Professional Documents

Culture Documents

LKJH

LKJH

Uploaded by

Tk KimCopyright:

Available Formats

You might also like

- Surviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlFrom EverandSurviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlNo ratings yet

- C7,8 - ExercisesDocument31 pagesC7,8 - ExercisesTÂM MAI0% (1)

- OM PS2 InventoryDocument3 pagesOM PS2 InventoryNavneeth KrishnaNo ratings yet

- Cost Accounting - GuerreroDocument18 pagesCost Accounting - GuerreroRose Ann De Guzman43% (7)

- Quiz Finman Invty MNGTDocument4 pagesQuiz Finman Invty MNGTZoey Alvin EstarejaNo ratings yet

- 6091fd8f6f2df151707cb223 1620184992 Big Picture C Inventory ManagementDocument7 pages6091fd8f6f2df151707cb223 1620184992 Big Picture C Inventory ManagementChi BellaNo ratings yet

- MAS 01 Working Capital ManagementDocument3 pagesMAS 01 Working Capital ManagementKris Dela CruzNo ratings yet

- Inventory MGMT ComprehensiveDocument4 pagesInventory MGMT ComprehensivebigbaekNo ratings yet

- Inventories ATs Garcia CristineJoy G BSA-1BDocument4 pagesInventories ATs Garcia CristineJoy G BSA-1BCj GarciaNo ratings yet

- Inventory Management FIN 301Document12 pagesInventory Management FIN 301Nusrat JahanNo ratings yet

- Inventory Management and Short Term Financing ManagementDocument2 pagesInventory Management and Short Term Financing ManagementYOSH 47No ratings yet

- Safety Stocks FinalDocument44 pagesSafety Stocks FinalSangeeth BhoopaalanNo ratings yet

- This Study Resource Was: Assignment: 2, 3, 6, 7, and 9Document2 pagesThis Study Resource Was: Assignment: 2, 3, 6, 7, and 9Shaneen Angelique MoralesNo ratings yet

- MGMT Final Examination Problems Part 2Document2 pagesMGMT Final Examination Problems Part 2IPray ForUNo ratings yet

- Chapter 13A Reorder Point and Safety StockDocument5 pagesChapter 13A Reorder Point and Safety StockJeane Mae BooNo ratings yet

- (MANAGEMENT SCIENCE) EOQ Model QuizDocument3 pages(MANAGEMENT SCIENCE) EOQ Model QuizzackrembrandtNo ratings yet

- Inventory ManagementDocument23 pagesInventory ManagementAiron Keith Along67% (3)

- 3 Inventory Management - CompressDocument5 pages3 Inventory Management - Compressforacademicfiles.01No ratings yet

- OSM Notes PDFDocument24 pagesOSM Notes PDFGodsonNo ratings yet

- Chapter 2 Multiple Choice Computational Cost Acc Guerrero 2018 EdDocument14 pagesChapter 2 Multiple Choice Computational Cost Acc Guerrero 2018 EdJuan FrivaldoNo ratings yet

- Required:: Difficulty: Objective: Terms To Learn: Economic Order Quantity (EOQ)Document8 pagesRequired:: Difficulty: Objective: Terms To Learn: Economic Order Quantity (EOQ)Maha HamdyNo ratings yet

- Inventory 1Document5 pagesInventory 1Kim Ivy May FabunanNo ratings yet

- Chapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 Ed. Chapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 EdDocument14 pagesChapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 Ed. Chapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 EdKelton Cyrel Rosales0% (1)

- 3 - Inventory ManagementDocument5 pages3 - Inventory ManagementAngela Shaine Castro GarciaNo ratings yet

- 11 D Inventory Management Problems KEYDocument3 pages11 D Inventory Management Problems KEYCharisse BuquidNo ratings yet

- 01 Material CostingDocument8 pages01 Material CostingPappu LalNo ratings yet

- Inventory Management SOLUTIONSDocument6 pagesInventory Management SOLUTIONSJack HererNo ratings yet

