Professional Documents

Culture Documents

Asphalt Particle Loss: AUSTROADS Asphalt Test AST 07:2000

Asphalt Particle Loss: AUSTROADS Asphalt Test AST 07:2000

Uploaded by

तिप्लोकाची तिरुनचिपल्ली केरकेट्टाCopyright:

Available Formats

You might also like

- AASHTO T 166-05 Bulk Specific Gravity of Compacted Hot Mix Asphalt Using Saturated Surface-Dry Specimens-FinalDocument6 pagesAASHTO T 166-05 Bulk Specific Gravity of Compacted Hot Mix Asphalt Using Saturated Surface-Dry Specimens-Finalclint sil100% (1)

- Reconfirmation Notice: AS 1141.5-2000 (Reconfirmed) 2016-07-15Document9 pagesReconfirmation Notice: AS 1141.5-2000 (Reconfirmed) 2016-07-15Alexandru LetNo ratings yet

- S406 Specifications For The Supply of StoneDocument6 pagesS406 Specifications For The Supply of StoneRui Lourenco100% (1)

- ASTM C1403-13 Standard Test Method For Rate of Water AbsorptionDocument4 pagesASTM C1403-13 Standard Test Method For Rate of Water AbsorptionEdwin R Ruiz100% (1)

- Astm D 903Document3 pagesAstm D 903rajupetalokeshNo ratings yet

- Emc WaiverDocument1 pageEmc WaiverZumbaShellNo ratings yet

- General Safety Orientation Guidelines (Replaced Irp 16)Document29 pagesGeneral Safety Orientation Guidelines (Replaced Irp 16)dinuveraNo ratings yet

- Stripping Potential of Asphalt - Tensile Strength Ratio: AUSTROADS Asphalt Test AST 02:2000Document7 pagesStripping Potential of Asphalt - Tensile Strength Ratio: AUSTROADS Asphalt Test AST 02:2000तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Commentary To Ag:Pt/T232 - Stripping Potential of Asphalt - Tensile Strength RatioDocument10 pagesCommentary To Ag:Pt/T232 - Stripping Potential of Asphalt - Tensile Strength Ratiofilo821No ratings yet

- LS-297 - Rev 34 - May 2020Document9 pagesLS-297 - Rev 34 - May 2020ming_zhu10No ratings yet

- LS-297 R26 123Document6 pagesLS-297 R26 123Gourav GoelNo ratings yet

- ASTM D3173 - Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument3 pagesASTM D3173 - Standard Test Method For Moisture in The Analysis Sample of Coal and CokeFabian E. Quesada-Plata80% (5)

- Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument7 pagesStandard Test Method For Moisture in The Analysis Sample of Coal and CokemuchtarNo ratings yet

- LS-628 R23 PDFDocument7 pagesLS-628 R23 PDFqwerysqlNo ratings yet

- Reconfirmation Notice: AS 1012.12.2-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.12.2-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Aashto T 283Document6 pagesAashto T 283Noraziana Azi75% (4)

- Bulk Specific Gravity of Compacted Bituminous Mixtures Using Water Displacement Measured by Pressure SensorDocument3 pagesBulk Specific Gravity of Compacted Bituminous Mixtures Using Water Displacement Measured by Pressure SensorWaleed AhmedNo ratings yet

- Laboratory WorksDocument32 pagesLaboratory WorksCliff Jude ZehnderNo ratings yet

- D3173Document2 pagesD3173Timothy Ferguson100% (1)

- Asphalt Binder Content (Ignition Oven Method) : AUSTROADS Asphalt Test AST 04:2000Document7 pagesAsphalt Binder Content (Ignition Oven Method) : AUSTROADS Asphalt Test AST 04:2000तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- C 948 PDFDocument2 pagesC 948 PDFGrato Jr Singco100% (1)

- Argillaceous Swellingxocks - Methods For Laboratory TestingDocument16 pagesArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20No ratings yet

