Professional Documents

Culture Documents

Empirical Modeling of Urea Synthesis Chemical Equilibria

Empirical Modeling of Urea Synthesis Chemical Equilibria

Uploaded by

Rungrawin NgamkhumOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Empirical Modeling of Urea Synthesis Chemical Equilibria

Empirical Modeling of Urea Synthesis Chemical Equilibria

Uploaded by

Rungrawin NgamkhumCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/336485790

Empirical modeling of urea synthesis chemical equilibria

Article in International Journal of Innovative Technology and Exploring Engineering · October 2019

DOI: 10.35940/ijitee.L3024.1081219

CITATIONS READS

0 583

1 author:

Moustafa Aly Soliman

The British University in Egypt

201 PUBLICATIONS 1,100 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Numerical solutions of reaction–diffusion systems View project

Hydrogen production by solar energy View project

All content following this page was uploaded by Moustafa Aly Soliman on 07 December 2019.

The user has requested enhancement of the downloaded file.

International Journal of Innovative Technology and Exploring Engineering (IJITEE)

ISSN: 2278-3075, Volume-8, Issue-12, October 2019

Empirical Modeling of Urea Synthesis Chemical

Equilibria

Moustafa Aly Soliman

temperature and pressure. At high temperature and pressure,

Abstract: In this paper empirical formulas for the chemical there are models that include all ionic species

equilibrium of reactions involved in urea synthesis are derived. NH4+,HCO3-,NH2COO-, (Isla et al. [1]), models that contain

Their accuracy is checked against data obtained from the only molecular species (Satyro et al.[2]) and models that

application of Aspen plus to a urea plant based on Stamicarbon

technology. The accurate results obtained support their contain no bicarbonate (Lemkowitz et al.[3],Piotrowski et al

application in the simulation of the reactions involved in urea [4]). This last model assumes that CO2 exists as free CO2 or as

synthesis. Carbamate. Also the models themselves vary in complexity.

That of Isla [1] uses UNIQUAC for Liquid and Nikamura et

Keywords: Chemical equilibrium, Empirical modeling, High al.[5] for gas whereas that of Piotrowski [4] uses empirical

pressure, Urea synthesis correlations for liquid activities. Hamidipour et al [6] assumes

the gas is ideal and the liquid properties are modeled using

I. INTRODUCTION

Wilson equations.

Other papers related to the thermodynamics of urea

The commercial production of urea is based on the synthesis are listed in references [7-22]

reaction of ammonia and carbon dioxide at high pressure and

temperature to form ammonium carbamate, which is Reactor models also vary in complexity. Irazoqui et al

dehydrated into urea and water: [23] assume that all components are in liquid phase and there

is countercurrent flow between the coil and the bulk of the

2NH 3 l CO 2 l NH 2 COONH 4 (1)

reactor. Hamidipour et al.[6] assumes that the flow is

cocurrent and that CO2 reacts with ammonia in the gas phase

ΔH 157.60 kJ mol

to give ammonium carbamate as liquid phase . They include

biuret formation in their model. Dente et al. [24,25] assumes

2NH 3 l CO 2 l NH 2 COONH 4 (2) mass transfer between gas and liquid. One can even assume

ΔH 26.46 kJ mol that the reactor is an equilibrium one and assume certain

efficiency for urea formation. Zhang et al [26] assume

Reaction 1 is fast, highly exothermic, and goes essentially equilibrium between the gas and liquid phases and that the

to completion under normal industrial processing conditions, reaction takes place between liquid phases.

Papers [27-29] deal with the reaction of urea to biuret.

while reaction 2 is slow, and endothermic. Ammonia is

usually in excess and thus conversion is reported as

percentage of carbon dioxide reacting.

II. METHODOLOGY

Different urea production technologies basically differ on We thought that if we use a simple empirical

how urea is separated from the reactants and how ammonia thermodynamic model, it might be more useful than a

and carbon dioxide are recycled. Optimization of these comprehensive model that we do not know for sure the actual

production technologies would aim at increasing carbon concentrations for components like the carbamate and the

dioxide conversion, optimization of heat recovery and utility bicarbonate.

consumption reduction. To achieve these objectives, a

simulation code which accurately describes material and We thus turned our attention to the empirical model of

energy balances and design equations, is needed. Piotrowski et al 1998 which does not assume the presence of

any ionic species, only the reactants and products.

