Professional Documents

Culture Documents

Air Motor Test Pump

Air Motor Test Pump

Uploaded by

Bodega 3001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Motor Test Pump

Air Motor Test Pump

Uploaded by

Bodega 3001Copyright:

Available Formats

323640-4

Service Guide 323640-A1

Air Motor

Description

Air motor Models 323640-4 and 323640-A1 power a Air Exhaust

variety or fluid and material pumps.

The pump tubes that connect to these motors can be

either divorced or of a non-divorced design.

Divorced and Non-Divorced

Overview

Pumps that disassemble into separate air motor and

pump tube entities are considered divorced. These Air Inlet

assemblies connect via a coupling arrangement that is

open to atmosphere. The material outlet on divorced

pumps is on the pump tube.

Non-divorced pumps contain a body that fits directly

Material 19-3/8 "

into the motor. This body distributes the product through

Outlet (49.2 cm)

an outlet in the air motor base. See Figure 1.

Separation of this design requires the pump tube to

be unthreaded from the base of the air motor.

Air Motor for Divorced Design

Air motor Model 323640-A1 is constructed for

divorced design and can be purchased separately.

This motor contains the hardware necessary for

pump tube attachment. Material Outlet on Air Motor Base

for Non-Divorced Pumps Only

Figure 1 Air Motor Models 323640-4 and 323640-A1

Specifications

Piston Diameter x Air Motor for Non-Divorced Design

Stroke Max. Air

Air Inlet Air Outlet

Pressure The air motor connected with pump tubes in a non-

Inches Centimeters

divorced design is Model 323640-4.

6x4 15.2 x 10.2 3/4 " NPTF (f) 3/4 " NPTF (f) *

This air motor is available as an assembly with the pump

Table 1 Air Motor Model 323640 Series Specifications tube.

* For information on the maximum air pressure for the

air motor, refer to the pump’s Service Guide.

Alemite Corporation

PO Box 473515, Charlotte, North Carolina 28247-3515

Copyright © 1998 by Alemite Corporation

This document contains confidential information that is the property of Alemite Corporation

SER 323640-4

397897 and is not to be copied, used, or disclosed to others without express written permission. Revision (2-98)

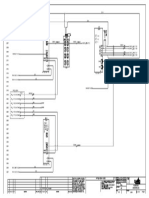

SER 323640-4 Air Motor

1 Appy 9 15

Teflon Tape 6

Here Drain 11 14

2 5 7 Hole

8 13

10 12

16

3 17

18

4 20

19 21

22

27

23

Up 24

29 25

28 38

Down

30

31 42

Use 5/32"

Allen Wrench 39

Apply

43 26

Loctite 242 28

Here

33 40

32 42

44

Apply Apply

Loctite 222 Loctite 242

Here Outlet

Here Hole

34

Early 52

Model

35 41

36

51

50

37

49

36 48

47

a 45

46

Kit Component Divorced Non-Divorced

for Non-Divorced Pump

Figure 2 Air Motor Models 323640-4 and 323640-A1 - Exploded View

Revision (2-98) 2 Alemite Corporation

Air Motor SER 323640-4

Item Part No. Description Qty Notes Numeric Order

No. Part # (Item #)

1 48925 Plug, Pipe, 3/8 " NPT 1 11828 (52)

2 324076 Plug,1-3/4 " -12 (m) x 3/8 " NPT (f) 1 14546 (45)

3 171009-29 O-Ring, 1-9/16 " ID x 1-3/4 " OD 1 48925 (1)

4 324432 Nut, Upper Trip Rod, 3-3/8 " Long 1 77807 (50)

5 171130 Nut, Elastic Stop, 1/2 " -20 8 171000-12 (42)

6 323487 Setscrew, 5/16 " -18 x 1/2 " 2 171003-34 (28)

7 Plug, Socket Pipe, 3/8 " NPT 1 171006-15 (31)

8 323482 Gasket, 1.646 " OD (Copper) 2 171009-4 (35)

9 323450 Plunger 2 171009-29 (3)

10 323464 Toggle 2 171009-33 (49)

11 323486 Spring, 3.00 " Long 2 171009-35 (a)

12 323481 Cylinder, 1-5/16 " -20 2 171009-47 (24)

13 323484 Washer, 0.7 " ID 2 171130 (5)

14 323485 Spring, 1-5/16 " Long 2 172013 (21)

15 323483 Cap 2 172207-4 (51)

