Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 views7.4. Plasticity Modeling: Softening Behavior 383

7.4. Plasticity Modeling: Softening Behavior 383

Uploaded by

ahmed shakerThis document discusses different material behaviors that can be exhibited in stress-strain diagrams, including elastic-plastic behavior, progressively fracturing behavior, and combined plastic-fracturing behavior. It focuses on the strain-softening behavior of concrete in compression, which exhibits plastic-fracturing characteristics. The document considers modeling this softening behavior using strain-space plasticity formulations and examines the limitations of interpreting fracturing solely as plastic flow.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Dynamic Models For Structural Plasticity (1993)Document296 pagesDynamic Models For Structural Plasticity (1993)Alem LoajnerNo ratings yet

- BA USi Safety - ENDocument107 pagesBA USi Safety - ENAditya Arun KumarNo ratings yet

- Bilinear Isotropic Hardening BehaviorDocument7 pagesBilinear Isotropic Hardening BehaviorricardoborNo ratings yet

- 240concrete Damaged Plasticity)Document19 pages240concrete Damaged Plasticity)netkasiaNo ratings yet

- Program A Cao Nao LinearDocument5 pagesProgram A Cao Nao LinearJerfsonLimaNo ratings yet

- Plasticity-Failure Theories Lecture NotesDocument12 pagesPlasticity-Failure Theories Lecture Noteszaheer50% (2)

- Plasticity Failure Theories Lecture Notes PDFDocument12 pagesPlasticity Failure Theories Lecture Notes PDFVeli YılmazNo ratings yet

- Beigelzimer (1994) Continuum Model of The Structural-Inhomogeneous Porous Body and Its Application For The Study of Stability and Viscous FractureDocument12 pagesBeigelzimer (1994) Continuum Model of The Structural-Inhomogeneous Porous Body and Its Application For The Study of Stability and Viscous FractureЯн БейгельзимерNo ratings yet

- Assal 4Document4 pagesAssal 4Endarto Mas EndNo ratings yet

- Assal 5Document5 pagesAssal 5Endarto Mas EndNo ratings yet

- Damaged Plasticity Model For ConcreteDocument13 pagesDamaged Plasticity Model For ConcretehityouNo ratings yet

- Benchmark Experiments and Characteristic Cyclic Plasticity DeformationDocument35 pagesBenchmark Experiments and Characteristic Cyclic Plasticity DeformationOmar Al-AbriNo ratings yet

- CDP - AbaqusDocument16 pagesCDP - AbaqusClaudio PazNo ratings yet

- InTech-Phenomenological Modelling of Cyclic PlasticityDocument28 pagesInTech-Phenomenological Modelling of Cyclic Plasticitydroessaert_stijnNo ratings yet

- Das 3DPlasticityModelSandySoils ACCM 2013Document7 pagesDas 3DPlasticityModelSandySoils ACCM 2013fatima ezzahraa latifiNo ratings yet

- Edited Bubble ModelDocument12 pagesEdited Bubble ModelEva SmithNo ratings yet

- New Bubble ModelDocument12 pagesNew Bubble ModelEva SmithNo ratings yet

- Edited Bubble ModelDocument12 pagesEdited Bubble ModelEva SmithNo ratings yet

- Basic Computational PlasticityDocument40 pagesBasic Computational PlasticityadnanhasanovicNo ratings yet

- Using The Hollomon Model To Predict Strain-Hardening in MetalsDocument4 pagesUsing The Hollomon Model To Predict Strain-Hardening in MetalsGuilherme ResendeNo ratings yet

- Material Behaviour For Material ModelsDocument3 pagesMaterial Behaviour For Material ModelsmercilessturkNo ratings yet

- Jimma Institute of Technology: Product Design Mechanical PropertiesDocument26 pagesJimma Institute of Technology: Product Design Mechanical PropertiesfayzaNo ratings yet

- EMTL 250 Module 2 2017Document27 pagesEMTL 250 Module 2 2017Mwongera MwaraniaNo ratings yet

- Plastic Analysis of Framed StructuresDocument65 pagesPlastic Analysis of Framed Structuresgirma kebedeNo ratings yet

- Viscoelasticity 01 IntroDocument4 pagesViscoelasticity 01 IntroJohn Mario CanroNo ratings yet

- 08 Plasticity 01 IntroductionDocument11 pages08 Plasticity 01 Introductionabhi16No ratings yet

- Visco Plasticity WikipediaDocument14 pagesVisco Plasticity WikipediaKresimir TrdakNo ratings yet