There are different thermodynamic models with different

degrees of complexity. There are models for high pressure, Equation (8) of, Piotrowski et al 1998 predicts low

high temperature conditions with ammonia as the main conversion to ammonium carbamate. On the other hand

solvent, and there are models for aqueous solutions at low Lemkowitz et al 1973 data predicts high conversion to

ammonium carbamata. Data obtained from the scrubber of an

Revised Manuscript Received on September 05, 2019.. industrial plant shows high conversion to carbamate because

* Correspondence Author of the large amount of heat that should be removed due to the

Moustafa Aly Soliman*, Professor of Chemical Engineering, The exothermic reaction of

British University in Egypt, El Shorouk City, Cairo, Egypt. Email:

moustafa.aly@bue.edu.eg

carbamate formation. Thus

equation (8), Piotrowski et al

Retrieval Number: L30241081219/2019©BEIESP

Published By:

DOI: 10.35940/ijitee.L3024.1081219 Blue Eyes Intelligence Engineering

1 & Sciences Publication

Empirical Modeling of Urea Synthesis Chemical Equilibria

1998 for the equilibrium constant for equation (1) is modified where the c’s are constants to be determined.

to A least square analysis of equation (12) for different values

of a, b, t using MATLAB

Log K1

4350

7.7 (3)

leads to

t

x x

where t is temperature in K K 2 5 3 exp[( 2938.555 1577.719a

x4

Let 14.31545a 2 452.6036b 51.51285ab

a = the ratio of the initial concentration of ammonia to (13)

3.20745t 0.032943t 2 4.740364 *10 5 t 3

carbon dioxide

b=the ratio of the initial concentration of water to carbon 1.670736 *10 2 at 2 11.308775at

dioxide 0.0121076a 2 t 0.564388bt ) / t ] / K1

y= the fraction of carbon dioxide converted to urea and

ammonium carbamate at equilibrium In the next section we apply equations (3,13) to the reactor

st=fraction of carbon dioxide converted to urea at section of high pressure synthesis loop of a urea plant

equilibrium simulated as an example in Aspen Plus.

the mole fractions of carbon dioxide x1, ammonia x2, water

x3, ammonium carbamate x4, and urea x5 are given by

III RESULTS AND DISCUSSION

x1

1 y (4) Aspen Plus gave an example of the steady state simulation

N of the high-pressure synthesis loop of urea plant producing

x2

a 2 y (5)

1050 metric ton per day and is based on the Stamicarbon CO2

N Stripping Process. The model for the thermodynamic

x3

b st (6)

properties of the NH3-CO2-H2O-UREA-CARB-N2-O2 system

N is based upon the SR-POLAR model. This model contains an

x4

y st (7)

equation of state and extension for accurate estimation of

phase and chemical equilibria. The high-pressure synthesis

N

loop operates at a pressure of about 141 kg/cm2 and consists

st

x5 (8) of urea reactor where ammonium carbamate is dehydrated to

N

urea, CO2 stripper to decompose carbamate present with urea,

N 1 a b-2 y st (9)

condenser to form carbamate from CO2 and NH3 and scrubber

x4 to absorb unreacted gases from the reactor.

K1 (10)

x1*x22

The reactor is equipped with sieve plates in order to realize

Empirical correlations are available for (st). We choose a number of CSTRs (Continuous Stirred Tank Reactors) by

that of Piotrowski et al 1998 which plug flow regime is approached.

st 3.4792 8.2677 *10 1 a 1.8998 *10 2 a 2

2.3155 *10 1 b 1.144 *10 1 t 100

The Urea Reactor is 2.2921 m in diameter and 28.956 m in

(11)

length, and is modeled with an RPLUG block. The kinetics is

2.9879 *10 2 ab 1.3294 *10 1 at 100 provided by the user subroutine USURA in the RPLUG

4.5348 *10 1 t 100 5.5339 *10 2 t 100

2 3

block.

These data are obtained for the following range of The simulation results of this model are reasonable

parameters compared with similar plant operations.

t from 433 to 483 K For example, a plant which produces 1750 metric ton per

a from 2. to 6. day has streams with flowrates of 1.66 (1750/1050) that of

and b from 0 to 1.2 Aspen plus model. The diameter of the reactor is 2.957 m.

This gives a cross sectional area ratio of 1.664. This keeps

Using equation (3) the definition of K1 and equation (10) of fluid velocity in the reactor unchanged.

Piotrowski et al 1998, we obtain a non-linear equation in (y) Increasing the length of the reactor does not affect the

which is solved for the range of parameters for which equation conversion to urea. This means that the conversion is very

(11) is obtained. close to equilibrium. The default kinetics of the simulation is

For the equilibrium conversion of carbon dioxide to urea, we relatively fast. We have the option to change the rate of

are able to fit the data to the following expression for the reaction. In practice if we are far from equilibrium, we can

equilibrium constant for the conversion of ammonium increase the number of sieve plates in the reactor or use high

carbamate to urea (equation (12)) efficiency trays.