- CRD c513Document2 pagesCRD c513azharbNo ratings yet

- Moisture in The Analysis Sample of Coal and Coke: Standard Test Method ForDocument5 pagesMoisture in The Analysis Sample of Coal and Coke: Standard Test Method Formohamed fathiNo ratings yet

- C 602 - 95a R01 QZYWMGDocument3 pagesC 602 - 95a R01 QZYWMGHumberto Gutierrez100% (1)

- D 5101 Â " 01 RDUXMDEDocument8 pagesD 5101 Â " 01 RDUXMDEdorbarelNo ratings yet

- Abrasion TestDocument5 pagesAbrasion TestMae Lingan-LasqueroNo ratings yet

- Emulsified Bitumens Used As Protective Coatings: Standard Test Methods ForDocument7 pagesEmulsified Bitumens Used As Protective Coatings: Standard Test Methods FordaovandongpktNo ratings yet

- AASHTO T 283 Dr. LiuDocument9 pagesAASHTO T 283 Dr. LiuRamy HusseinNo ratings yet

- C 123 - 03 - QzeymwDocument3 pagesC 123 - 03 - QzeymwAnonymous 6SHxUn1xd1No ratings yet

- Astm C123Document3 pagesAstm C123renzoNo ratings yet

- Resistance of Compacted Asphalt Mixtures To Moisture-Induced DamageDocument8 pagesResistance of Compacted Asphalt Mixtures To Moisture-Induced Damagediegoelpotro.24No ratings yet

- Fatigue Life of Compacted Bituminous Mixes Subject To Repeated Flexural BendingDocument14 pagesFatigue Life of Compacted Bituminous Mixes Subject To Repeated Flexural Bendingतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- C 35 - 95 r00 - Qzm1ltk1ujawDocument3 pagesC 35 - 95 r00 - Qzm1ltk1ujaw2010civ164No ratings yet

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasNo ratings yet

- Sampling & Testing Procedures 01aug2009Document12 pagesSampling & Testing Procedures 01aug2009akclams77No ratings yet

- Asphalt Roll Roofing, Cap Sheets, and Shingles: Standard Test Methods ForDocument9 pagesAsphalt Roll Roofing, Cap Sheets, and Shingles: Standard Test Methods FordaovandongpktNo ratings yet

- Asphalt Binder Drain-Off: AUSTROADS Asphalt Test AST 06:2000Document3 pagesAsphalt Binder Drain-Off: AUSTROADS Asphalt Test AST 06:2000तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Aashto T 283-14Document9 pagesAashto T 283-14Chandrasekhar Chintada100% (1)

- C 452 - 95 Qzq1mi1sruq - PDFDocument4 pagesC 452 - 95 Qzq1mi1sruq - PDFAlejandro MuñozNo ratings yet

- AASHTO T 265-93 (2008) Standard Method of Test For Laboratory Determination of Moisture Content of Soils PDFDocument2 pagesAASHTO T 265-93 (2008) Standard Method of Test For Laboratory Determination of Moisture Content of Soils PDFJulius Gatchalian100% (1)

- Particle Size Analysis of Soils: Test Procedure ForDocument13 pagesParticle Size Analysis of Soils: Test Procedure ForDayner M Sanchez GarciaNo ratings yet

- D 2939 - 98 Rdi5mzktukveDocument9 pagesD 2939 - 98 Rdi5mzktukvedaovandongpktNo ratings yet

- Sieve Analysis of Surfacing For Asphalt Roofing Products: Standard Test Method ForDocument2 pagesSieve Analysis of Surfacing For Asphalt Roofing Products: Standard Test Method ForNuMbNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- AASHTO T 166-Standard Method of Test For Bulk Specific Gravity of Compacted Bituminous MixturesDocument4 pagesAASHTO T 166-Standard Method of Test For Bulk Specific Gravity of Compacted Bituminous MixturesDonnabel CaleNo ratings yet

- Standard Method of Test For Bulk Specific Gravity (G) of Compacted Asphalt Mixtures Using Saturated Surface-Dry SpecimensDocument6 pagesStandard Method of Test For Bulk Specific Gravity (G) of Compacted Asphalt Mixtures Using Saturated Surface-Dry SpecimensHugo EscalanteNo ratings yet

