Professional Documents

Culture Documents

Irrigation Installation Erection

Irrigation Installation Erection

Uploaded by

Raghad GCopyright:

Available Formats

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- OTHM L6 OHS - Assignment Briefs January 2021Document34 pagesOTHM L6 OHS - Assignment Briefs January 2021Raghad G100% (1)

- CDA Technical Bulletin - Application of Dam Safety Guidelines To Mining Dams (CDA, 2014)Document49 pagesCDA Technical Bulletin - Application of Dam Safety Guidelines To Mining Dams (CDA, 2014)Adrian Luis Hernandez GarciaNo ratings yet

- OPSS 450 Nov12Document11 pagesOPSS 450 Nov12jkhgvdj mnhsnjkhgNo ratings yet

- Specification For Prefabricated Vertical DrainsDocument7 pagesSpecification For Prefabricated Vertical DrainsRecep Caner Akyılmaz100% (2)

- Siphonic System Spec (05.02.2014)Document9 pagesSiphonic System Spec (05.02.2014)zeroicesnowNo ratings yet

- Terrain Drainage Design Dubai MunicipalityDocument16 pagesTerrain Drainage Design Dubai MunicipalityChamara Chinthaka Ranasinghe100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- FW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesDocument2 pagesFW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesRaghad GNo ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Nanoparticles AssignmentDocument14 pagesNanoparticles AssignmentGamze Ide50% (2)

- Florida BLDG Code Appendix FDocument17 pagesFlorida BLDG Code Appendix FSarah GlennNo ratings yet

- Volume 2-Employer's Requirements Sewage Treatment Plant at KaggadasapuraDocument5 pagesVolume 2-Employer's Requirements Sewage Treatment Plant at Kaggadasapurasharan kommiNo ratings yet

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Design Guidelines Electromagnetic Flow MetersDocument7 pagesDesign Guidelines Electromagnetic Flow Metersaugur8866124No ratings yet

- Api 570 NotesDocument3 pagesApi 570 NotesErdi Erdogan100% (1)

- Section 14 - Irrigation Design and ConstructionDocument6 pagesSection 14 - Irrigation Design and ConstructionJason DavidsonNo ratings yet

- Npelf40 40 PDFDocument16 pagesNpelf40 40 PDFKVRamananNo ratings yet

- Landscap IRRIGATIONDocument29 pagesLandscap IRRIGATIONFrancis KairaNo ratings yet

- Plumbing Works Technology-1Document32 pagesPlumbing Works Technology-1neilNo ratings yet

- Section L Technical Provisions For The Construction of Sanitary Sewer Lift Stations SectionDocument13 pagesSection L Technical Provisions For The Construction of Sanitary Sewer Lift Stations SectionDeepa SinghNo ratings yet

- Fact Sheet: Criteria For Large-Capacity On-Site Sewage Disposal SystemsDocument12 pagesFact Sheet: Criteria For Large-Capacity On-Site Sewage Disposal SystemsAlipasha GeramifardNo ratings yet

- SW Manual Chapter 100-700 - Combined - Final - 2022may - Chapter 500Document26 pagesSW Manual Chapter 100-700 - Combined - Final - 2022may - Chapter 500WahidCesarRNo ratings yet

- British Standard 8515:2009 ExplainedDocument5 pagesBritish Standard 8515:2009 ExplainedsachinthaNo ratings yet

- Technical Document #WTS-14 Pumping Station Design & Submittal CriterionDocument7 pagesTechnical Document #WTS-14 Pumping Station Design & Submittal CriterionEngGhanemNo ratings yet

- VolDocument110 pagesVoldep_vinNo ratings yet

- 2023 Submitter Substantiations Committee StatementsDocument102 pages2023 Submitter Substantiations Committee StatementsPapel506No ratings yet

- GB1516 Sac 240 CV RP 0006 - ADocument10 pagesGB1516 Sac 240 CV RP 0006 - AkkkkNo ratings yet

- Waterflow Indicator PDFDocument8 pagesWaterflow Indicator PDFambition1340cnNo ratings yet

- Multy Outlet PipelineDocument3 pagesMulty Outlet Pipelinehekayat71No ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurNo ratings yet

- Method Statement For Testing and Installation of Firefighting SprinklerDocument5 pagesMethod Statement For Testing and Installation of Firefighting SprinklerDeepak Patil100% (3)

- GAPS Guidelines: Conducting Water Supply TestsDocument6 pagesGAPS Guidelines: Conducting Water Supply Testsasad khanNo ratings yet

- 1.hydrostatic Test and Flushing (R2)Document19 pages1.hydrostatic Test and Flushing (R2)sethu109189% (9)