- Chapter 5 - Managing Working Capital - GUI HVDocument44 pagesChapter 5 - Managing Working Capital - GUI HVTấn Phú LêNo ratings yet

- Inventory ManagementDocument13 pagesInventory Managementparkjenaa09No ratings yet

- 07 - Cash, Receivables, Inventory Managment ProblemsDocument6 pages07 - Cash, Receivables, Inventory Managment ProblemsMerr Fe PainaganNo ratings yet

- Inventory NumericalsDocument2 pagesInventory NumericalssushmaNo ratings yet

- MSC Math 129Document6 pagesMSC Math 129Arshdeep kaurNo ratings yet

- Chapter 20 Exercise: RequiredDocument5 pagesChapter 20 Exercise: RequiredNitinNo ratings yet

- Acctg For MaterialsDocument12 pagesAcctg For MaterialsFilnara RaguroNo ratings yet

- Inventory ManagementDocument1 pageInventory Managementf4farhansiddiqui17No ratings yet

- Asignment Financial Management IIDocument1 pageAsignment Financial Management IItame kibruNo ratings yet

- Cost Accounting - MaterialsDocument18 pagesCost Accounting - MaterialsSaad Khan YTNo ratings yet

- Chapter 6 Accounting For MaterialsDocument3 pagesChapter 6 Accounting For MaterialsIbrahim SameerNo ratings yet

- 411 Final Exam - ForuploadDocument4 pages411 Final Exam - ForuploadJustin CorillaNo ratings yet

- Assignment 1 (BBA & BBIS) SUB: OM Inventory Management: EOQ 200 Units & ROL 40 L, L Lead TimeDocument3 pagesAssignment 1 (BBA & BBIS) SUB: OM Inventory Management: EOQ 200 Units & ROL 40 L, L Lead Timesajal koiralaNo ratings yet

- Managing Working Capital Inventory ManagementDocument10 pagesManaging Working Capital Inventory ManagementAjay Kumar TakiarNo ratings yet

- Material Assignment PDFDocument21 pagesMaterial Assignment PDFjoeyNo ratings yet

- Practice Session ThreeDocument3 pagesPractice Session ThreeKUMAR ABHISHEKNo ratings yet

- Hospitality Financial Management Ch.3-Current Asset ManagementDocument14 pagesHospitality Financial Management Ch.3-Current Asset ManagementMuhammad Salihin Jaafar0% (1)

- II.3 Management of InventoriesDocument44 pagesII.3 Management of InventoriesKin SaysonNo ratings yet

- Assignment 1 OM PDFDocument3 pagesAssignment 1 OM PDFSuman ChaudharyNo ratings yet

- Chapter 7-Acctng For Materials ActivityDocument3 pagesChapter 7-Acctng For Materials ActivityDonna Mae PinatNo ratings yet

- CMA Mock S24-QP-By Sir Waseem AkramDocument5 pagesCMA Mock S24-QP-By Sir Waseem AkramOmair HasanNo ratings yet

- MaterialDocument5 pagesMaterialQuestionscastle FriendNo ratings yet

- Inventory ManagementDocument8 pagesInventory ManagementFareha Riaz100% (1)

- (B) (1) Re-Order Level 1,500 Units (I) Safety Stock 1,000 UnitsDocument5 pages(B) (1) Re-Order Level 1,500 Units (I) Safety Stock 1,000 UnitsAbhijit HoroNo ratings yet

- Chapter 6 Accounting For MaterialDocument4 pagesChapter 6 Accounting For MaterialIbrahim SameerNo ratings yet

- Chapter 3Document32 pagesChapter 3Angela Marie PenarandaNo ratings yet

- MGT613 Solved Mcqs From Book Inventory Management FINalssssssssDocument20 pagesMGT613 Solved Mcqs From Book Inventory Management FINalssssssssNoman SajjadNo ratings yet

- OM - Sessions 18 - 23 - Inventory ManagementDocument64 pagesOM - Sessions 18 - 23 - Inventory ManagementSiddhant SinghNo ratings yet

- Operations Management (TQM) Bsentoumn 2-2Document22 pagesOperations Management (TQM) Bsentoumn 2-2Jemimah Joy OriendoNo ratings yet