- Is - 4253-2004Document6 pagesIs - 4253-2004Sahil AggarwalNo ratings yet

- Lap Shear Strength of Hot-Applied Sealants: Standard Test Method ForDocument4 pagesLap Shear Strength of Hot-Applied Sealants: Standard Test Method ForRufo CascoNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityFrom EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNo ratings yet

- Nanostructured Polymer Membranes, Volume 1: Processing and CharacterizationFrom EverandNanostructured Polymer Membranes, Volume 1: Processing and CharacterizationNo ratings yet

- ButaneDocument6 pagesButaneRatu Fajrina HanifaNo ratings yet

- Baypren® 320-1 Safety Data SheetDocument10 pagesBaypren® 320-1 Safety Data SheetXiaofeng MengNo ratings yet

- Anatomy and Cardiovascular AssessmentDocument52 pagesAnatomy and Cardiovascular AssessmentNaomi Anne AsuntoNo ratings yet

- Rus 01Document36 pagesRus 01outchoiNo ratings yet

- Extraordinary Attorney WooDocument5 pagesExtraordinary Attorney WooAnuska ThapaNo ratings yet

- Dutch Compaies in IndiaDocument28 pagesDutch Compaies in IndiaSourabh GargNo ratings yet

- Immigration Reform and Control Act of 1986Document3 pagesImmigration Reform and Control Act of 1986d8nNo ratings yet

- Aubert Et Al. 2018Document3 pagesAubert Et Al. 2018LhuissetNo ratings yet

- Marital RapeDocument12 pagesMarital RapeKrati Yadav - 65No ratings yet

- Penguard Express ZP: Technical Data Sheet Application GuideDocument8 pagesPenguard Express ZP: Technical Data Sheet Application GuideAzar SKNo ratings yet

- The Organization of Modern KitchensDocument9 pagesThe Organization of Modern KitchensJohnson Macayan FernándezNo ratings yet

- Sludge TreatmentDocument34 pagesSludge TreatmentNurul Fatihah SyazwaniNo ratings yet

- Plasma TV: Service ManualDocument34 pagesPlasma TV: Service ManualClaudelino ToffolettiNo ratings yet

- MESL - Algebra 2Document7 pagesMESL - Algebra 2Mark-Lorie Duculan NonesNo ratings yet

- Minetruck MT65: Underground Truck With 65-Tonne Load CapacityDocument5 pagesMinetruck MT65: Underground Truck With 65-Tonne Load CapacityAlvaro Patricio Garcia AlfaroNo ratings yet

- Neuropsychiatry High Yield Notes PDFDocument6 pagesNeuropsychiatry High Yield Notes PDFTolaniNo ratings yet

- William M Leahey - Bullying The BulliesDocument8 pagesWilliam M Leahey - Bullying The BullieswilliammleaheyNo ratings yet

- Delivery, Inspection and Quality Assurance: Learning Outcomes (Co1-Po4)Document14 pagesDelivery, Inspection and Quality Assurance: Learning Outcomes (Co1-Po4)nadewhoNo ratings yet

- Here There Be Tygers by Stephen KingDocument3 pagesHere There Be Tygers by Stephen KingxXPizzaPresidentXx100% (1)

- Ezprene 9085aDocument2 pagesEzprene 9085aalejandrocharlescollNo ratings yet

- SCIENCE P1 - (PHYSICS) G10-12 eBOOK PDFDocument209 pagesSCIENCE P1 - (PHYSICS) G10-12 eBOOK PDFPaul HymanNo ratings yet

- Ent Emergencies: DR Mohammad Almayouf Associat Consultant ENTDocument27 pagesEnt Emergencies: DR Mohammad Almayouf Associat Consultant ENTMuhammad ANo ratings yet

- Isa Cem: Comparatives and SuperlativesDocument7 pagesIsa Cem: Comparatives and SuperlativesAnonymous 7xhhVAWCXNo ratings yet