- CH 12Document64 pagesCH 12LeonardoMadeira11No ratings yet

- Plastic Hinge Analysis ReviewDocument16 pagesPlastic Hinge Analysis Reviewscience ResearchNo ratings yet

- Superficies RupturaDocument10 pagesSuperficies Rupturaf_tavares225No ratings yet

- Mechanical Properties of Materials NotesDocument28 pagesMechanical Properties of Materials NotesMat MatttNo ratings yet

- Introduction of PlasticityDocument11 pagesIntroduction of PlasticityYang LuNo ratings yet

- 08 Plasticity CompleteDocument85 pages08 Plasticity CompleteSebastiao SilvaNo ratings yet

- 08 Plasticity 01 Introduction PDFDocument11 pages08 Plasticity 01 Introduction PDFAmmar A. AliNo ratings yet

- Plasticity Complete PDFDocument85 pagesPlasticity Complete PDFMISBAH UL HAQUENo ratings yet

- Nazim Cad 8Document5 pagesNazim Cad 8Shrinish VhanbatteNo ratings yet

- A Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Document25 pagesA Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Melete GashawNo ratings yet

- 2019 DSSIMULIA - Established - An Inelastic Constitutive Model For ConcreteDocument10 pages2019 DSSIMULIA - Established - An Inelastic Constitutive Model For ConcretePhan Đào Hoàng HiệpNo ratings yet

- Assal 6Document6 pagesAssal 6Endarto Mas EndNo ratings yet

- Research Progress in Modelling of Ageing Viscoelastic Properties Cement PasteDocument14 pagesResearch Progress in Modelling of Ageing Viscoelastic Properties Cement PastepoornimNo ratings yet

- Explicit Modeling of Damping of A Single-Layer Latticed Dome With Isolation System (Zhang, Et Al. 2014)Document12 pagesExplicit Modeling of Damping of A Single-Layer Latticed Dome With Isolation System (Zhang, Et Al. 2014)Jose ManuelNo ratings yet

- Executive Summary: Simplified Methods For Analysis of Response To Dynamic LoadingDocument1 pageExecutive Summary: Simplified Methods For Analysis of Response To Dynamic LoadingwearplayNo ratings yet

- Module 1 Theory of PlasticityDocument20 pagesModule 1 Theory of Plasticityxavier sethuNo ratings yet

- ECE 4215 Lecture 4Document22 pagesECE 4215 Lecture 4dantezNo ratings yet

- Rigid Origami Structures With Vacuumatics: Geometric ConsiderationsDocument8 pagesRigid Origami Structures With Vacuumatics: Geometric ConsiderationsUsuario2000No ratings yet

- NormalityDocument1 pageNormalitynetname1No ratings yet

- Material Engineering Lecture 3Document5 pagesMaterial Engineering Lecture 3Mohannad OrabiNo ratings yet

- SVT Collge of Engg. Structure II Lecture Notes..1245Document38 pagesSVT Collge of Engg. Structure II Lecture Notes..1245Shams KhattakNo ratings yet

- A.Mechanical Properties of Engineering Materials: F/A F/ADocument11 pagesA.Mechanical Properties of Engineering Materials: F/A F/AsrknotesNo ratings yet

- Assal 8Document8 pagesAssal 8Endarto Mas EndNo ratings yet

- Fully Plastic + ElastoplasticDocument19 pagesFully Plastic + ElastoplasticMilad RadNo ratings yet

- International Journal of Solids and Structures: A. Edalat Behbahani, J.A.O. Barros, A. Ventura-GouveiaDocument21 pagesInternational Journal of Solids and Structures: A. Edalat Behbahani, J.A.O. Barros, A. Ventura-GouveiaEngr Aizaz AhmadNo ratings yet

- Modelling of The Hysteretic Behaviour of Buckling Restrained BracesDocument8 pagesModelling of The Hysteretic Behaviour of Buckling Restrained BracesCristian Camilo Martinez JimenezNo ratings yet

- 1 D Plasticity by Louie L. YawDocument25 pages1 D Plasticity by Louie L. YawshakibbrNo ratings yet

- Pavement Materials KJJDocument44 pagesPavement Materials KJJAlfred KameyaNo ratings yet

- Stress Strain Curve ExampleDocument8 pagesStress Strain Curve ExampleRayhan saiaf binNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- 482 8. General Theorems of Limit Analysis and Their ApplicationsDocument1 page482 8. General Theorems of Limit Analysis and Their Applicationsahmed shakerNo ratings yet