- Internal Control of Fixed Assets: A Controller and Auditor's GuideFrom EverandInternal Control of Fixed Assets: A Controller and Auditor's GuideRating: 4 out of 5 stars4/5 (1)

- Additive Manufacturing and Strategic Technologies in Advanced CeramicsFrom EverandAdditive Manufacturing and Strategic Technologies in Advanced CeramicsKiyoshi ShimamuraNo ratings yet

- Financial Risk Management: Applications in Market, Credit, Asset and Liability Management and Firmwide RiskFrom EverandFinancial Risk Management: Applications in Market, Credit, Asset and Liability Management and Firmwide RiskNo ratings yet

- At 8503Document12 pagesAt 8503Tk KimNo ratings yet

- Types of ResearchDocument1 pageTypes of ResearchTk KimNo ratings yet

- Marks: Taxation (Pakistan) and Marking SchemeDocument2 pagesMarks: Taxation (Pakistan) and Marking SchemeTk KimNo ratings yet

- Corporate LiquidationDocument2 pagesCorporate LiquidationTk KimNo ratings yet

- FCL Midterm WPS OfficeDocument7 pagesFCL Midterm WPS OfficeTk KimNo ratings yet

- QUIZ 2 - ESTATE TAX (Late Quiz)Document3 pagesQUIZ 2 - ESTATE TAX (Late Quiz)Tk KimNo ratings yet

- Afar SolutionDocument2 pagesAfar SolutionTk KimNo ratings yet

- SW#1 - Specialized IndustriesDocument1 pageSW#1 - Specialized IndustriesTk KimNo ratings yet

- AuditDocument4 pagesAuditTk KimNo ratings yet

- A. Condonation or Remission of A DebtDocument3 pagesA. Condonation or Remission of A DebtTk KimNo ratings yet

- Chapter Review: I. Unit-Based Product CostingDocument6 pagesChapter Review: I. Unit-Based Product CostingTk KimNo ratings yet

- FB Cash FlowsDocument3 pagesFB Cash FlowsTk KimNo ratings yet

- General Overview of Accounting Research: Teresa P. Gordon and Jason C. PorterDocument8 pagesGeneral Overview of Accounting Research: Teresa P. Gordon and Jason C. PorterTk KimNo ratings yet

- Mas 1Document1 pageMas 1Tk KimNo ratings yet

- Break Even Analysis - Biopure CaseDocument4 pagesBreak Even Analysis - Biopure CaseYagyaaGoyalNo ratings yet

- Procurement at Betapharm CorpDocument3 pagesProcurement at Betapharm CorpDakshNo ratings yet

- Free Value Chain Analysis Template PowerPoint DownloadDocument5 pagesFree Value Chain Analysis Template PowerPoint DownloadGretchen DawatonNo ratings yet

- Scrum Events or CeremoniesDocument2 pagesScrum Events or CeremoniesMamoon20No ratings yet

- Group 4 - Assignment 5 PDFDocument20 pagesGroup 4 - Assignment 5 PDFriasatNo ratings yet

- It Application Lifecycle Management Vendor Landscape Storyboard SampleDocument12 pagesIt Application Lifecycle Management Vendor Landscape Storyboard SampleRobson MamedeNo ratings yet

- Principal of ManagementDocument9 pagesPrincipal of ManagementGau Rav AsharaNo ratings yet

- MB1A, B, C - SerialDocument2 pagesMB1A, B, C - SerialVarunNo ratings yet

- Brand Gap AnalysisDocument1 pageBrand Gap Analysisamitsharma28No ratings yet

- Battle Card - Resilient Finance and Operations - 7.30 - 47834 - 2020!08!03204704729Document2 pagesBattle Card - Resilient Finance and Operations - 7.30 - 47834 - 2020!08!03204704729AhmedNo ratings yet

- Ba 152 NotesDocument19 pagesBa 152 NotesKoi CallejaNo ratings yet

- Communicating Key Audit Matters in The Independent Auditor'S ReportDocument12 pagesCommunicating Key Audit Matters in The Independent Auditor'S Reportjessica judeNo ratings yet