- Examination of The Child With CerebralpalsyDocument52 pagesExamination of The Child With CerebralpalsyRiaz KhanNo ratings yet

- Advertiser & Agency AgreementDocument3 pagesAdvertiser & Agency AgreementmacruvNo ratings yet

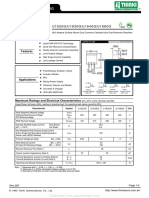

- U1620G Thru U1660G: U1620G/U1630G/U1640G/U1660GDocument2 pagesU1620G Thru U1660G: U1620G/U1630G/U1640G/U1660GTeles SilvaNo ratings yet

- Nurs 3021 Journal OneDocument5 pagesNurs 3021 Journal Oneapi-313199824No ratings yet

- Laparoscopic Bilateral Tubal LigationDocument2 pagesLaparoscopic Bilateral Tubal Ligationapi-3712326100% (1)

Asphalt Particle Loss: AUSTROADS Asphalt Test AST 07:2000

Asphalt Particle Loss: AUSTROADS Asphalt Test AST 07:2000

Uploaded by

तिप्लोकाची तिरुनचिपल्ली केरकेट्टाOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asphalt Particle Loss: AUSTROADS Asphalt Test AST 07:2000

Asphalt Particle Loss: AUSTROADS Asphalt Test AST 07:2000

Uploaded by

तिप्लोकाची तिरुनचिपल्ली केरकेट्टाCopyright:

Available Formats

AUSTROADS Asphalt Test AST 07:2000

Asphalt Particle Loss

PREFACE

This Asphalt Test Method was prepared by the Austroads National Asphalt Research Co-ordination

Group on behalf of the Austroads Pavement Reference Group. Representatives of Austroads and the

Australian Asphalt Pavement Association have been involved in the development and review of this

test method.

____________________

FOREWORD

Open Graded Asphalt (OGA) mixes particularly rely on the binder content and binder properties for

cohesion between the aggregate particles, more so than other types of mixes where there is a greater

degree of aggregate particle interlock. The Particle Loss test is used as an indicator of cohesion for a

given binder type and content by measuring particle loss (or abrasion) after turns in a Los Angeles

machine. This method is based procedures originally developed in Spain where it was commonly

referred to as Cantabro Abrasion Loss Test.

____________________

METHOD

1 SCOPE This test method sets out the procedures for determining particle loss

(abrasion) from laboratory prepared specimens of open graded asphalt. The test may be performed on

dry samples or after period of moisture conditioning.

2 REFERENCED DOCUMENTS The following documents are referred to in this test

method:

AS /NZS

2891 Methods for Sampling and Testing of Asphalt

2891.7.1 Determination of the maximum density of asphalt –Water presaturation method

2891.9.3 Determination of the bulk density of compacted asphalt – Mensuration method

1141.23 Los Angeles Value

AUSTROADS

APRG Report No. 18 Selection and Design of Asphalt Mixes: Australian Provisional Guide,

Revision No. 1, Austroads, Sydney, Australia, July 1998

3 APPARATUS The following apparatus is required:

3.1 For particle loss test

(a) Los Angeles machine as defined in AS 1141.23.

(b) Balance – of at least 5kg capacity with a limit of performance not exceeding ± 0.5 g.

October 2000- Version 1 Page 1 of 3

AUSTROADS AST O7:2000

(c) Temperature controlled environment – a chamber or enclosure large enough to hold the Los

Angeles machine and capable of maintaining a temperature of 23 ± 3°C during the test, this

temperature being measured in the air close to the Los Angeles machine.

3.2 For moisture conditioning of specimens

(a) Water bath - capable of maintaining a temperature of 25 ± 1°C.

(b) Vacuum pump - capable of maintaining a vacuum pressure of 600 ± 25 mm Hg.

(c) Vacuum desiccator - with tap.

(d) Timer - readable to the nearest second.

(e) Towel - dampened and wrung by hand to remove excess water.

4 PREPARATION OF SPECIMENS

4.1 Sampling and Compaction

(a) Obtain samples from a single batch of asphalt prepared in accordance with AS 2891.2.1.