Similar observations are noticed for a plant producing 1950

x x K metric ton per day.

t ln 5 3 1 c1 c2 a c3 a 2 c4 b c5 ab (12)

x4 From Aspen Plus simulation, the

following is the mole fractions of

c6 t c7 t 2 c8 t 3 c9 at 2 c10 at c11a 2 t c12bt

Retrieval Number: L30241081219/2019©BEIESP Published By:

DOI: 10.35940/ijitee.L3024.1081219 Blue Eyes Intelligence Engineering

2 & Sciences Publication

International Journal of Innovative Technology and Exploring Engineering (IJITEE)

ISSN: 2278-3075, Volume-8, Issue-12, October 2019

the liquid phase exiting the reactor, 6. M. Hamidipour, N. Moustifi, and R. Sotudeh-Gharebagh, “Modeling

the synthesis section of an industrial urea plant,” Chem. Eng. J. vol. 106,

x1=0.012175, x2=0.3492, x3=0.3272, x4=0.12175, 2005, pp. 249–260.

x5=0.18851 7. S. M. Lemkowitz, J. Goedegebuur, and P. J. van den Berg, “Bubble

from which we can calculate point measurements in the ammonia-carbon dioxide system,” J. Appl.

a=3.0017, b=0.4293 Chem. Biotechnol. vol. 21, 1971, pp. 229.

8. S. M. Lemkowitz, J. Zuidam, and P. J. van den Berg, “Phase behavior in

the exit temperature of the product from the reactor is 456 K. the ammonia-carbon dioxide system at and above urea synthesis

substituting these values in equations (3,13) we obtain conditions,” J. Appl. Chem. Biotechnol. vol 22, 1972, pp. 727.

9. E. A. Kotula, “A VLE model of the NH3–CO2–H2O–urea system at

elevated pressure,” J. Chem. Technol. Biotechnol. vol. 31, 1981, pp.

K1 69.1 103–110.

K1 * K 2 41.19 10. T. J. Edwards, G. Maurer, J. Newman, and J. M. Prausnitz,

“Vapor-liquid equilibria in multicomponent aqueous solutions of

Whereas from the definition of the equilibrium constants, volatile weak electrolytes,” AIChE J. vol. 24, 1978, pp. 966–976.

we have 11. E. M. Pawlikowski, J. Newman, and J. M. Prausnitz, “Phase equilibria

x4 for aqueous solutions of ammonia and carbon dioxide,” Ind. Eng. Chem.

K1

x1 * x22 82.0 Proc. Des. Dev. vol. 21, 1982, pp. 764–770.

12. K. Kawazuizhi and J. M. Prausnitz, “Correlation of vapor-liquid

x 3 x5 equilibrium for the system ammonia-carbon dioxide-water,” Ind. Eng.

K1 * K 2 41.55 Chem. Res. vol. 26, 1987, pp. 1482–1485.

x1 x22 13. S. Wicar, “Calculation of vapour-liquid equilibrium in the system urea,

ammonia, carbon dioxide and water,” Brit. Chem. Eng. vol. 8, 1963, pp.

818–822.

This shows that the equilibrium constant (K1*K2) which 14. I. Mavrovic, "Find equilibrium urea yield," Hydr. Proc. vol. 50, 1971,

expresses urea mole fraction at equilibrium conditions is pp. 161-162.

accurately predicted. K1 which expresses carbamate mole 15. V. I. Kucheryavyi, D. M. Gorlovskii, and T. N. Konkina, “Equilibrium

degree of the conversion of carbon dioxide in the synthesis of urea,”

fraction is less accurately predicted. In practice we are more Khim. Prom. vol. 45, 1969.

concerned about urea concentration. Ammonia to CO2 ratio in 16. S. Inoue, K. Kanai, and E. Otsuka, “Equilibrium of urea synthesis. I.,”

the recycle loop is in the range of 3. This means that ammonia Bull. Chem. Soc. Jpn. vol. 45, 1972, pp. 1339–1345.

