRIC 01

PLOT B/L PLOT B/L BRACKETS

6.0M.

DRIVEN C) DISCHARGE PRESSURE 255 BARG

1.0M. DIA HUME PIPE COLUMN

H.P.C.L.SIGN CULVERT SAND STATIONARY CASCADE (3000 WL) CAPACITY 3000 WL CONSISTING OF 40

14000mm 12000mm 14000mm RCC BLOCKS 2 01

300

FILLING ON COMPRESSOR TOP CYLINDER OF 75 LITER EACH

75

PCC 1:2:4 BASE PLATE CAPACITY 3000 WL CONSISTING OF 40

23000mm 3 MOBILE CASCADE (3000 WL) 01

OUT RCC STRIP CYLINDER OF 75 LITER EACH

PCC STRIP1:2:4 TANK LENGTH=L DRIVE WAY LVL

RAFT 1:2:4

1.5

IN SEC. ALONG LENGHT

4

1 CAR & 1 CAR/BUS COMBO DISPENSER

02 BODY STAINLESS STEEL

SEC. ALONG DIAMETRE APP.CCE.NO.P-6(3)60 OF 6/10/2005 (Cap.=15 Kg/Min.)

P. W. D. O P E N L A N D APP.CCE.NO.P-6(3)60 OF 6/10/2005 SCALE-N.T.S CANOPY DETAIL

SCALE-N.T.S AS PER IS:2062 GR A, IS:800, IS:1786. 5 CO2 01 4.5Kg Co2 INSIDE ELECTRICAL ROOM

(N.T.S.)

10KgFORCNGDS

I PENSER1,0KGFOR

6 FIRE EXTINGUISHER/DCP 03

19000mm COMPRESSOR&10KGFORMOBL IECASCADE

7 AIR COMPRESSOR (FDN. SIZE 1400x600) 01 51

.CFMW

,P

.1.0Kgc/m2g

CO2 FLOODING SYSTEM

R21994mm

40mm DIA DIP PIPE 40mm DIA SUCTION PIPE

8 01 -

38mm DIA VENT (FDN. SIZE 1000x1000)

TO NIGOHI 65mm DIA FILL PIPE PIPE 4M.HIGH

4000mm

C.L.OF 4.0M.WIDE POWAYAN-NIGOHI ROAD GROUND LEVEL

600mm

TO POWAYAN

LEGEND

2260mm

LAY OUT PLAN M.S.PLATE N - ``NO SMOKING" SIGN

(SCALE- 1:200) 100mm GAP.

F - ``NO OPEN FLAME PERMITTED" SIGN

5590mm FOR 16 KL

G - ``FLAMMABLE GAS" SIGN

6009mm

DETAILS OF U/G TANK V - STOP VEHICLE SIGN

(CAPACITY:22KL & 16KL)(N.T.S.)

3000WL STORAGE CASCADE S - SAND BUCKET STAND

3000WL STORAGE CASCADE INTER DISTANCES BETWEEN VARIOUS FACILITIES OF E - EARTHING PIT

NATURAL GAS HANDLING AT INSTALLATION (OISD-STD-179) M - "NO MOBILE PHONE" SIGN

1 2 3 4 5 6 7

1520

1520

- FLAME PROOF LIGHT

SFRC PRECAST COVER

VENT

150

AS PER SPECIFICATION

S. NO. FACILITIES CNG OUTER O - "SWITCH OFF THE MOBILE PHONES" SIGN

CNG STORAGE MS/HSD OFMS/HSD U/G FILLING POINT

150 450 150 DISPENSING BOUNDARY

TOP OF PAVEMENT COMPRESSOR CASCADE DISPENSER STORAGE OF MS/HSD

UNIT WALL/CLF

1250

1250

TANK P - SIGN SHOWING DETAILED PRECAUTIONS PROCEDURE OF REFUELLING.