(b) Compact three samples in accordance with AS 2891.2.2. so that each specimen has air voids

within the design voids range at 80 compaction cycles with the Gyratory compactor and a height

of 65 ±1 mm for a 100 mm diameter specimen or 80 ±1 mm for a 150 mm diameter specimen

(c) Determine the bulk density of each specimen in accordance with AS 2891 9.3.

(d) Determine the maximum density (ρmax) of the mix in accordance with AS 2891.7.1.

(e) Calculate the air voids content of each specimen in accordance with AS 2891.8.

4.2 Moisture Conditioning (optional) If required, moisture condition each specimen as

follows:

(a) Determine and record the dry mass of the specimen, (m1).

(b) Place the specimen in a water bath at 25 ±1°C for at least 5 minutes.

(c) Remove the specimen from the water bath and place it in a vacuum desiccator and cover it with

water at room temperature. Reduce the pressure in the desiccator until a vacuum of 600 ± 25 Hg

is attained. Maintain this vacuum for 10 ±1 minutes.

(d) Gently release the vacuum. Remove the specimen and place it the water bath at 25 ±1°C for 20

±1 hours.

(e) Remove the specimen from the water bath and dry the surface of the specimen by blotting with

the damp towel.

5 PROCEDURE Laboratory prepared specimens shall stored prior to testing for at

least 2 days at a temperature of not more than 25°C and tested within 7 days of manufacture.

For each unconditioned specimen, i:

(a) Record the dry mass of the specimen (m i 1).

(b) Allow the specimen to attain a temperature of 25 ±1°C.

(c) Place the specimen in the drum of the Los Angeles machine without the steel balls. Close the lid

on the drum and allow to rotate for 300 revolutions at the rate prescribed in AS 1141.23.

October 2000- Version 1 Page 2 of 3

AUSTROADS AST O7:2000

(d) Open the lid and remove the largest remaining fragment of the asphalt specimen. Determine the

mass of this fragment (mi2). Remove the residue from the drum.

For each moisture conditioned sample, i;

(e) Immediately after blotting the damp specimen with the damp towel, place the specimen in the

drum of the Los Angeles machine without the steel balls. Close the lid on the drum and allow to

rotate for 300 revolutions at the rate prescribed in AS 1141.23.

(f) Open the lid and remove the largest remaining fragment of the asphalt specimen. Dry to constant

mass and determine the mass of this fragment (mi2). Remove the residue from the drum.

6 CALCULATIONS Calculate the following:

(a) The particle loss (PLi) for each specimen from the following equation:

(mi1 − mi 2 )

PLi = × 100

mi1

(b) The mean particle loss (PL) for the three specimens.

NOTE: If the PLi for any specimen is greater than 50%, repeat the test for an additional three specimens.

7 REPORTING Report the following:

7.1 For all specimens:

(a) the particle loss for each specimen to the nearest 1%;

(b) the mean particle loss for the three specimens to the nearest 1%;

(c) the percent air voids for each specimen to the nearest 0.1%;

(d) whether laboratory prepared or field sampled;

(e) the bulk density to the nearest 0.001 t/m3;

(f) the maximum density of the mix to the nearest 0.001 t/m3.

(g) the date and method of manufacture.

(h) Whether the samples were conditioned or not.

October 2000- Version 1 Page 3 of 3

You might also like

- AASHTO T 166-05 Bulk Specific Gravity of Compacted Hot Mix Asphalt Using Saturated Surface-Dry Specimens-FinalDocument6 pagesAASHTO T 166-05 Bulk Specific Gravity of Compacted Hot Mix Asphalt Using Saturated Surface-Dry Specimens-Finalclint sil100% (1)

- Reconfirmation Notice: AS 1141.5-2000 (Reconfirmed) 2016-07-15Document9 pagesReconfirmation Notice: AS 1141.5-2000 (Reconfirmed) 2016-07-15Alexandru LetNo ratings yet