16 323468 Gasket, 2-13/16 " OD (Rubber) 1 311738 (7)

17 Seat, Valve 1 314632 (48)

18 323469 Stop 2 323443 (26)

19 323830 Guide, Valve 2 323444-2 (43)

20 Lockwasher, 5/16 " 4 323466-4 (25)

21 Screw, Cap, 5/16 " -18 x 1 " 4 323450 (9)

22 Slide, Valve 1 323451-3 (40)

23 323473 Shuttle 1 323459-2 (32)

24 171009-47 O-Ring, 2-11/16 " ID x 2-7/8 " OD 1 323460 (38)

25 323466-4 Inlet, Air 1 323464 (10)

26 323443 Screw, Cap, 3/8 " -16 x 7/8 " 4 323467 (17)

27 333206-D1 Head Assembly, Casting 1 323468 (16)

28 171003-34 O-Ring, 5-3/4 " ID x 6 " OD 2 323469 (18)

29 324290 V-Packing 1 323470 (22)

30 323474 Washer, 0.52 " ID 1 323473 (23)

31 171006-15 Ring, Retaining, 7/8 " Diameter 1 323474 (30)

32 323459-2 Rod, Tie, 1/2 " -13 x 1/2 " -20 8 323478 (34)

33 326471-1 Rod, Trip 1 323479 (39)

34 323478 Retainer, Piston 1 323481 (12)

35 171009-4 O-Ring, 5/8 " ID x 3/4 " OD 1 323482 (8)

36 326476 Washer 2 323483 (15)

37 326475 Packing 1 323484 (13)

38 323460 Nut, Piston 1 323485 (14)

39 323479 Nut, Lower Trip Rod, 1-5/8 " Long 1 323486 (11)

40 323451-3 Rod, Piston 1 323487 (6)

41 326473-2 Cylinder 1 323550 (47)

42 171000-12 O-Ring, 5/8 " ID x 13/16 " OD 2 323551 (46)

43 323444-2 Tube 1 323830 (19)

44 326472-B4 Base, Air Motor (w/ outlet hole) 1 Replacement-Both Models 324076 (2)

45 Washer, 1/2 " 3 Model 323640-A1 324290 (29)

46 Screw, 1/2 " -13 x 7/8 " 3 Model 323640-A1 324432 (4)

47 323550 Retainer, Packing (Brass) 1 Model 323640-A1 326471-1 (33)

48 314632 V-Packing 1 Model 323640-A1 326472-B4 (44)

49 171009-33 O-Ring, 1-13/16 " ID x 2 " OD 1 Model 323640-A1 326473-2 (41)

50 Nut, 1/2 " -20 4 Model 323640-A1 326475 (37)

51 Lockwasher, 1/2 " 4 Model 323640-A1 326476 (36)

52 Screw, Cap, 1/2 " -20 x 2 " 4 Model 323640-A1 333206-D1 (27)

a 171009-35 O-Ring, 1-15/16 " ID x 2-18 " OD 1 Model 323640-4 384232 (20)

Legend:

Part numbers left blank (or in italics) are not available separately

designates a repair kit item

Repair Kits

Part No. Kit Symbol Description

394233-2 Kit, Major Repair (Includes Tube of 394009 Loctite 242 and 398030 Viscous H Lubricant)

398989 Kit, Slide Valve, Seat, and Gasket

Alemite Corporation 3 Revision (2-98)

SER 323640-4 Air Motor

Service Hints

Refer to the Overhaul Procedures for Details

Measure the Depth of the Nut in the Rod

Shuttle may not Operate Properly

Do not Misalign the Washer

in the Cap

Toggle Assembly will not

Function Properly

Remove and Install Valve Seat with Care

Air Leakage will Occur

Use Loctite 242 and Primer

on each End of the Trip Rod

Components will Loosen

Measure the Depth of the Nut in the Rod

Shuttle may not Operate Properly

Never Grip Piston Rod Flats

to Loosen any Component

Epoxy Seal may be Broken

Non-Divorced

Revision (2-98) 4 Alemite Corporation

Air Motor SER 323640-4

Accessories Overhaul

Accessory items applicable to the these motors are IMPORTANT: Prior to performing any

illustrated in Figure 3. maintenance procedure, the following safety

precautions must be observed. Personal

injury may occur.