- Strategi Pengembangan Bisnis Pt. Adhi Persada PropertiDocument10 pagesStrategi Pengembangan Bisnis Pt. Adhi Persada PropertiNur Ihsan MuzakkiNo ratings yet

- Active DetergentDocument16 pagesActive DetergentRAZIA SULTANNo ratings yet

- Marketing, StrategyDocument13 pagesMarketing, Strategy911targaNo ratings yet

- IMDA's Open Innovation PlatformDocument11 pagesIMDA's Open Innovation PlatformArun KumarNo ratings yet

- Business Plan TemplateDocument4 pagesBusiness Plan TemplateFahadKhanNo ratings yet

- Bu121 Final Exam Review Guide 2023 UpdatedDocument4 pagesBu121 Final Exam Review Guide 2023 UpdatedLanxi WangNo ratings yet

- BSBHRM614 Simulation PackDocument39 pagesBSBHRM614 Simulation Packsupriya dusadNo ratings yet

- Retail Glossary of Terminology: Product Service Advertising Design Symbolic Logo Color Schemes Symbols ValuesDocument12 pagesRetail Glossary of Terminology: Product Service Advertising Design Symbolic Logo Color Schemes Symbols ValuesParidhi_Nigam_8487No ratings yet

- Lean Chapter 4Document15 pagesLean Chapter 4WinterMist11No ratings yet

- SfsDocument1 pageSfsJehanzeb KayaniNo ratings yet

- Ey Insurance Maintaining Internal Controls and Trust While Remote Working During Covid 19Document11 pagesEy Insurance Maintaining Internal Controls and Trust While Remote Working During Covid 19Arun RajanNo ratings yet

- Foundation S of Internal AuditDocument4 pagesFoundation S of Internal AuditS4M1Y4No ratings yet

- Methodology in Business Ethics Research: A Review and Critical AssessmentDocument15 pagesMethodology in Business Ethics Research: A Review and Critical Assessmenttrendsetters80No ratings yet

- Strategy FormulationDocument36 pagesStrategy FormulationKarthik Cm100% (1)

- Pre Final PPT 4 Lean ERPDocument28 pagesPre Final PPT 4 Lean ERPbinnivenus100% (1)

- Standard Costing and Variance AnalysisDocument13 pagesStandard Costing and Variance AnalysisSigei Leonard100% (1)

- BEPDocument11 pagesBEPNald PerezNo ratings yet

- 5 Project Quality Management (D)Document23 pages5 Project Quality Management (D)GeorgeNo ratings yet

LKJH

LKJH

Uploaded by

Tk KimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LKJH

LKJH

Uploaded by

Tk KimCopyright:

Available Formats

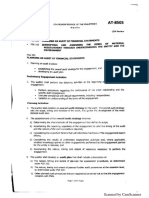

61.

A softdrinks distributor which buys in a pre-sell basis, is discussing with the route salesmen on the

proper cases to be ordered and the frequency of call. From the route book and other records, the

following are available: prior year’s purchases, 50,000 cases; carrying cost per case of inventory,

P1.20; distributor’s discount, 1 case for every 10 cases bought; cost of placing an order, P3.00;

weekly demand is approximately 962 cases. Safety stock required is 140 cases. No change in

demand is expected this year. (Use a 365-day, 52-week year).

Determine the economic order quantity (EOQ), and the reorder point assuming a two-day lead-

time.

A. B. C. D.

EOQ 250 cases 481 cases 500 cases 962 cases

Reorder point 280 cases 500 cases 414 cases 275 cases

62. If Ferry Company has a safety stock of 160 units and the average daily demand is 20 units, how

many days can be covered if the shipment from the supplier is delayed by 12 days?