- S406 Specifications For The Supply of StoneDocument6 pagesS406 Specifications For The Supply of StoneRui Lourenco100% (1)

- ASTM C1403-13 Standard Test Method For Rate of Water AbsorptionDocument4 pagesASTM C1403-13 Standard Test Method For Rate of Water AbsorptionEdwin R Ruiz100% (1)

- Astm D 903Document3 pagesAstm D 903rajupetalokeshNo ratings yet

- Emc WaiverDocument1 pageEmc WaiverZumbaShellNo ratings yet

- General Safety Orientation Guidelines (Replaced Irp 16)Document29 pagesGeneral Safety Orientation Guidelines (Replaced Irp 16)dinuveraNo ratings yet

- Stripping Potential of Asphalt - Tensile Strength Ratio: AUSTROADS Asphalt Test AST 02:2000Document7 pagesStripping Potential of Asphalt - Tensile Strength Ratio: AUSTROADS Asphalt Test AST 02:2000तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Commentary To Ag:Pt/T232 - Stripping Potential of Asphalt - Tensile Strength RatioDocument10 pagesCommentary To Ag:Pt/T232 - Stripping Potential of Asphalt - Tensile Strength Ratiofilo821No ratings yet

- LS-297 - Rev 34 - May 2020Document9 pagesLS-297 - Rev 34 - May 2020ming_zhu10No ratings yet

- LS-297 R26 123Document6 pagesLS-297 R26 123Gourav GoelNo ratings yet

- ASTM D3173 - Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument3 pagesASTM D3173 - Standard Test Method For Moisture in The Analysis Sample of Coal and CokeFabian E. Quesada-Plata80% (5)

- Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument7 pagesStandard Test Method For Moisture in The Analysis Sample of Coal and CokemuchtarNo ratings yet

- LS-628 R23 PDFDocument7 pagesLS-628 R23 PDFqwerysqlNo ratings yet

- Reconfirmation Notice: AS 1012.12.2-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.12.2-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Aashto T 283Document6 pagesAashto T 283Noraziana Azi75% (4)

- Bulk Specific Gravity of Compacted Bituminous Mixtures Using Water Displacement Measured by Pressure SensorDocument3 pagesBulk Specific Gravity of Compacted Bituminous Mixtures Using Water Displacement Measured by Pressure SensorWaleed AhmedNo ratings yet

- Laboratory WorksDocument32 pagesLaboratory WorksCliff Jude ZehnderNo ratings yet

- D3173Document2 pagesD3173Timothy Ferguson100% (1)

- Asphalt Binder Content (Ignition Oven Method) : AUSTROADS Asphalt Test AST 04:2000Document7 pagesAsphalt Binder Content (Ignition Oven Method) : AUSTROADS Asphalt Test AST 04:2000तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- C 948 PDFDocument2 pagesC 948 PDFGrato Jr Singco100% (1)

- Argillaceous Swellingxocks - Methods For Laboratory TestingDocument16 pagesArgillaceous Swellingxocks - Methods For Laboratory Testingvenkatraman20No ratings yet

- CRD c513Document2 pagesCRD c513azharbNo ratings yet

- Moisture in The Analysis Sample of Coal and Coke: Standard Test Method ForDocument5 pagesMoisture in The Analysis Sample of Coal and Coke: Standard Test Method Formohamed fathiNo ratings yet

- C 602 - 95a R01 QZYWMGDocument3 pagesC 602 - 95a R01 QZYWMGHumberto Gutierrez100% (1)

- D 5101 Â " 01 RDUXMDEDocument8 pagesD 5101 Â " 01 RDUXMDEdorbarelNo ratings yet

- Abrasion TestDocument5 pagesAbrasion TestMae Lingan-LasqueroNo ratings yet

- Emulsified Bitumens Used As Protective Coatings: Standard Test Methods ForDocument7 pagesEmulsified Bitumens Used As Protective Coatings: Standard Test Methods FordaovandongpktNo ratings yet

- AASHTO T 283 Dr. LiuDocument9 pagesAASHTO T 283 Dr. LiuRamy HusseinNo ratings yet