AS PER OISD - 3.0M 2.0M 3.0M 6.0M 6.0M T1 (MIN.- 3) CO 2

CNG - CO2 FIRE EXTINGUISHER 4.5kg

100 75 75 75 125 1

EQ

100x100x8 THK. COMPRESSOR ACTUAL - 16.0M 2.5M 3.0M 16.0M 24.0M 25.0M

600

INSERT PLATE D.C.P. 10 Kg - DRY CHEMICAL POWDER

2300

@ 1000 c/c CNG AS PER OISD 3.0M - 2.0M 4.0M 6.0M 4.0M T1 (MIN.- 3)

EQ

2 DISPENSING

UNIT ACTUAL 16.0M - 16.0M 8.5M 7.0M 25.0M 25.0M

150

75(TYP)

AS PER OISD 2.0M 2.0M - T1 T1 (MIN.- 6) T1 (MIN.- 4) T1 (MIN.- 3) PROPOSED FACILITIES

COMPRESSOR COMPRESSOR STORAGE

300

FOUNDATION FOUNDATION 3

CASCADE ACTUAL 2.5M 16.0M - 3.0M 16.0M 27.0M 27.0M

75 THK PCC 1:4:8 EXISTING FACILITIES

ISA 50x50x6 @ 1000 c/c WELDED

SS TUBING (TYP) WITH INSERT PLATE OUTER AS PER OISD 3.0M 4.0M T1 - 6.0M 4.0M T1 (MIN.- 3)

2200 3400 4 BOUNDARY EXISTING FACILITIES DEMOLISH

SECTION X-X

WALL/CLF ACTUAL 3.0M 8.5M 3.0M - 17.0M 4.0M 6.0M

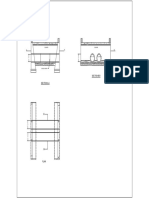

COMPRESSOIR SIDE VIEW COMPRESSOIR ELEVATION VIEW 450 WIDE SS TUBE TRENCH DETAIL

T1 (MIN.- 6) T1 (MIN.- 3)

This document is the property of TRACTEBEL ENGINEERING INDIA, any duplication or transmition to third parties is forbidden without its prior approval.

MS/HSD AS PER OISD 6.0M 6.0M 6.0M - 6.0M

5

DISPENSER ACTUAL 16.0M 7.0M 16.0M 17.0M - 13.0M 12.0M ISSUED FOR PESO APPROVAL

VENT OFMS/HSD AS PER OISD 6.0M 4.0M T1 (MIN.- 4) 4.0M 6.0M - 6.0M

6 U/G STORAGE

TANK ACTUAL 24.0M 25.0M 27.0M 4.0M 13.0M - *

AS PER OISD T1 (MIN.- 3) T1 (MIN.- 3) T1 (MIN.- 3) T1 (MIN.- 3) T1 (MIN.- 3) 6.0M *

FILLING POINT

7

GALVANISED BARBED WIRE OF MS/HSD ACTUAL 25.0M 25.0M 27.0M 6.0M 12.0M * -

600

ISA 50x50X6

COPING IN CC 1:2:4

50

75

SUPPORT

NOTES:-

VENT PIPE 0 22.10.2020 ISSUED FOR APPROVAL JV KK SME KNS

BRICK MASONRY IN CM 1:6

THREE WAY

1) ALL DIMENSION ARE IN MM EXCEPT OTHERWISE STATED.

2) NUMBER OF ILUMINATION POLES ARE TENTATIVE. Rev. D M Y Modifications Drawn Checked Approved Validated

VALVE

QUICK CONNECTOR

2000

230 3) UNDERGROUND PIPELINES SHALL RUN THROUGH HUME PIPE SLEEVES OF 150DIA.

GAP CUSTOMER

EXPANSION PRIORITY BOX CONFIRMATION:- HINDUSTAN PETROLEUM CORPORATION LTD.