- SofregazDocument26 pagesSofregazAbdulkadir Berk MalkoçNo ratings yet

- QCS-2010 Section 19 Part 6 Commissioning of SystemsDocument6 pagesQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106No ratings yet

- Cea 132 3B BarreDocument10 pagesCea 132 3B BarreRayyan JamaluddinNo ratings yet

- RP10 Installation Manual-Revision M - Jan 2010Document7 pagesRP10 Installation Manual-Revision M - Jan 2010mutazsalihNo ratings yet

- Water Main Installation Instructions - 2017 01 09Document11 pagesWater Main Installation Instructions - 2017 01 09RogNo ratings yet

- Local Laws CombinedDocument22 pagesLocal Laws CombinedAshar HassanNo ratings yet

- Design Guidelines Wastewater Networks - Gravity Foul Sewers SystemsDocument13 pagesDesign Guidelines Wastewater Networks - Gravity Foul Sewers Systemshajer100% (1)

- SECTION3 DesignCriteriaforSewerSystemFacilitiesDocument6 pagesSECTION3 DesignCriteriaforSewerSystemFacilitiesMoses KaswaNo ratings yet

- Baher M. EL-Gendy Section (2) B.N.Document7 pagesBaher M. EL-Gendy Section (2) B.N.Baher M. El-GendyNo ratings yet

- 2012 Plumbing Design Guides PDFDocument29 pages2012 Plumbing Design Guides PDFIonut SomneaNo ratings yet

- Cross Connection-Air Gap-2020Document2 pagesCross Connection-Air Gap-2020manalfathishady63No ratings yet

- Wet System ManualDocument38 pagesWet System ManualLalit MalhotraNo ratings yet

- Ut2 EstebanDocument9 pagesUt2 EstebanJoshua TupasNo ratings yet

- Fire Protection Water Mist SystemDocument18 pagesFire Protection Water Mist SystemAhmed MahmoudNo ratings yet

- 22 00 00PlumbingGeneralDocument4 pages22 00 00PlumbingGeneralle minhNo ratings yet

- Bill of QuantityDocument11 pagesBill of Quantitymehmet akildizNo ratings yet

- Intro To Wastewater Collection and PumpingDocument84 pagesIntro To Wastewater Collection and PumpingMoh'd KhadNo ratings yet

- Fire Sprinkler System DesignDocument3 pagesFire Sprinkler System DesignAhrian BenaNo ratings yet

- Design Specifications For Sewage Disposal Systems: 9?ma/) LGL') Aj ) Ka - Fyf/Eyafl) FyfDocument51 pagesDesign Specifications For Sewage Disposal Systems: 9?ma/) LGL') Aj ) Ka - Fyf/Eyafl) FyfMark GoducoNo ratings yet

- Fire Protection SystemsDocument26 pagesFire Protection Systemsmahdi_gNo ratings yet

- RP Is 009 009 FS+2214Document8 pagesRP Is 009 009 FS+2214Prabath KNo ratings yet

- Sanitary Sewer System Design and Construction ManualDocument209 pagesSanitary Sewer System Design and Construction Manualsdvitko89% (9)

- Part E - 6 - Public Health - Sanitary Drainage System Design (DS)Document15 pagesPart E - 6 - Public Health - Sanitary Drainage System Design (DS)Mahmoud ElkazazNo ratings yet

- Phe TD Water Piping Specs r0Document27 pagesPhe TD Water Piping Specs r0Golekha mallickNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringFrom EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

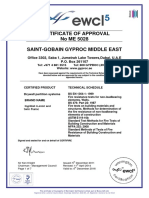

- ME5028 Saint Gobain GyprocDocument7 pagesME5028 Saint Gobain GyprocRaghad G100% (1)

- Customer Service Process Flow Chart: Your Company NameDocument15 pagesCustomer Service Process Flow Chart: Your Company NameRaghad GNo ratings yet

- 16mm Double Layer - Thomas Bell WrightDocument1 page16mm Double Layer - Thomas Bell WrightRaghad GNo ratings yet

- HFMDocument17 pagesHFMRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 11 Answers PDFDocument2 pages7th Grammar Worksheet Unit 11 Answers PDFRaghad GNo ratings yet

- 7th Voc Unit 11 PDFDocument1 page7th Voc Unit 11 PDFRaghad GNo ratings yet

- 7th Grammar in Use Worksheet Unit 9 Answers PDFDocument1 page7th Grammar in Use Worksheet Unit 9 Answers PDFRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 11 Answers PDFDocument2 pages7th Grammar Worksheet Unit 11 Answers PDFRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 9 Answers PDFDocument1 page7th Grammar Worksheet Unit 9 Answers PDFRaghad GNo ratings yet