17. M. Bernardis, G. Carvoli, and M. Santini, “Urea–NH3–CO2–H2O: VLE

is in excess. Large values for K1 indicate that most of CO2 in calculations using an extended UNIQUAC equation,” Fluid Ph.

the liquid phase is in the form of carbamate. Some Equilibria. vol. 53, 1989, pp. 207.

investigators assume free CO2 is 1% of total CO2. 18. M. J. Joncich, B. H. Solka, and J. E. Bower “The thermodynamic

properties of ammonium carbamate. An experiment in heterogeneous

equilibrium,” J. Chem. Educ. vol. 44, 1967, pp. 598–600.

Another indicator is equilibrium conversion of equation (11) 19. E. P. Egan, J. E. Potts, and G. D. Potts, “Dissociation pressure of

which gives a value of 0.6114. For the simulated plant this ammonium carbamate,” Ind. Eng. Chem. vol. 38, 1946, pp. 454–456.

value is (0.18851/(0.18851+0.12175+0.012175)=0.5846) 20. B. Claudel, E. Brousse, and G. Shehadeh, “Novel thermodynamics and

kinetics investigation of ammonium carbamate decomposition into urea

and water,” Thermochim. Acta. vol. 102, 1986, 357–371.

IV CONCLUSION 21. M. Brouwer. (2009). Thermodynamics of the urea process. Process

paper. http://www.ureaknowhow.com

In this paper empirical equations for the chemical equilibria 22. A. L. Voskov and G. F. Voronin, “Thermodynamic model of the urea

for the reactions occurring in urea synthesis are obtained. synthesis process,” J. Chem. Eng. Data. vol. 61, 2016, pp. 4110-4122.

Equation (13) can be used to check if equilibrium conversion 23. H. A. Irazoqui, M. A. Isla, and C. M. Genoud, “Simulation of a urea

of urea is approached. If equilibrium is not approached, we synthesis reactor. 2. Reactor model,” Ind. Eng. Chem. Res. vol. 32,

1993, pp. 2671–2680.

can think of increasing the sieve plates in the reactor or use 24. M. Dente, S. Pierucci, A. Sogaro, G. Carloni, and E. Rigolli,

high efficiency trays. In addition the equilibria constants are “Simulation program for urea plants,” Comput. Chem. Eng. vol. 21,

needed in the kinetic expression for carbamate and urea 1988, pp. 389–400.

25. M. Dente, M. Rovaglio, G. Bozzano, and A. Sogaro, “Gas-liquid

formation. reactor in the synthesis of urea”, Chem. Eng. Sci. vol. 47, 1992, pp.

Knowledge of the carbamate concentration in different 2475–2480.

streams is also important since its formation is associated with 26. X. Zhang, S. Zhang, P. Yao, and Y. Yuan, “Modeling and simulation

of high pressure urea synthesis loop,” Comput. Chem. Eng. vol. 29,

the liberation of large amount of heat. 2005, pp. 983-992.

27. C. E. Redemann, F. C. Riesenfeld, and F. S. Laviola, “Formation of

REFERENCES biuret from urea”, Ind. Eng. Chem. vol. 50, 1958, pp. 633–636.

28. P. J. C. Kaasenbrood, P. J. Van der Berg, and L. J. Revallier, “Biuret

1. M. A. Isla, H. A. Irazoqui, and C. M. Genoud, “Simulation of an urea formation in the manufacture of urea”, vol. 11, 1963, pp. 39–43.

synthesis reactor. 1. Thermodynamic framework,” Ind. Eng. Chem. Res. 29. R. C. Shen, “Rate of biuret formation from urea,” J. Agric. Food

vol. 32, 1993, pp. 2662–2670. Chem. vol. 7, 1959, pp. 762–763.

2. M. A. Satyro, Y. K. Li, R. K. Agarwal, and O. J. Santollani. (2001).

Modeling urea processes: a new thermodynamic model and software

AUTHOR PROFILE

integration paradigm. http://www.cheresources.com

3. S. M. Lemkowitz, M. G. R. T. de Cooker, and P. J. van den Berg, “An Moustafa Aly Soliman, earned his bachelor’s

empirical thermodynamic model for the ammonia-water-carbon dioxide and master’s degrees in chemical engineering from

system at urea synthesis conditions,” J. Appl. Chem. Biotechnol. vol. 23, Cairo University; and his PhD in chemical

1973, pp. 63–76. engineering from the University of Waterloo. His

4. J. Piotrowski, R. Kozak, and M. Kujawaska, "Thermodynamic Model of pioneering research has resulted in three books,

Chemical and Phase Equilibrium in the Urea Synthesis Process,” Chem. more than 170 journal and conference papers, and

Eng. Sci. vol. 53, 1998, pp. 183–186. five patents.