EXISTING FLOOR RAILING

FGL 3000 1) VENT PIPE SHALL BE 4.0M HIGH WITH 4.0M CLEARANCE ALLAROUND. THE VENT SUBJECT

HOOD SHALL BE COVERED WITH 2 LAYERS OF NON CORROSIVE METAL MESH (11 MESH/SQ. CM). PLOT PLAN OF CNG FILLING STATION (DBS/ONLINE)

2) FILL OR EXTENDED FILL POINT SHALL HAVE 4.0M CLEARANCE ALL AROUND. M/S MANJEET ARGO FILLING STATION

3) 4 NOS. OF 9KG. CAPACITY DRY CHEMICHAL POWDER TYPE FIRE EXTINGUISHERS.

DISTT. - SHAJAHANPUR (U.P.)

250

345 STEEL 4) 4 NOS. OF FIRE BUCKETS FILLED WITH DRY SAND SHALL BE PROVIDED AT

TOP OF STAIR SUITABLE Size Scale Sheet Rev.

AS PER STRUCTURAL DESIGN PAVEMENT

7000 LOCATION AS PER CONDITION 20 OF LICENCE FORM XIV.

CROSS SECTION OF MOBILE CASCADE

5) DPS BOARD SHALL BE MIN. 1.5M ABOVE FLOOR LEVEL. A1 1:200 1 of 1 0

TYPICAL BOUNDARY WALL MOBILE CASCADE ELEVATION MOBILE CASCADE 6) NO-SMOKING SIGN & EXPLOSIVE LICENSE NUMBER AND THE COPY OF LICENCE Project No. Discipline Code System Code Serial No.

SECTION AROUND CNG PREMISES (MEDIUM/LIGHT COMMERCIAL VECHILE REAR ELEVATION LOADING/ DECANTING POINT

SHALL BE CONSPICUOUSLY DISPLAYED AT THE FUEL STATION.

TRACTEBEL Engineering pvt. ltd. P.014902 G 21095 M545

You might also like

- Wa0011Document578 pagesWa0011raghavendramuthuru100% (1)

- Jonathan's Last Day: Reading Comprehension QuizDocument3 pagesJonathan's Last Day: Reading Comprehension QuizLoja Vtr43% (7)

- MonkDocument121 pagesMonkCindy Yusseny Ayala MenjivarNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFIraj Farooq100% (1)

- Cover SheetDocument13 pagesCover Sheetsudipta mandalNo ratings yet

- Box Culvert 2X2Document6 pagesBox Culvert 2X2abhishek singhNo ratings yet

- Culvert Design NewDocument67 pagesCulvert Design NewsheikNo ratings yet

- Bus Shelter Assembly 15' Revised-1 PDFDocument1 pageBus Shelter Assembly 15' Revised-1 PDFsamirbendre1No ratings yet

- Summary Sheet: E-Tender Specification No: BHE/PW/PUR/URI-CIVIL/2328Document19 pagesSummary Sheet: E-Tender Specification No: BHE/PW/PUR/URI-CIVIL/2328rajNo ratings yet

- Submitted For Approval Information Reference Record ConstructionDocument25 pagesSubmitted For Approval Information Reference Record ConstructionRana BiswasNo ratings yet

- Project: Rev. Drawing No. Client: Authority Engineer:: Roads & Buildings DepartmentDocument2 pagesProject: Rev. Drawing No. Client: Authority Engineer:: Roads & Buildings DepartmentNilay GandhiNo ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- 60 MTR Bow String Girder: S.No Description Items Diamansions Sub Qty Total Qty L W T 1Document4 pages60 MTR Bow String Girder: S.No Description Items Diamansions Sub Qty Total Qty L W T 1Vinay VaishlaNo ratings yet

- NH 16 To Venkatrao PalliDocument91 pagesNH 16 To Venkatrao PallilardhanNo ratings yet

- Drawing of Chimney Frame PDFDocument1 pageDrawing of Chimney Frame PDFsridharNo ratings yet