- 588 9. Limit Analysis of Engineering Struetures: - Size - PrismDocument1 page588 9. Limit Analysis of Engineering Struetures: - Size - Prismahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-325 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-325 PDFahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-562Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-562ahmed shakerNo ratings yet

- 9.5. Limit Analysis of Plates 527: 4 y !4 XY !4 YxDocument1 page9.5. Limit Analysis of Plates 527: 4 y !4 XY !4 Yxahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers 1988-119 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers 1988-119 PDFahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-260Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-260ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-384Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-384ahmed shakerNo ratings yet

- 8.6. Example Problems in Plane Stress, Plane Strain, and 3-D 475Document1 page8.6. Example Problems in Plane Stress, Plane Strain, and 3-D 475ahmed shakerNo ratings yet

- 394 7. Implementation in Concretes: Stress and Strain IncrementsDocument1 page394 7. Implementation in Concretes: Stress and Strain Incrementsahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-485Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-485ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-472Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-472ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-318Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-318ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-454Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-454ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-531Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-531ahmed shakerNo ratings yet

- 156 3. Elastic Stress-Strain Relations: T (KenDocument1 page156 3. Elastic Stress-Strain Relations: T (Kenahmed shakerNo ratings yet

- Kinematic Hardening Case (Fig. 1.9 (Ii) ) : The Yield Stress at Point B IsDocument1 pageKinematic Hardening Case (Fig. 1.9 (Ii) ) : The Yield Stress at Point B Isahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-489Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-489ahmed shakerNo ratings yet

- (V) - (1 - 0) (JL) J: 6.6. Bounding Surface Theory 325Document1 page(V) - (1 - 0) (JL) J: 6.6. Bounding Surface Theory 325ahmed shakerNo ratings yet

- B K Constrained Modulus.: 4.9. Prandtl-Reuss Material Model (12 Theory) 213 ADocument1 pageB K Constrained Modulus.: 4.9. Prandtl-Reuss Material Model (12 Theory) 213 Aahmed shakerNo ratings yet

- 2.1.6. Octahedral Stresses: 2.1. Stress 59Document1 page2.1.6. Octahedral Stresses: 2.1. Stress 59ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-70Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-70ahmed shakerNo ratings yet

- (Un, SN) (Un (2.102) (Un, SN) A'B' N N (Un, SN) (Un, SN) D'. A'B'Document1 page(Un, SN) (Un (2.102) (Un, SN) A'B' N N (Un, SN) (Un, SN) D'. A'B'ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-39 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-39 PDFahmed shakerNo ratings yet

- Pair of Linear Equations in Two Variables PDFDocument7 pagesPair of Linear Equations in Two Variables PDFVrushab MNo ratings yet

- X Maths KS Sample Paper 12Document6 pagesX Maths KS Sample Paper 12Mukul SinghNo ratings yet

- UNIT III Beta Gamma FunctionsDocument27 pagesUNIT III Beta Gamma FunctionsSatuluri Satyanagendra RaoNo ratings yet

- Hall Effect SensorDocument3 pagesHall Effect SensorUli LolexNo ratings yet

- BASF Rheology Modifiers Product Recomendation (Europe)Document1 pageBASF Rheology Modifiers Product Recomendation (Europe)Akshai RedwalkerNo ratings yet

- 09 Christensen NCHRP09-59updateDocument41 pages09 Christensen NCHRP09-59updates pradhanNo ratings yet

- Design Experiment (Experiment Number) : (Title) : (Name of Group Members Separated by Commas. (Given Name M.I. Surname) )Document3 pagesDesign Experiment (Experiment Number) : (Title) : (Name of Group Members Separated by Commas. (Given Name M.I. Surname) )MA. CARMELA BEATRIZ SACDALANNo ratings yet

- Bolt Preloading and DesignDocument10 pagesBolt Preloading and DesignDianna LambertNo ratings yet

- Introduction To Earthquake EngineeringDocument4 pagesIntroduction To Earthquake EngineeringAjay AjaiNo ratings yet

- Activity 6 Product Disassembly ChartDocument5 pagesActivity 6 Product Disassembly Chartapi-504977947No ratings yet

- FM Lab 1Document3 pagesFM Lab 1Waleed NasirNo ratings yet

- Evaluation of The Particle Sizes of Four Clay Minerals Tan2016Document12 pagesEvaluation of The Particle Sizes of Four Clay Minerals Tan2016Laura Ximena Giraldo100% (1)