- Template 1: Your Text Here FeedbackDocument5 pagesTemplate 1: Your Text Here FeedbackRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 9 Answers PDFDocument1 page7th Grammar Worksheet Unit 9 Answers PDFRaghad G100% (1)

- Inspection and Contract Administration Manual For Mndot Landscape Projects, 2017 EditionDocument241 pagesInspection and Contract Administration Manual For Mndot Landscape Projects, 2017 EditionRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 11 Answers PDFDocument2 pages7th Grammar Worksheet Unit 11 Answers PDFRaghad GNo ratings yet

- Usace Quality Plan SampleDocument17 pagesUsace Quality Plan SampleRaghad G50% (2)

- 7th Workbook Answers Units (9,10,11) PDFDocument13 pages7th Workbook Answers Units (9,10,11) PDFRaghad GNo ratings yet

- Unit 1 Assessment AssessmentDocument19 pagesUnit 1 Assessment AssessmentRaghad GNo ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Ăŷěɛđăɖŝŷő Essentials Qa/Qc Plan Sample: Good For Smaller Projects and Bid QualificationsDocument10 pagesĂŷěɛđăɖŝŷő Essentials Qa/Qc Plan Sample: Good For Smaller Projects and Bid QualificationsRaghad GNo ratings yet

- Chapter 9. Scale Deposition, Removal, and Prevention (Energi)Document11 pagesChapter 9. Scale Deposition, Removal, and Prevention (Energi)Anonymous tTk3BfaHNo ratings yet

- Xirtec 7 Pur - Lovoc 1 17Document2 pagesXirtec 7 Pur - Lovoc 1 17erinepeachNo ratings yet

- FPSO - General Overview of Conversion & Topside Process DescriptionDocument2 pagesFPSO - General Overview of Conversion & Topside Process DescriptionNilesh GohelNo ratings yet

- Grade 4 Natural Sciences and Technology Task 21Document35 pagesGrade 4 Natural Sciences and Technology Task 21TshegofatsoNo ratings yet

- Cbse Ncert Management of Natural Resources Notes Biology 10thDocument5 pagesCbse Ncert Management of Natural Resources Notes Biology 10thapurba mNo ratings yet

- De Mineral Izer ManualDocument33 pagesDe Mineral Izer ManualSarangNo ratings yet

- خواص صخور المكمن رقم 9Document31 pagesخواص صخور المكمن رقم 9maamoun ramyNo ratings yet

- SBR Chapter - 3Document45 pagesSBR Chapter - 3Noureddine MerahNo ratings yet

- Tehri Dam: An Engineering Marvel: Basistha Raj AdhikariDocument5 pagesTehri Dam: An Engineering Marvel: Basistha Raj AdhikariEr.Puranjan BishwakarmaNo ratings yet

- 3sample - DPR Ornamental Fish CulturchangeDocument6 pages3sample - DPR Ornamental Fish CulturchangeMyra Jane LeuterioNo ratings yet

- Assertion & Reason Basic 01Document5 pagesAssertion & Reason Basic 01chaostheoristNo ratings yet

- Alfa Laval PDFDocument42 pagesAlfa Laval PDFCristian ParaschivNo ratings yet

- Basf Masterseal 550 Tds PDFDocument3 pagesBasf Masterseal 550 Tds PDFashayshaNo ratings yet

- Answer: B: Selected/modified From Brown Et Al: Chemistry The Central Science, 10e, 12e, 13e TestbanksDocument10 pagesAnswer: B: Selected/modified From Brown Et Al: Chemistry The Central Science, 10e, 12e, 13e Testbanksفاطمة كليبNo ratings yet

- Green Tourism: A Road Map For TransformationDocument20 pagesGreen Tourism: A Road Map For TransformationTri'echa'RahayuWulansariNo ratings yet

- Code-5 GeographyDocument17 pagesCode-5 GeographySakshi PriyaNo ratings yet

- Kwale Workshop ReportDocument24 pagesKwale Workshop ReportFrancisco SilvaNo ratings yet

- SUBJECT: Science Test Yourself Worksheet Class: Ix Subject Code-086Document6 pagesSUBJECT: Science Test Yourself Worksheet Class: Ix Subject Code-086Vedant SinghalNo ratings yet

- CHAPTER 7 Exp BiologyDocument2 pagesCHAPTER 7 Exp BiologyAdy Phanterz100% (1)

- EX - CX - 044 - Master Inspection Characteristics MICDocument61 pagesEX - CX - 044 - Master Inspection Characteristics MICyramasapNo ratings yet