5. R. C. Nakamura, V. J. F. Bread, and J. M. Prausnitz, “Thermodynamic

representation of gas mixtures containing common polar and nonpolar

components,” Ind. Eng. Chem. Process. Des. Dev. vol. 15, 1976, pp.

557–564.

Retrieval Number: L30241081219/2019©BEIESP

Published By:

DOI: 10.35940/ijitee.L3024.1081219 Blue Eyes Intelligence Engineering

View publication stats

3 & Sciences Publication

You might also like

- 5 Steps To A 5 Ap Chemistry 2023 Elite Student Edition John Moore Full ChapterDocument67 pages5 Steps To A 5 Ap Chemistry 2023 Elite Student Edition John Moore Full Chapterdanny.johnson56691% (11)

- Empirical Modeling of Urea Synthesis Chemical Equilibria: Moustafa Aly SolimanDocument3 pagesEmpirical Modeling of Urea Synthesis Chemical Equilibria: Moustafa Aly SolimanteeeeeeeeeeeeeeeeeeeeeeeeeeeeettNo ratings yet

- 1 s2.0 S0360544219310308 MainDocument7 pages1 s2.0 S0360544219310308 MainhNo ratings yet

- Modeling and Simulation of An Isothermal Reactor For Methanol Steam ReformingDocument7 pagesModeling and Simulation of An Isothermal Reactor For Methanol Steam ReformingLeonardo Almeida de CamposNo ratings yet

- Simulation of A Reactor Considering The Stamicarbon, Snamprogetti, and Toyo Patentes For Obtaining UreaDocument7 pagesSimulation of A Reactor Considering The Stamicarbon, Snamprogetti, and Toyo Patentes For Obtaining UreaMISHEL ROSARIO ROMERO MARAVINo ratings yet

- Rate of The Year in IndiaDocument7 pagesRate of The Year in IndiaVigneshwaran SantharamNo ratings yet

- Dynamic Optimization Strategies of A Heterogeneous Reactor For CO Conversion To MethanolDocument7 pagesDynamic Optimization Strategies of A Heterogeneous Reactor For CO Conversion To MethanolSarang GohNo ratings yet

- Kinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO AdsorptionDocument7 pagesKinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO Adsorptionprash_13No ratings yet

- Journal of Environmental Chemical Engineering: Steve Kabore, Ryusei Ito, Naoyuki FunamizuDocument8 pagesJournal of Environmental Chemical Engineering: Steve Kabore, Ryusei Ito, Naoyuki FunamizusaraNo ratings yet

- Methanol Production by CO Hydrogenation: Analysis and Simulation of Reactor PerformanceDocument19 pagesMethanol Production by CO Hydrogenation: Analysis and Simulation of Reactor PerformancehelloNo ratings yet

- [Wang-etal,2022] Measuring_and_modeling_the_solubility_of_carbon_dioxide_in_PILsDocument12 pages[Wang-etal,2022] Measuring_and_modeling_the_solubility_of_carbon_dioxide_in_PILslucas.eq.cardosoNo ratings yet

- Electrochemical Reduction of Carbon Dioxide To Formic AcidDocument14 pagesElectrochemical Reduction of Carbon Dioxide To Formic AcidJoeNo ratings yet

- 1 s2.0 S0360319919340479 MainDocument17 pages1 s2.0 S0360319919340479 MainReviana RevitasariNo ratings yet

- Production of Ammonia at Relatively Low P, T: Aspen Process Economic AnalysisDocument6 pagesProduction of Ammonia at Relatively Low P, T: Aspen Process Economic Analysisroaanaseem267No ratings yet

- Wu - 18 - Modelling of A Post-Combustion Carbon Dioxide Capture Absorber Using Potassium Carbonate Solvent in Aspen Custom ModellerDocument10 pagesWu - 18 - Modelling of A Post-Combustion Carbon Dioxide Capture Absorber Using Potassium Carbonate Solvent in Aspen Custom ModellerRohit Kumar PandeyNo ratings yet

- 1 s2.0 S002196142100224X MainDocument9 pages1 s2.0 S002196142100224X MainPara DiseNo ratings yet

- Review of Electrochemical Ammonia Production Technologies and MaterialsDocument19 pagesReview of Electrochemical Ammonia Production Technologies and MaterialsAlejandro Duvan Lopez RojasNo ratings yet

- Hydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionDocument6 pagesHydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionBiruk GetachewNo ratings yet

- Kinetics and Mass Transfer of Carbon Dioxide Absorption Into Aqueous AmmoniaDocument8 pagesKinetics and Mass Transfer of Carbon Dioxide Absorption Into Aqueous AmmoniaGuido PalazzoNo ratings yet