A. 6.7 days C. 10.0 days

B. 8.0 days D. 12.0 days

63. Each stockout of Product AX sold by Axiom Inc. costs P87,500 per occurrence. The carrying cost

per unit of inventory is P250 per year, and the company orders 1,500 units of product 24 times a

year at a cost of P5,000 per order. The probability of stockout at various levels of safety stock is

Units of Safety Stock Probability of a stockout

0 0.50

100 0.30

200 0.14

300 0.05

400 0.01

The optimal safety stock level for the company is

A. 0 units. C. 300 units.

B. 100 units. D. 400 units.

64. Vera Cruz Corporation seeks to determine the quantity of safety stock for product ST that they

should maintain that will result in the lowest cost to the company. Each stockout will cost P600 and

the carrying cost of each unit of safety stock will be P8. Product ST will be ordered five times a

year. Which of the following will produce the lowest cost?

A. A safety stock of 15 units which is associated with a 35% probability of running out of stock

during an order period.

B. A safety stock of 25 units which is associated with a 25% probability of running out of stock

during an order period.

C. A safety stock of 35 units which is associated with a 10% probability of running out of stock

during an order period.

D. A safety stock of 75 units associated with a 5% probability of running out of stock during an

order period.

65. Arnold Enterprises uses the EOQ model for inventory control. The company has an annual

demand of 50,000 units for part number 101 and has computed an optimal lot size of 6,250 units.

Per-unit carrying costs and stockout costs are $13 and $3, respectively. The following data have

been gathered in an attempt to determine an appropriate safety stock level:

Number of Times Short

Units Short Because of Excess in the last 40 Reorder Cycles

Demand during the Lead Time Period

200 6

300 12

You might also like

- Surviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlFrom EverandSurviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlNo ratings yet

- C7,8 - ExercisesDocument31 pagesC7,8 - ExercisesTÂM MAI0% (1)

- OM PS2 InventoryDocument3 pagesOM PS2 InventoryNavneeth KrishnaNo ratings yet

- Cost Accounting - GuerreroDocument18 pagesCost Accounting - GuerreroRose Ann De Guzman43% (7)

- Quiz Finman Invty MNGTDocument4 pagesQuiz Finman Invty MNGTZoey Alvin EstarejaNo ratings yet

- 6091fd8f6f2df151707cb223 1620184992 Big Picture C Inventory ManagementDocument7 pages6091fd8f6f2df151707cb223 1620184992 Big Picture C Inventory ManagementChi BellaNo ratings yet

- MAS 01 Working Capital ManagementDocument3 pagesMAS 01 Working Capital ManagementKris Dela CruzNo ratings yet

- Inventory MGMT ComprehensiveDocument4 pagesInventory MGMT ComprehensivebigbaekNo ratings yet

- Inventories ATs Garcia CristineJoy G BSA-1BDocument4 pagesInventories ATs Garcia CristineJoy G BSA-1BCj GarciaNo ratings yet

- Inventory Management FIN 301Document12 pagesInventory Management FIN 301Nusrat JahanNo ratings yet

- Inventory Management and Short Term Financing ManagementDocument2 pagesInventory Management and Short Term Financing ManagementYOSH 47No ratings yet

- Safety Stocks FinalDocument44 pagesSafety Stocks FinalSangeeth BhoopaalanNo ratings yet

- This Study Resource Was: Assignment: 2, 3, 6, 7, and 9Document2 pagesThis Study Resource Was: Assignment: 2, 3, 6, 7, and 9Shaneen Angelique MoralesNo ratings yet

- MGMT Final Examination Problems Part 2Document2 pagesMGMT Final Examination Problems Part 2IPray ForUNo ratings yet

- Chapter 13A Reorder Point and Safety StockDocument5 pagesChapter 13A Reorder Point and Safety StockJeane Mae BooNo ratings yet

- (MANAGEMENT SCIENCE) EOQ Model QuizDocument3 pages(MANAGEMENT SCIENCE) EOQ Model QuizzackrembrandtNo ratings yet

- Inventory ManagementDocument23 pagesInventory ManagementAiron Keith Along67% (3)

- 3 Inventory Management - CompressDocument5 pages3 Inventory Management - Compressforacademicfiles.01No ratings yet