- C 123 - 03 - QzeymwDocument3 pagesC 123 - 03 - QzeymwAnonymous 6SHxUn1xd1No ratings yet

- Astm C123Document3 pagesAstm C123renzoNo ratings yet

- Resistance of Compacted Asphalt Mixtures To Moisture-Induced DamageDocument8 pagesResistance of Compacted Asphalt Mixtures To Moisture-Induced Damagediegoelpotro.24No ratings yet

- Fatigue Life of Compacted Bituminous Mixes Subject To Repeated Flexural BendingDocument14 pagesFatigue Life of Compacted Bituminous Mixes Subject To Repeated Flexural Bendingतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- C 35 - 95 r00 - Qzm1ltk1ujawDocument3 pagesC 35 - 95 r00 - Qzm1ltk1ujaw2010civ164No ratings yet

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocument2 pagesSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasNo ratings yet

- Sampling & Testing Procedures 01aug2009Document12 pagesSampling & Testing Procedures 01aug2009akclams77No ratings yet

- Asphalt Roll Roofing, Cap Sheets, and Shingles: Standard Test Methods ForDocument9 pagesAsphalt Roll Roofing, Cap Sheets, and Shingles: Standard Test Methods FordaovandongpktNo ratings yet

- Asphalt Binder Drain-Off: AUSTROADS Asphalt Test AST 06:2000Document3 pagesAsphalt Binder Drain-Off: AUSTROADS Asphalt Test AST 06:2000तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Aashto T 283-14Document9 pagesAashto T 283-14Chandrasekhar Chintada100% (1)

- C 452 - 95 Qzq1mi1sruq - PDFDocument4 pagesC 452 - 95 Qzq1mi1sruq - PDFAlejandro MuñozNo ratings yet

- AASHTO T 265-93 (2008) Standard Method of Test For Laboratory Determination of Moisture Content of Soils PDFDocument2 pagesAASHTO T 265-93 (2008) Standard Method of Test For Laboratory Determination of Moisture Content of Soils PDFJulius Gatchalian100% (1)

- Particle Size Analysis of Soils: Test Procedure ForDocument13 pagesParticle Size Analysis of Soils: Test Procedure ForDayner M Sanchez GarciaNo ratings yet

- D 2939 - 98 Rdi5mzktukveDocument9 pagesD 2939 - 98 Rdi5mzktukvedaovandongpktNo ratings yet

- Sieve Analysis of Surfacing For Asphalt Roofing Products: Standard Test Method ForDocument2 pagesSieve Analysis of Surfacing For Asphalt Roofing Products: Standard Test Method ForNuMbNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- CRD c260 PDFDocument8 pagesCRD c260 PDFJersey Mae PerlasNo ratings yet

- AASHTO T 166-Standard Method of Test For Bulk Specific Gravity of Compacted Bituminous MixturesDocument4 pagesAASHTO T 166-Standard Method of Test For Bulk Specific Gravity of Compacted Bituminous MixturesDonnabel CaleNo ratings yet

- Standard Method of Test For Bulk Specific Gravity (G) of Compacted Asphalt Mixtures Using Saturated Surface-Dry SpecimensDocument6 pagesStandard Method of Test For Bulk Specific Gravity (G) of Compacted Asphalt Mixtures Using Saturated Surface-Dry SpecimensHugo EscalanteNo ratings yet

- Is - 4253-2004Document6 pagesIs - 4253-2004Sahil AggarwalNo ratings yet

- Lap Shear Strength of Hot-Applied Sealants: Standard Test Method ForDocument4 pagesLap Shear Strength of Hot-Applied Sealants: Standard Test Method ForRufo CascoNo ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityFrom EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleNo ratings yet

- Nanostructured Polymer Membranes, Volume 1: Processing and CharacterizationFrom EverandNanostructured Polymer Membranes, Volume 1: Processing and CharacterizationNo ratings yet