- North Western Railway: Sr. Den (Co) /JP CBE....... JPDocument1 pageNorth Western Railway: Sr. Den (Co) /JP CBE....... JPEr Navneet JassiNo ratings yet

- Drop ManholeDocument1 pageDrop ManholeorganicspolybondNo ratings yet

- Retaining Wall U Wall Type Estimate With Box PushingDocument8 pagesRetaining Wall U Wall Type Estimate With Box PushingApurva ParikhNo ratings yet

- Bus Shelter - Option 3Document1 pageBus Shelter - Option 3Manish KapadneNo ratings yet

- BERKHEDA PUMP HOUSE FINAL-ModelDocument1 pageBERKHEDA PUMP HOUSE FINAL-ModelvishalNo ratings yet

- Bar Bending Schedule For Box Culverts at CH: 128+820 For Service Road Total Length 40.092mDocument4 pagesBar Bending Schedule For Box Culverts at CH: 128+820 For Service Road Total Length 40.092mIrfan PatahnNo ratings yet

- Pricelist-Tubes & ValvesDocument39 pagesPricelist-Tubes & ValvesHKRajesh100% (1)

- Section Properties: Properties of Tata Structura (Circular Hollow Sections) YST 310 GradeDocument1 pageSection Properties: Properties of Tata Structura (Circular Hollow Sections) YST 310 GradeZankar R ParikhNo ratings yet

- GA DRAWING OF SHOT BLAST SHED DRAWING-Layout1Document1 pageGA DRAWING OF SHOT BLAST SHED DRAWING-Layout1harish gowdaNo ratings yet

- R1Document76 pagesR1Ashish GNo ratings yet

- DBM Mould Casting Indivisual Weights: Sample Weights Sample WeightsDocument104 pagesDBM Mould Casting Indivisual Weights: Sample Weights Sample Weightspujan patelNo ratings yet

- Is SP 34 1987Document19 pagesIs SP 34 1987ankitNo ratings yet

- Is.14946.2001 Zinc Content in Paint Film PDFDocument17 pagesIs.14946.2001 Zinc Content in Paint Film PDFajayukarandeNo ratings yet

- Abutment: W Ing W AllDocument2 pagesAbutment: W Ing W AllRam Prasad Awasthi100% (1)

- B. Super Impose Load Due To WaterDocument2 pagesB. Super Impose Load Due To WaterMohanSharmaNo ratings yet

- Longitudinal Section: Drain From Alok Nagar To ManikpurDocument9 pagesLongitudinal Section: Drain From Alok Nagar To ManikpurDipankarHaloiNo ratings yet

- SLRB 70Document1 pageSLRB 70Anonymous oVmxT9Kzrb100% (1)

- 001.gad Bow String Steel Bridge 200 M SpanDocument1 page001.gad Bow String Steel Bridge 200 M SpanManvendra NigamNo ratings yet

- RRM Breast Wall Drawings (1.5M To 4M)Document2 pagesRRM Breast Wall Drawings (1.5M To 4M)Yovan BaggaNo ratings yet

- RCC Corrosion PDFDocument126 pagesRCC Corrosion PDFPreitee Ranjan PradhanNo ratings yet

- 1.3 B-002 - Master Template With MedianDocument6 pages1.3 B-002 - Master Template With MediankanagarajodishaNo ratings yet

- 2x2 Box CulvertDocument5 pages2x2 Box CulvertRE Solar AdaniNo ratings yet

- 1X3X3 WITH 2.5 M Cast-In-situDocument56 pages1X3X3 WITH 2.5 M Cast-In-situGajendra BishtNo ratings yet

- Bar Bending Schedule (BBS) Project Name:-For A2 Abutment Cap at Br. No. 1282/1 (R1)Document6 pagesBar Bending Schedule (BBS) Project Name:-For A2 Abutment Cap at Br. No. 1282/1 (R1)sonuNo ratings yet