- FSN3 10 1520Document7 pagesFSN3 10 1520Chandrima JashNo ratings yet

- Rocor NB Liquid 25 LTRDocument3 pagesRocor NB Liquid 25 LTRaldrin de guzmanNo ratings yet

- Production of Ethanol: Project Year 1Document16 pagesProduction of Ethanol: Project Year 1gongweejie93100% (1)

- Environment Impact AssessmentDocument15 pagesEnvironment Impact AssessmentAyush BhadauriaNo ratings yet

- Monthly Global Point Current Affairs May 2020Document93 pagesMonthly Global Point Current Affairs May 2020Nawab Ali MalikNo ratings yet

- 002a REFRESHER PLUMBING CODE PDFDocument601 pages002a REFRESHER PLUMBING CODE PDFDoms DominguezNo ratings yet

- Water Supply Scheme in IndiaDocument39 pagesWater Supply Scheme in IndiaAde NovanNo ratings yet

- Evaluation of Groundwater Quality and Its Suitability For Drinking and Agricultural Use in Thanjavur City, Tamil Nadu, IndiaDocument45 pagesEvaluation of Groundwater Quality and Its Suitability For Drinking and Agricultural Use in Thanjavur City, Tamil Nadu, IndiaHanjiNo ratings yet

Irrigation Installation Erection

Irrigation Installation Erection

Uploaded by

Raghad GOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Irrigation Installation Erection

Irrigation Installation Erection

Uploaded by

Raghad GCopyright:

Available Formats

Irrigation Rev.: 1.

0 Statu IFU

s:

System

Installation

Erection

Document No.: BAZ-KSA-SOP- Page: 1 of 6

323

Irrigation System Installation Erection

This guide lists normally required inspections for irrigation Erections. There may be

more or fewer required inspections at the discretion of the Building Official in order to

verify code compliance. It is the responsibility of the job superintendent or homeowner

to assure that the project is ready for inspection and accessible for the inspector.

1. Irrigation plans submittals

The irrigation plan must include complete coverage of the area to be irrigated. If a

system does not provide complete coverage of the area to be irrigated, it must be noted

on the irrigation plan.

All irrigation plans used for construction must be drawn to scale. The plan must

include, at a minimum, the following information:

The irrigator's seal, signature, and date of signing

All major physical features and the boundaries of the areas to be watered

The zone flow measurement for each zone

Location and type of controller and sensor (or example, but not limited to, rain,

moisture, wind, flow, or freeze)

The scale used

The design pressure

Location, type, and size of each of the following:

Water source, such as, but not limited to a water meter and point(s) of connection

Backflow prevention device

Water emission device, including, but not limited to, spray heads, rotary sprinkler heads,

quick-couplers, bubblers, drip, or micro-sprays

Valve, including, but not limited to, zone valves, master valves, and isolation valves

Pressure regulation component

Main line and lateral piping

2. All inspections for irrigation installation/erection.

Proper address clearly visible from the street.

City-approved Plans on site.

Leave Correction or approval notice at all inspections.

Verify previous notice on re-inspections.

Verify inspections comments from printout on re-inspections.

Check general cleanliness of job sites.

Irrigation Rev.: 1.0 Statu IFU

s:

System

Installation

Erection

Document No.: BAZ-KSA-SOP- Page: 2 of 6

323

3. Backflow assembly inspection (one inspection)

Locate backflow preventer and League City test report sheet.

Verify information on the sheet matches the backflow preventer serial number and address.

Verify that the test results are correct.

4. One stop inspection

Locate backflow preventer and test report sheet.

Verify information on the sheet matches the backflow preventer serial number and address.

Verify that the test results are correct.

Pop up or spray heads used in new irrigation systems must be direct flow away from a hard

scape.

Spray heads must not spray water over concrete, asphalt, brick, wood, stones set with mortar,

or other impervious materials on walls, fences, sidewalks, streets, etc.

Supply line to backflow preventer to be insulated and the backflow preventer to be a minimum of

one foot above the highest spray head.

5. Minimum design and installation requirements

No irrigation design or installation shall require the use of any component, including the water

meter, in a way which exceeds the manufacturer's published performance limitations for the

component.

The maximum spacing between emission devices must not exceed the manufacturer's published

radius or spacing of the device(s). The radius or spacing is determined by referring to the

manufacturer's published specifications for a specific emission device at a specific operating

pressure.