- Evacuation Center (Design of Beam2)Document35 pagesEvacuation Center (Design of Beam2)jerick calingasanNo ratings yet

- Process Dynamic and Control 1Document30 pagesProcess Dynamic and Control 1Ankushkumar MaliNo ratings yet

- Circuit Theory: Report BigprojectDocument10 pagesCircuit Theory: Report BigprojectVũ Hoàng LongNo ratings yet

- Oct New Normal Accomplishment Report Copy 2Document2 pagesOct New Normal Accomplishment Report Copy 2Joseph Gerson BalanaNo ratings yet

- Questions To Accompany The Viewing of NOVA's "Hunting The Hidden Dimension" Video.Document1 pageQuestions To Accompany The Viewing of NOVA's "Hunting The Hidden Dimension" Video.npriccaNo ratings yet

- Types of Beam-Restricting Devices: 1. Aperture DiaphragmsDocument5 pagesTypes of Beam-Restricting Devices: 1. Aperture DiaphragmsRachelle Dela Rosa100% (2)

- Basic Simulation LabDocument3 pagesBasic Simulation LabGautam KumarNo ratings yet

- Jan-2020 MS (P2 M1)Document18 pagesJan-2020 MS (P2 M1)Syed Aziz HaiderNo ratings yet

- Black Board Problems For JEE Advanced Set-8Document7 pagesBlack Board Problems For JEE Advanced Set-8DikshantNo ratings yet

- SFA-Vessels Guide E-Oct17Document35 pagesSFA-Vessels Guide E-Oct17flcwkNo ratings yet

- Gauss-Codazzi EquationsDocument5 pagesGauss-Codazzi EquationsaguiNo ratings yet

- Checklist Pavement AnalysisDocument2 pagesChecklist Pavement Analysisp.v.n. lakshmanNo ratings yet

- All Stainless Steel Pressure Gauges With Bourdon TubeDocument2 pagesAll Stainless Steel Pressure Gauges With Bourdon TubetitiNo ratings yet

- Lesson 5 - Models of CommunicationDocument9 pagesLesson 5 - Models of CommunicationJessica Cabildo CalbanNo ratings yet

- The Value of Surface Tension of A Liquid at Critical Temperature IsDocument10 pagesThe Value of Surface Tension of A Liquid at Critical Temperature Issagarchidre114No ratings yet

- Dgca Module 06 Part 07Document14 pagesDgca Module 06 Part 07Gaurav SinghNo ratings yet

- Why Do We Study Physics - Socratic PDFDocument1 pageWhy Do We Study Physics - Socratic PDFMon LuffyNo ratings yet

7.4. Plasticity Modeling: Softening Behavior 383

7.4. Plasticity Modeling: Softening Behavior 383

Uploaded by

ahmed shaker0 ratings0% found this document useful (0 votes)

14 views1 pageThis document discusses different material behaviors that can be exhibited in stress-strain diagrams, including elastic-plastic behavior, progressively fracturing behavior, and combined plastic-fracturing behavior. It focuses on the strain-softening behavior of concrete in compression, which exhibits plastic-fracturing characteristics. The document considers modeling this softening behavior using strain-space plasticity formulations and examines the limitations of interpreting fracturing solely as plastic flow.

Original Description:

Original Title

W._F._Chen,_Plasticity_for_Structural_Engineers,_1988-390

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses different material behaviors that can be exhibited in stress-strain diagrams, including elastic-plastic behavior, progressively fracturing behavior, and combined plastic-fracturing behavior. It focuses on the strain-softening behavior of concrete in compression, which exhibits plastic-fracturing characteristics. The document considers modeling this softening behavior using strain-space plasticity formulations and examines the limitations of interpreting fracturing solely as plastic flow.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 page7.4. Plasticity Modeling: Softening Behavior 383

7.4. Plasticity Modeling: Softening Behavior 383

Uploaded by

ahmed shakerThis document discusses different material behaviors that can be exhibited in stress-strain diagrams, including elastic-plastic behavior, progressively fracturing behavior, and combined plastic-fracturing behavior. It focuses on the strain-softening behavior of concrete in compression, which exhibits plastic-fracturing characteristics. The document considers modeling this softening behavior using strain-space plasticity formulations and examines the limitations of interpreting fracturing solely as plastic flow.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

7.4.

Plasticity Modeling: Softening Behavior 383

because it can lead to an exaggerative volume expansion for concrete

materials. A nonassociated ftow rule with a variable dilatancy factor

is therefore suggested in the present formulation of the constitutive

stress-strain relation of concrete.