- ButaneDocument6 pagesButaneRatu Fajrina HanifaNo ratings yet

- Baypren® 320-1 Safety Data SheetDocument10 pagesBaypren® 320-1 Safety Data SheetXiaofeng MengNo ratings yet

- Anatomy and Cardiovascular AssessmentDocument52 pagesAnatomy and Cardiovascular AssessmentNaomi Anne AsuntoNo ratings yet

- Rus 01Document36 pagesRus 01outchoiNo ratings yet

- Extraordinary Attorney WooDocument5 pagesExtraordinary Attorney WooAnuska ThapaNo ratings yet

- Dutch Compaies in IndiaDocument28 pagesDutch Compaies in IndiaSourabh GargNo ratings yet

- Immigration Reform and Control Act of 1986Document3 pagesImmigration Reform and Control Act of 1986d8nNo ratings yet

- Aubert Et Al. 2018Document3 pagesAubert Et Al. 2018LhuissetNo ratings yet

- Marital RapeDocument12 pagesMarital RapeKrati Yadav - 65No ratings yet

- Penguard Express ZP: Technical Data Sheet Application GuideDocument8 pagesPenguard Express ZP: Technical Data Sheet Application GuideAzar SKNo ratings yet

- The Organization of Modern KitchensDocument9 pagesThe Organization of Modern KitchensJohnson Macayan FernándezNo ratings yet

- Sludge TreatmentDocument34 pagesSludge TreatmentNurul Fatihah SyazwaniNo ratings yet

- Plasma TV: Service ManualDocument34 pagesPlasma TV: Service ManualClaudelino ToffolettiNo ratings yet

- MESL - Algebra 2Document7 pagesMESL - Algebra 2Mark-Lorie Duculan NonesNo ratings yet

- Minetruck MT65: Underground Truck With 65-Tonne Load CapacityDocument5 pagesMinetruck MT65: Underground Truck With 65-Tonne Load CapacityAlvaro Patricio Garcia AlfaroNo ratings yet

- Neuropsychiatry High Yield Notes PDFDocument6 pagesNeuropsychiatry High Yield Notes PDFTolaniNo ratings yet

- William M Leahey - Bullying The BulliesDocument8 pagesWilliam M Leahey - Bullying The BullieswilliammleaheyNo ratings yet

- Delivery, Inspection and Quality Assurance: Learning Outcomes (Co1-Po4)Document14 pagesDelivery, Inspection and Quality Assurance: Learning Outcomes (Co1-Po4)nadewhoNo ratings yet

- Here There Be Tygers by Stephen KingDocument3 pagesHere There Be Tygers by Stephen KingxXPizzaPresidentXx100% (1)

- Ezprene 9085aDocument2 pagesEzprene 9085aalejandrocharlescollNo ratings yet

- SCIENCE P1 - (PHYSICS) G10-12 eBOOK PDFDocument209 pagesSCIENCE P1 - (PHYSICS) G10-12 eBOOK PDFPaul HymanNo ratings yet

- Ent Emergencies: DR Mohammad Almayouf Associat Consultant ENTDocument27 pagesEnt Emergencies: DR Mohammad Almayouf Associat Consultant ENTMuhammad ANo ratings yet

- Isa Cem: Comparatives and SuperlativesDocument7 pagesIsa Cem: Comparatives and SuperlativesAnonymous 7xhhVAWCXNo ratings yet

- Examination of The Child With CerebralpalsyDocument52 pagesExamination of The Child With CerebralpalsyRiaz KhanNo ratings yet

- Advertiser & Agency AgreementDocument3 pagesAdvertiser & Agency AgreementmacruvNo ratings yet

- U1620G Thru U1660G: U1620G/U1630G/U1640G/U1660GDocument2 pagesU1620G Thru U1660G: U1620G/U1630G/U1640G/U1660GTeles SilvaNo ratings yet

- Nurs 3021 Journal OneDocument5 pagesNurs 3021 Journal Oneapi-313199824No ratings yet

- Laparoscopic Bilateral Tubal LigationDocument2 pagesLaparoscopic Bilateral Tubal Ligationapi-3712326100% (1)