1 2

WARNING

Do not use halogenated hydrocarbon

solvents such as methylene chloride or 1,1,1-

trichlorethane in this motor. An explosion can

result within an enclosed device capable of

containing pressure when aluminum and/or zinc-

plated parts come in contact with halogenated

hydrocarbon solvents.

Release all pressure within the system prior to

performing any overhaul procedure.

• Disconnect the air supply line from the motor.

• Into an appropriate container, operate the

pump’s control valve to discharge remaining

pressure within the system.

Never point a control valve at any portion of your

body or another person. Accidental discharge of

pressure and/or material can result in injury.

Read each step of the instructions carefully. Make

sure a proper understanding is achieved before

proceeding.

NOTE : Refer to Figure 2 for component

identification on all overhaul procedures.

Disassembly

Separate Pump from Motor (Non-Divorced)

3 1. Clamp the Air Motor vertically in a soft-jaw vise.

4 2. Loosen the Jam Nut that secures the Pump Tube

assembly to the Air Motor assembly.

CAUTION

Item No. Part No. Description Support the Pump Tube assembly during removal.

Damage to components can occur.

1 324170 Muffler, 3/4 " NPTF (m)

2 323842 Eye Bolt, 3/8 " NPTF (m)

3 328037 Connector, 3/4 " NPTF (m) 3. Unscrew the Pump Tube [with attached components]

from the Air Motor.

4 328031 Air Coupler, 1/2 " NPTF (f)

4. Pull on the Pump Tube to expose the Coupling.

Figure 3 Air Motor Model 323640 Series Accessories

Alemite Corporation 5 Revision (2-98)

SER 323640-4 Air Motor

5. Remove the upper Spring Clip that secures the air 22. Remove O-Ring (28) from the Head Assembly.

motor Piston Rod to the Coupling.

23. Remove the Shuttle, Toggles (10), Plungers (9), and

6. Unscrew the Coupling from the air motor Piston Rod. Slide Valve (22) from the Head Assembly.

• Rotate the entire Pump Tube assembly.

24. Remove Screws (21) and Lockwashers (20) that secure

NOTE : For disassembly procedures of the Valve Guides (19), Stops (18), and Valve Seat (17) to

components in Air Motor Base (44), refer to the Head Assembly.

the Pump SER Service Guide for details. • Remove the Valve Guides and Stops.

Separate Motor from Pump (Divorced) I M P O R TA N T: R e m o v e t h e Va l v e S e a t

squarely from the Head Assembly. Should the

7. With the pump in a soft-jaw vise, remove Screws (52), Valve Seat cock during removal, realign and

Lockwashers (51), and Nuts (50) that secure the Pump start again.

to the Air Motor Housing.

25. Remove the Valve Seat from the Head Assembly.

8. Remove the Spring Clip that secures the air motor

26. Remove Gasket (16) from the Head Assembly.

Piston Rod to the Coupling.

27. Remove Retaining Ring (31) that secures Washer (30)

9. Unscrew the Coupling from the air motor Piston Rod.

and V-Packing (29) in the Head Assembly.

• Rotate the entire Air Motor assembly.

• Remove the Washer and the V-Packing.

Air Motor 28. Remove Plug (7) from the Head Assembly as necessary.

Head Assembly 29. Place each Cap in a soft-jaw vise.

10. Place the Air Motor vertically in a soft-jaw vise. 30. Unscrew Cylinder (12) from the Cap.

• Use a drift and a small hammer.

11. Unscrew Plug (2) from Head Assembly (27).

• Remove O-Ring (3) from the Plug. 31. Remove Washer (13) and Spring (14).

12. Remove Plug (1) from Plug (2) as necessary. Air Motor Base

13. Remove Screws (26) that secure Air Inlet (25) to the 32. Remove Tube (43) from the Air Motor Base (44).

Head Assembly.

33. Remove O-Rings (42) from each end of the Tube.

• Remove the Air Inlet from the Head Assembly.

34. Remove Cylinder (41) from the Air Motor Base.

14. Remove O-Ring (24) from the Air Inlet.

35. Remove the Trip Rod and Piston Rod assembly from

15. Loosen Setscrews (6) that secure Caps (15) to the

the Air Motor Base.

Head Assembly.

• Unscrew each Cap from the Head Assembly. IMPORTANT: Do not grip the flats of the Pis-

ton Rod during the following procedure.

16. Remove Springs (11) from each Cap.

36. Grip Piston Nut (38) and Piston Retainer (34) and

17. Remove Gaskets (8) from the Head Assembly. unscrew the Piston Nut until it seats on the shoulder of

Piston Rod (40).