7.4. Plasticity Modeling: Softening Behavior

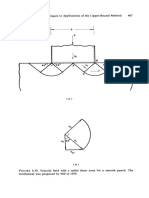

As discussed in Section 7.1, axial compression tests on concrete specimens

exhibit, in general, the softening behavior of the material in the postfailure

regime. The strain-softening behavior, i.e., the negative slope of the load-

deformation curve, will be considered in the following as a material property

and will be treated by the strain-space plasticity formulation. Before we

do this, we shall first examine some material behaviors shown in Fig. 7.22.

7.4.1. Types of Material Behaviors

7.4.1.1. ELASTIC-PLASTIC SOLlOS

Figure 7.22a shows a stress-strain diagram of a hardening-softening solid,

in which the unloading-reloading lines follow straight !ines that are parallei

to the initial tangent of the stress-strain curve, i.e., the slope of the unload-

ing-reloading line does not change with plastic deformation. This is a typical

behavior of an elastic-plastic solid.

7.4.1.2. PROGRESSlYELy FRACTURING SOLIDS

The behavior described in the previous section is not the case for many

engineering materials such as concrete. For example, the elastic modulus

or the stiffness usually decreases with increasing strainingo This sort of

behavior is considered to be due to microcracking or fracturing. Thus, on

the other extreme, an ideal material model, called a progressively fracturing

solid and shown in Fig. 7.22b, was proposed by Dougill (1975). This ideal

material is perfectly elastic. Upon unloading, the material retums to its

initial stress- and strain-free state; no permanent (plastic) strain occurs.

Since the stiffness degradation behavior is due mainly to fracturing

(microcracking), which is different from s!ip, it cannot be satisfactorily

interpreted within the framework of plasticity. Recognizing the difference

between fracturing and plastic ftow, Dougill (1975, 1976) proposed a theory

called fracturing theory. This idea is further realized in the development of

the more recent so-called damage theory.

7.4.1.3. PLASTIc-FRACTURING SOLIDS

A material exhibiting both plastic deformation and stiffness degradation

behaviors is shown in Fig. 7.22c. Concretes fall into this category, par-

ticularly in their softening range. To account for both behaviors, a combined

You might also like

- Dynamic Models For Structural Plasticity (1993)Document296 pagesDynamic Models For Structural Plasticity (1993)Alem LoajnerNo ratings yet

- BA USi Safety - ENDocument107 pagesBA USi Safety - ENAditya Arun KumarNo ratings yet

- Bilinear Isotropic Hardening BehaviorDocument7 pagesBilinear Isotropic Hardening BehaviorricardoborNo ratings yet

- 240concrete Damaged Plasticity)Document19 pages240concrete Damaged Plasticity)netkasiaNo ratings yet

- Program A Cao Nao LinearDocument5 pagesProgram A Cao Nao LinearJerfsonLimaNo ratings yet

- Plasticity-Failure Theories Lecture NotesDocument12 pagesPlasticity-Failure Theories Lecture Noteszaheer50% (2)

- Plasticity Failure Theories Lecture Notes PDFDocument12 pagesPlasticity Failure Theories Lecture Notes PDFVeli YılmazNo ratings yet

- Beigelzimer (1994) Continuum Model of The Structural-Inhomogeneous Porous Body and Its Application For The Study of Stability and Viscous FractureDocument12 pagesBeigelzimer (1994) Continuum Model of The Structural-Inhomogeneous Porous Body and Its Application For The Study of Stability and Viscous FractureЯн БейгельзимерNo ratings yet

- Assal 4Document4 pagesAssal 4Endarto Mas EndNo ratings yet

- Assal 5Document5 pagesAssal 5Endarto Mas EndNo ratings yet

- Damaged Plasticity Model For ConcreteDocument13 pagesDamaged Plasticity Model For ConcretehityouNo ratings yet

- Benchmark Experiments and Characteristic Cyclic Plasticity DeformationDocument35 pagesBenchmark Experiments and Characteristic Cyclic Plasticity DeformationOmar Al-AbriNo ratings yet

- CDP - AbaqusDocument16 pagesCDP - AbaqusClaudio PazNo ratings yet

- InTech-Phenomenological Modelling of Cyclic PlasticityDocument28 pagesInTech-Phenomenological Modelling of Cyclic Plasticitydroessaert_stijnNo ratings yet