- Natural Gas Based Hydrogen Production WiDocument16 pagesNatural Gas Based Hydrogen Production WiManuel PavanNo ratings yet

- Marcelli 2010Document4 pagesMarcelli 2010Angélica Andrea SalinasNo ratings yet

- Rate-Based Modelling of CO Capture Process by Reactive Absorption With MEADocument6 pagesRate-Based Modelling of CO Capture Process by Reactive Absorption With MEARohan PrajapatiNo ratings yet

- ATR Compared To Other Shit PDFDocument7 pagesATR Compared To Other Shit PDFĐỗ Vũ ThưNo ratings yet

- Material and Energy Balance Analysis For Urea Production From Biomass Via Methane Steam ReformingDocument11 pagesMaterial and Energy Balance Analysis For Urea Production From Biomass Via Methane Steam ReformingIJAERS JOURNALNo ratings yet

- Simulation of A Urea Synthesis Reactor. 1. ThermodynamicDocument10 pagesSimulation of A Urea Synthesis Reactor. 1. ThermodynamicYaraKanawatiNo ratings yet

- Ayodele 2015Document10 pagesAyodele 2015Reyner ParreirasNo ratings yet

- 1 s2.0 S0360319921005115 MainDocument14 pages1 s2.0 S0360319921005115 MainPatrice PariNo ratings yet

- Estudo KeqDocument9 pagesEstudo KeqLuiz Rodrigo AssisNo ratings yet

- Modelacion UreaDocument20 pagesModelacion UreaJesus Enrique Alfonzo RiveroNo ratings yet

- The Conversion of Carbon Dioxide To Methanol SimulDocument9 pagesThe Conversion of Carbon Dioxide To Methanol SimulSabba CabbaNo ratings yet

- Kinetic Modeling of Methanol Synthesis Over Commercial - 2014 - Fuel ProcessingDocument9 pagesKinetic Modeling of Methanol Synthesis Over Commercial - 2014 - Fuel ProcessingArindam DasNo ratings yet

- Regeneration Section of CO Capture Plant by MEA Scrubbing With A Rate-Based ModelDocument6 pagesRegeneration Section of CO Capture Plant by MEA Scrubbing With A Rate-Based Modeltrilok corporationNo ratings yet

- Simulation of CO2 Capture by MEA Scrubbing With ADocument11 pagesSimulation of CO2 Capture by MEA Scrubbing With Asekarkumala.studyNo ratings yet

- 2016 Chinese JCEYuanDocument12 pages2016 Chinese JCEYuaneko handoyoNo ratings yet

- Phenomenological Based Model of H - Alkaline Self Pressurized ElectrolyzerDocument6 pagesPhenomenological Based Model of H - Alkaline Self Pressurized ElectrolyzerJesús Javier Antuña CouceiroNo ratings yet

- Urea ModelingDocument20 pagesUrea ModelingekmagisNo ratings yet

- Application of Numerical Simulation On Biomass GasDocument6 pagesApplication of Numerical Simulation On Biomass GasJoseph OtengNo ratings yet

- Bustflame 2020 06 024Document15 pagesBustflame 2020 06 024task51.hevtcpNo ratings yet

- Lan 2013Document7 pagesLan 2013Ahmad AlShahrourNo ratings yet

- Methanol Production From Natural Gas Reforming and CO2 CapturingDocument12 pagesMethanol Production From Natural Gas Reforming and CO2 Capturingguigoal2010No ratings yet

- 1 s2.0 S036031990901355X Main PDFDocument11 pages1 s2.0 S036031990901355X Main PDFVeeturiVarunNo ratings yet

- Sahu 2008Document8 pagesSahu 2008tamil vaananNo ratings yet

- Chem Eng Technol - 2017 - Ghodoosi - Mathematical Modeling of Reverse Water Gas Shift Reaction in A Fixed Bed ReactorDocument10 pagesChem Eng Technol - 2017 - Ghodoosi - Mathematical Modeling of Reverse Water Gas Shift Reaction in A Fixed Bed Reactorqwerty fkvorkcjdkNo ratings yet

- Applied Energy: Won-Jun Jang, Dae-Woon Jeong, Jae-Oh Shim, Hak-Min Kim, Hyun-Seog Roh, in Hyuk Son, Seung Jae LeeDocument12 pagesApplied Energy: Won-Jun Jang, Dae-Woon Jeong, Jae-Oh Shim, Hak-Min Kim, Hyun-Seog Roh, in Hyuk Son, Seung Jae LeeWassachol SumarasinghaNo ratings yet