18. Lift Shuttle (23) upward and hold Trip Rod (33) with

• Continue rotation to separate the Piston Retainer

an open-end wrench.

from the Piston Rod.

NOTE: Early model Trip Rods did not con-

37. Remove the assembly from the Piston Rod.

tain a flat. Use a 5/32 " allen wrench to pre-

vent rotation of the Rod. See Figure 2. 38. Unscrew Nut (39) from Trip Rod (33).

• Separate the Piston Retainer from the Trip Rod.

19. Unscrew Nut (4) from the Trip Rod.

39. Remove O-Ring (35) from the Piston Retainer.

20. Unscrew Nuts (5) from Tie Rods (32).

• Remove the Head Assembly from the Tie Rods 40. Remove Washers (36) and Packing (37) from the Piston

Nut.

21. Place the Head Assembly assembly on a flat surface.

Revision (2-98) 6 Alemite Corporation

Air Motor SER 323640-4

41. Remove O-Ring (28) from the Air Motor Base. Assembly

42. Unscrew the Piston Nut from the Piston Rod as needed. NOTE: Prior to assembly, certain compo-

nents require lubrication. Refer to Table 2.

Model 323640-A1 Only

Air Motor Base

43. Remove Screws (46) and Washers (45) that secure

Packing Retainer (47) to the Base. NOTE: Refer to Figure 2 and Figure 4 for

• Remove the Packing Retainer. component identification on all assembly

procedures.

44. Remove V-Packing (48) and O-Ring (49) from the

Packing Retainer. Model 323640-A1 Only

Clean and Inspect 1. Install V-Packing (48) [lips upward] into the top of

Packing Retainer (47).

NOTE: Use the appropriate repair kit for

replacement parts. Make sure all the compo- 2. Install O-Ring (49) onto the Packing Retainer.

nents are included in the kit before discard-

ing used parts. 3. Install the Packing Retainer assembly into Air Motor

Base (44).

1. Clean all metal parts in a modified petroleum-based

solvent. The solvent should be environmentally safe. 4. Install Washers (45) and Screws (46) into the Air

Motor Base.

2. Inspect all parts for wear and/or damage. • Tighten the Screws securely.

• Replace as necessary.

All Models

3. Remove old Loctite from threads of Trip Rod (33),

Upper Trip Rod Nut (4), and Lower Trip Rod Nut (39). 5. Install O-Ring (28) onto the Air Motor Base.

4. Inspect the large diameter of the Trip Rod and the 6. Screw Piston Nut (38) [hexagon end downward] onto

inside diameter of Cylinder (41) closely for score the top of Piston Rod (40).

marks. • Make sure the Piston Nut bottoms on the Piston Rod.

• Replace as necessary.

7. Install Washer (36), Packing (37) and additional

5. Press the Ball on each Valve Guide (18) to ensure the Washer (36) onto the Piston Nut.

Spring operates properly. Replace as necessary.

8. Install and seat O-Ring (35) onto Piston Rod (40).

6. Closely inspect the mating surfaces of Valve Seat (17)

and Valve Slide (22). Ensure a smooth and clean 9. Place the Piston Retainer [hexagon end upward] onto

contact is obtained. the bottom of Trip Rod (33).

• Replace with a minor kit if necessary.

Item No. Description Item No. Description

Clean Oil

3 O-Ring, 1-9/16 " ID x 1-3/4 " OD 35 O-Ring, 5/8 " ID x 3/4 " OD

24 O-Ring, 2-11/16 " ID x 2-7/8 " OD 42 O-Ring, 5/8 " ID x 13/16 " OD

28 O-Ring, 5-3/4 " ID x 6 " OD 48 V-Packing

29 V-Packing 49 O-Ring, 1-13/16 " ID x 2 " OD

Viscous H Lubricant

9 Plunger - Outside Diameter and Toggle Socket 23 Shuttle - Inside Diameter and Toggle Sockets

11 Spring - Coated 27 Head Assembly - 1/4 oz. (7 gms) in Cavity

14 Spring - Coated 37 Packing - Outside Diameter

22 Slide Valve - Surface in Contact with Shuttle 41 Cylinder - Inside Bore

Table 2 Lubricated Components

Alemite Corporation 7 Revision (2-98)

SER 323640-4 Air Motor

1-5/16 "