- Das 3DPlasticityModelSandySoils ACCM 2013Document7 pagesDas 3DPlasticityModelSandySoils ACCM 2013fatima ezzahraa latifiNo ratings yet

- Edited Bubble ModelDocument12 pagesEdited Bubble ModelEva SmithNo ratings yet

- New Bubble ModelDocument12 pagesNew Bubble ModelEva SmithNo ratings yet

- Edited Bubble ModelDocument12 pagesEdited Bubble ModelEva SmithNo ratings yet

- Basic Computational PlasticityDocument40 pagesBasic Computational PlasticityadnanhasanovicNo ratings yet

- Using The Hollomon Model To Predict Strain-Hardening in MetalsDocument4 pagesUsing The Hollomon Model To Predict Strain-Hardening in MetalsGuilherme ResendeNo ratings yet

- Material Behaviour For Material ModelsDocument3 pagesMaterial Behaviour For Material ModelsmercilessturkNo ratings yet

- Jimma Institute of Technology: Product Design Mechanical PropertiesDocument26 pagesJimma Institute of Technology: Product Design Mechanical PropertiesfayzaNo ratings yet

- EMTL 250 Module 2 2017Document27 pagesEMTL 250 Module 2 2017Mwongera MwaraniaNo ratings yet

- Plastic Analysis of Framed StructuresDocument65 pagesPlastic Analysis of Framed Structuresgirma kebedeNo ratings yet

- Viscoelasticity 01 IntroDocument4 pagesViscoelasticity 01 IntroJohn Mario CanroNo ratings yet

- 08 Plasticity 01 IntroductionDocument11 pages08 Plasticity 01 Introductionabhi16No ratings yet

- Visco Plasticity WikipediaDocument14 pagesVisco Plasticity WikipediaKresimir TrdakNo ratings yet

- CH 12Document64 pagesCH 12LeonardoMadeira11No ratings yet

- Plastic Hinge Analysis ReviewDocument16 pagesPlastic Hinge Analysis Reviewscience ResearchNo ratings yet

- Superficies RupturaDocument10 pagesSuperficies Rupturaf_tavares225No ratings yet

- Mechanical Properties of Materials NotesDocument28 pagesMechanical Properties of Materials NotesMat MatttNo ratings yet

- Introduction of PlasticityDocument11 pagesIntroduction of PlasticityYang LuNo ratings yet

- 08 Plasticity CompleteDocument85 pages08 Plasticity CompleteSebastiao SilvaNo ratings yet

- 08 Plasticity 01 Introduction PDFDocument11 pages08 Plasticity 01 Introduction PDFAmmar A. AliNo ratings yet

- Plasticity Complete PDFDocument85 pagesPlasticity Complete PDFMISBAH UL HAQUENo ratings yet

- Nazim Cad 8Document5 pagesNazim Cad 8Shrinish VhanbatteNo ratings yet

- A Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Document25 pagesA Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Melete GashawNo ratings yet

- 2019 DSSIMULIA - Established - An Inelastic Constitutive Model For ConcreteDocument10 pages2019 DSSIMULIA - Established - An Inelastic Constitutive Model For ConcretePhan Đào Hoàng HiệpNo ratings yet

- Assal 6Document6 pagesAssal 6Endarto Mas EndNo ratings yet

- Research Progress in Modelling of Ageing Viscoelastic Properties Cement PasteDocument14 pagesResearch Progress in Modelling of Ageing Viscoelastic Properties Cement PastepoornimNo ratings yet

- Explicit Modeling of Damping of A Single-Layer Latticed Dome With Isolation System (Zhang, Et Al. 2014)Document12 pagesExplicit Modeling of Damping of A Single-Layer Latticed Dome With Isolation System (Zhang, Et Al. 2014)Jose ManuelNo ratings yet

- Executive Summary: Simplified Methods For Analysis of Response To Dynamic LoadingDocument1 pageExecutive Summary: Simplified Methods For Analysis of Response To Dynamic LoadingwearplayNo ratings yet

- Module 1 Theory of PlasticityDocument20 pagesModule 1 Theory of Plasticityxavier sethuNo ratings yet

- ECE 4215 Lecture 4Document22 pagesECE 4215 Lecture 4dantezNo ratings yet

- Rigid Origami Structures With Vacuumatics: Geometric ConsiderationsDocument8 pagesRigid Origami Structures With Vacuumatics: Geometric ConsiderationsUsuario2000No ratings yet

- NormalityDocument1 pageNormalitynetname1No ratings yet

- Material Engineering Lecture 3Document5 pagesMaterial Engineering Lecture 3Mohannad OrabiNo ratings yet