- Obt AmoniacoDocument16 pagesObt AmoniacoNatalia ParedesNo ratings yet

- Open 202000275Document8 pagesOpen 202000275Gokul KannanNo ratings yet

- Tem UreaDocument21 pagesTem UreaChaeeon LimNo ratings yet

- Generalized Thermodynamic Analysis of Methanol Synthes - 2015 - Journal of CO2 UDocument10 pagesGeneralized Thermodynamic Analysis of Methanol Synthes - 2015 - Journal of CO2 UArindam DasNo ratings yet

- Energetic Modeling, Simulation and ExperimentalDocument13 pagesEnergetic Modeling, Simulation and ExperimentalCabang ITSTEKNONo ratings yet

- The Canadian Journal of Chemical Engineering Volume 93 Issue 1 2015Document10 pagesThe Canadian Journal of Chemical Engineering Volume 93 Issue 1 2015Widya Isti AriantiNo ratings yet

- Dynamic Simulation and Optimization of An Industrial-ScaleDocument8 pagesDynamic Simulation and Optimization of An Industrial-ScaleYogesh PatilNo ratings yet

- Hydrogen Production From Biomass Combining Pyrolysis and The Secondary DecompositionDocument6 pagesHydrogen Production From Biomass Combining Pyrolysis and The Secondary Decompositioncosmicbabe_2000No ratings yet

- Reaction RatesDocument8 pagesReaction RatesAbolhasan AmeriNo ratings yet

- SIMS2021 Article Ecp21185444Document6 pagesSIMS2021 Article Ecp21185444العنود راشدNo ratings yet

- 1 s2.0 S0167732217349449 MainDocument9 pages1 s2.0 S0167732217349449 MainKaique TozziNo ratings yet

- Fuel Cells and Green Hydrogen (Chmen206)Document3 pagesFuel Cells and Green Hydrogen (Chmen206)Yatharth AgrawalNo ratings yet

- Gas Hydrate Equilibria For CO 2 - N 2 and CO 2 - CH 4 Gas Mixtures-Experimental Studies and Thermodynamic ModellingDocument20 pagesGas Hydrate Equilibria For CO 2 - N 2 and CO 2 - CH 4 Gas Mixtures-Experimental Studies and Thermodynamic ModellingAarya PatelNo ratings yet

- Urea SynthesisDocument10 pagesUrea SynthesisCHEMICALNo ratings yet

- AEA November 2021 V11novDocument34 pagesAEA November 2021 V11novrriveram1299No ratings yet

- Journal Pre-Proof: Chinese Journal of Chemical EngineeringDocument35 pagesJournal Pre-Proof: Chinese Journal of Chemical EngineeringRungrawin NgamkhumNo ratings yet

- Cyclohexane Purchase Specifications: Property ASTM Method SpecificationDocument1 pageCyclohexane Purchase Specifications: Property ASTM Method SpecificationRungrawin NgamkhumNo ratings yet

- Catalyst Support Effects: Gas-Phase Hydrogenation of Phenol Over PalladiumDocument12 pagesCatalyst Support Effects: Gas-Phase Hydrogenation of Phenol Over PalladiumRungrawin NgamkhumNo ratings yet

- Product Safety Summary: CyclohexaneDocument3 pagesProduct Safety Summary: CyclohexaneRungrawin NgamkhumNo ratings yet

- Co2 Utilization Developments in Conversion ProcessesDocument44 pagesCo2 Utilization Developments in Conversion ProcessesRungrawin Ngamkhum100% (1)

- Bioresource Technology: Yixiang Xu, Loren Isom, Milford A. HannaDocument9 pagesBioresource Technology: Yixiang Xu, Loren Isom, Milford A. HannaRungrawin NgamkhumNo ratings yet

- The Determination of The Composition of Complex Ions in Solution by A Spectrophotometric MethodDocument5 pagesThe Determination of The Composition of Complex Ions in Solution by A Spectrophotometric MethodA/P SUPAYA SHALININo ratings yet

- Fundamentals of Steam Reforming H PlantsDocument8 pagesFundamentals of Steam Reforming H PlantsAkkiNo ratings yet

- E-Umang - XI JEE - Course PlannerDocument6 pagesE-Umang - XI JEE - Course PlannerRkvNo ratings yet

- Vikaas Ja PDFDocument4 pagesVikaas Ja PDFBharat KaseraNo ratings yet

- Mass Balance of A Sugarmill With CompounDocument22 pagesMass Balance of A Sugarmill With CompounJeffersonPalaciosNo ratings yet