(33.3 mm) 2 14

15

18 13

17 9

3

16 12

4 11

22

10

8

19

23

Cap Assembly

25

24

5

42 27 29

30

28

33 31

34

35

37 36

38

32

9/16 "

43 (14.3 mm)

39

40

41

28

48

42 49

47

44

45

46

Refer to Figure 2 Parts List

for Parts Identification

Divorced

Figure 4 Air Motor Model 323640-A1 - Section View

Revision (2-98) 8 Alemite Corporation

Air Motor SER 323640-4

10. Screw Nut (39) into the bottom of the Trip Rod [fewer 22. Install Gasket (16) into the Head Assembly.

threads] and tighten from 17-20 ft. lbs. (23 - 27 Nm).

IMPORTANT: Install the Valve Seat squarely

• Make sure to apply Loctite 242 to the Trip Rod.

into the Head Assembly. Should the Valve

• Follow the thread sealant manufacturer’s

Seat cock during installation, realign and

recommendations.

start again.

11. Measure the depth the Nut extends beyond the Trip

23. Install Valve Seat (17) into the Head Assembly.

Rod. The measurement must be 9/16 " (14.3 mm). See

Figure 4. 24. Install Stops (18), and Valve Guides (19) into the Head

Assembly.

IMPORTANT: The O-Ring must seat on the

Piston Rod or leakage occurs. 25. Install Lockwashers (20) and Screws (21) that secure

the Valve Guides and Seat to the Head Assembly.

12. Screw and seat the Piston Retainer assembly tight onto

• Tighten the Screws from 45 to 50 in. lbs

the Piston Rod.

(5.1 - 5.7 Nm) in a crisscross pattern.

13. Screw the Piston Nut against the Piston Retainer. 26. Install Slide Valve (22) onto the Valve Seat.

• Tighten securely.

IMPORTANT: Make sure the drain hole on

NOTE: It is normal for the Washers and Plungers (9) and the smaller diameter on

Packing to wobble on the Piston Nut and Shuttle (23) point downward. See Figure 2.

Piston Retainer.

27. Install one Toggle (10) and Plunger (9) to Shuttle (23).

• Install the assembly into the Head Assembly.

CAUTION

Use care installing the Trip Rod and Piston Rod Head Assembly Caps

assembly into the Packing Retainer. Damage to the 28. Place each Cap (15) vertically in a soft-jaw vise.

Packing can occur (Model 323640-A1 Only).

29. Install Spring (14) and Washer (13) into each Cap.

• Make sure the Washer centers and seats properly.

14. Install the Trip Rod and Piston Rod assembly into the

Air Motor Base. 30. Screw Cylinder (12) into each Cap.

• Use a drift and a small hammer.

15. Install Cylinder (41) onto the Air Motor Base.

• Use care passing the O-Ring. I M P O R TA N T: Te m p o ra r i l y i n s t a l l t h e

remaining Plunger into each Cap. Press

NOTE: Make sure Packing (37) contacts the down on the Plunger to ensure the Washer is

Cylinder evenly. seated properly. If the Spring does not move,

remove the Cylinder and reinstall the

16. Install O-Rings (42) onto each end of Tube (43).

Washer.

17. Install the Tube into the Air Motor Base. 31. Install Springs (11) into each Cap.

18. Install Tie Rods (32) into the Air Motor Base.

• Make sure to apply Loctite 222 to the bottom threads

Head Assembly (Continued)

of the Tie Rod. 32. Install the remaining Toggle and Plunger to the

• Follow the thread sealant manufacturer’s Shuttle.

recommendations.

33. Install Gaskets (8) into the Head Assembly.

Head Assembly 34. Screw each Cap assembly loosely into the Head

19. Install O-Ring (28) onto Head Assembly (27). Assembly.

• Make sure Springs (11) align with the Plunger.

20. Install and seat V-Packing (29) [lips upward] into the

bottom of the Head Assembly. 35. Install and seat the Head Assembly assembly onto Tie

Rods (32) and Cylinder (41).

21. Install Washer (30) and Retaining Ring (31). • Make sure the Shuttle aligns with the Trip Rod and

• Make sure the Retaining Ring seats properly in the Tube (43).

groove.

Alemite Corporation 9 Revision (2-98)

SER 323640-4 Air Motor

36. Screw Nuts (5) onto the Tie Rods. Connection

• Tighten the Nuts securely in a crisscross pattern.