- SVT Collge of Engg. Structure II Lecture Notes..1245Document38 pagesSVT Collge of Engg. Structure II Lecture Notes..1245Shams KhattakNo ratings yet

- A.Mechanical Properties of Engineering Materials: F/A F/ADocument11 pagesA.Mechanical Properties of Engineering Materials: F/A F/AsrknotesNo ratings yet

- Assal 8Document8 pagesAssal 8Endarto Mas EndNo ratings yet

- Fully Plastic + ElastoplasticDocument19 pagesFully Plastic + ElastoplasticMilad RadNo ratings yet

- International Journal of Solids and Structures: A. Edalat Behbahani, J.A.O. Barros, A. Ventura-GouveiaDocument21 pagesInternational Journal of Solids and Structures: A. Edalat Behbahani, J.A.O. Barros, A. Ventura-GouveiaEngr Aizaz AhmadNo ratings yet

- Modelling of The Hysteretic Behaviour of Buckling Restrained BracesDocument8 pagesModelling of The Hysteretic Behaviour of Buckling Restrained BracesCristian Camilo Martinez JimenezNo ratings yet

- 1 D Plasticity by Louie L. YawDocument25 pages1 D Plasticity by Louie L. YawshakibbrNo ratings yet

- Pavement Materials KJJDocument44 pagesPavement Materials KJJAlfred KameyaNo ratings yet

- Stress Strain Curve ExampleDocument8 pagesStress Strain Curve ExampleRayhan saiaf binNo ratings yet

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- 482 8. General Theorems of Limit Analysis and Their ApplicationsDocument1 page482 8. General Theorems of Limit Analysis and Their Applicationsahmed shakerNo ratings yet

- 588 9. Limit Analysis of Engineering Struetures: - Size - PrismDocument1 page588 9. Limit Analysis of Engineering Struetures: - Size - Prismahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-35 PDFahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-325 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-325 PDFahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-562Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-562ahmed shakerNo ratings yet

- 9.5. Limit Analysis of Plates 527: 4 y !4 XY !4 YxDocument1 page9.5. Limit Analysis of Plates 527: 4 y !4 XY !4 Yxahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers 1988-119 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers 1988-119 PDFahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-260Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-260ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-384Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-384ahmed shakerNo ratings yet

- 8.6. Example Problems in Plane Stress, Plane Strain, and 3-D 475Document1 page8.6. Example Problems in Plane Stress, Plane Strain, and 3-D 475ahmed shakerNo ratings yet

- 394 7. Implementation in Concretes: Stress and Strain IncrementsDocument1 page394 7. Implementation in Concretes: Stress and Strain Incrementsahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-485Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-485ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-472Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-472ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-318Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-318ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-454Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-454ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-531Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-531ahmed shakerNo ratings yet

- 156 3. Elastic Stress-Strain Relations: T (KenDocument1 page156 3. Elastic Stress-Strain Relations: T (Kenahmed shakerNo ratings yet

- Kinematic Hardening Case (Fig. 1.9 (Ii) ) : The Yield Stress at Point B IsDocument1 pageKinematic Hardening Case (Fig. 1.9 (Ii) ) : The Yield Stress at Point B Isahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-489Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-489ahmed shakerNo ratings yet

- (V) - (1 - 0) (JL) J: 6.6. Bounding Surface Theory 325Document1 page(V) - (1 - 0) (JL) J: 6.6. Bounding Surface Theory 325ahmed shakerNo ratings yet

- B K Constrained Modulus.: 4.9. Prandtl-Reuss Material Model (12 Theory) 213 ADocument1 pageB K Constrained Modulus.: 4.9. Prandtl-Reuss Material Model (12 Theory) 213 Aahmed shakerNo ratings yet

- 2.1.6. Octahedral Stresses: 2.1. Stress 59Document1 page2.1.6. Octahedral Stresses: 2.1. Stress 59ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-70Document1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-70ahmed shakerNo ratings yet

- (Un, SN) (Un (2.102) (Un, SN) A'B' N N (Un, SN) (Un, SN) D'. A'B'Document1 page(Un, SN) (Un (2.102) (Un, SN) A'B' N N (Un, SN) (Un, SN) D'. A'B'ahmed shakerNo ratings yet

- W. F. Chen, Plasticity For Structural Engineers, 1988-39 PDFDocument1 pageW. F. Chen, Plasticity For Structural Engineers, 1988-39 PDFahmed shakerNo ratings yet