- Schedules A To DDocument146 pagesSchedules A To DAnonymous x7VY8VF7No ratings yet

- Zn-Al Tank-175kL Design 12M STAGING - SMTDocument63 pagesZn-Al Tank-175kL Design 12M STAGING - SMTRajendra MittalNo ratings yet

- 36 MTR SpanDocument13 pages36 MTR SpanAnonymous sfkedkymNo ratings yet

- 2.isolated FootingsDocument47 pages2.isolated Footingsjuliyet strucNo ratings yet

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocument6 pagesAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNo ratings yet

- Cost Estimate of WarehouseDocument16 pagesCost Estimate of WarehouseAnil SuryawanshiNo ratings yet

- Summary Safe of Structural Design of Box and WallDocument7 pagesSummary Safe of Structural Design of Box and WallRatul PalodhiNo ratings yet

- Aor Cantilever 6m SignDocument6 pagesAor Cantilever 6m SignDaljit624No ratings yet

- ADMIN BLDG - Design Calculations PDFDocument96 pagesADMIN BLDG - Design Calculations PDFEr.Ruchik SoniNo ratings yet

- Drainage SpoutDocument2 pagesDrainage SpoutSunil KumarNo ratings yet

- Wall DesignFi PDFDocument4 pagesWall DesignFi PDFKathiravan26926190100% (1)

- LTA-SDRE14-6-VIG5 (A) Vehicular Impact Guardrails - Thrie-Beam Transition PDFDocument1 pageLTA-SDRE14-6-VIG5 (A) Vehicular Impact Guardrails - Thrie-Beam Transition PDFNURLINURLINDANo ratings yet

- Culvert DrawingDocument1 pageCulvert DrawingANKESH SHRIVASTAVANo ratings yet

- Bus-Shelter nh86 PDFDocument5 pagesBus-Shelter nh86 PDFVipinSahuNo ratings yet

- Rev - Design 125 - MergedDocument23 pagesRev - Design 125 - MergedTamil Arasu SNo ratings yet

- Practice BBS As Per MOST&HDocument1 pagePractice BBS As Per MOST&HHegdeVenugopalNo ratings yet

- CRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFDocument28 pagesCRJGR Aayu STS Inf S2.0 CNS RTW 00004C CC 22 11 PDFHazim AffendiNo ratings yet

- VVVMC Ring Road Rob Structural Quantities NalasoparaDocument4 pagesVVVMC Ring Road Rob Structural Quantities Nalasoparasamirbendre1No ratings yet

- Box3 x2Document46 pagesBox3 x2veevimalNo ratings yet

- Revision 3 Methodology & AP Design - Balaji - Ludhiana-MinDocument38 pagesRevision 3 Methodology & AP Design - Balaji - Ludhiana-MinHemant Yesaji100% (1)

- Bar Bending Schedule - RCC Slab NewDocument10 pagesBar Bending Schedule - RCC Slab NewGourav SachdevaNo ratings yet

- FINAL Bandist Prekshagarh - 26 FEBDocument1 pageFINAL Bandist Prekshagarh - 26 FEBSUMEET PATILNo ratings yet

- Re Wall Panel Re Wall Panel: Hill Side Hill SideDocument1 pageRe Wall Panel Re Wall Panel: Hill Side Hill SidekanagarajodishaNo ratings yet

- Mini-C Exchange ID String - Rev - C PDFDocument4 pagesMini-C Exchange ID String - Rev - C PDFGeta EnacheNo ratings yet

- Role of Open Surgical Drainage or Aspiration in Management of Amoebic Liver AbscessDocument9 pagesRole of Open Surgical Drainage or Aspiration in Management of Amoebic Liver AbscessIJAR JOURNALNo ratings yet