Connect Pump to Motor (Non-Divorced)

37. Lift the Shuttle upward and hold the Trip Rod with an

open-end wrench (grip earlier model Trip Rod with 49.Clamp the Air Motor vertically in a soft-jaw vise.

a 5/32 " allen wrench).

50.Pull on the Pump Tube to expose the Coupling as

38. Screw Nut (4) onto the Trip Rod (with Loctite 242) necessary.

and tighten from 17-20 ft. lbs. (23 - 27 Nm).

• Follow the thread sealant manufacturer’s

recommendations. CAUTION

39. Measure the depth the Nut extends beyond the Trip Support the Pump Tube assembly during installa-

Rod. The measurement must be 1-5/16 " (33.3 mm). tion. Damage to components can occur.

See Figure 4.

NOTE: Check to ensure the Toggles are cen- 51.Screw the Coupling into the air motor Piston Rod.

tered in the Shuttle prior to securing the • Rotate the entire Pump Tube assembly.

Caps into the Head Assembly.

52.Install the upper Spring Clip that secures the air motor

40. Tighten each Cap assembly into the Head Assembly. Rod to the Coupling.

• Tighten sufficiently to properly crush Gaskets (8).

53.Screw the Pump Tube into the Air Motor.

41. Install Setscrews (6) that secure the Caps to the Head

Assembly. 54.Tighten the Jam Nut that secures the Pump Tube

• Tighten the Setscrews securely. assembly to the Air Motor assembly.

42. Install O-Ring (24) onto Air Inlet (25). Connect Motor to Pump (Divorced)

43. Install the Air Inlet into the Head Assembly. 55.Clamp the Pump in a soft-jaw vise.

• Make sure the O-Ring seats properly.

56.Screw the Coupling into the pump tube Piston Rod.

44. Install Screws (26) that secure the Air Inlet to the Head • Rotate the entire Air Motor assembly.

Assembly.

• Tighten the Screws securely in a crisscross pattern. 57.Install the Spring Clip that secures the Pump Tube

Rod to the Coupling.

45. Install O-Ring (3) onto Plug (2).

46. Screw the Plug into the Head Assembly. 58. Install Screws (52), Lockwashers (51), and Nuts (50)

• Tighten the Plug securely. that secure the Pump to the Air Motor Housing.

• Tighten the Screws securely.

47. Install Plug (1) into Plug (2).

• Use Teflon tape and tighten the Plug securely. Pump Operation

48. Install and secure Plug (7) into the Head Assembly.

Bench Test and Prime

NOTE: For assembly procedures of the

components in the base of the air motor, With air pressure at zero:

refer to the Pump SER Service Guide for 1. Place the pump in the product to be dispensed.

details.

NOTE: Do not allow the pressure to exceed

Motor Operation 50 psi (3.4 Bars).

2. Slowly supply air pressure to the pump’s motor.

Bench Test

3. Allow the pump to cycle slowly until the system and

Apply 10 psi (0.7 Bar) air pressure to the motor. product is free of air.

• The motor should cycle.

If the pump assembly does not prime, refer to the

If the motor does not cycle, refer to the Troubleshooting Chart for details.

Troubleshooting Chart for details.

Revision (2-98) 10 Alemite Corporation

Air Motor SER 323640-4

Stall Test Installation

Additional items that should be incorporated into the

WARNING air piping system are listed in Table 3.

Should leakage occur anywhere within the Part Number Description

system, disconnect air to the motor. Personal

338862 Moisture Separator/Regulator & Gauge Combination

injury can occur.

5608-2 Moisture Separator

7608-B Regulator and Gauge

With air pressure at zero:

5908-2 Lubricator *

4. Attach a control valve to the outlet hose of the pump.

Table 3 Air Line Components

5. Set the air pressure to 100 psi (6.9 Bar).

* Although the air motor is lubricated at the factory, the

6. Operate the control valve into a container. life of the motor can be extended with the use of a

lubricator.

7. Allow the pump to cycle until the system and product

is once again free of air.

8. Shut off the control valve.

• The pump should not cycle.

If the pump cycles more than once or twice an hour,

refer to the Pump SER Service Guide for details.

9. Check the motor for air leakage.

If the motor leaks, refer to the Troubleshooting Chart

for details.