- OSM Notes PDFDocument24 pagesOSM Notes PDFGodsonNo ratings yet

- Chapter 2 Multiple Choice Computational Cost Acc Guerrero 2018 EdDocument14 pagesChapter 2 Multiple Choice Computational Cost Acc Guerrero 2018 EdJuan FrivaldoNo ratings yet

- Required:: Difficulty: Objective: Terms To Learn: Economic Order Quantity (EOQ)Document8 pagesRequired:: Difficulty: Objective: Terms To Learn: Economic Order Quantity (EOQ)Maha HamdyNo ratings yet

- Inventory 1Document5 pagesInventory 1Kim Ivy May FabunanNo ratings yet

- Chapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 Ed. Chapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 EdDocument14 pagesChapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 Ed. Chapter 2 Multiple Choice Computational - Cost Acc Guerrero 2018 EdKelton Cyrel Rosales0% (1)

- 3 - Inventory ManagementDocument5 pages3 - Inventory ManagementAngela Shaine Castro GarciaNo ratings yet

- 11 D Inventory Management Problems KEYDocument3 pages11 D Inventory Management Problems KEYCharisse BuquidNo ratings yet

- 01 Material CostingDocument8 pages01 Material CostingPappu LalNo ratings yet

- Inventory Management SOLUTIONSDocument6 pagesInventory Management SOLUTIONSJack HererNo ratings yet

- Chapter 5 - Managing Working Capital - GUI HVDocument44 pagesChapter 5 - Managing Working Capital - GUI HVTấn Phú LêNo ratings yet

- Inventory ManagementDocument13 pagesInventory Managementparkjenaa09No ratings yet

- 07 - Cash, Receivables, Inventory Managment ProblemsDocument6 pages07 - Cash, Receivables, Inventory Managment ProblemsMerr Fe PainaganNo ratings yet

- Inventory NumericalsDocument2 pagesInventory NumericalssushmaNo ratings yet

- MSC Math 129Document6 pagesMSC Math 129Arshdeep kaurNo ratings yet

- Chapter 20 Exercise: RequiredDocument5 pagesChapter 20 Exercise: RequiredNitinNo ratings yet

- Acctg For MaterialsDocument12 pagesAcctg For MaterialsFilnara RaguroNo ratings yet

- Inventory ManagementDocument1 pageInventory Managementf4farhansiddiqui17No ratings yet

- Asignment Financial Management IIDocument1 pageAsignment Financial Management IItame kibruNo ratings yet

- Cost Accounting - MaterialsDocument18 pagesCost Accounting - MaterialsSaad Khan YTNo ratings yet

- Chapter 6 Accounting For MaterialsDocument3 pagesChapter 6 Accounting For MaterialsIbrahim SameerNo ratings yet

- 411 Final Exam - ForuploadDocument4 pages411 Final Exam - ForuploadJustin CorillaNo ratings yet

- Assignment 1 (BBA & BBIS) SUB: OM Inventory Management: EOQ 200 Units & ROL 40 L, L Lead TimeDocument3 pagesAssignment 1 (BBA & BBIS) SUB: OM Inventory Management: EOQ 200 Units & ROL 40 L, L Lead Timesajal koiralaNo ratings yet

- Managing Working Capital Inventory ManagementDocument10 pagesManaging Working Capital Inventory ManagementAjay Kumar TakiarNo ratings yet

- Material Assignment PDFDocument21 pagesMaterial Assignment PDFjoeyNo ratings yet

- Practice Session ThreeDocument3 pagesPractice Session ThreeKUMAR ABHISHEKNo ratings yet

- Hospitality Financial Management Ch.3-Current Asset ManagementDocument14 pagesHospitality Financial Management Ch.3-Current Asset ManagementMuhammad Salihin Jaafar0% (1)

- II.3 Management of InventoriesDocument44 pagesII.3 Management of InventoriesKin SaysonNo ratings yet

- Assignment 1 OM PDFDocument3 pagesAssignment 1 OM PDFSuman ChaudharyNo ratings yet