- Pair of Linear Equations in Two Variables PDFDocument7 pagesPair of Linear Equations in Two Variables PDFVrushab MNo ratings yet

- X Maths KS Sample Paper 12Document6 pagesX Maths KS Sample Paper 12Mukul SinghNo ratings yet

- UNIT III Beta Gamma FunctionsDocument27 pagesUNIT III Beta Gamma FunctionsSatuluri Satyanagendra RaoNo ratings yet

- Hall Effect SensorDocument3 pagesHall Effect SensorUli LolexNo ratings yet

- BASF Rheology Modifiers Product Recomendation (Europe)Document1 pageBASF Rheology Modifiers Product Recomendation (Europe)Akshai RedwalkerNo ratings yet

- 09 Christensen NCHRP09-59updateDocument41 pages09 Christensen NCHRP09-59updates pradhanNo ratings yet

- Design Experiment (Experiment Number) : (Title) : (Name of Group Members Separated by Commas. (Given Name M.I. Surname) )Document3 pagesDesign Experiment (Experiment Number) : (Title) : (Name of Group Members Separated by Commas. (Given Name M.I. Surname) )MA. CARMELA BEATRIZ SACDALANNo ratings yet

- Bolt Preloading and DesignDocument10 pagesBolt Preloading and DesignDianna LambertNo ratings yet

- Introduction To Earthquake EngineeringDocument4 pagesIntroduction To Earthquake EngineeringAjay AjaiNo ratings yet

- Activity 6 Product Disassembly ChartDocument5 pagesActivity 6 Product Disassembly Chartapi-504977947No ratings yet

- FM Lab 1Document3 pagesFM Lab 1Waleed NasirNo ratings yet

- Evaluation of The Particle Sizes of Four Clay Minerals Tan2016Document12 pagesEvaluation of The Particle Sizes of Four Clay Minerals Tan2016Laura Ximena Giraldo100% (1)

- Evacuation Center (Design of Beam2)Document35 pagesEvacuation Center (Design of Beam2)jerick calingasanNo ratings yet

- Process Dynamic and Control 1Document30 pagesProcess Dynamic and Control 1Ankushkumar MaliNo ratings yet

- Circuit Theory: Report BigprojectDocument10 pagesCircuit Theory: Report BigprojectVũ Hoàng LongNo ratings yet

- Oct New Normal Accomplishment Report Copy 2Document2 pagesOct New Normal Accomplishment Report Copy 2Joseph Gerson BalanaNo ratings yet

- Questions To Accompany The Viewing of NOVA's "Hunting The Hidden Dimension" Video.Document1 pageQuestions To Accompany The Viewing of NOVA's "Hunting The Hidden Dimension" Video.npriccaNo ratings yet

- Types of Beam-Restricting Devices: 1. Aperture DiaphragmsDocument5 pagesTypes of Beam-Restricting Devices: 1. Aperture DiaphragmsRachelle Dela Rosa100% (2)

- Basic Simulation LabDocument3 pagesBasic Simulation LabGautam KumarNo ratings yet

- Jan-2020 MS (P2 M1)Document18 pagesJan-2020 MS (P2 M1)Syed Aziz HaiderNo ratings yet

- Black Board Problems For JEE Advanced Set-8Document7 pagesBlack Board Problems For JEE Advanced Set-8DikshantNo ratings yet

- SFA-Vessels Guide E-Oct17Document35 pagesSFA-Vessels Guide E-Oct17flcwkNo ratings yet

- Gauss-Codazzi EquationsDocument5 pagesGauss-Codazzi EquationsaguiNo ratings yet

- Checklist Pavement AnalysisDocument2 pagesChecklist Pavement Analysisp.v.n. lakshmanNo ratings yet

- All Stainless Steel Pressure Gauges With Bourdon TubeDocument2 pagesAll Stainless Steel Pressure Gauges With Bourdon TubetitiNo ratings yet

- Lesson 5 - Models of CommunicationDocument9 pagesLesson 5 - Models of CommunicationJessica Cabildo CalbanNo ratings yet

- The Value of Surface Tension of A Liquid at Critical Temperature IsDocument10 pagesThe Value of Surface Tension of A Liquid at Critical Temperature Issagarchidre114No ratings yet

- Dgca Module 06 Part 07Document14 pagesDgca Module 06 Part 07Gaurav SinghNo ratings yet

- Why Do We Study Physics - Socratic PDFDocument1 pageWhy Do We Study Physics - Socratic PDFMon LuffyNo ratings yet