Alemite Corporation 11 Revision (2-98)

SER 323640-4 Air Motor

Troubleshooting Chart

Indications Possible Problems Solution

Air Motor and/or Pump 1. Insufficient air pressure 1. Increase air pressure

does not cycle 2. Pump tube jammed and/or contains 2. Rebuild pump tube

loose components

Pump Assembly

Pump will not prime 1. Excessive cycling speed 1. Reduce air pressure

2. Air leak before pump tube 2. Tighten connection

3. Pump leaking internally 3. See Pump SER Service Guide

Pump cycles rapidly Product source empty Replenish product and inspect Air Motor

Air Motor

External Leaks

Air leakage at top or bottom 1. Worn or damaged O-Rings (28) 1. Replace O-Rings (28)

of Cylinder (41) 2. Worn or damaged Cylinder (41) 2. Replace Cylinder (41)

Air leakage at Tube (43) 1. Worn or damaged O-Rings (42) 1. Replace O-Rings (42)

2. Worn or damaged Tube (43) 2. Replace Tube (43)

Air leakage at Plug (2) 1. Worn or damaged O-Ring (3) 1. Replace O-Ring (3)

2. Initial tightening of Plug (2) to Head 2. Tighten Plug (2) to Head Assembly (27)

Assembly (27) not sufficient

Air leakage at Plug (1) Initial tightening of Plug (1) to Plug (2) Apply Teflon Tape to Plug (1) and tighten

not sufficient and/or improper or no

sealant

Air leakage at Air Inlet (25) 1. Worn or damaged O-Ring (42) 1. Replace O-Ring (42)

2. Initial tightening of Screws (26) to 2. Tighten Screws (26)

Head Assembly (27) not sufficient

Air leakage at Cap (15) 1. Initial tightening of Cap (15) to Head 1. Tighten Cap (15) to Head Assembly (27)

Assembly (27) not sufficient

2. Damaged Gasket (8) 2. Replace Gasket (8)

Air leakage at Packing 1. Worn or damaged V-Packing (48) 1. Replace V-Packing (48)

Retainer (48) 2. Worn or damaged O-Ring (49) 2. Replace O-Ring (49)

3. Initial tightening of Screws (46) to 3. Tighten Screws (46)

Air Motor Base (44) not sufficient

Internal Leaks

Air leakage felt at Exhaust 1. Worn or damaged V-Packing (29) 1. Disassemble air motor, clean, inspect, and

2. Worn or damaged Packing (37) replace worn or damaged components.

3. Damaged Gasket (16)

4. Worn or damaged Valve Slide (22)

5. Worn or damaged Valve Seat (17)

6. Worn or damaged O-Ring (35)

7. Initial tightening of Piston Retainer 2. Screw and seat Piston Retainer (34) onto

(34) to Piston Rod (40) improper and/ Piston Rod (40). Screw and seat Piston

or not sufficient Nut (38) into the Piston Retainer.

Changes Since Last Printing

Made Pump SER responsible for Air Motor’s Max. Air Pressure Specification

Revision (2-98) 12 Alemite Corporation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MicroProcessor Assignment1Document4 pagesMicroProcessor Assignment1RitikaNo ratings yet

- Oilwell A600-Pt PartslistDocument14 pagesOilwell A600-Pt PartslistBodega 3001100% (1)

- Model Ra-D: Instruction ManualDocument128 pagesModel Ra-D: Instruction ManualBruce Adorno0% (1)

- Butech Hydrogen Valves, Fittings & Tubing NEEDLEDocument8 pagesButech Hydrogen Valves, Fittings & Tubing NEEDLEBodega 3001No ratings yet

- Pipe Spinner Mark-30Document119 pagesPipe Spinner Mark-30Bodega 3001100% (1)

- Data Sheets Kunkle Series 6000 Safety Valves Kunkle Valve en en 5197462Document12 pagesData Sheets Kunkle Series 6000 Safety Valves Kunkle Valve en en 5197462Bodega 3001No ratings yet

- WASHPIPE 3in SOUTHWEST QC64-2 CANRIGDocument1 pageWASHPIPE 3in SOUTHWEST QC64-2 CANRIGBodega 3001No ratings yet

- Cameron Style H2' Choke PartsDocument2 pagesCameron Style H2' Choke PartsBodega 300150% (2)

- MAN RIDER INGERSOLL RAND FA150KGiDocument21 pagesMAN RIDER INGERSOLL RAND FA150KGiBodega 3001No ratings yet

- ALLMAND Night-Lite PRO II Parts ManualDocument93 pagesALLMAND Night-Lite PRO II Parts ManualBodega 3001No ratings yet