New irrigation systems shall not utilize above-ground spray emission devices in landscapes that

are not including the impervious surfaces in either length or width and which contain impervious

pedestrian or vehicular traffic surfaces along two or more perimeters. If pop-up sprays or rotary

sprinkler heads are used in a new irrigation system, the sprinkler heads must direct flow away

from any adjacent surface such as, but not limited to, a building foundation, fence, concrete,

asphalt, pavers, or stones set with mortar.

Narrow paved walkways, jogging paths, golf cart paths or other small areas located in cemeteries,

parks, golf courses or other public areas may be exempted from this requirement if the runoff

drains into a landscaped area.

For water pressure, emission devices must be installed to operate at the minimum and not above the

maximum sprinkler head pressure as published by the manufacturer for the nozzle and head spacing

that is used. Methods to achieve the water pressure requirements include, but are not limited to,

.

Zones must be designed and installed so that all of the emission devices in that zone irrigate at the

same precipitation rate.

Irrigation systems shall not spray water over surfaces made of concrete, asphalt, brick, wood,

stones set with mortar, or any other impervious material, such as, but not limited to, walls,

fences, sidewalks, streets, etc.

When provided, a master valve shall be installed on the discharge side of the backflow

prevention device on all new installations.

All new irrigation systems that are installed using PVC pipe and fittings shall be primed with a

colored primer prior to applying the PVC cement.

All new automatically controlled irrigation systems must include sensors or other technology

designed to inhibit or interrupt operation of the irrigation system during periods of moisture or

rainfall. Rain or moisture shut-off technology must be installed according to the manufacturer's

published recommendations. Repairs to existing automatic irrigation systems that require

replacement of an existing controller must include a sensor or other technology designed to inhibit

or interrupt operation of the irrigation system during periods of moisture or rainfall. El Paso,

Hudspeth, Culberson, Jeff Davis, Presidio, Brewster, Terrell, Loving, Winkler, Ward, Reeves,

Ector, Crane, and Pecos are excluded from this requirement.

All new irrigation systems must include an isolation valve between the water meter and the

backflow prevention device.

Piping in all irrigation systems must be installed according to the manufacturer's published

specifications for depth coverage of piping.

If the manufacturer has not published specifications for depth coverage of piping, the piping must

be installed to provide minimum depth coverage of 6” of select backfill, between the top of the pipe

and the natural grade of the topsoil. All portions of the irrigation system that fail to meet this

standard must be noted on the irrigation plan. If the area being irrigated has rock at a depth of 6” or

less, select backfill may be mounded over the pipe. Mounding must be noted on the irrigation plan

and discussed with the irrigation system owner or owner's representative to address any safety

issues.

All trenches and holes created during installation of an irrigation system must be backfilled and

compacted to the original grade.

Underground electrical wiring used to connect an automatic controller to any electrical

component of the irrigation system must be listed by Underwriters Laboratories as acceptable

for burial underground. Electrical wiring that connects any electrical components of an

irrigation system must be sized according to the manufacturer's recommendation.

Electrical wire splices which may be exposed to moisture must be waterproof as

certified by the wire splice manufacturer.

Water contained within the piping of an irrigation system is deemed to be non-potable If a hose bib

(an outdoor water faucet that has hose threads on the spout) is connected to an irrigation system for

the purpose of providing supplemental water to an area, the hose bib must be installed using a quick

coupler key on a quick coupler installed in a covered purple valve box and the hose bib and any

hoses connected to the bib must be labeled "non-potable, not safe for drinking." An isolation valve

must be installed upstream of a quick coupler connecting a hose bib to an irrigation system.

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- OTHM L6 OHS - Assignment Briefs January 2021Document34 pagesOTHM L6 OHS - Assignment Briefs January 2021Raghad G100% (1)

- CDA Technical Bulletin - Application of Dam Safety Guidelines To Mining Dams (CDA, 2014)Document49 pagesCDA Technical Bulletin - Application of Dam Safety Guidelines To Mining Dams (CDA, 2014)Adrian Luis Hernandez GarciaNo ratings yet

- OPSS 450 Nov12Document11 pagesOPSS 450 Nov12jkhgvdj mnhsnjkhgNo ratings yet

- Specification For Prefabricated Vertical DrainsDocument7 pagesSpecification For Prefabricated Vertical DrainsRecep Caner Akyılmaz100% (2)

- Siphonic System Spec (05.02.2014)Document9 pagesSiphonic System Spec (05.02.2014)zeroicesnowNo ratings yet

- Terrain Drainage Design Dubai MunicipalityDocument16 pagesTerrain Drainage Design Dubai MunicipalityChamara Chinthaka Ranasinghe100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- FW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesDocument2 pagesFW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesRaghad GNo ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Nanoparticles AssignmentDocument14 pagesNanoparticles AssignmentGamze Ide50% (2)