- Chapter 7-Acctng For Materials ActivityDocument3 pagesChapter 7-Acctng For Materials ActivityDonna Mae PinatNo ratings yet

- CMA Mock S24-QP-By Sir Waseem AkramDocument5 pagesCMA Mock S24-QP-By Sir Waseem AkramOmair HasanNo ratings yet

- MaterialDocument5 pagesMaterialQuestionscastle FriendNo ratings yet

- Inventory ManagementDocument8 pagesInventory ManagementFareha Riaz100% (1)

- (B) (1) Re-Order Level 1,500 Units (I) Safety Stock 1,000 UnitsDocument5 pages(B) (1) Re-Order Level 1,500 Units (I) Safety Stock 1,000 UnitsAbhijit HoroNo ratings yet

- Chapter 6 Accounting For MaterialDocument4 pagesChapter 6 Accounting For MaterialIbrahim SameerNo ratings yet

- Chapter 3Document32 pagesChapter 3Angela Marie PenarandaNo ratings yet

- MGT613 Solved Mcqs From Book Inventory Management FINalssssssssDocument20 pagesMGT613 Solved Mcqs From Book Inventory Management FINalssssssssNoman SajjadNo ratings yet

- OM - Sessions 18 - 23 - Inventory ManagementDocument64 pagesOM - Sessions 18 - 23 - Inventory ManagementSiddhant SinghNo ratings yet

- Operations Management (TQM) Bsentoumn 2-2Document22 pagesOperations Management (TQM) Bsentoumn 2-2Jemimah Joy OriendoNo ratings yet

- Internal Control of Fixed Assets: A Controller and Auditor's GuideFrom EverandInternal Control of Fixed Assets: A Controller and Auditor's GuideRating: 4 out of 5 stars4/5 (1)

- Additive Manufacturing and Strategic Technologies in Advanced CeramicsFrom EverandAdditive Manufacturing and Strategic Technologies in Advanced CeramicsKiyoshi ShimamuraNo ratings yet

- Financial Risk Management: Applications in Market, Credit, Asset and Liability Management and Firmwide RiskFrom EverandFinancial Risk Management: Applications in Market, Credit, Asset and Liability Management and Firmwide RiskNo ratings yet

- At 8503Document12 pagesAt 8503Tk KimNo ratings yet

- Types of ResearchDocument1 pageTypes of ResearchTk KimNo ratings yet

- Marks: Taxation (Pakistan) and Marking SchemeDocument2 pagesMarks: Taxation (Pakistan) and Marking SchemeTk KimNo ratings yet

- Corporate LiquidationDocument2 pagesCorporate LiquidationTk KimNo ratings yet

- FCL Midterm WPS OfficeDocument7 pagesFCL Midterm WPS OfficeTk KimNo ratings yet

- QUIZ 2 - ESTATE TAX (Late Quiz)Document3 pagesQUIZ 2 - ESTATE TAX (Late Quiz)Tk KimNo ratings yet

- Afar SolutionDocument2 pagesAfar SolutionTk KimNo ratings yet

- SW#1 - Specialized IndustriesDocument1 pageSW#1 - Specialized IndustriesTk KimNo ratings yet

- AuditDocument4 pagesAuditTk KimNo ratings yet

- A. Condonation or Remission of A DebtDocument3 pagesA. Condonation or Remission of A DebtTk KimNo ratings yet

- Chapter Review: I. Unit-Based Product CostingDocument6 pagesChapter Review: I. Unit-Based Product CostingTk KimNo ratings yet

- FB Cash FlowsDocument3 pagesFB Cash FlowsTk KimNo ratings yet

- General Overview of Accounting Research: Teresa P. Gordon and Jason C. PorterDocument8 pagesGeneral Overview of Accounting Research: Teresa P. Gordon and Jason C. PorterTk KimNo ratings yet

- Mas 1Document1 pageMas 1Tk KimNo ratings yet

- Break Even Analysis - Biopure CaseDocument4 pagesBreak Even Analysis - Biopure CaseYagyaaGoyalNo ratings yet

- Procurement at Betapharm CorpDocument3 pagesProcurement at Betapharm CorpDakshNo ratings yet