- 1 MobilePass VPNDocument8 pages1 MobilePass VPNYashpal SinghNo ratings yet

- Modul 9 B Inggris Kelas 4 - KD 3.9 - 4.9 PDFDocument16 pagesModul 9 B Inggris Kelas 4 - KD 3.9 - 4.9 PDFFendi SetiyantoNo ratings yet

- CCR Load Calculator 2014-03-13Document41 pagesCCR Load Calculator 2014-03-13Yahya AlkaffNo ratings yet

- PCK303 Understanding The Lesson 9Document2 pagesPCK303 Understanding The Lesson 9Japhet BagsitNo ratings yet

- Facility Preventive Maintenance ChecklistDocument5 pagesFacility Preventive Maintenance ChecklistFaisalNo ratings yet

- Osek Os: Session Speaker Deepak VDocument60 pagesOsek Os: Session Speaker Deepak VDaour DiopNo ratings yet

- Bannari Amman Institute of Technology Department of Information TechnologyDocument7 pagesBannari Amman Institute of Technology Department of Information Technologyinvincible_shalin6954No ratings yet

- SCS Method PDFDocument55 pagesSCS Method PDFWesley BridgemohansinghNo ratings yet

- An Argument For Working Capital AdjustmentsDocument4 pagesAn Argument For Working Capital AdjustmentschristianNo ratings yet

- New Text DocumentDocument24 pagesNew Text DocumentGledajte Kod NasNo ratings yet

- Full Download Test Bank For Workshop Statistics Discovery With Data 4th Edition Allan J Rossman Beth L Chance PDF Full ChapterDocument36 pagesFull Download Test Bank For Workshop Statistics Discovery With Data 4th Edition Allan J Rossman Beth L Chance PDF Full Chapterpithsomeknockingsawv100% (24)

- Triangular Sum Labeling NEWDocument33 pagesTriangular Sum Labeling NEWMurugananthamParamasivamNo ratings yet

- SACH Tooth Brush - Launch Docket PDFDocument13 pagesSACH Tooth Brush - Launch Docket PDFSami ShaikhNo ratings yet

- Neyhns: Eticket ItineraryDocument3 pagesNeyhns: Eticket Itineraryadi saputraNo ratings yet

- LEFORT, Claude. Thinking With and Against Hannah ArendtDocument14 pagesLEFORT, Claude. Thinking With and Against Hannah ArendtGabriel VecchiettiNo ratings yet

- Lección 11 - How MuchDocument4 pagesLección 11 - How Muchyo no fuiNo ratings yet

- KVT FP Quick Fasteners en 21-03-2013 WebDocument16 pagesKVT FP Quick Fasteners en 21-03-2013 WebWK SinnNo ratings yet

- Responsibility AccountingDocument14 pagesResponsibility AccountingJignesh TogadiyaNo ratings yet

- Pexip Infinity Microsoft Teams Deployment Guide V31.aDocument111 pagesPexip Infinity Microsoft Teams Deployment Guide V31.asaqer_11No ratings yet

- Fussion3000 MackieDocument8 pagesFussion3000 MackieMarco BruceNo ratings yet

- Cost Effective Housing PDFDocument16 pagesCost Effective Housing PDFSaurav ShresthaNo ratings yet

- 01 August 2023 - Manifest Boat Babo - LNGDocument1 page01 August 2023 - Manifest Boat Babo - LNGSeverinus SHIPBintuniNo ratings yet

- Answer:: Free Exam/Cram Practice Materials - Best Exam Practice MaterialsDocument3 pagesAnswer:: Free Exam/Cram Practice Materials - Best Exam Practice MaterialsAmine BoubakeurNo ratings yet

- Mistibushi Servo Drive PDFDocument350 pagesMistibushi Servo Drive PDFnitin hadkeNo ratings yet

- Atkins Diet MenuDocument6 pagesAtkins Diet MenuSohaila KhaledNo ratings yet

- Gs This That Those - ExercisesDocument2 pagesGs This That Those - ExercisesWilvertein C ChambiNo ratings yet