- Florida BLDG Code Appendix FDocument17 pagesFlorida BLDG Code Appendix FSarah GlennNo ratings yet

- Volume 2-Employer's Requirements Sewage Treatment Plant at KaggadasapuraDocument5 pagesVolume 2-Employer's Requirements Sewage Treatment Plant at Kaggadasapurasharan kommiNo ratings yet

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Design Guidelines Electromagnetic Flow MetersDocument7 pagesDesign Guidelines Electromagnetic Flow Metersaugur8866124No ratings yet

- Api 570 NotesDocument3 pagesApi 570 NotesErdi Erdogan100% (1)

- Section 14 - Irrigation Design and ConstructionDocument6 pagesSection 14 - Irrigation Design and ConstructionJason DavidsonNo ratings yet

- Npelf40 40 PDFDocument16 pagesNpelf40 40 PDFKVRamananNo ratings yet

- Landscap IRRIGATIONDocument29 pagesLandscap IRRIGATIONFrancis KairaNo ratings yet

- Plumbing Works Technology-1Document32 pagesPlumbing Works Technology-1neilNo ratings yet

- Section L Technical Provisions For The Construction of Sanitary Sewer Lift Stations SectionDocument13 pagesSection L Technical Provisions For The Construction of Sanitary Sewer Lift Stations SectionDeepa SinghNo ratings yet

- Fact Sheet: Criteria For Large-Capacity On-Site Sewage Disposal SystemsDocument12 pagesFact Sheet: Criteria For Large-Capacity On-Site Sewage Disposal SystemsAlipasha GeramifardNo ratings yet

- SW Manual Chapter 100-700 - Combined - Final - 2022may - Chapter 500Document26 pagesSW Manual Chapter 100-700 - Combined - Final - 2022may - Chapter 500WahidCesarRNo ratings yet

- British Standard 8515:2009 ExplainedDocument5 pagesBritish Standard 8515:2009 ExplainedsachinthaNo ratings yet

- Technical Document #WTS-14 Pumping Station Design & Submittal CriterionDocument7 pagesTechnical Document #WTS-14 Pumping Station Design & Submittal CriterionEngGhanemNo ratings yet

- VolDocument110 pagesVoldep_vinNo ratings yet

- 2023 Submitter Substantiations Committee StatementsDocument102 pages2023 Submitter Substantiations Committee StatementsPapel506No ratings yet

- GB1516 Sac 240 CV RP 0006 - ADocument10 pagesGB1516 Sac 240 CV RP 0006 - AkkkkNo ratings yet

- Waterflow Indicator PDFDocument8 pagesWaterflow Indicator PDFambition1340cnNo ratings yet

- Multy Outlet PipelineDocument3 pagesMulty Outlet Pipelinehekayat71No ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurNo ratings yet

- Method Statement For Testing and Installation of Firefighting SprinklerDocument5 pagesMethod Statement For Testing and Installation of Firefighting SprinklerDeepak Patil100% (3)

- GAPS Guidelines: Conducting Water Supply TestsDocument6 pagesGAPS Guidelines: Conducting Water Supply Testsasad khanNo ratings yet

- 1.hydrostatic Test and Flushing (R2)Document19 pages1.hydrostatic Test and Flushing (R2)sethu109189% (9)

- SofregazDocument26 pagesSofregazAbdulkadir Berk MalkoçNo ratings yet

- QCS-2010 Section 19 Part 6 Commissioning of SystemsDocument6 pagesQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106No ratings yet

- Cea 132 3B BarreDocument10 pagesCea 132 3B BarreRayyan JamaluddinNo ratings yet

- RP10 Installation Manual-Revision M - Jan 2010Document7 pagesRP10 Installation Manual-Revision M - Jan 2010mutazsalihNo ratings yet

- Water Main Installation Instructions - 2017 01 09Document11 pagesWater Main Installation Instructions - 2017 01 09RogNo ratings yet

- Local Laws CombinedDocument22 pagesLocal Laws CombinedAshar HassanNo ratings yet

- Design Guidelines Wastewater Networks - Gravity Foul Sewers SystemsDocument13 pagesDesign Guidelines Wastewater Networks - Gravity Foul Sewers Systemshajer100% (1)

- SECTION3 DesignCriteriaforSewerSystemFacilitiesDocument6 pagesSECTION3 DesignCriteriaforSewerSystemFacilitiesMoses KaswaNo ratings yet

- Baher M. EL-Gendy Section (2) B.N.Document7 pagesBaher M. EL-Gendy Section (2) B.N.Baher M. El-GendyNo ratings yet