- Swaco' Style Drilling Choke PartsDocument1 pageSwaco' Style Drilling Choke PartsBodega 3001No ratings yet

- OILWELL A1400PTpump - PLDocument15 pagesOILWELL A1400PTpump - PLBodega 3001No ratings yet

- NBD8004R-PL (EP) : Hangzhou Xiongmai Technology Co.,LtdDocument1 pageNBD8004R-PL (EP) : Hangzhou Xiongmai Technology Co.,LtdСемён СемёновичNo ratings yet

- Installation Clean Agent SystemsDocument14 pagesInstallation Clean Agent Systems721917114 47No ratings yet

- AcerTravelmate 8481 Service GuideDocument229 pagesAcerTravelmate 8481 Service GuideAdrianNo ratings yet

- Sheet 2Document3 pagesSheet 2Mohamed AlfarashNo ratings yet

- 2023 OL ICT 596 Mark GuidesDocument9 pages2023 OL ICT 596 Mark Guideslove birds konohaNo ratings yet

- PowerEdge R640 Technical GuideDocument51 pagesPowerEdge R640 Technical GuidephongnkNo ratings yet

- MSOFTX3000 (ATCA) - Hardware System PortuguêsDocument58 pagesMSOFTX3000 (ATCA) - Hardware System PortuguêsrobelmouraNo ratings yet

- Aula Ch2 2Document27 pagesAula Ch2 2Charles ChavesNo ratings yet

- Ethernet x520 Server Adapters BriefDocument5 pagesEthernet x520 Server Adapters Brieftepotat479No ratings yet

- Spek BusductDocument12 pagesSpek Busductsepta ibnuNo ratings yet

- Prevention and Recovery Procedure C308 C368 C258Document8 pagesPrevention and Recovery Procedure C308 C368 C258zahid IqbalNo ratings yet

- SMI - AOC - Display 2020 01 31 10 - 13 - 15Document3 pagesSMI - AOC - Display 2020 01 31 10 - 13 - 15devino grasioNo ratings yet

- Operating Systems MCQsDocument8 pagesOperating Systems MCQsZainab ArifNo ratings yet

- C8500 Ordering GuideDocument35 pagesC8500 Ordering GuideSAMIR BEN HASSEN .GMAILNo ratings yet

- 560AIR01 CS enDocument6 pages560AIR01 CS enHo Van ToanNo ratings yet

- GXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Document4 pagesGXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Emmanuel Hernandez100% (1)

- USER GUIDE - Web - ZERO-Pi - Easy PDFDocument17 pagesUSER GUIDE - Web - ZERO-Pi - Easy PDFfbaldnerNo ratings yet

- Computer Organization and ArchitectureDocument2 pagesComputer Organization and ArchitecturemoviessmovirNo ratings yet

- Ach Ith Acn Alc Itl Ihu 2020 Arh Are Iil Iml Imh 2019 Irh Iwl Api 2018 Ich Ikb ArrDocument8 pagesAch Ith Acn Alc Itl Ihu 2020 Arh Are Iil Iml Imh 2019 Irh Iwl Api 2018 Ich Ikb Arr1154816584qq.comNo ratings yet

- PackingslipDocument3 pagesPackingslipEiichi WatanabeNo ratings yet

- Manuale Di Istruzione Jumpstarter MiniDocument50 pagesManuale Di Istruzione Jumpstarter MiniSönke HutschenreuterNo ratings yet

- Instruction Manual ControltromikDocument10 pagesInstruction Manual ControltromikVoştinar IoanNo ratings yet

- Manual Provit B&R 2200Document332 pagesManual Provit B&R 2200Fredy Mauricio Diaz VargasNo ratings yet

- Perfbook 2023 06 11aDocument662 pagesPerfbook 2023 06 11aIsmael Abdulkarim AliNo ratings yet

- 01 HW-SW Job Openings BcubeDocument2 pages01 HW-SW Job Openings BcubeNasirMahmoodNo ratings yet

- Tusb3410 EngDocument4 pagesTusb3410 EngEsteban FernandoNo ratings yet

- We Sing at Pleasure Score and PartsDocument14 pagesWe Sing at Pleasure Score and PartsCarmenCaleroNo ratings yet

- Phoenix Contact: Network Interfaces Network InterfacesDocument1 pagePhoenix Contact: Network Interfaces Network InterfacesZinou ZizouNo ratings yet