- Free Value Chain Analysis Template PowerPoint DownloadDocument5 pagesFree Value Chain Analysis Template PowerPoint DownloadGretchen DawatonNo ratings yet

- Scrum Events or CeremoniesDocument2 pagesScrum Events or CeremoniesMamoon20No ratings yet

- Group 4 - Assignment 5 PDFDocument20 pagesGroup 4 - Assignment 5 PDFriasatNo ratings yet

- It Application Lifecycle Management Vendor Landscape Storyboard SampleDocument12 pagesIt Application Lifecycle Management Vendor Landscape Storyboard SampleRobson MamedeNo ratings yet

- Principal of ManagementDocument9 pagesPrincipal of ManagementGau Rav AsharaNo ratings yet

- MB1A, B, C - SerialDocument2 pagesMB1A, B, C - SerialVarunNo ratings yet

- Brand Gap AnalysisDocument1 pageBrand Gap Analysisamitsharma28No ratings yet

- Battle Card - Resilient Finance and Operations - 7.30 - 47834 - 2020!08!03204704729Document2 pagesBattle Card - Resilient Finance and Operations - 7.30 - 47834 - 2020!08!03204704729AhmedNo ratings yet

- Ba 152 NotesDocument19 pagesBa 152 NotesKoi CallejaNo ratings yet

- Communicating Key Audit Matters in The Independent Auditor'S ReportDocument12 pagesCommunicating Key Audit Matters in The Independent Auditor'S Reportjessica judeNo ratings yet

- Strategi Pengembangan Bisnis Pt. Adhi Persada PropertiDocument10 pagesStrategi Pengembangan Bisnis Pt. Adhi Persada PropertiNur Ihsan MuzakkiNo ratings yet

- Active DetergentDocument16 pagesActive DetergentRAZIA SULTANNo ratings yet

- Marketing, StrategyDocument13 pagesMarketing, Strategy911targaNo ratings yet

- IMDA's Open Innovation PlatformDocument11 pagesIMDA's Open Innovation PlatformArun KumarNo ratings yet

- Business Plan TemplateDocument4 pagesBusiness Plan TemplateFahadKhanNo ratings yet

- Bu121 Final Exam Review Guide 2023 UpdatedDocument4 pagesBu121 Final Exam Review Guide 2023 UpdatedLanxi WangNo ratings yet

- BSBHRM614 Simulation PackDocument39 pagesBSBHRM614 Simulation Packsupriya dusadNo ratings yet

- Retail Glossary of Terminology: Product Service Advertising Design Symbolic Logo Color Schemes Symbols ValuesDocument12 pagesRetail Glossary of Terminology: Product Service Advertising Design Symbolic Logo Color Schemes Symbols ValuesParidhi_Nigam_8487No ratings yet

- Lean Chapter 4Document15 pagesLean Chapter 4WinterMist11No ratings yet

- SfsDocument1 pageSfsJehanzeb KayaniNo ratings yet

- Ey Insurance Maintaining Internal Controls and Trust While Remote Working During Covid 19Document11 pagesEy Insurance Maintaining Internal Controls and Trust While Remote Working During Covid 19Arun RajanNo ratings yet

- Foundation S of Internal AuditDocument4 pagesFoundation S of Internal AuditS4M1Y4No ratings yet

- Methodology in Business Ethics Research: A Review and Critical AssessmentDocument15 pagesMethodology in Business Ethics Research: A Review and Critical Assessmenttrendsetters80No ratings yet

- Strategy FormulationDocument36 pagesStrategy FormulationKarthik Cm100% (1)

- Pre Final PPT 4 Lean ERPDocument28 pagesPre Final PPT 4 Lean ERPbinnivenus100% (1)

- Standard Costing and Variance AnalysisDocument13 pagesStandard Costing and Variance AnalysisSigei Leonard100% (1)

- BEPDocument11 pagesBEPNald PerezNo ratings yet

- 5 Project Quality Management (D)Document23 pages5 Project Quality Management (D)GeorgeNo ratings yet