- 2012 Plumbing Design Guides PDFDocument29 pages2012 Plumbing Design Guides PDFIonut SomneaNo ratings yet

- Cross Connection-Air Gap-2020Document2 pagesCross Connection-Air Gap-2020manalfathishady63No ratings yet

- Wet System ManualDocument38 pagesWet System ManualLalit MalhotraNo ratings yet

- Ut2 EstebanDocument9 pagesUt2 EstebanJoshua TupasNo ratings yet

- Fire Protection Water Mist SystemDocument18 pagesFire Protection Water Mist SystemAhmed MahmoudNo ratings yet

- 22 00 00PlumbingGeneralDocument4 pages22 00 00PlumbingGeneralle minhNo ratings yet

- Bill of QuantityDocument11 pagesBill of Quantitymehmet akildizNo ratings yet

- Intro To Wastewater Collection and PumpingDocument84 pagesIntro To Wastewater Collection and PumpingMoh'd KhadNo ratings yet

- Fire Sprinkler System DesignDocument3 pagesFire Sprinkler System DesignAhrian BenaNo ratings yet

- Design Specifications For Sewage Disposal Systems: 9?ma/) LGL') Aj ) Ka - Fyf/Eyafl) FyfDocument51 pagesDesign Specifications For Sewage Disposal Systems: 9?ma/) LGL') Aj ) Ka - Fyf/Eyafl) FyfMark GoducoNo ratings yet

- Fire Protection SystemsDocument26 pagesFire Protection Systemsmahdi_gNo ratings yet

- RP Is 009 009 FS+2214Document8 pagesRP Is 009 009 FS+2214Prabath KNo ratings yet

- Sanitary Sewer System Design and Construction ManualDocument209 pagesSanitary Sewer System Design and Construction Manualsdvitko89% (9)

- Part E - 6 - Public Health - Sanitary Drainage System Design (DS)Document15 pagesPart E - 6 - Public Health - Sanitary Drainage System Design (DS)Mahmoud ElkazazNo ratings yet

- Phe TD Water Piping Specs r0Document27 pagesPhe TD Water Piping Specs r0Golekha mallickNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringFrom EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- ME5028 Saint Gobain GyprocDocument7 pagesME5028 Saint Gobain GyprocRaghad G100% (1)

- Customer Service Process Flow Chart: Your Company NameDocument15 pagesCustomer Service Process Flow Chart: Your Company NameRaghad GNo ratings yet

- 16mm Double Layer - Thomas Bell WrightDocument1 page16mm Double Layer - Thomas Bell WrightRaghad GNo ratings yet

- HFMDocument17 pagesHFMRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 11 Answers PDFDocument2 pages7th Grammar Worksheet Unit 11 Answers PDFRaghad GNo ratings yet

- 7th Voc Unit 11 PDFDocument1 page7th Voc Unit 11 PDFRaghad GNo ratings yet

- 7th Grammar in Use Worksheet Unit 9 Answers PDFDocument1 page7th Grammar in Use Worksheet Unit 9 Answers PDFRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 11 Answers PDFDocument2 pages7th Grammar Worksheet Unit 11 Answers PDFRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 9 Answers PDFDocument1 page7th Grammar Worksheet Unit 9 Answers PDFRaghad GNo ratings yet

- Template 1: Your Text Here FeedbackDocument5 pagesTemplate 1: Your Text Here FeedbackRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 9 Answers PDFDocument1 page7th Grammar Worksheet Unit 9 Answers PDFRaghad G100% (1)

- Inspection and Contract Administration Manual For Mndot Landscape Projects, 2017 EditionDocument241 pagesInspection and Contract Administration Manual For Mndot Landscape Projects, 2017 EditionRaghad GNo ratings yet

- 7th Grammar Worksheet Unit 11 Answers PDFDocument2 pages7th Grammar Worksheet Unit 11 Answers PDFRaghad GNo ratings yet

- Usace Quality Plan SampleDocument17 pagesUsace Quality Plan SampleRaghad G50% (2)

- 7th Workbook Answers Units (9,10,11) PDFDocument13 pages7th Workbook Answers Units (9,10,11) PDFRaghad GNo ratings yet

- Unit 1 Assessment AssessmentDocument19 pagesUnit 1 Assessment AssessmentRaghad GNo ratings yet

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 pagesMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GNo ratings yet

- Ăŷěɛđăɖŝŷő Essentials Qa/Qc Plan Sample: Good For Smaller Projects and Bid QualificationsDocument10 pagesĂŷěɛđăɖŝŷő Essentials Qa/Qc Plan Sample: Good For Smaller Projects and Bid QualificationsRaghad GNo ratings yet