- Chem 11-12 2122Document4 pagesChem 11-12 2122Kaib PelaezNo ratings yet

- 61 01Document126 pages61 01dana capbunNo ratings yet

- KNO3 ProductionDocument7 pagesKNO3 ProductionMambaulkNo ratings yet

- Chemistry HL P1Document14 pagesChemistry HL P1Juan Fernando Velasco ForeroNo ratings yet

- Equilibrium and Le Chatelier'S Principle: Chemistry For Engineers - Laboratory Activity 6Document4 pagesEquilibrium and Le Chatelier'S Principle: Chemistry For Engineers - Laboratory Activity 6Moguri OwowNo ratings yet

- Module Dynamic of EquilibriumDocument9 pagesModule Dynamic of EquilibriumsinagtalaNo ratings yet

- Absorption of Chlorine in Aqueous Solutions of Sodium HydroxideDocument15 pagesAbsorption of Chlorine in Aqueous Solutions of Sodium Hydroxidediego marquesNo ratings yet

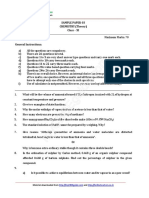

- Sample Paper-03 CHEMISTRY (Theory) Class - XI: Material Downloaded From andDocument4 pagesSample Paper-03 CHEMISTRY (Theory) Class - XI: Material Downloaded From andSarthakNo ratings yet

- Chapter 6 Solubility and Complex Ion EquilibriaDocument41 pagesChapter 6 Solubility and Complex Ion Equilibriantranh58No ratings yet

- Winmostar tutorial: Gromacs Viscosity・Dielectric constantDocument12 pagesWinmostar tutorial: Gromacs Viscosity・Dielectric constantEliasSMonteiroFilhoNo ratings yet

- 9701 w09 QP 12Document6 pages9701 w09 QP 12FahmiAlziePutraNo ratings yet

- 1961 - Reference Electrodes - Ives and JanzDocument332 pages1961 - Reference Electrodes - Ives and Janzlondemon100% (1)

- Unpacked Competencies in Gen Chem 2Document18 pagesUnpacked Competencies in Gen Chem 2Zaifel PacillosNo ratings yet

- NEST 2021: National Entrance Screening Test 2021Document25 pagesNEST 2021: National Entrance Screening Test 2021rashmitha chigullapallyNo ratings yet

- Chemical Reactions at HomeDocument20 pagesChemical Reactions at Home201911371No ratings yet

- Membrane Filtration of Manure WastewaterDocument38 pagesMembrane Filtration of Manure Wastewaterpedro41No ratings yet

- 10 1021@ie0107643Document7 pages10 1021@ie0107643noviNo ratings yet

- 10 11648 J Ajpc 20130206 11 PDFDocument5 pages10 11648 J Ajpc 20130206 11 PDFMohammed RaadNo ratings yet

- Daljeet Singh, Pramit Singh - Objective Chemistry For JEE Main With Boards Score Booster (13th Ed.) - Delta (2015) PDFDocument1,103 pagesDaljeet Singh, Pramit Singh - Objective Chemistry For JEE Main With Boards Score Booster (13th Ed.) - Delta (2015) PDFSampath Kumar100% (1)

- Dynamics of Protein and Mixed Protein Rsurfactant Adsorption Layers at The Water Rfluid InterfaceDocument44 pagesDynamics of Protein and Mixed Protein Rsurfactant Adsorption Layers at The Water Rfluid InterfaceqaeszNo ratings yet

- yokAcikBilim 10185403Document71 pagesyokAcikBilim 10185403gozdebstnciNo ratings yet

- JEE Main SAMPLE TEST 2 With SolutionDocument27 pagesJEE Main SAMPLE TEST 2 With SolutionVivek KumarNo ratings yet

- Definitions: - Electrochemistry - Electrochemical Engineering - Challenges - Course Content - Major Applications - HistoryDocument316 pagesDefinitions: - Electrochemistry - Electrochemical Engineering - Challenges - Course Content - Major Applications - History0721673895No ratings yet

- Equilibrium Practice Problems Answers 201314Document6 pagesEquilibrium Practice Problems Answers 201314Monceda Ramos MareinelleNo ratings yet

![[Wang-etal,2022] Measuring_and_modeling_the_solubility_of_carbon_dioxide_in_PILs](https://imgv2-2-f.scribdassets.com/img/document/747435626/149x198/25d71e4eba/1719967720?v=1)