- Chapter 9. Scale Deposition, Removal, and Prevention (Energi)Document11 pagesChapter 9. Scale Deposition, Removal, and Prevention (Energi)Anonymous tTk3BfaHNo ratings yet

- Xirtec 7 Pur - Lovoc 1 17Document2 pagesXirtec 7 Pur - Lovoc 1 17erinepeachNo ratings yet

- FPSO - General Overview of Conversion & Topside Process DescriptionDocument2 pagesFPSO - General Overview of Conversion & Topside Process DescriptionNilesh GohelNo ratings yet

- Grade 4 Natural Sciences and Technology Task 21Document35 pagesGrade 4 Natural Sciences and Technology Task 21TshegofatsoNo ratings yet

- Cbse Ncert Management of Natural Resources Notes Biology 10thDocument5 pagesCbse Ncert Management of Natural Resources Notes Biology 10thapurba mNo ratings yet

- De Mineral Izer ManualDocument33 pagesDe Mineral Izer ManualSarangNo ratings yet

- خواص صخور المكمن رقم 9Document31 pagesخواص صخور المكمن رقم 9maamoun ramyNo ratings yet

- SBR Chapter - 3Document45 pagesSBR Chapter - 3Noureddine MerahNo ratings yet

- Tehri Dam: An Engineering Marvel: Basistha Raj AdhikariDocument5 pagesTehri Dam: An Engineering Marvel: Basistha Raj AdhikariEr.Puranjan BishwakarmaNo ratings yet

- 3sample - DPR Ornamental Fish CulturchangeDocument6 pages3sample - DPR Ornamental Fish CulturchangeMyra Jane LeuterioNo ratings yet

- Assertion & Reason Basic 01Document5 pagesAssertion & Reason Basic 01chaostheoristNo ratings yet

- Alfa Laval PDFDocument42 pagesAlfa Laval PDFCristian ParaschivNo ratings yet

- Basf Masterseal 550 Tds PDFDocument3 pagesBasf Masterseal 550 Tds PDFashayshaNo ratings yet

- Answer: B: Selected/modified From Brown Et Al: Chemistry The Central Science, 10e, 12e, 13e TestbanksDocument10 pagesAnswer: B: Selected/modified From Brown Et Al: Chemistry The Central Science, 10e, 12e, 13e Testbanksفاطمة كليبNo ratings yet

- Green Tourism: A Road Map For TransformationDocument20 pagesGreen Tourism: A Road Map For TransformationTri'echa'RahayuWulansariNo ratings yet

- Code-5 GeographyDocument17 pagesCode-5 GeographySakshi PriyaNo ratings yet

- Kwale Workshop ReportDocument24 pagesKwale Workshop ReportFrancisco SilvaNo ratings yet

- SUBJECT: Science Test Yourself Worksheet Class: Ix Subject Code-086Document6 pagesSUBJECT: Science Test Yourself Worksheet Class: Ix Subject Code-086Vedant SinghalNo ratings yet

- CHAPTER 7 Exp BiologyDocument2 pagesCHAPTER 7 Exp BiologyAdy Phanterz100% (1)

- EX - CX - 044 - Master Inspection Characteristics MICDocument61 pagesEX - CX - 044 - Master Inspection Characteristics MICyramasapNo ratings yet

- FSN3 10 1520Document7 pagesFSN3 10 1520Chandrima JashNo ratings yet

- Rocor NB Liquid 25 LTRDocument3 pagesRocor NB Liquid 25 LTRaldrin de guzmanNo ratings yet

- Production of Ethanol: Project Year 1Document16 pagesProduction of Ethanol: Project Year 1gongweejie93100% (1)

- Environment Impact AssessmentDocument15 pagesEnvironment Impact AssessmentAyush BhadauriaNo ratings yet

- Monthly Global Point Current Affairs May 2020Document93 pagesMonthly Global Point Current Affairs May 2020Nawab Ali MalikNo ratings yet

- 002a REFRESHER PLUMBING CODE PDFDocument601 pages002a REFRESHER PLUMBING CODE PDFDoms DominguezNo ratings yet

- Water Supply Scheme in IndiaDocument39 pagesWater Supply Scheme in IndiaAde NovanNo ratings yet

- Evaluation of Groundwater Quality and Its Suitability For Drinking and Agricultural Use in Thanjavur City, Tamil Nadu, IndiaDocument45 pagesEvaluation of Groundwater Quality and Its Suitability For Drinking and Agricultural Use in Thanjavur City, Tamil Nadu, IndiaHanjiNo ratings yet